Cutting device for hollow fabric prepreg

A cutting device and prepreg technology, applied in metal processing, etc., can solve the problems of adding secondary cutting and cutting procedures, dislocation of upper and lower layers, waste of prepreg materials, etc., and achieve the effect of eliminating processing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with drawings and embodiments.

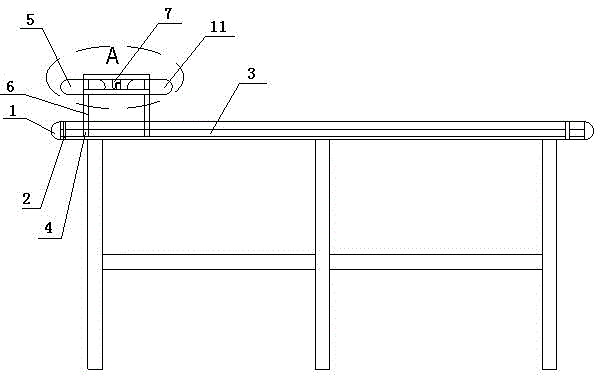

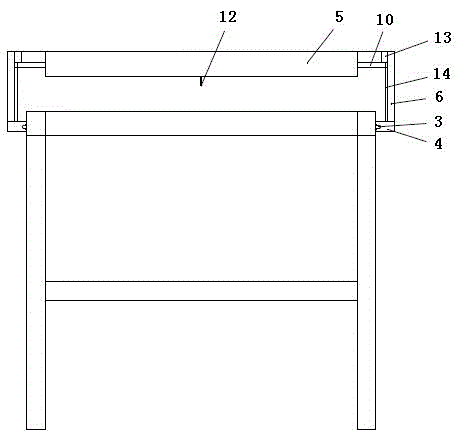

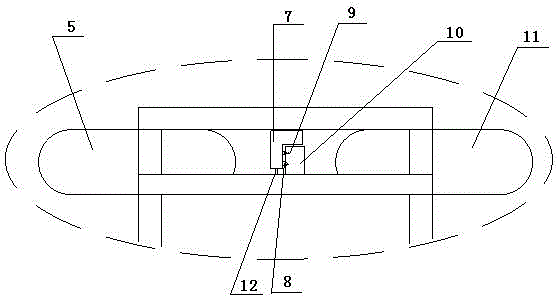

[0019] like figure 1 , 2 Shown in and 3, a kind of cutting device of hollow fabric prepreg comprises: the first rolling vacuum suction platform 1, the second rolling vacuum suction platform 5, the third rolling vacuum suction platform 11, the mobile bracket 6, the cutter seat 7 and The cutting tool 12 that is installed on the cutter seat 7; The both sides of the first rolling vacuum adsorption platform 1 are provided with longitudinally moving guide rail 3, and mobile bracket 6 is erected on the longitudinally moving guide rail 3 by longitudinally moving guide rail slider 4, and longitudinally moving guide rail 3 There is a limit block 2 on it; the second rolling vacuum adsorption platform 5 and the third rolling vacuum adsorption platform 11 are installed on the mobile support 6, and are respectively installed on both sides of the tool seat 7; the mobile support 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com