Precoated metal plate and manufacturing method thereof

A metal plate and pre-coating technology, which is applied in the direction of metal layered products, chemical instruments and methods, coatings, etc., can solve the problems of poor coating processing performance, great influence on film clarity, coating cracking, etc. , to save energy and equipment length, good transparency and mirror effect, smooth coating surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

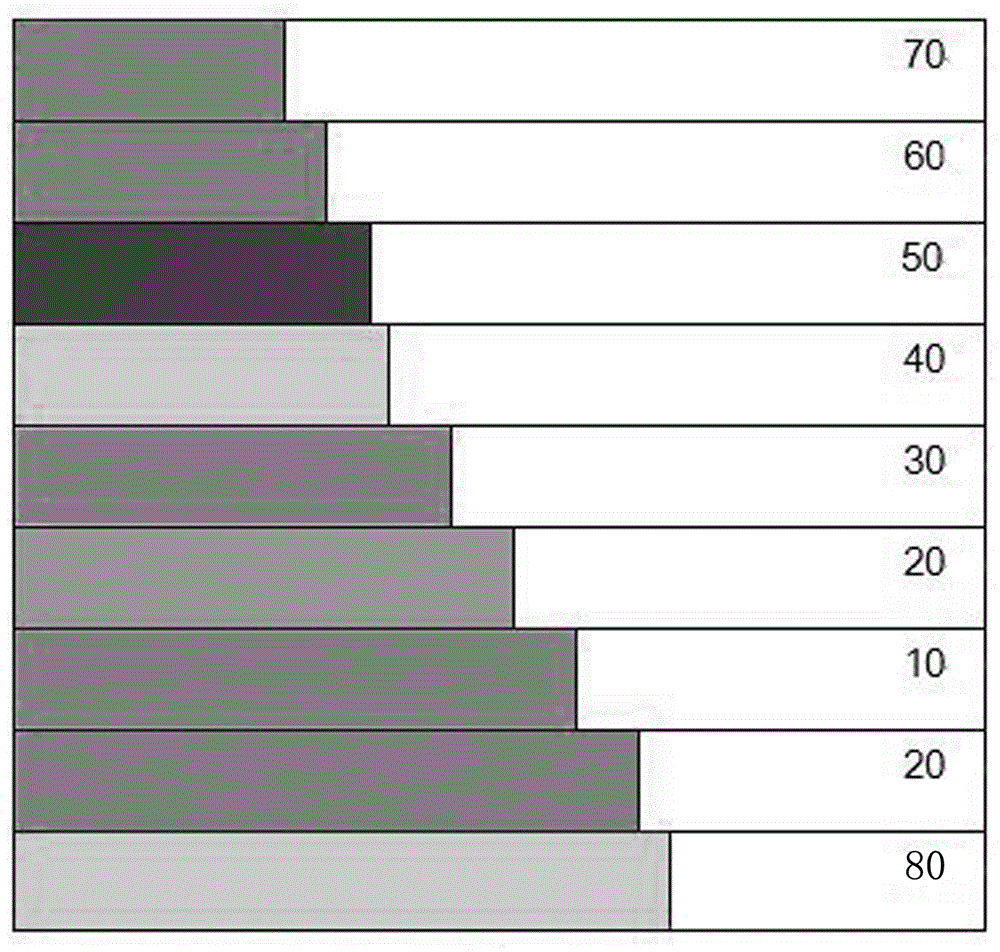

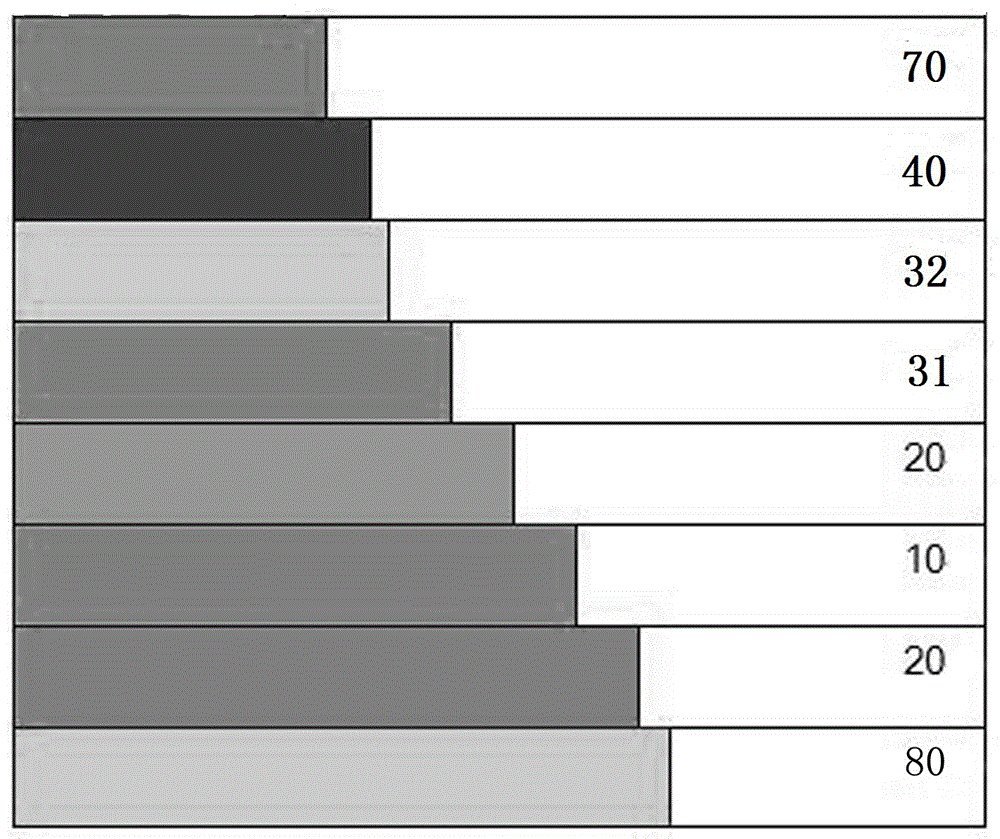

[0052] A pre-coated metal plate, the front side includes a metal substrate 10 and a chemical treatment layer 20, a solvent-based coating 30, a first UV coating 40, and a transfer pattern attached to the metal substrate 10 in sequence from bottom to top 50 , the second UV coating 60 and the protective film 70 . The backside comprises a chemical treatment layer 20 and a backside paint 80 .

[0053] The metal substrate 10 is a hot-dip galvanized substrate, the chemical treatment layer 20 is a chrome-free chemical treatment layer, the solvent-based coating 30 is a white polyester coating, and the first UV coating 40 is a transparent UV coating, the transfer pattern 50 adopts thermal curing ink transfer pattern, the second UV coating 60 adopts a transparent UV coating, the protective film 70 adopts a PE protective film, and the back paint 80 adopts a gray back paint.

[0054] The main components of the first UV coating 40 are 60% of polyurethane acrylate prepolymer, 30% of acryla...

Embodiment 2

[0059] A pre-coated metal plate, the front side includes a metal substrate 10 and a chemical treatment layer 20, a solvent-based coating 30, a first UV coating 40, and a transfer pattern attached to the metal substrate 10 in sequence from bottom to top 50. Second UV coating 60.

[0060] The metal substrate 10 is a stainless steel metal plate, the chemical treatment layer 20 is a chrome-free chemical treatment layer, the solvent-based coating 30 is a transparent polyester coating, and the first UV coating 40 is a transparent UV coating. layer, the transfer pattern 50 adopts UV-curable ink to transfer the pattern, and the second UV coating 60 adopts a transparent UV coating. The main components of the transparent polyester coating are 70% of saturated polyester resin, 8% of epoxy resin, 10% of amino resin, 11% of solvent, 0.7% of leveling and defoaming agent, and 0.3% of catalyst, all in percentage by weight, A small amount of color paste can be added.

[0061]The main compone...

Embodiment 3

[0065] A precoated metal plate, the front side includes a metal substrate 10 and a chemical treatment layer 20 attached to the metal substrate 10 from bottom to top, a solvent-based primer 31, a solvent-based mid-coat 32, a first UV coating 40 and protective film 70 . The back contains a chemical treatment layer 20 and a gray back paint 80 such as figure 2 .

[0066] The metal substrate 10 adopts a hot-dip galvanized substrate, the chemical treatment layer 20 adopts a chromium-free chemical treatment layer, the solvent-based primer layer 31 adopts a white polyester primer layer, and the solvent-based middle coat layer 32 adopts Black polyester middle coating, the first UV coating 40 adopts transparent UV coating, the protective film 70 adopts PE protective film, and the described back paint 80 adopts gray back paint.

[0067] Described white polyester undercoat is used for improving the corrosion resistance of hot-dip galvanized substrate, and improves and the adhesive forc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com