Automatic section cutting device for glasses arm support machining

An arm frame and automatic technology, which is applied in the field of automatic section cutting device for eyeglass arm frame processing, can solve the problems of poor applicability, lack of mobility, and inconvenient replacement of use positions, etc., and achieve the effect of increasing applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

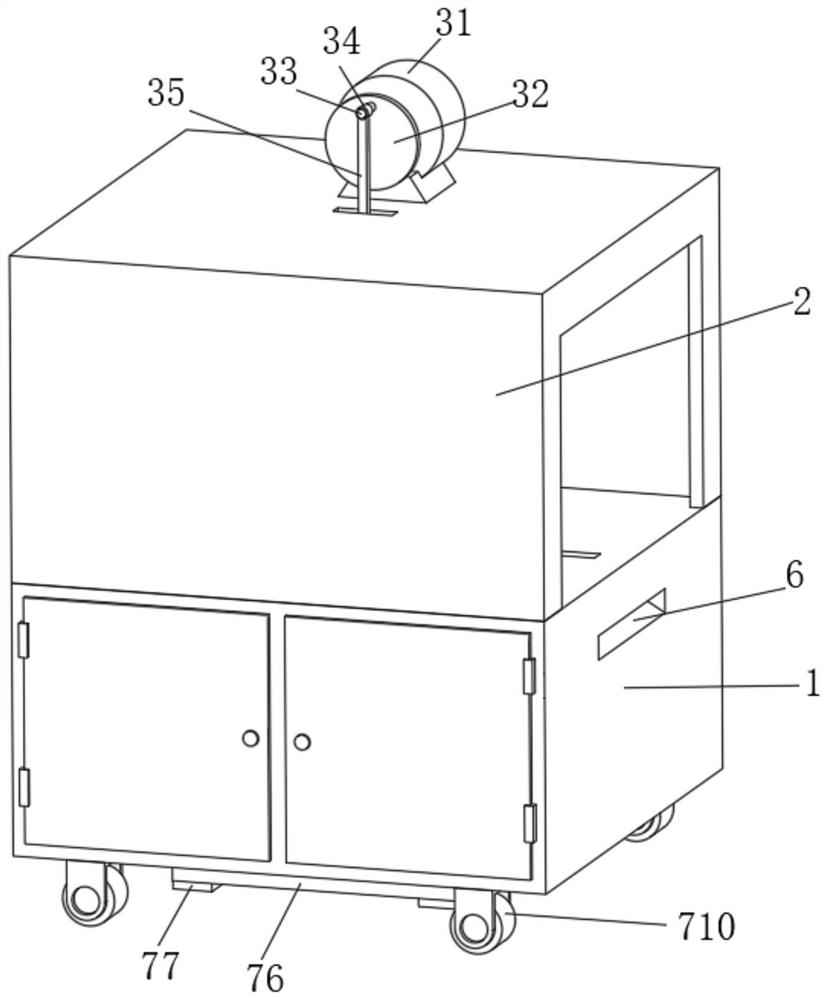

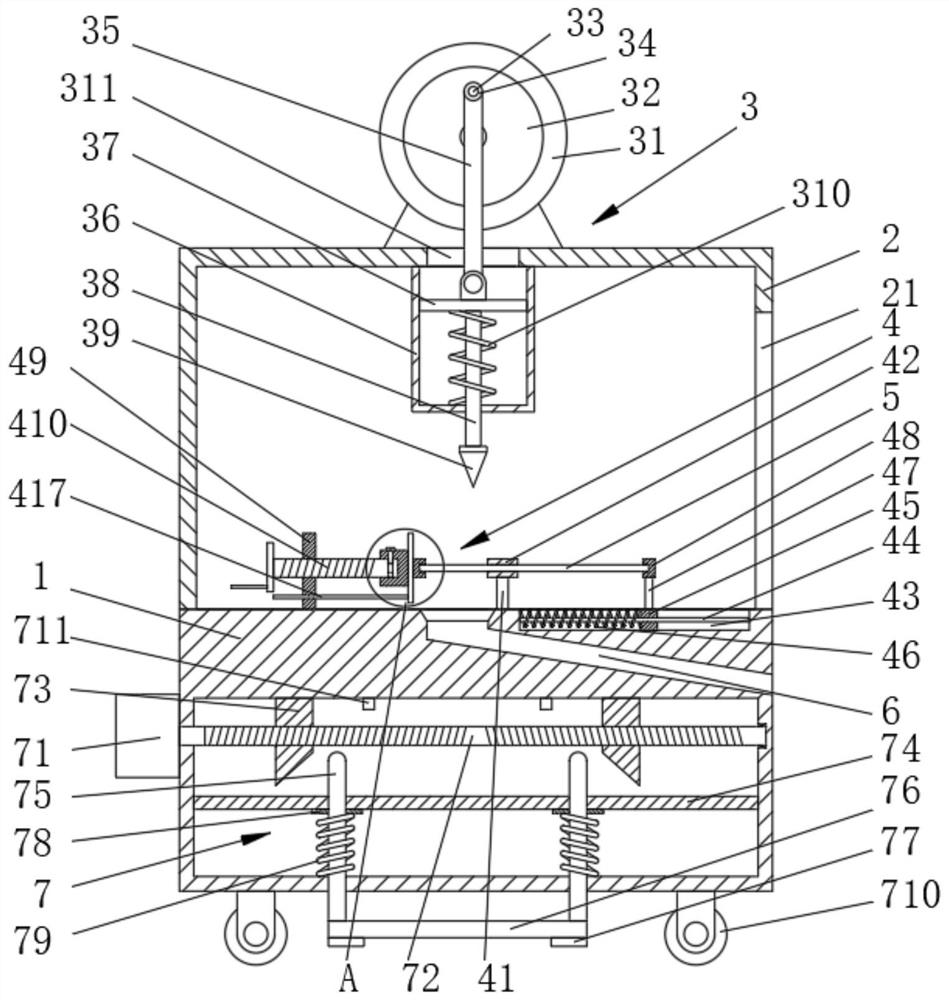

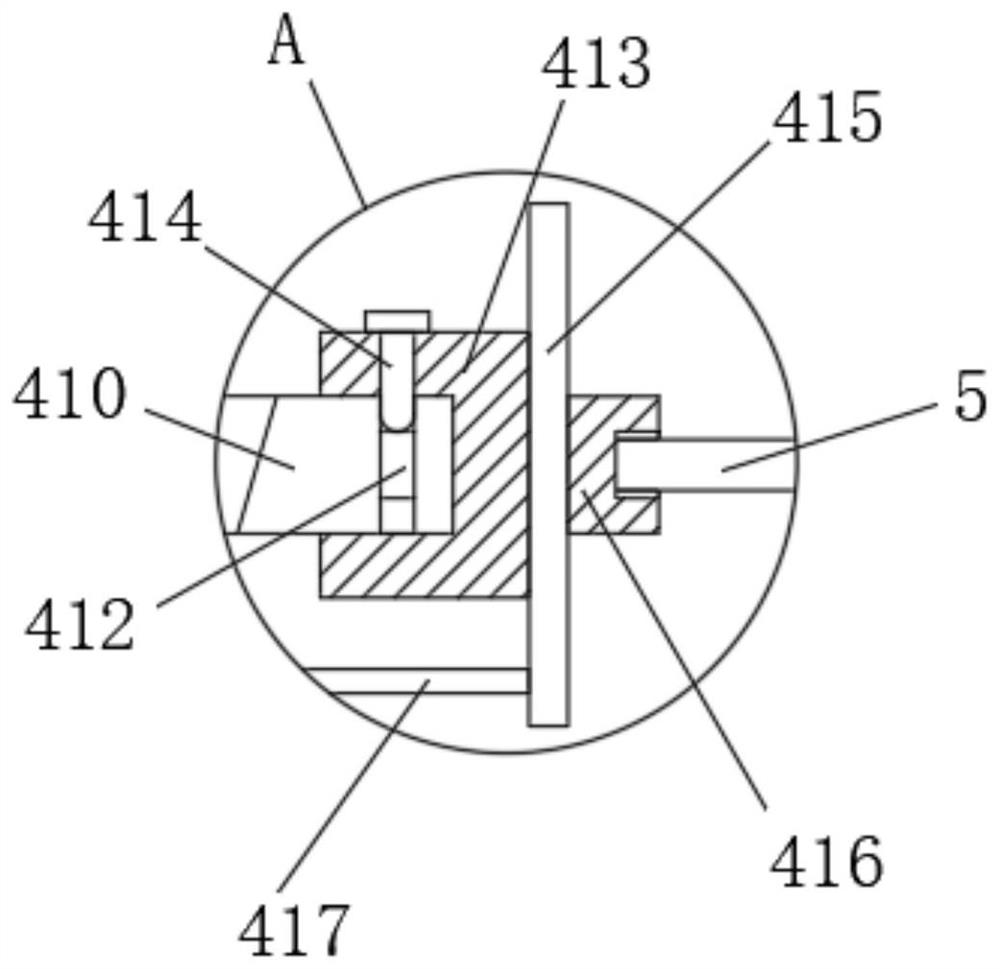

[0026] An automatic segment cutting device for eyeglass arm frame processing, comprising a body 1, a casing 2, a cutting mechanism 3, a positioning mechanism 4, a blank 5, a blanking channel 6, and a moving mechanism 7. The upper end of the body 1 is fixedly connected with The casing 2 is provided with an operation window 21, the top of the casing 2 is provided with a cutting mechanism 3, the body 1 is provided with a positioning mechanism 4, and the body 1 is provided with a feeding channel 6. The body 1 is provided with a moving mechanism 7 , and the bottom of the body 1 is provided with four evenly distributed rollers 710 . Wheels 710 provide mobility to the whole.

[0027] Wherein, the cutting mechanism 3 includes a motor 31, a rotating disk 32, a connecting shaft 33, a shaft sleeve 34, a connecting arm 35, a sleeve 36, a guide plate 37, a connecting rod 38, a cutting knife 39, a first spring 310, and a movable groove 311 , the top of the casing 2 is provided with a motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com