Automatic cutting machine

A cutting machine and automatic technology, which is applied in the direction of shearing devices, shearing machine accessories, shearing machine equipment, etc., can solve the problems of low cutting precision, excessive damage of cutting machine impact force, low degree of automation, etc., and achieve reduction Noise and service life of equipment, improvement of production efficiency and safety, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

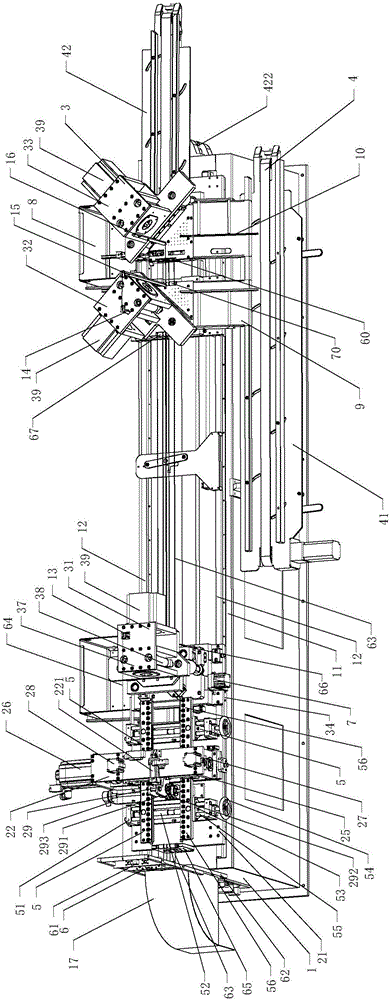

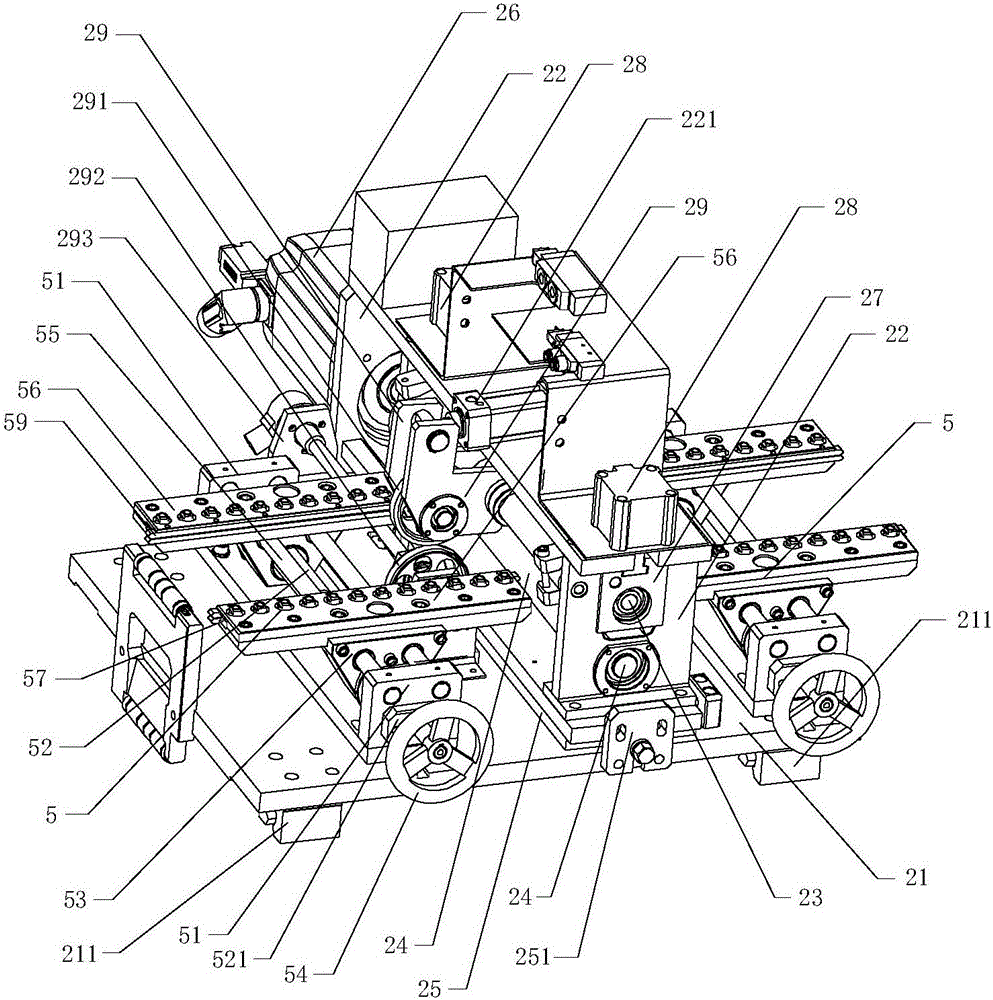

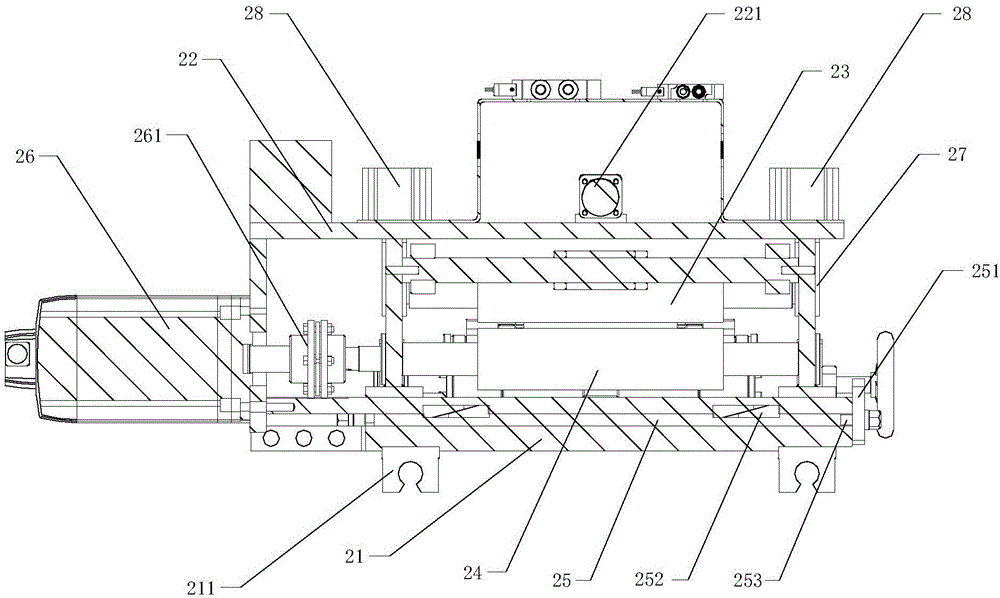

[0030] Embodiment 1, combining Figure 1 to Figure 11 , an automatic cutting machine, comprising an underframe 1, a feeding mechanism 2, a cutting unit 3 and a conveying device 4, a platform 11 is arranged above the underframe 1, guide rails 12 are respectively arranged on both sides of the platform 11, two guide rails 12 Parallel to each other, extending from the rear end of the platform 11 to its front end, the guide rail 12 is fixedly installed on the upper surface of the platform 11 through the guide rail seats located at its two ends. The feeding mechanism 2 is located above the rear of the platform 11, and the four corners below the large bottom plate 21 at the bottom are respectively equipped with sliding seats 211, and the large bottom plate 21 is slidably connected with the guide rail 12 through the sliding seats 211. The feeding mechanism 2 includes Feeding bracket 22, upper pressure roller 23 and lower pressure roller 24, adjusting plate 25 is arranged between the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com