High-lubrication universal total synthesis cutting fluid

A general-purpose, fully synthetic technology, used in lubricating compositions, petroleum industry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

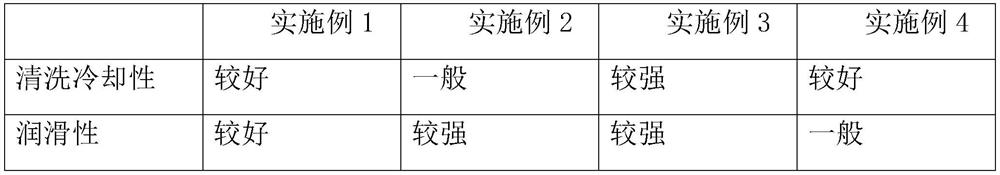

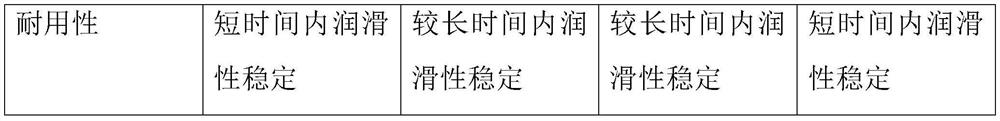

Embodiment 1

[0028] Embodiment 1, the present invention provides a high-lubrication general-purpose fully synthetic cutting fluid, comprising the following steps:

[0029] S1: Weigh raw materials according to weight percentage, the rust inhibitor is 8%, the alkali reserve agent is 15%, the metal ion chelating agent is 0.2%, the aluminum corrosion inhibitor is 0.1%, and the copper Corrosion inhibitor is 0.2%, the special lubricant is 5%, the wetting agent is 1%, the anti-hard water agent is 0.2%, the bactericidal antibacterial agent is 2%, and the sedimentation agent is 0.2%. %, the defoamer is 0.1%, and the diluent is 30%;

[0030] S2: Add rust inhibitor, alkali reserve agent, metal ion chelating agent, aluminum corrosion inhibitor, copper corrosion inhibitor, and special lubricant in sequence and stir evenly;

[0031] S3: The mixed solution of antirust agent, alkali reserve agent, metal ion chelating agent, aluminum corrosion inhibitor, copper corrosion inhibitor and special lubricant af...

Embodiment 2

[0037] Embodiment 2, the present invention provides a high-lubrication general-purpose fully synthetic cutting fluid, comprising the following steps:

[0038] S1: Weigh raw materials according to weight percentage, the rust inhibitor is 6%, the alkali reserve agent is 13%, the metal ion chelating agent is 0.3%, the aluminum corrosion inhibitor is 0.15%, the copper Corrosion inhibitor is 0.25%, the special lubricant is 6%, the wetting agent is 2%, the anti-hard water agent is 0.2%, the bactericidal antibacterial agent is 2.5%, and the sedimentation agent is 0.2%. %, the defoamer is 0.15%, and the diluent is 45%;

[0039] S2: Add rust inhibitor, alkali reserve agent, metal ion chelating agent, aluminum corrosion inhibitor, copper corrosion inhibitor, and special lubricant in sequence and stir evenly;

[0040] S3: The mixed solution of antirust agent, alkali reserve agent, metal ion chelating agent, aluminum corrosion inhibitor, copper corrosion inhibitor and special lubricant a...

Embodiment 3

[0046] Embodiment 3, the present invention provides a high-lubrication general-purpose fully synthetic cutting fluid, comprising the following steps:

[0047] S1: Weigh raw materials according to weight percentage, the rust inhibitor is 9%, the alkali reserve agent is 14%, the metal ion chelating agent is 0.15%, the aluminum corrosion inhibitor is 0.2%, the copper Corrosion inhibitor is 0.3%, the special lubricant is 8%, the wetting agent is 1.5%, the anti-hard water agent is 0.2%, the bactericidal antibacterial agent is 2%, and the sedimentation agent is 0.3% %, the defoamer is 0.15%, and the diluent is 55%;

[0048] S2: Add rust inhibitor, alkali reserve agent, metal ion chelating agent, aluminum corrosion inhibitor, copper corrosion inhibitor, and special lubricant in sequence and stir evenly;

[0049]S3: The mixed solution of antirust agent, alkali reserve agent, metal ion chelating agent, aluminum corrosion inhibitor, copper corrosion inhibitor and special lubricant afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com