Automatic clamping pipe cutting machine

An automatic clamping and pipe cutting machine technology, applied in clamping, pipe shearing devices, shearing devices, etc., can solve the problems of reducing production efficiency and manpower consumption, and achieve the goal of improving work efficiency, satisfying cutting requirements, and reducing labor force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

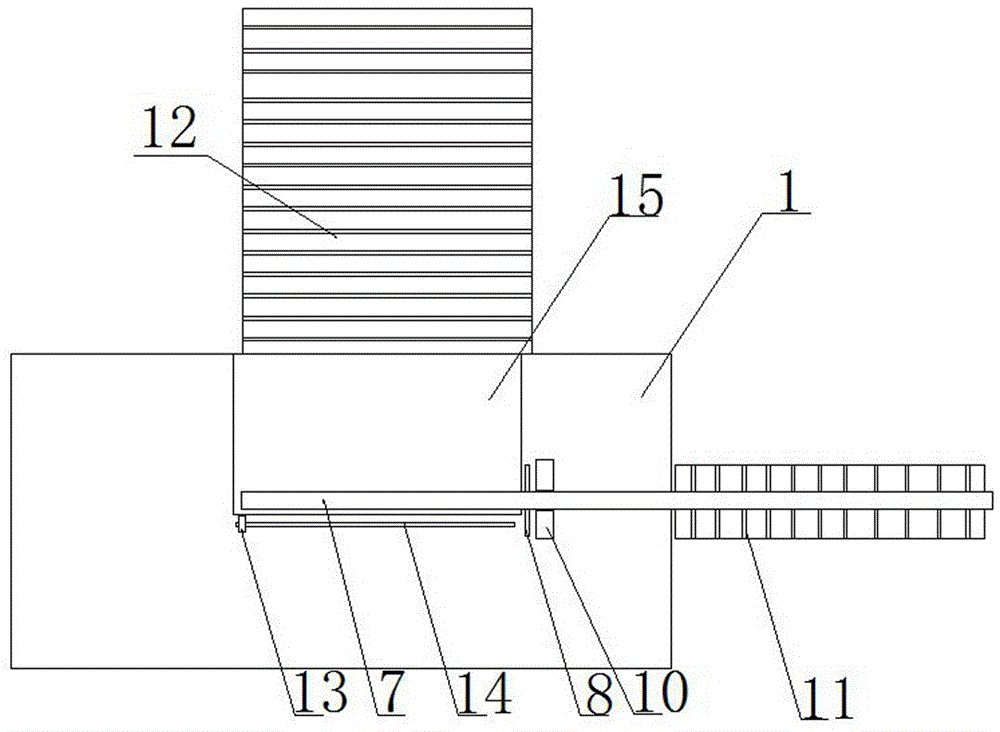

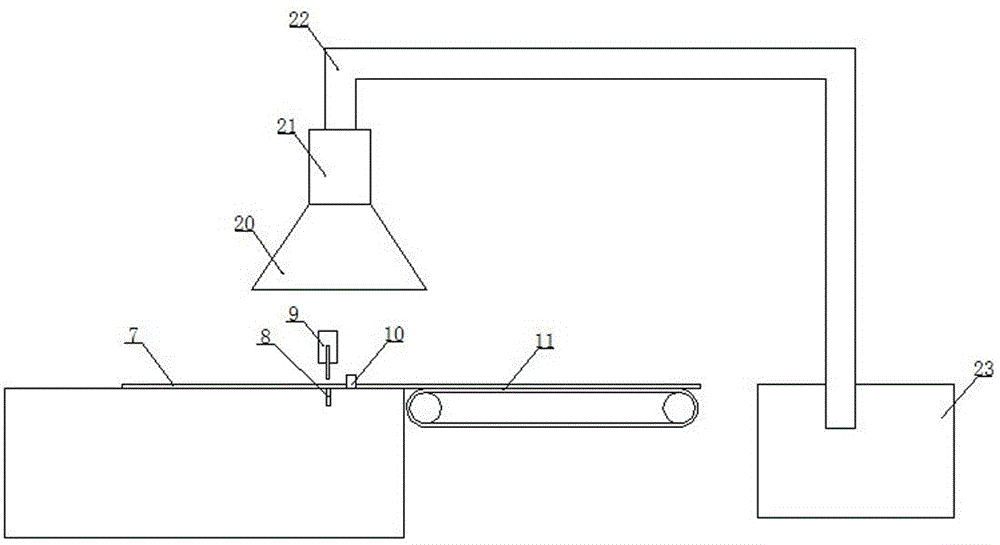

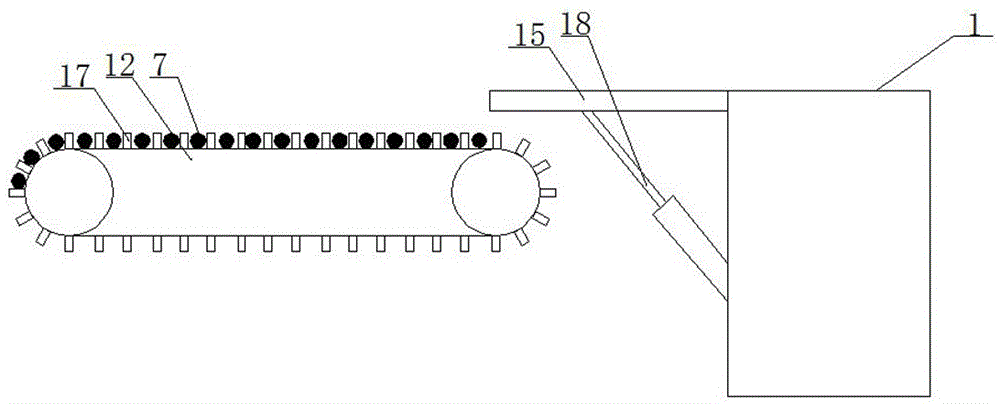

[0017] Figure 1-3 Shown is an automatic clamping pipe cutting machine provided by the present invention, including: steel pipe 7, cutting groove 8, cutting device 9, electromagnet clamping block 10, feed conveyor belt 11, discharge conveyor belt 12, Infrared sensor 13, chute 14, rotating plate 15, raised bar 17, cylinder 18 and body working surface 1. A pair of electromagnet clamping blocks 10 and an infrared sensor 13 can be slidably provided on the working surface 1 of the body; a cutting device 9 is provided on the working surface 1 of the body, and the knife edge of the cutting device 9 is between the moving end of the infrared sensor 13 A scale is provided; the body working surface 1 is rotatably provided with a rotating plate 15 flush with it, a cylinder 18 is provided between the rotating plate 15 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com