High-temperature-resistant ionic liquid cutting fluid with lubrication self-enhancement function

An ionic liquid and enhanced function technology, applied in the field of metal cutting, can solve the problems of high viscosity of cutting oil, high surface tension, poor penetration performance, etc., and achieve excellent lubricating performance, promote lubrication, and good lubricating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Weigh 50 g of 1-methylimidazole into a three-necked flask, heat it in a water bath at 40°C, and slowly add 60 g of bromoethane to it with a constant pressure dropping funnel under the protection of N2, stir magnetically, and reflux for 7 hours. After the reaction, the heating was stopped, and the solution was allowed to stand at room temperature for 6 h to obtain a white solid, which was dried in vacuo to obtain 1-ethyl-2,3-methylimidazolium bromide ([EMIM]Br).

[0027] Weigh 20g of [EMIM]Br into a 200mL single-neck flask, and weigh 15g of KPF 4 Dissolve in distilled water, slowly add KPF4 solution dropwise to a constant pressure dropping funnel, stir magnetically at 60°C for 10h, stand to cool, and precipitate light yellow [EMIm]PF 4 ionic liquid.

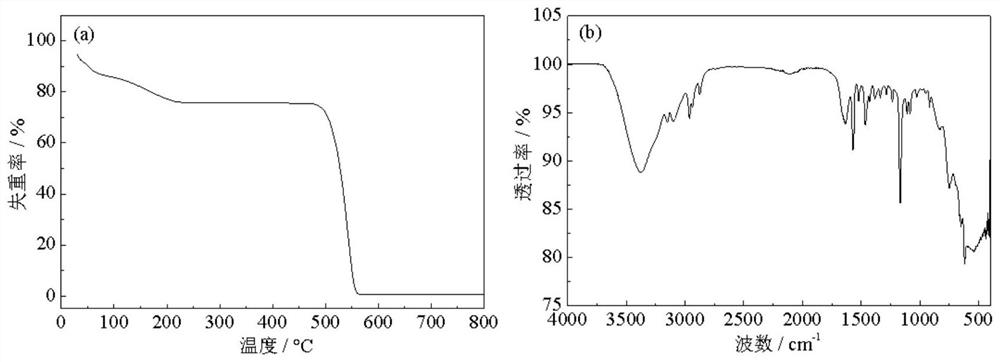

[0028] figure 1 Shown are the thermogravimetric and infrared spectroscopic analyses of the synthesized ionic liquids, given by figure 1 (a) Visible [EMIm]PF 4 The thermal decomposition temperature is around 500°C.

Embodiment 2

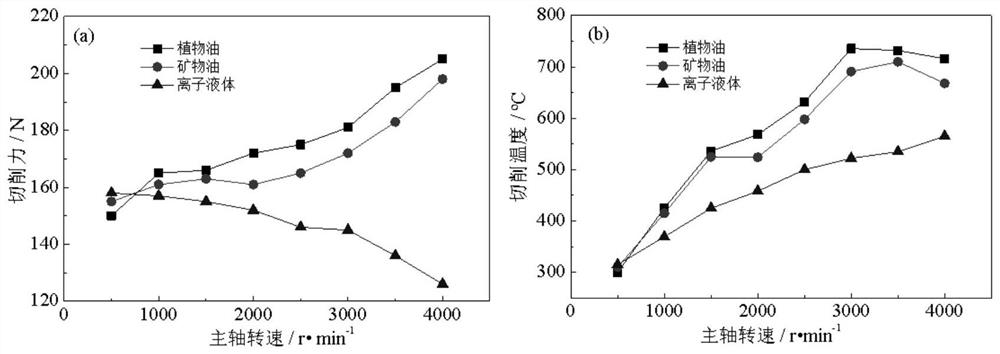

[0030] And compared with ordinary vegetable oil (ACCU-LUBE LB2000) and mineral oil (Mobil 1535) to carry out [EMIm]PF 4 Turning test of ionic liquids. The turning test was carried out on a CAK6136 lathe, GCr15 bearing steel was used as the workpiece, the cutting force was measured by Kistler 9129A dynamometer, the resultant force of the three-direction cutting force was used as the cutting force evaluation standard, and the RX4006D thermometer was used to measure the temperature of the cutting area. . Using Mitsubishi SNMG120404-MA UE6110 blade for processing, the workpiece size is Ф60mm×350mm, the spindle speed is 1000r / min, the amount of back cutting is 0.4mm, the cutting length is 150mm, the feed rate is f=0.08mm / r, and the cutting time is T=15min. The flow rate of MQL is 15ml / h and the air pressure is 2.0Mpa.

[0031] The variation trend of the measured cutting force and cutting temperature with the spindle speed is as follows: figure 2 shown. It can be seen that wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com