Slicing machine capable of improving medicinal material uniformity

A technology of uniformity and slicing machine, applied in the direction of metal processing, etc., can solve the problems of artificial completion due to human factors, uneven slice size and thickness, and inability to maintain slicing efficiency, etc., to achieve uniform thickness, improve the uniformity of medicinal materials, and improve the quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

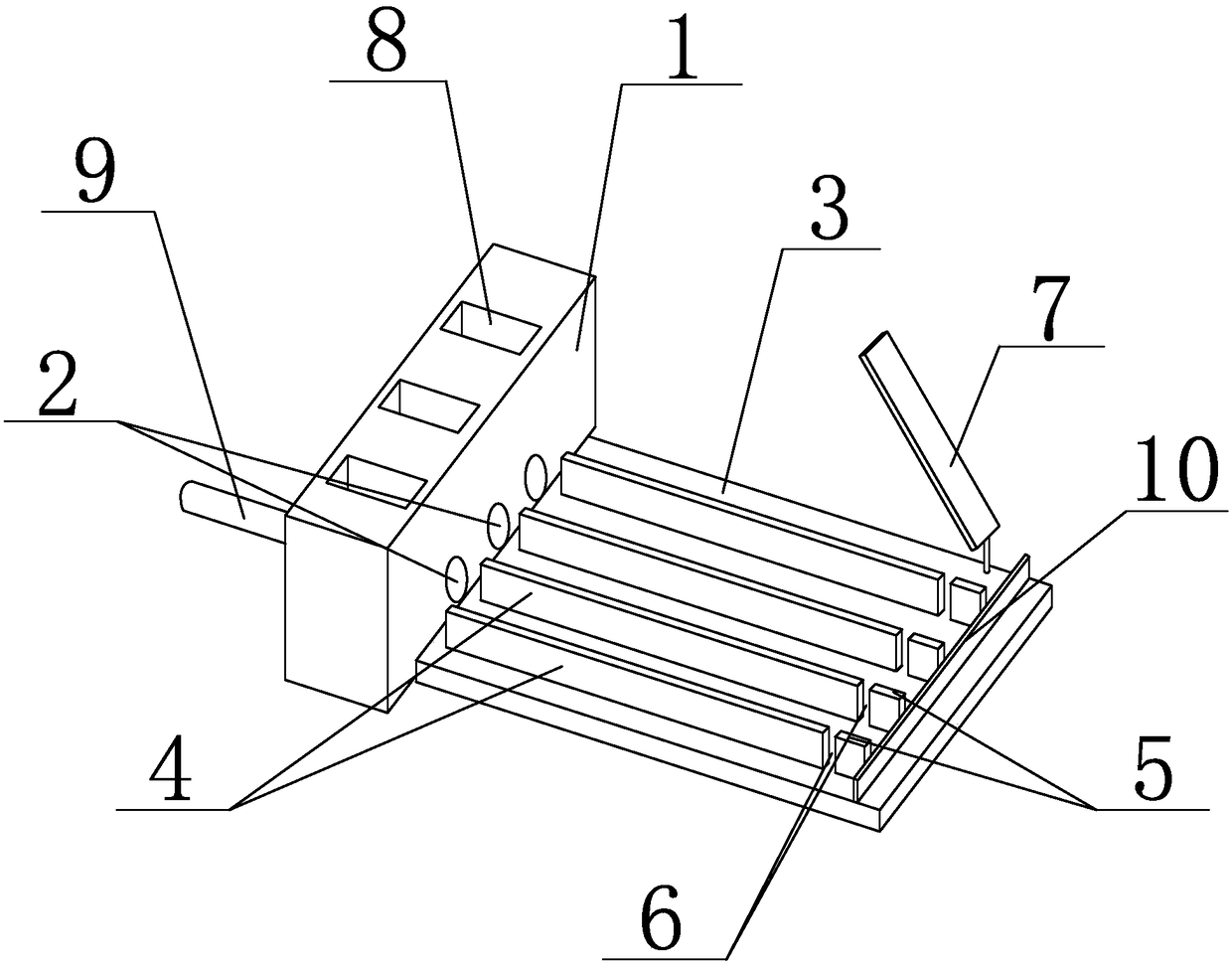

[0022] Such as figure 1 As shown, the slicer capable of improving the uniformity of medicinal materials in the present invention includes a feeding table 1, and a plurality of feeding holes 2 penetrating through both sides of the feeding table 1 are arranged on the side wall of the feeding table 1, and a plurality of feeding holes 2 Arranged horizontally side by side, one end of the feeding hole 2 is provided with a slice work plate 3 arranged horizontally, and a plurality of partition plates 4 are vertically arranged on the slice work plate 3, and the partition plates 4 are parallel to the feed hole 2 and the partition plates 4 is located on both sides of each feeding hole 2, and a cutting area is formed between every two adjacent partition plates 4, and a cutting area corresponds to a feeding hole 2 one by one, and the partition board 4 is far away from the feeding table One end of 1 is provided with a size clip 5, the size clip 5 is parallel to the partition plate 4 and a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com