Patents

Literature

36results about How to "Smooth and reliable adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

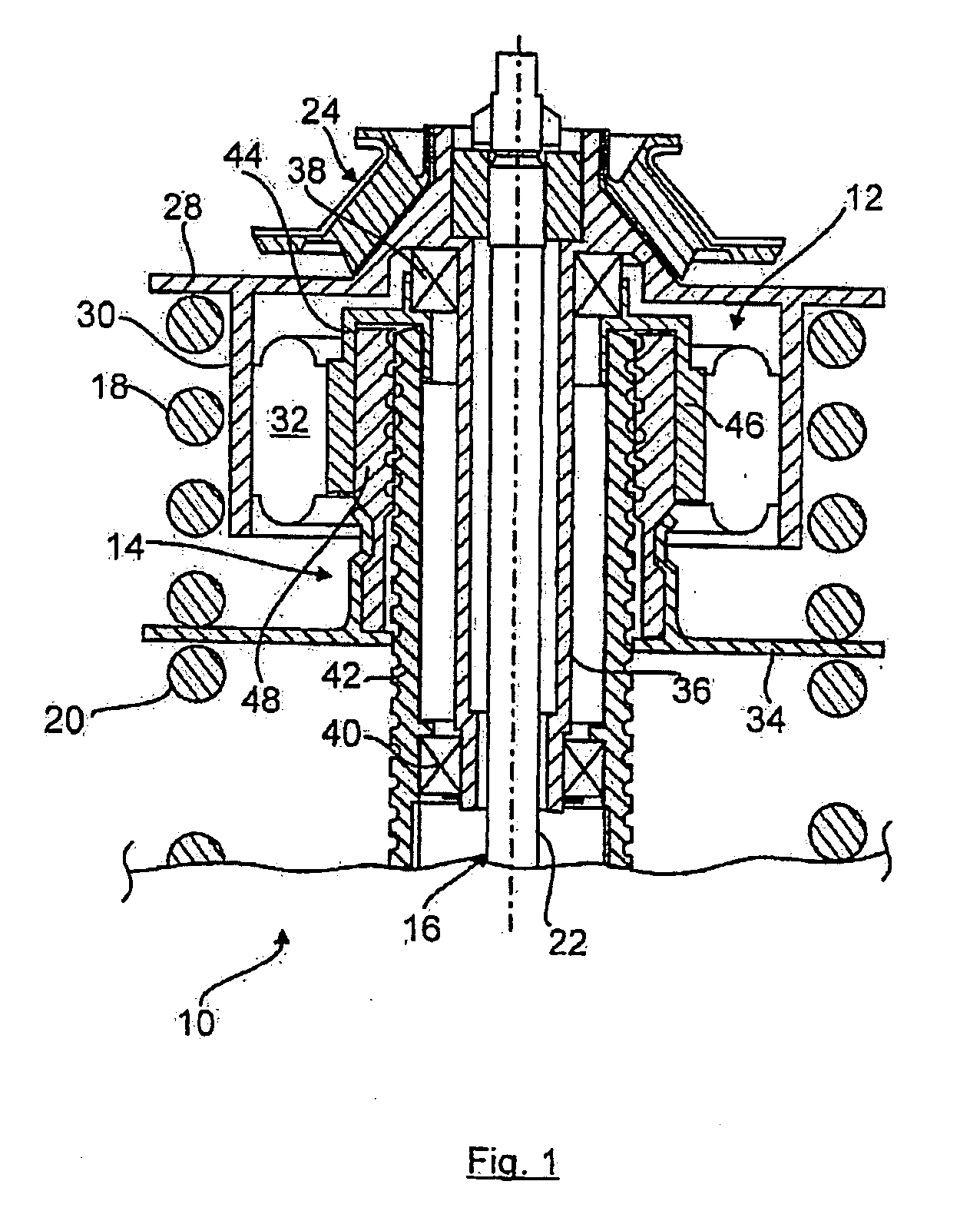

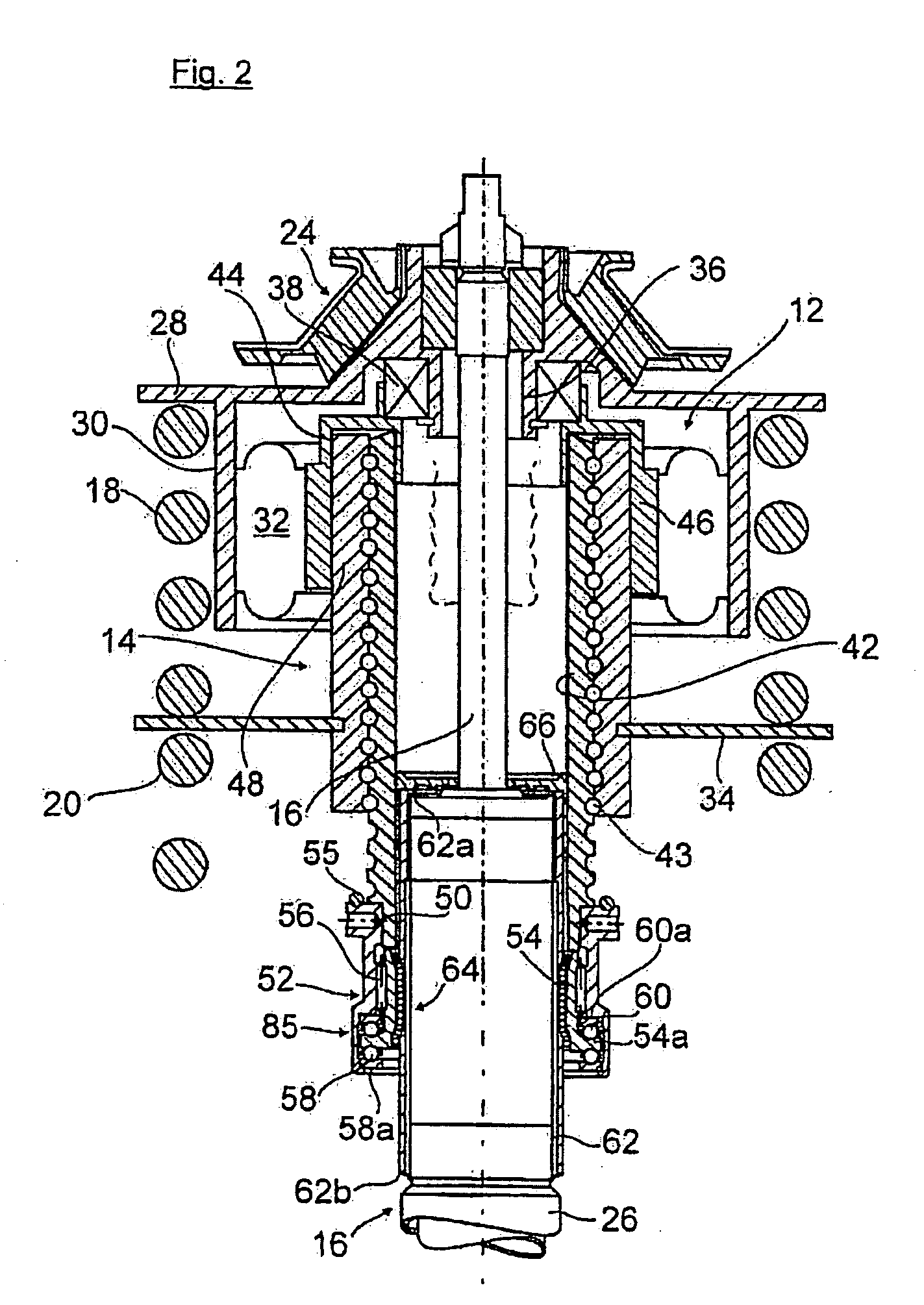

Strut for a wheel suspension of motor vehicles

InactiveUS8205864B2Smooth and reliable adjustmentAvoid overdetermination of the bearingMagnetic circuitNon-rotating vibration suppressionEngineeringShock absorber

Owner:AUDI AG

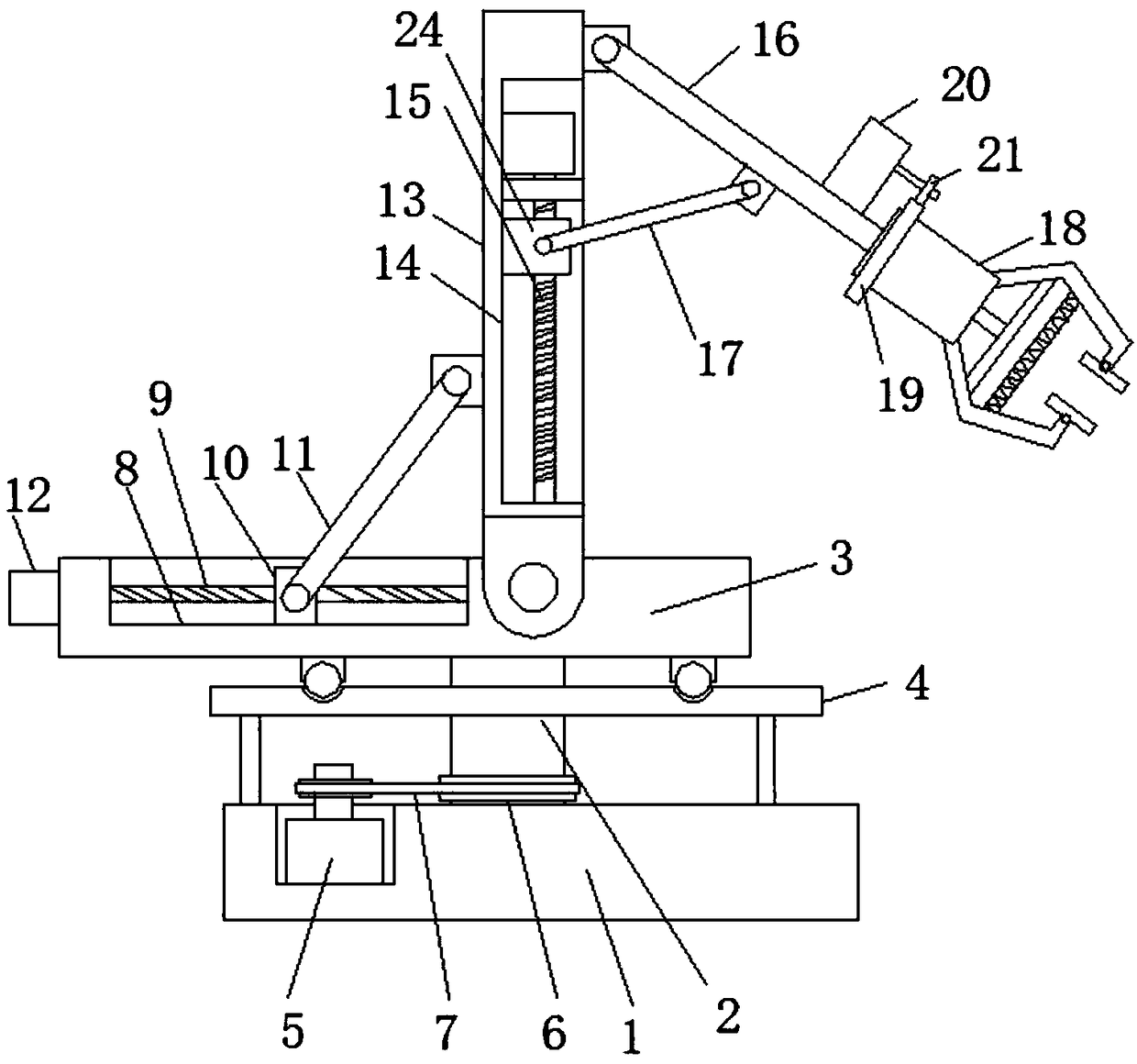

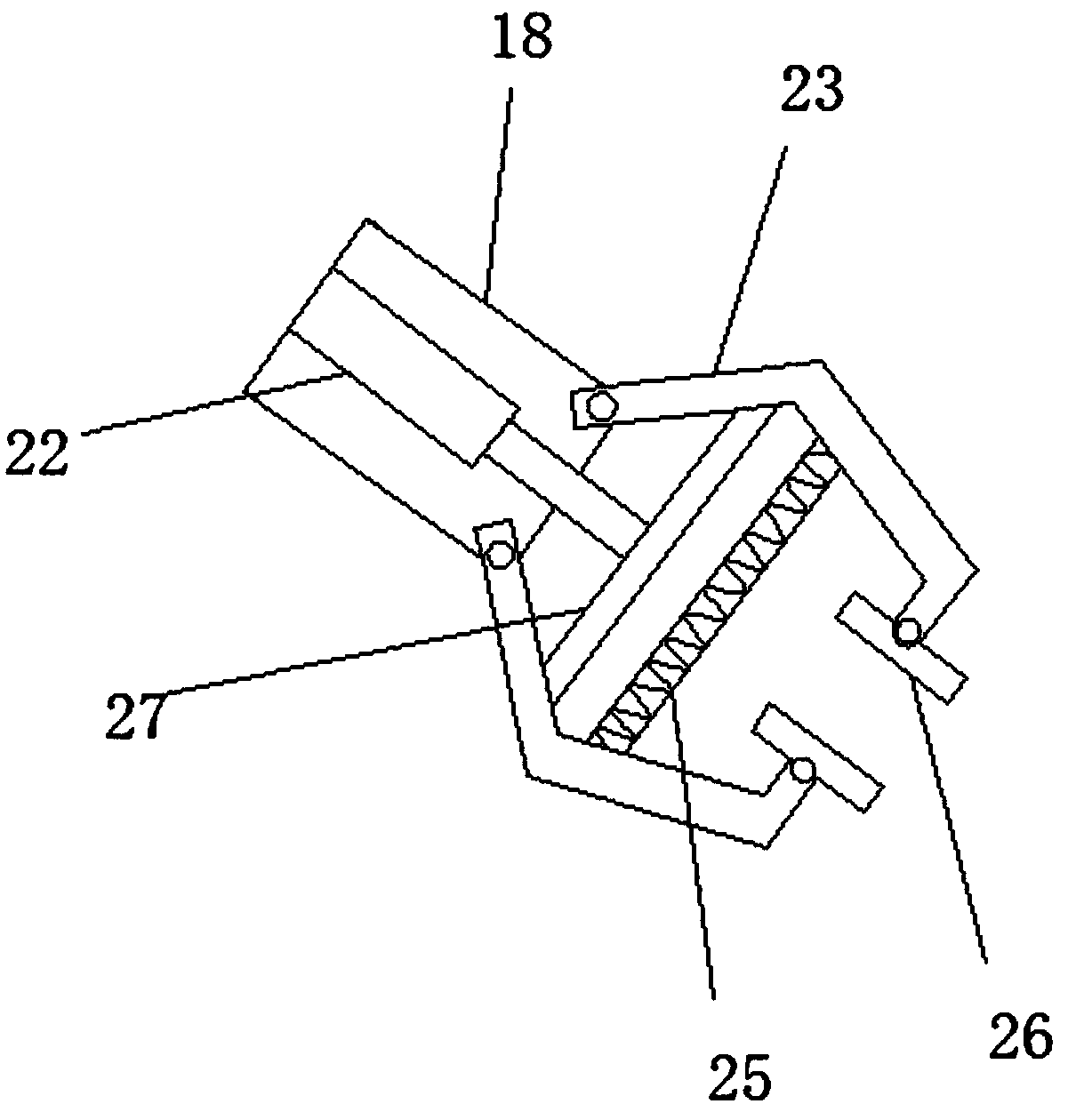

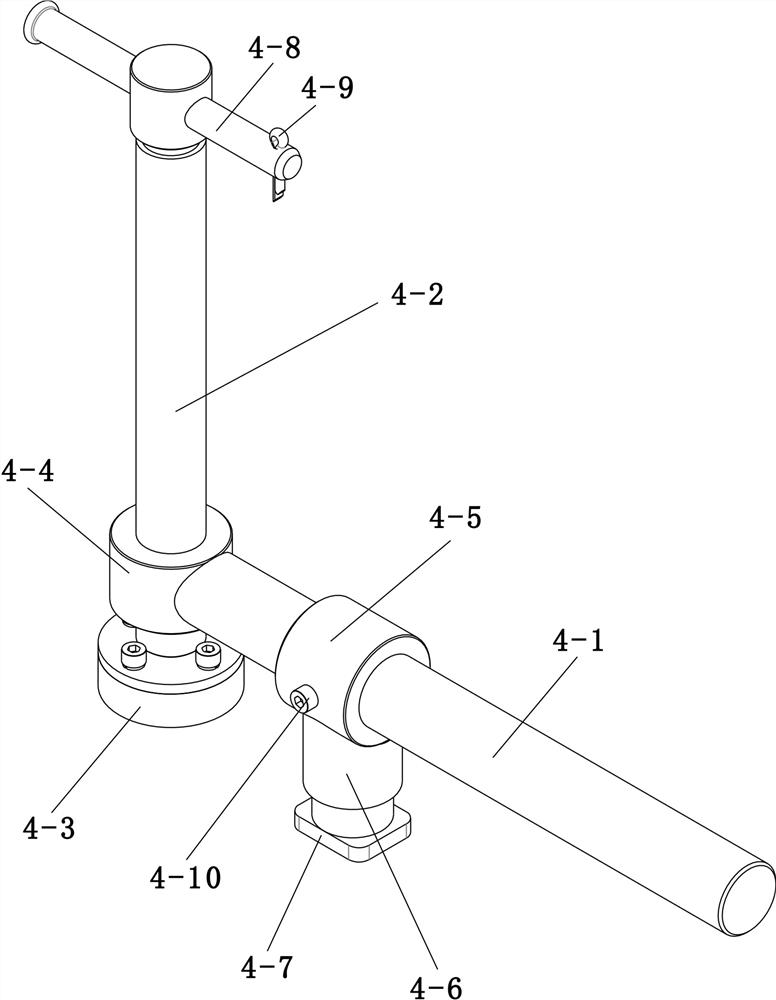

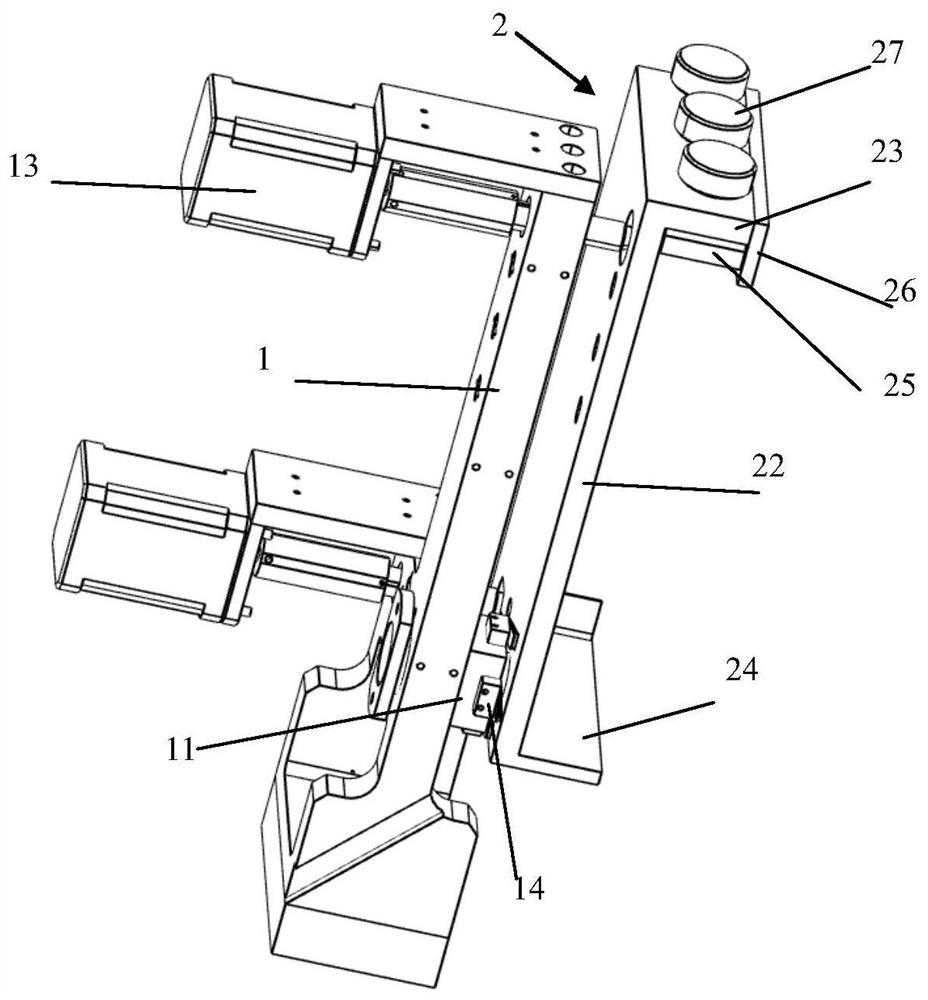

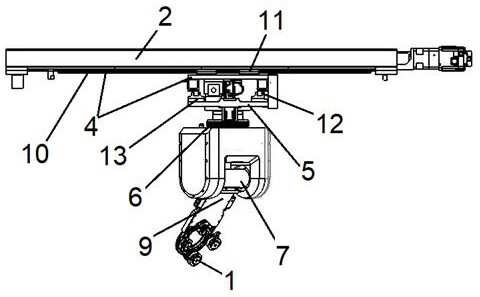

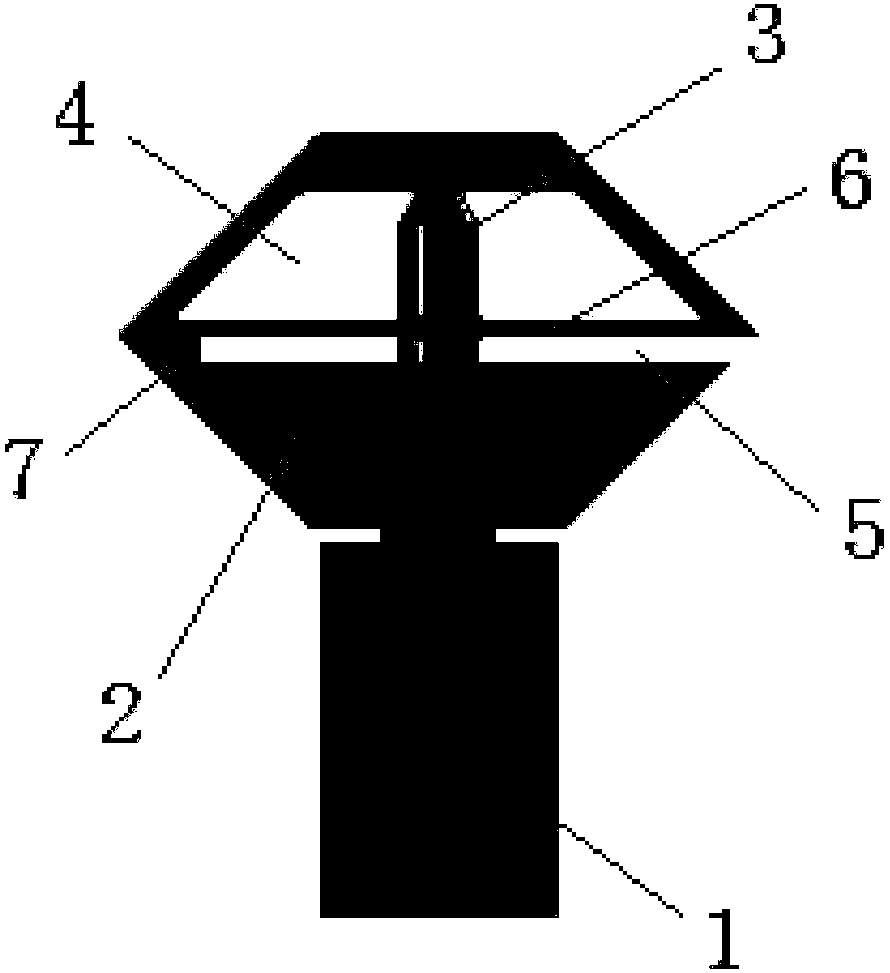

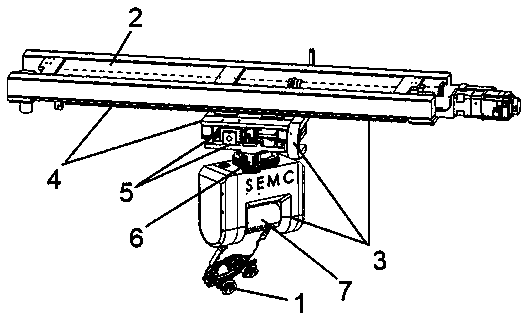

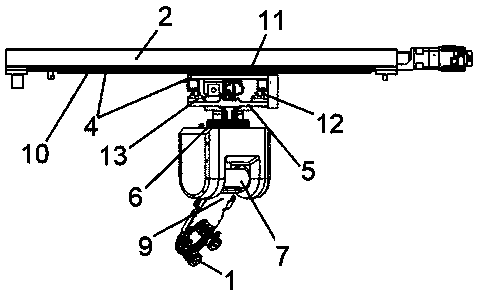

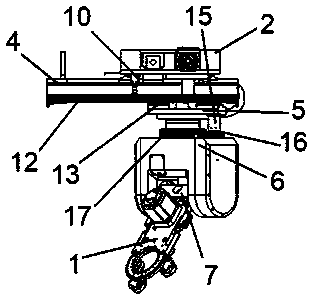

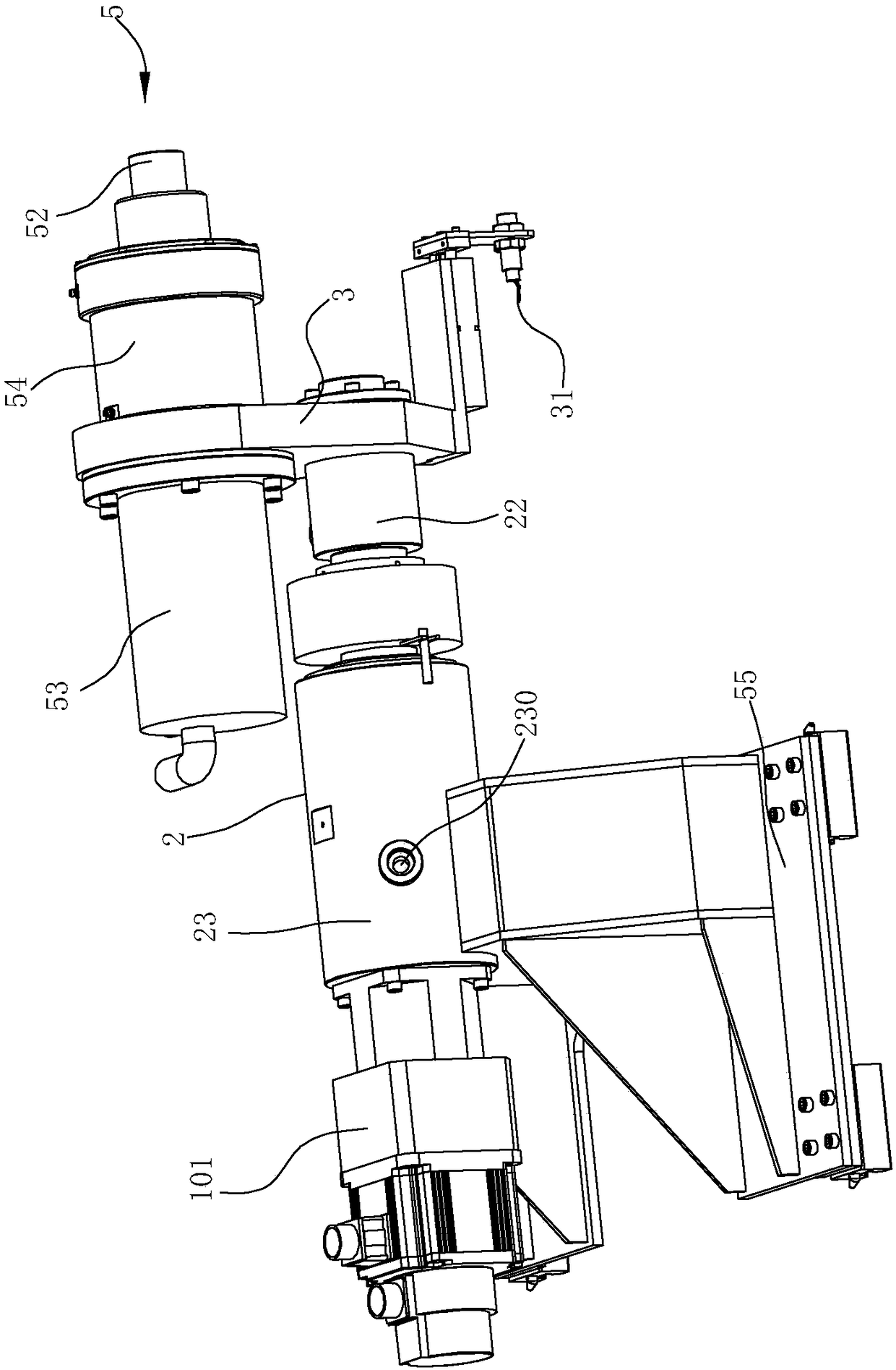

Rotatable manipulator

The invention discloses a rotatable manipulator. The rotatable manipulator comprises a base, a supporting column is rotationally installed on the top of the base, a supporting table is welded to the top of the supporting column, a supporting plate is arranged on the top of the base and located below the supporting table, a first groove is formed in the top of the supporting table, a screw rod is rotationally installed in the first groove, a movement block is installed on the screw rod in a threaded mode and is in sliding connection with the inner wall of the first groove, a linkage rod is hinged to the movement block, a first two-way motor is fixedly installed at one end of the supporting table, an output shaft of the first two-way motor is fixedly connected with the screw rod, a main armis hinged to the supporting table, one end of the linkage rod is hinged to the main arm, an adjusting groove is formed in one side of the main arm and rotationally provided with a threaded rod, and anadjusting block is installed on the threaded rod in a threaded mode. By means of the manipulator, machined products can be clamped stably and firmly, meanwhile, the manipulator can be adjusted at will, the adjusting range is wide, the manufacturing cost is low, and the products can be machined in all directions.

Owner:JINGDE COUNTY HANHAI NEBULA INTELLIGENTIZE TECH RES & DEV CO LTD

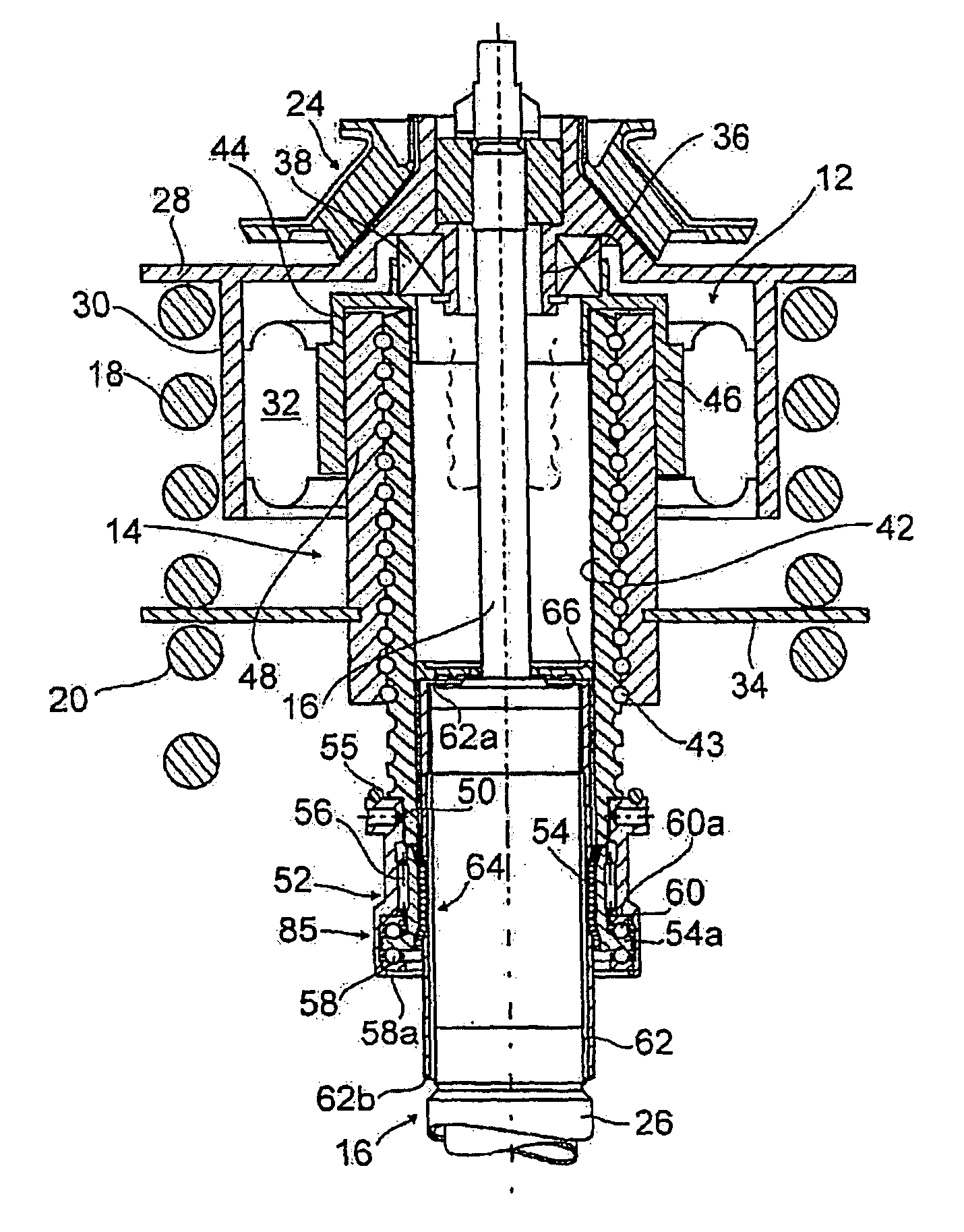

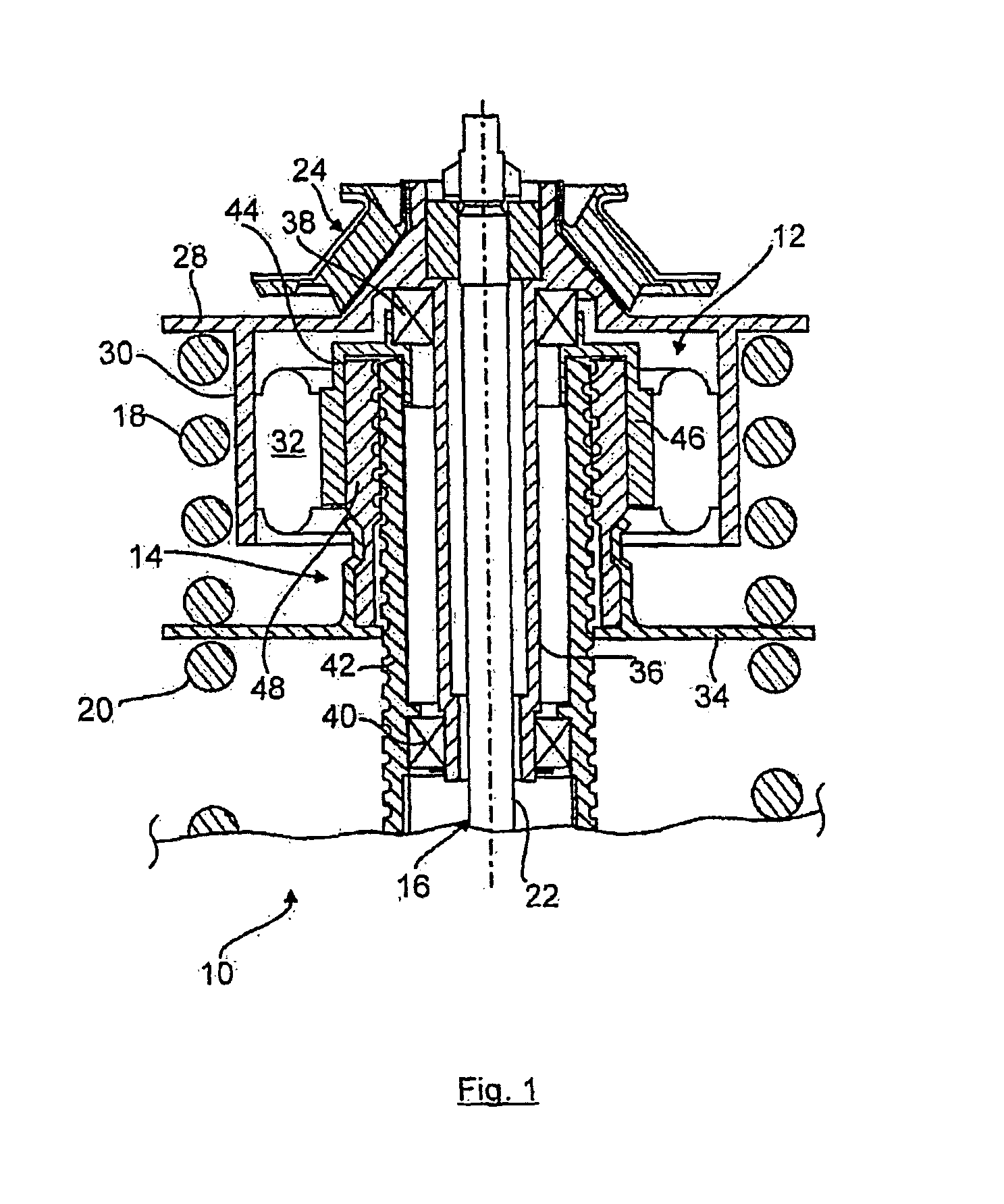

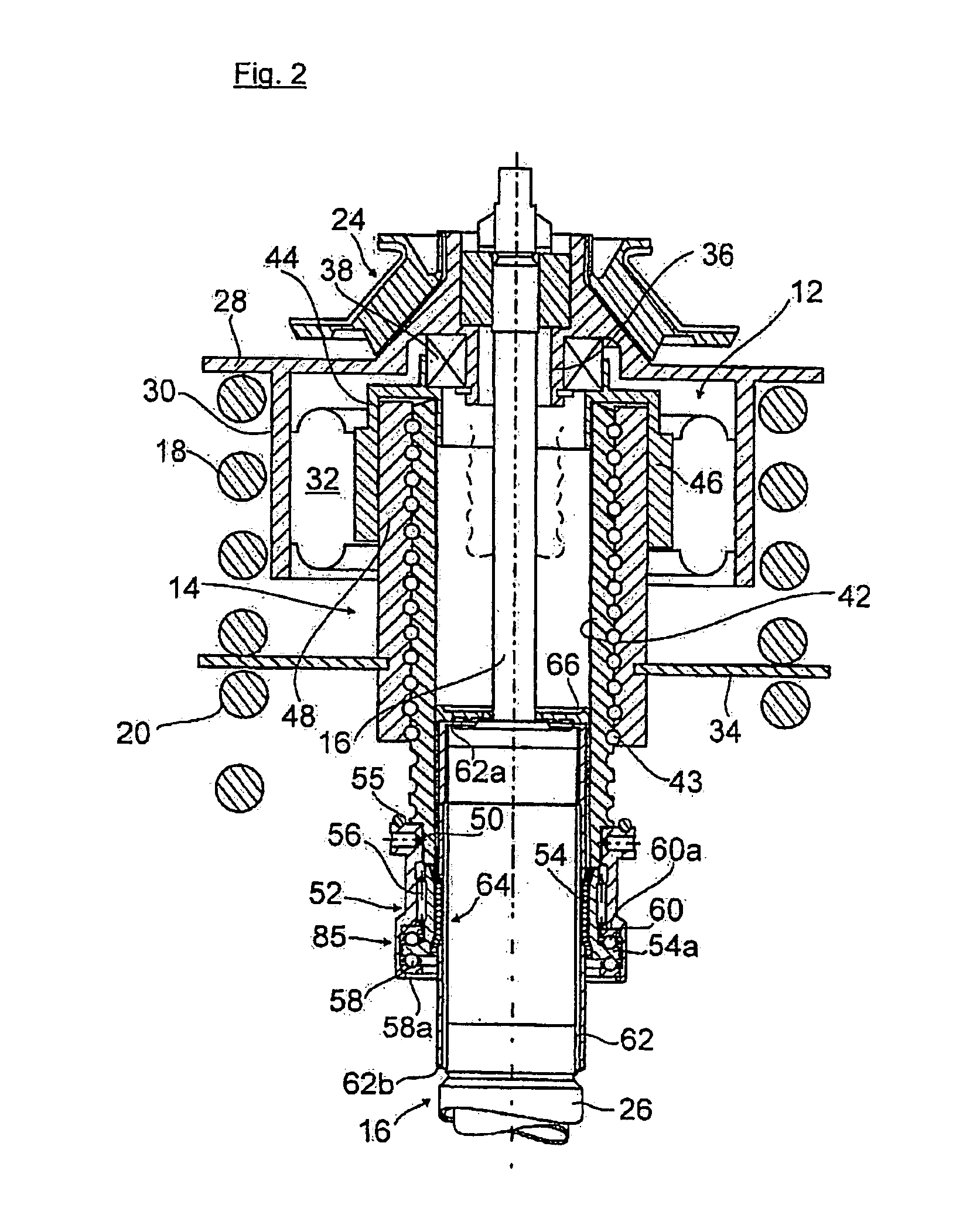

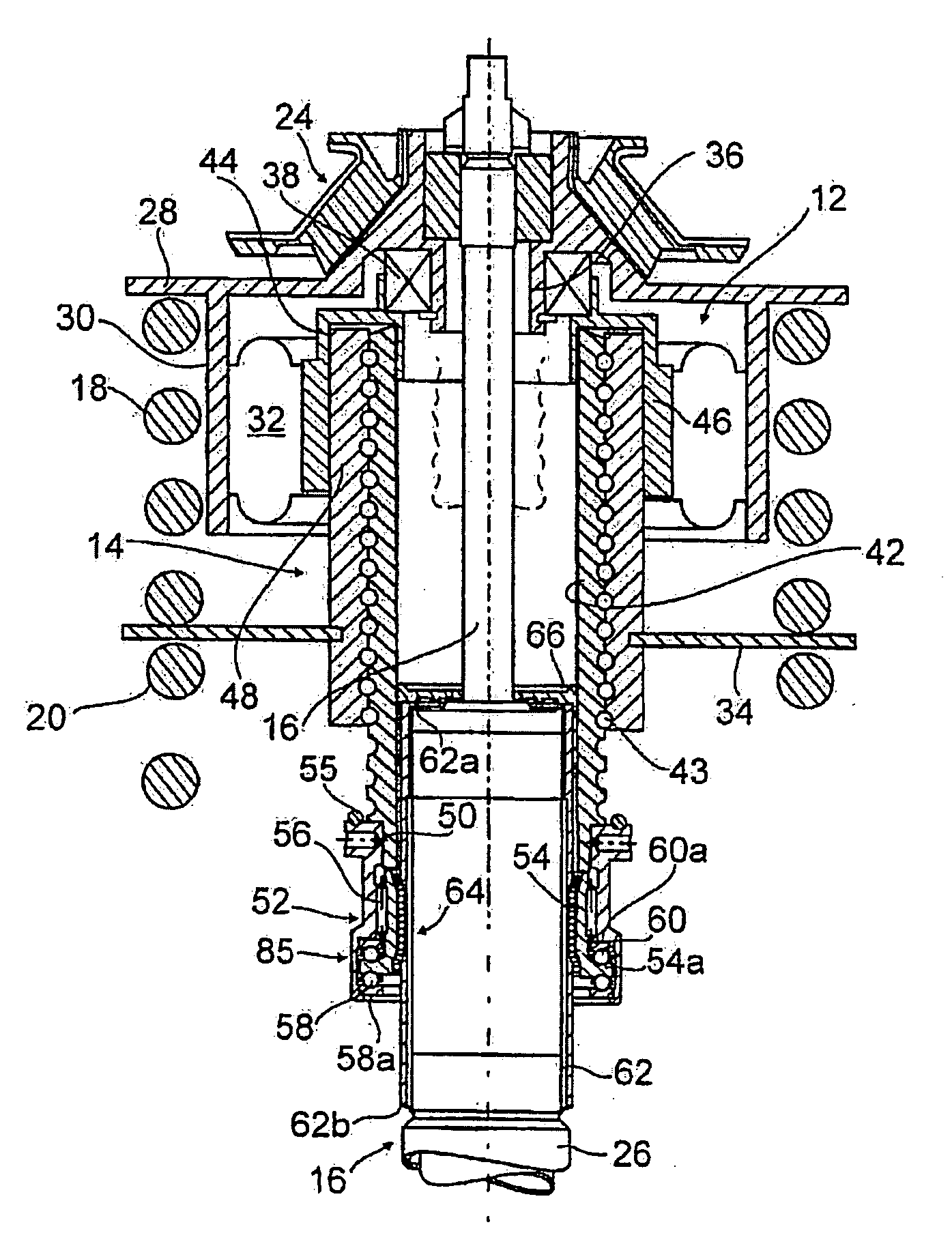

Strut for a Wheel Suspension of Motor Vehicles

InactiveUS20090057969A1Reliable vertical adjustmentSmooth and reliable adjustmentMagnetic circuitNon-rotating vibration suppressionShock absorber

The invention relates to a strut for a wheel suspension of motor vehicles, comprising a telescoping shock absorber and a support spring which surrounds it, as well as with a vertical adjustment means with a driven driving spindle which is pivoted by way of a body-mounted bearing on the engine housing side, which interacts with a vertically adjustable lifting element which is arranged to be non-rotatable and which bears the spring plate of the support spring. According to the invention, the driving spindle, in addition to the body-mounted bearing, is supported directly or indirectly on the cylinder tube of the shock absorber to be able to pivot and move axially relative to it.

Owner:AUDI AG

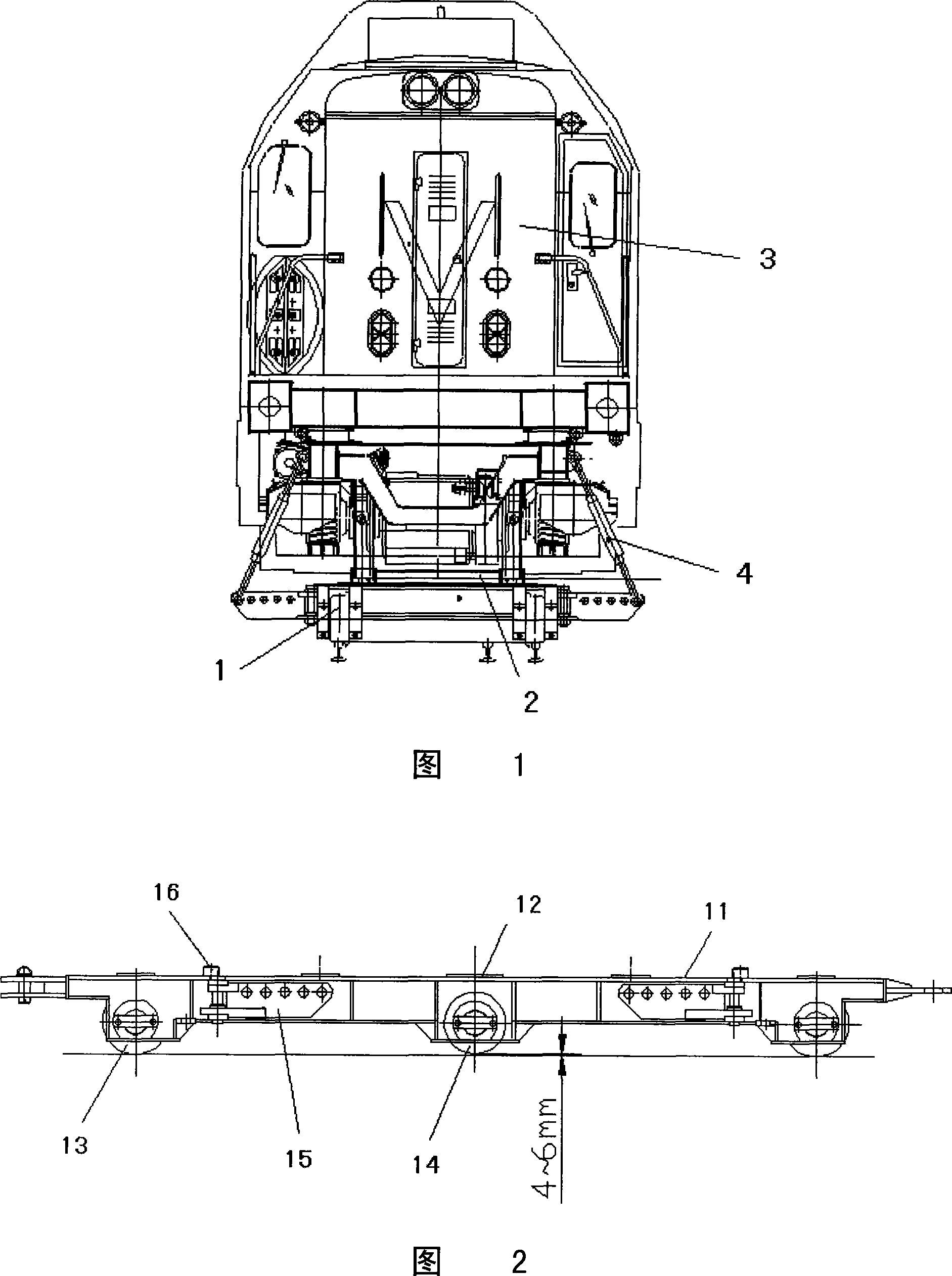

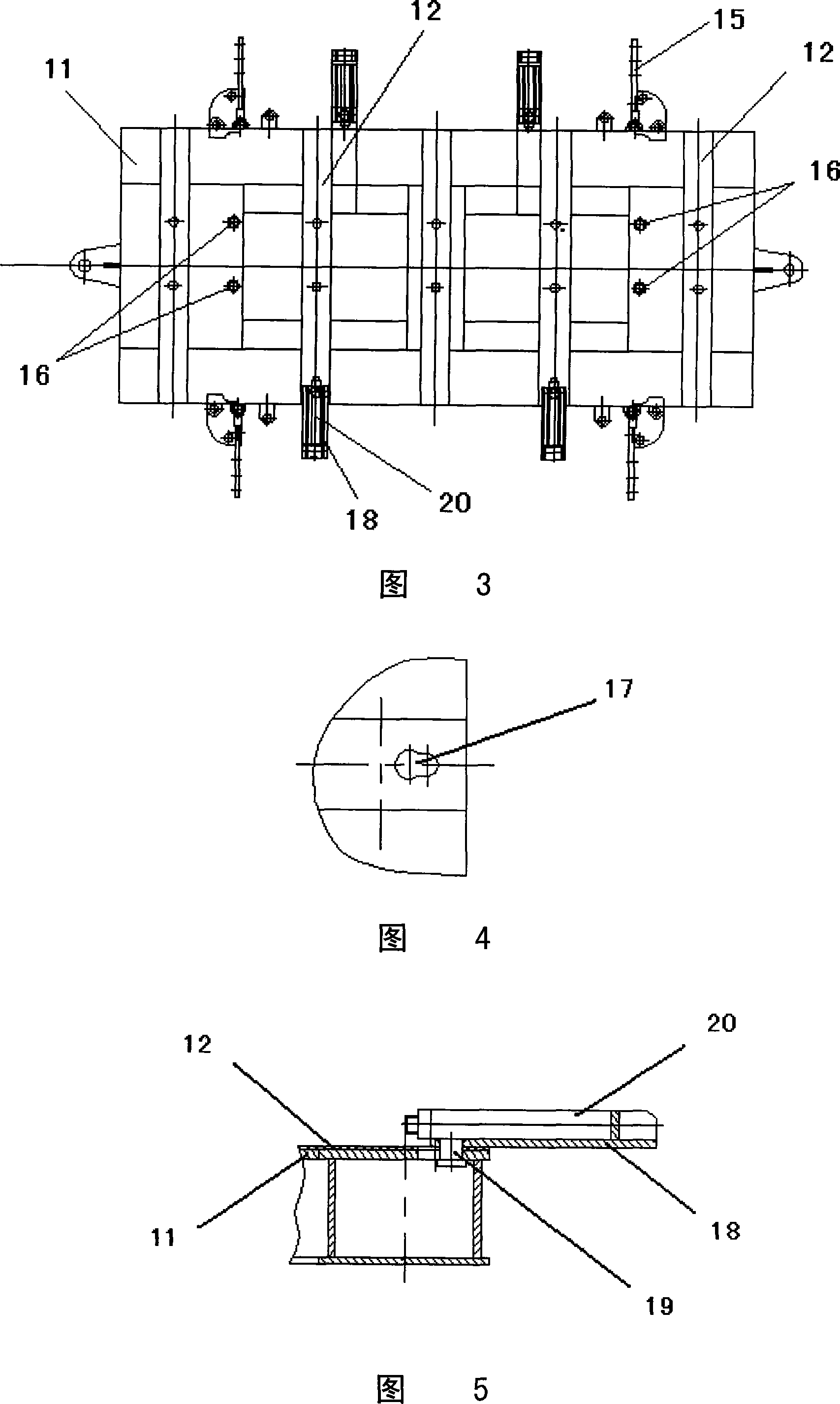

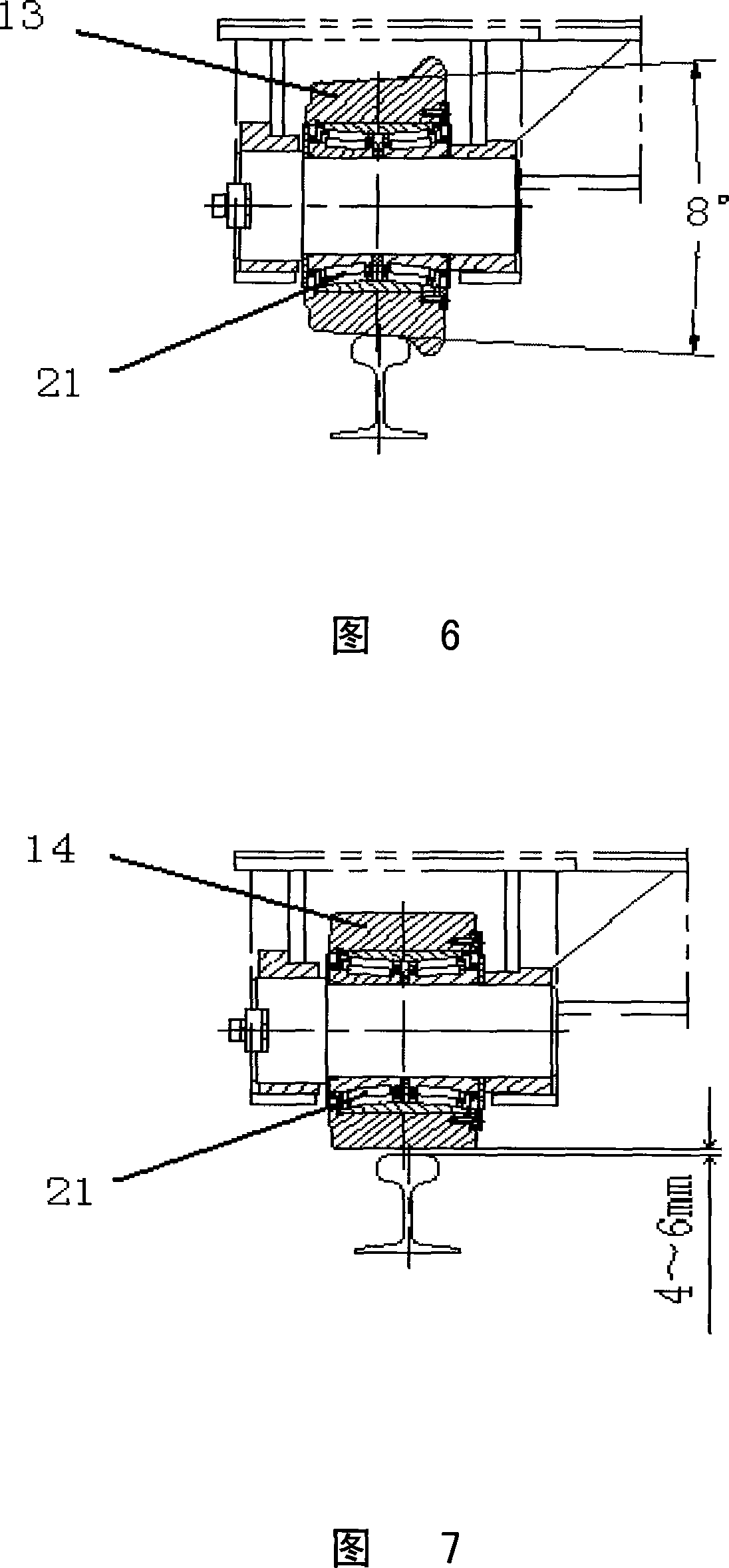

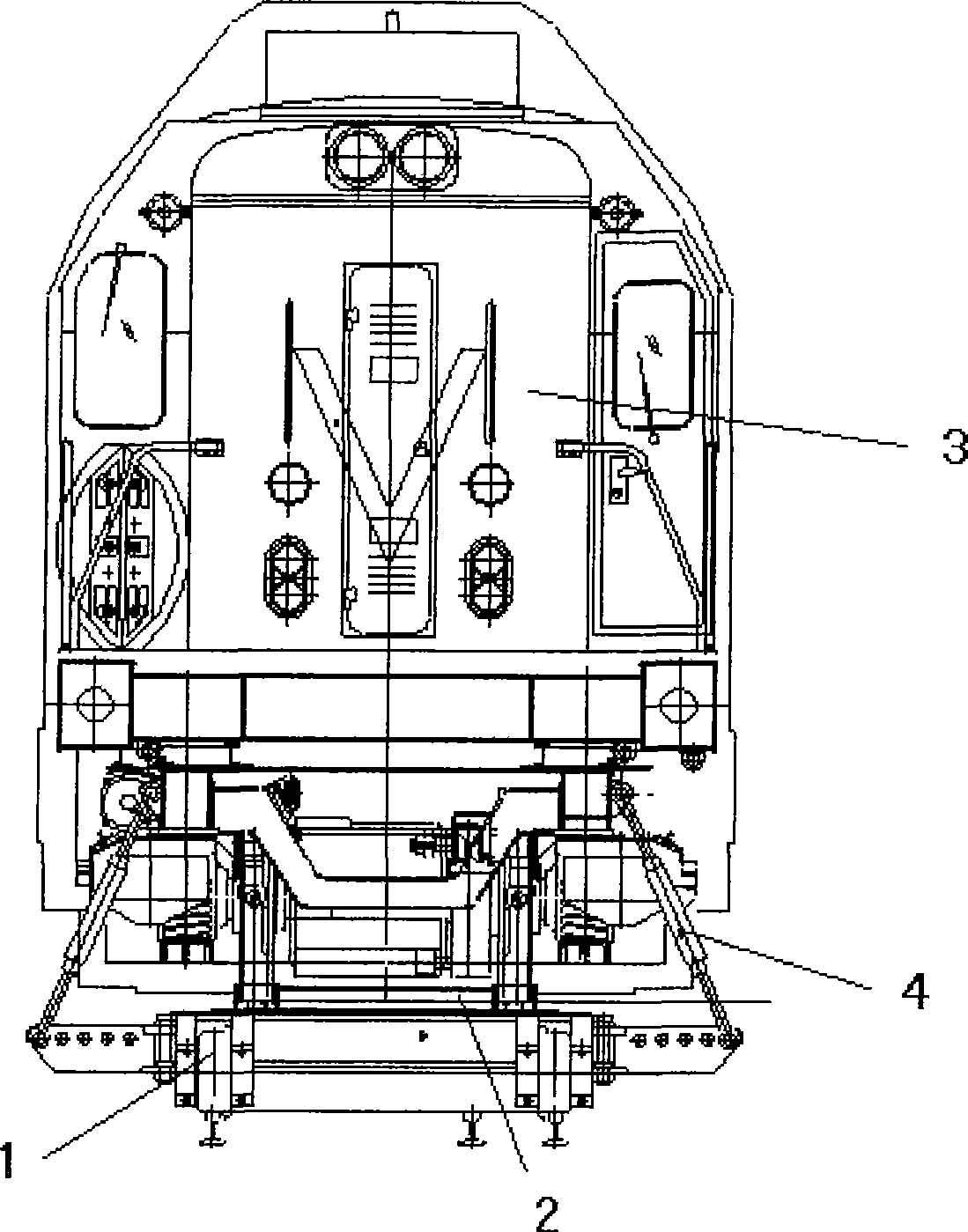

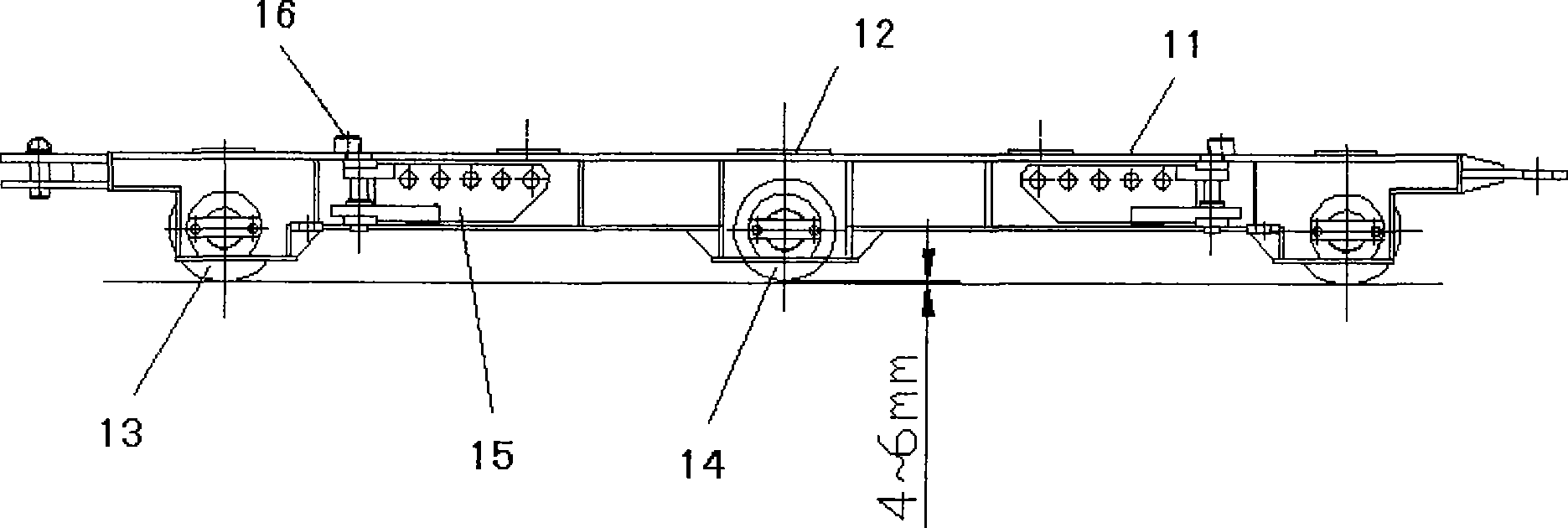

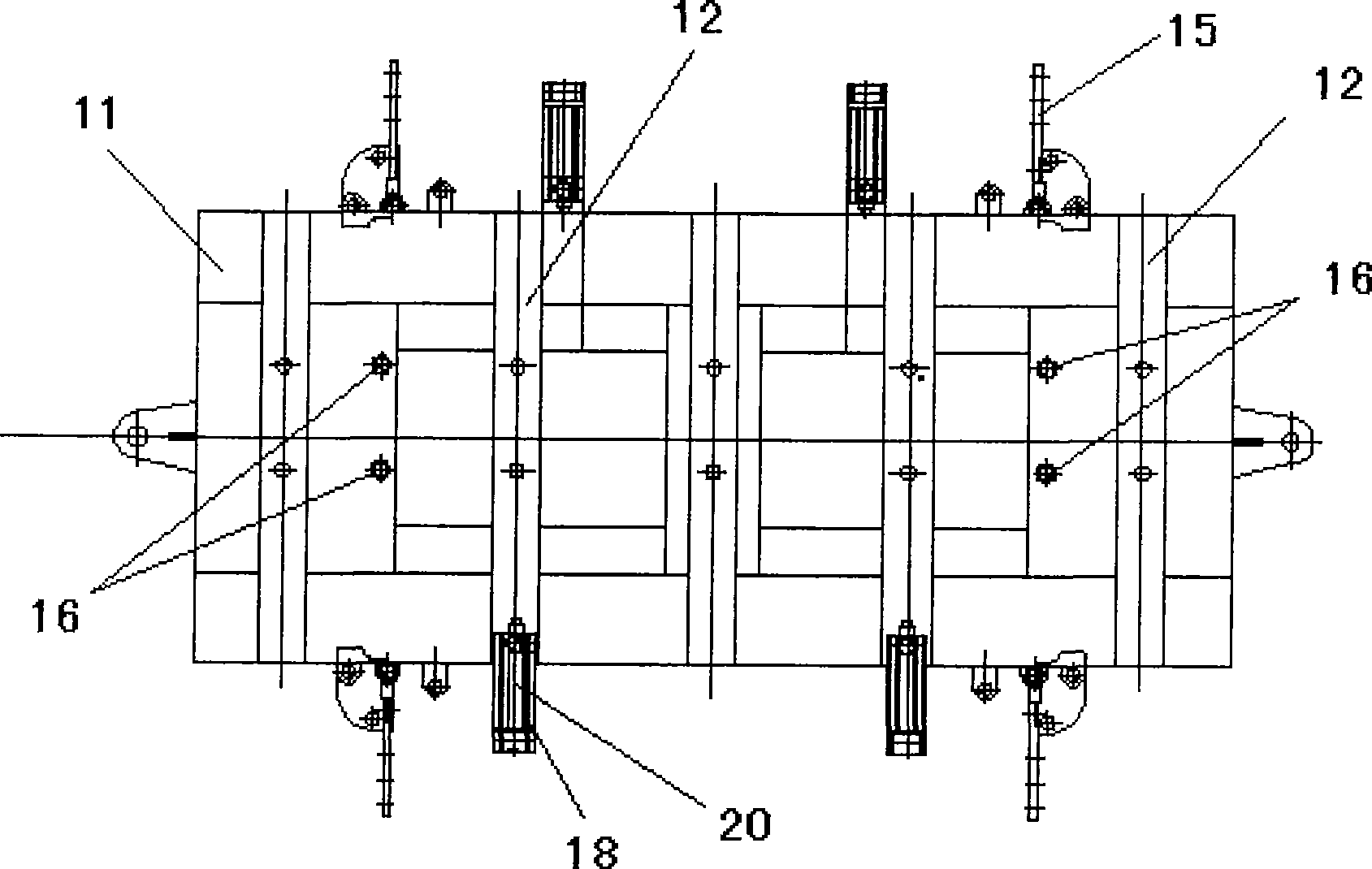

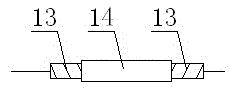

Device for transferring non-standard track space engine on the standard track space circuitry

InactiveCN101134466AImprove carrying capacitySmooth and reliable adjustmentTurntables/traversersEngineeringMechanical engineering

Owner:CRRC BEIJING ERQI LOCOMOTIVE CO LTD

Device for transferring non-standard track space engine on the standard track space circuitry

InactiveCN100503332CImprove carrying capacitySmooth and reliable adjustmentTurntables/traversersMechanical engineeringWheel chock

Owner:CRRC BEIJING ERQI LOCOMOTIVE CO LTD

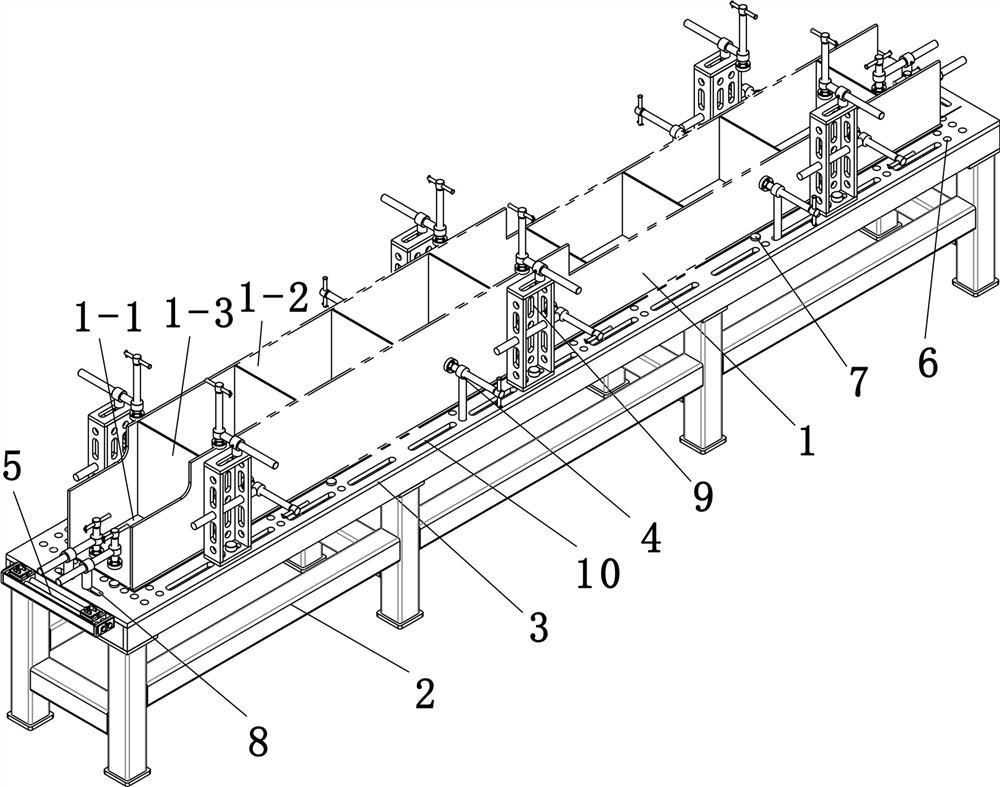

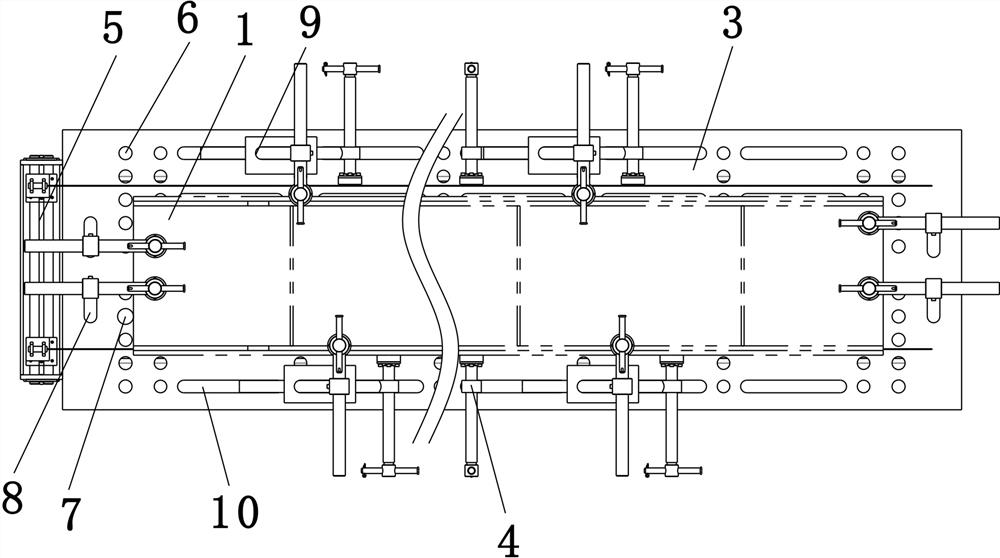

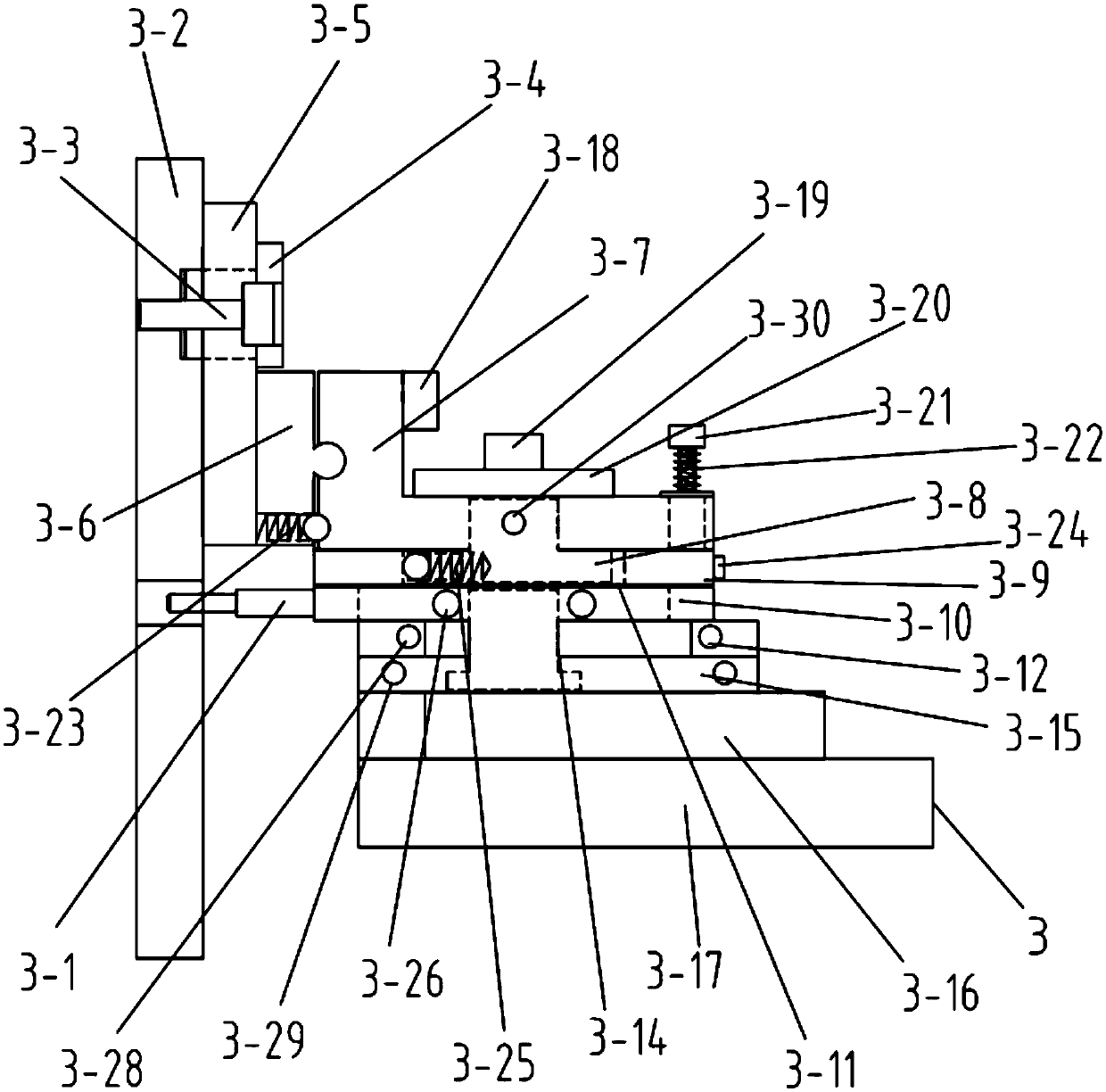

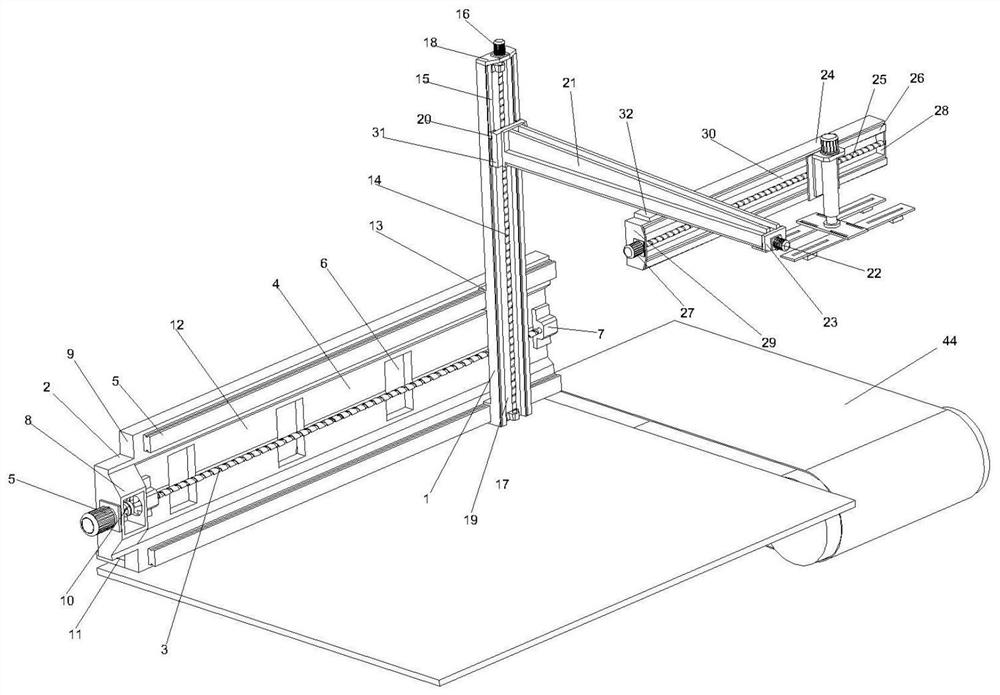

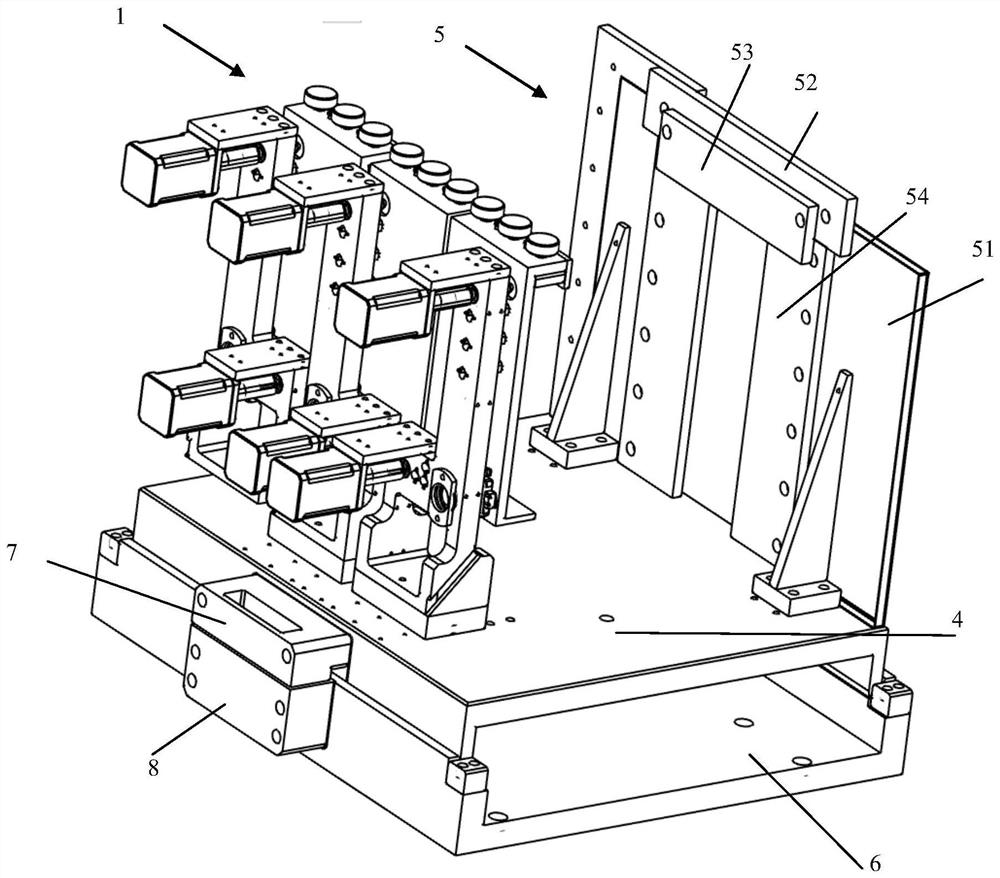

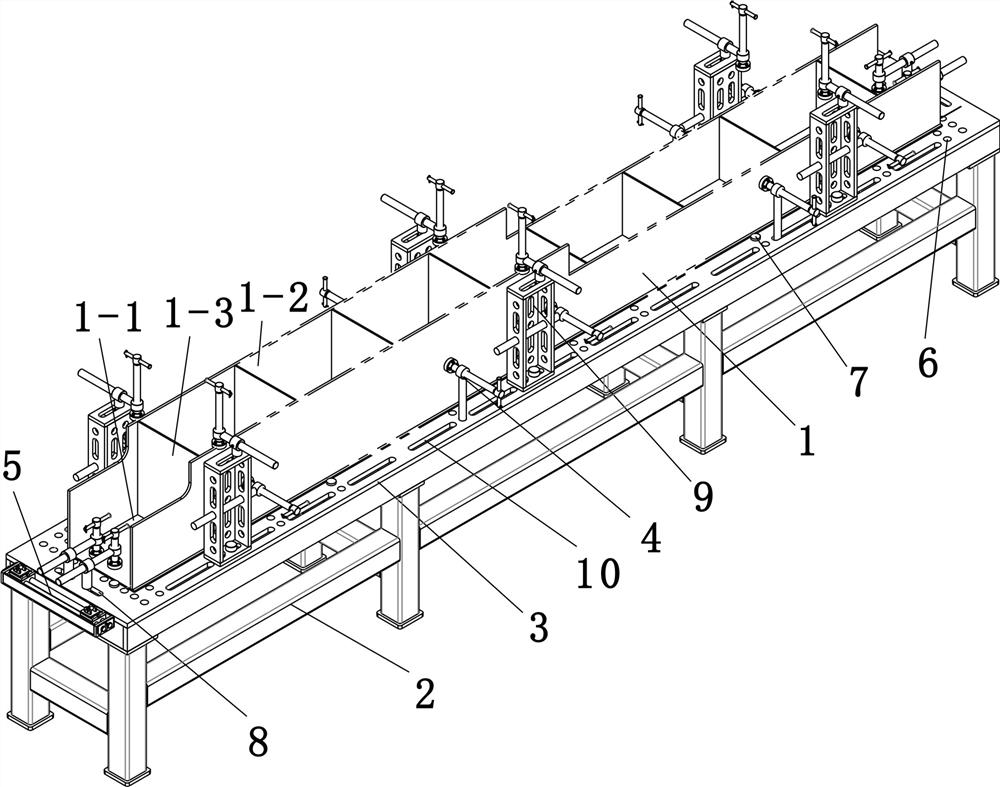

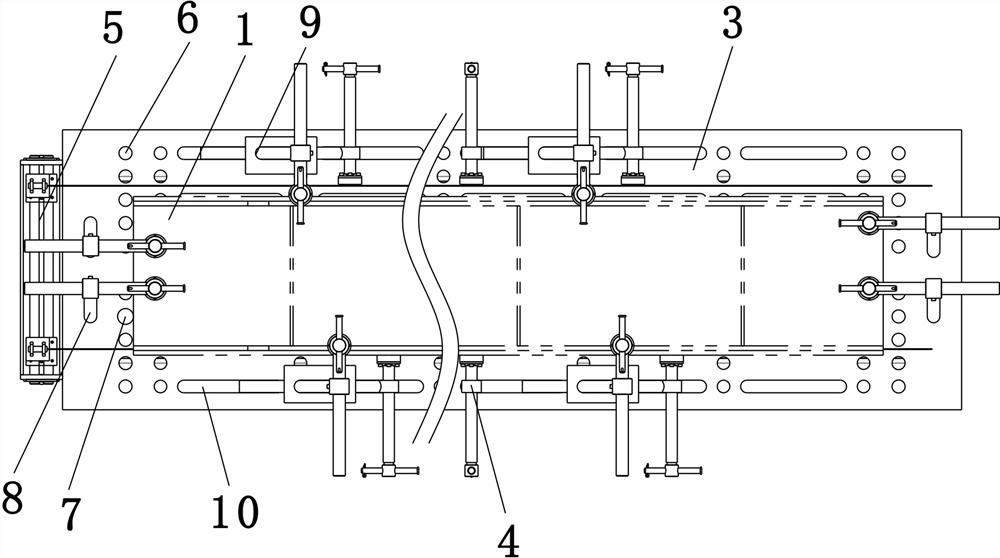

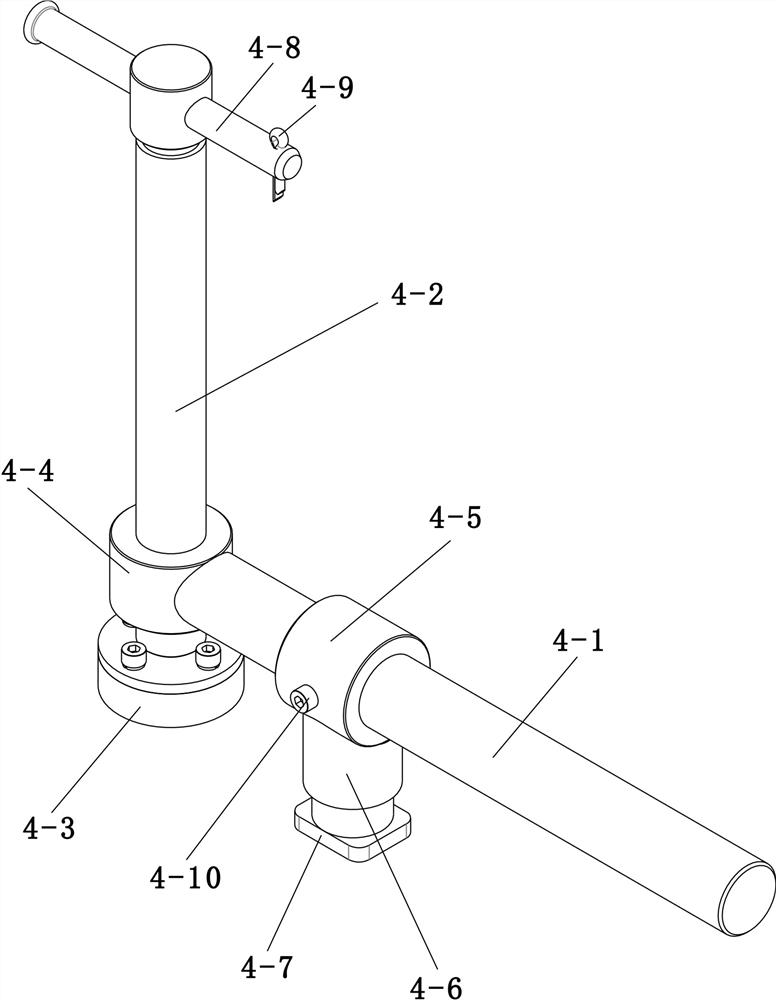

Welding process platform with marking device

ActiveCN112247442ASimple structureEasy to assembleFinal product manufactureWelding/cutting auxillary devicesEngineeringLaser assisted

The invention relates to a welding process platform with a marking device in the technical field of welding tools. The welding process platform comprises a box girder formed by correspondingly splicing a cover plate, web plates and rib plates, and further comprises a frame body, a platform plate, a pressing device and a laser auxiliary positioning device; the plurality of rib plates perpendicularto the cover plate are arranged on the plate surface of the cover plate at intervals in the length direction of the cover plate, the web plates perpendicular to the cover plate are arranged on two sides of the plate surface of the cover plate, and the rib plates are in corresponding vertical contact with the web plates; and the platform plate is arranged at the top of the frame body, a plurality of positioning holes are arrayed on the periphery, close to the edge, of the plate surface of the platform plate, the cover plate is horizontally arranged on the plate surface of the platform plate, and a plurality of positioning pins correspondingly inserted into the corresponding positioning holes are respectively arranged at one end and one side, corresponding to the cover plate, of the plate surface of the platform plate. According to the welding process platform, the labor intensity of workers is effectively reduced, the positioning accuracy is high, and the operation efficiency is high.

Owner:NUCLEON XINXIANG CRANE

Electric spark linear cutting machine

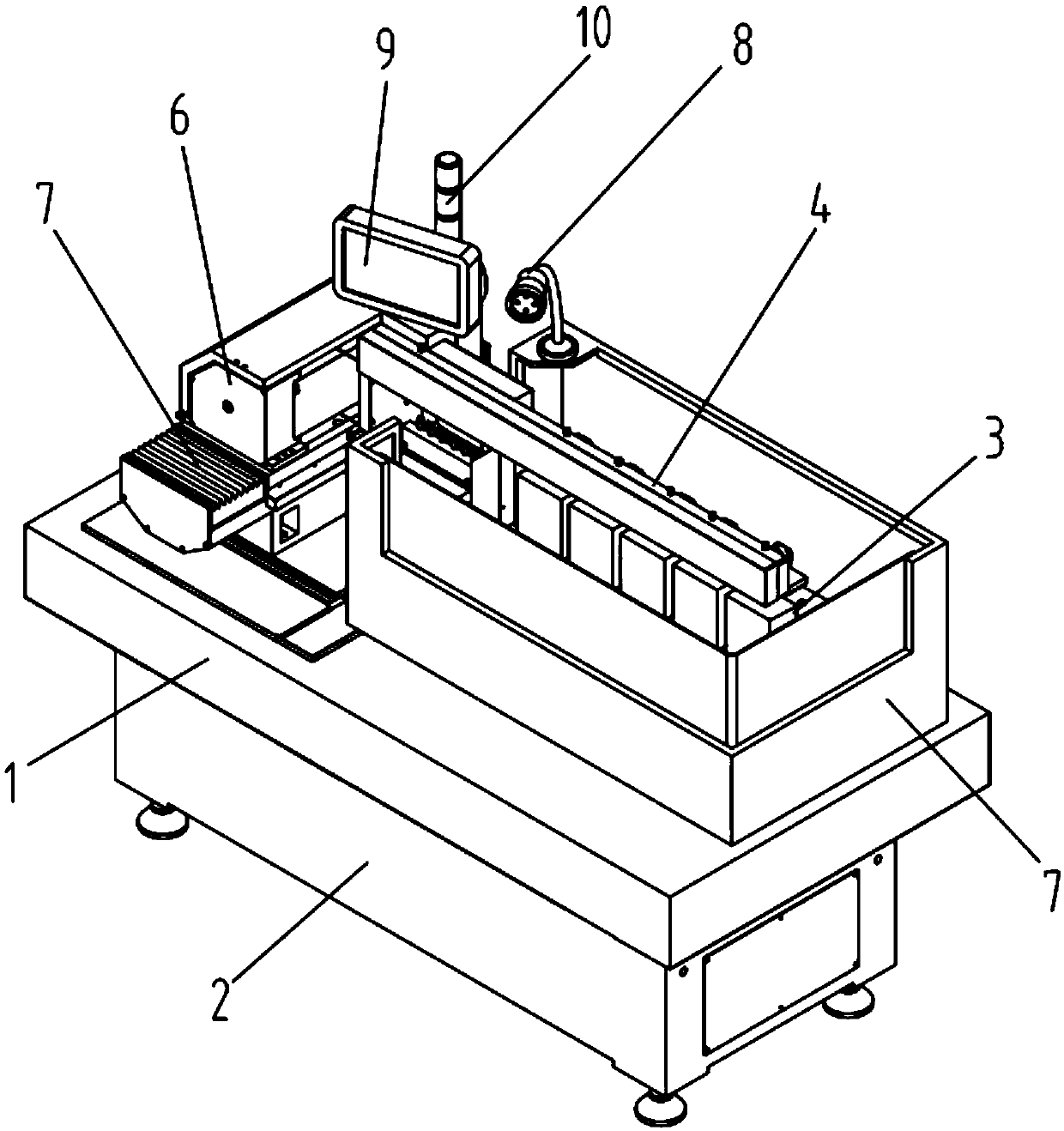

PendingCN109514014AEasy clampingEasy to adjustElectrical-based auxillary apparatusEngineeringMachine tool

The invention relates to the field of numerical control machine tools, particularly to an electric spark linear cutting machine. The electric spark linear cutting machine comprises a machine body anda machine base, wherein a universal fine turning mechanism, a wire rack mechanism, a wire electrode, a wire storage barrel and a wire conveying base are arranged on the machine body; and the universalfine turning mechanism comprises a connecting rod, a pasting plate, a connecting pillar, a first connecting plate, a swinging plate, a first supporting plate, a first sliding block, a second supporting plate, a second sliding block, a supporting block, a rotating plate, a second connecting plate, a supporting shaft, a third supporting plate, a fourth supporting plate and a base. According to theelectric spark linear cutting machine, the supporting shaft is connected to the third supporting plate in a sleeving manner, the rotating plate and all structures on the rotating plate can rotate around the supporting shaft through the structure design, and a user conveniently adjusts the position of the pasting plate; and besides, the pasting plate is fixedly connected with an external to-be-processed workpiece, so that the processing position of the workpiece can be rotated to be slightly adjusted, and the user conveniently clamps the to-be-processed workpiece.

Owner:宁波市江北数控设备厂

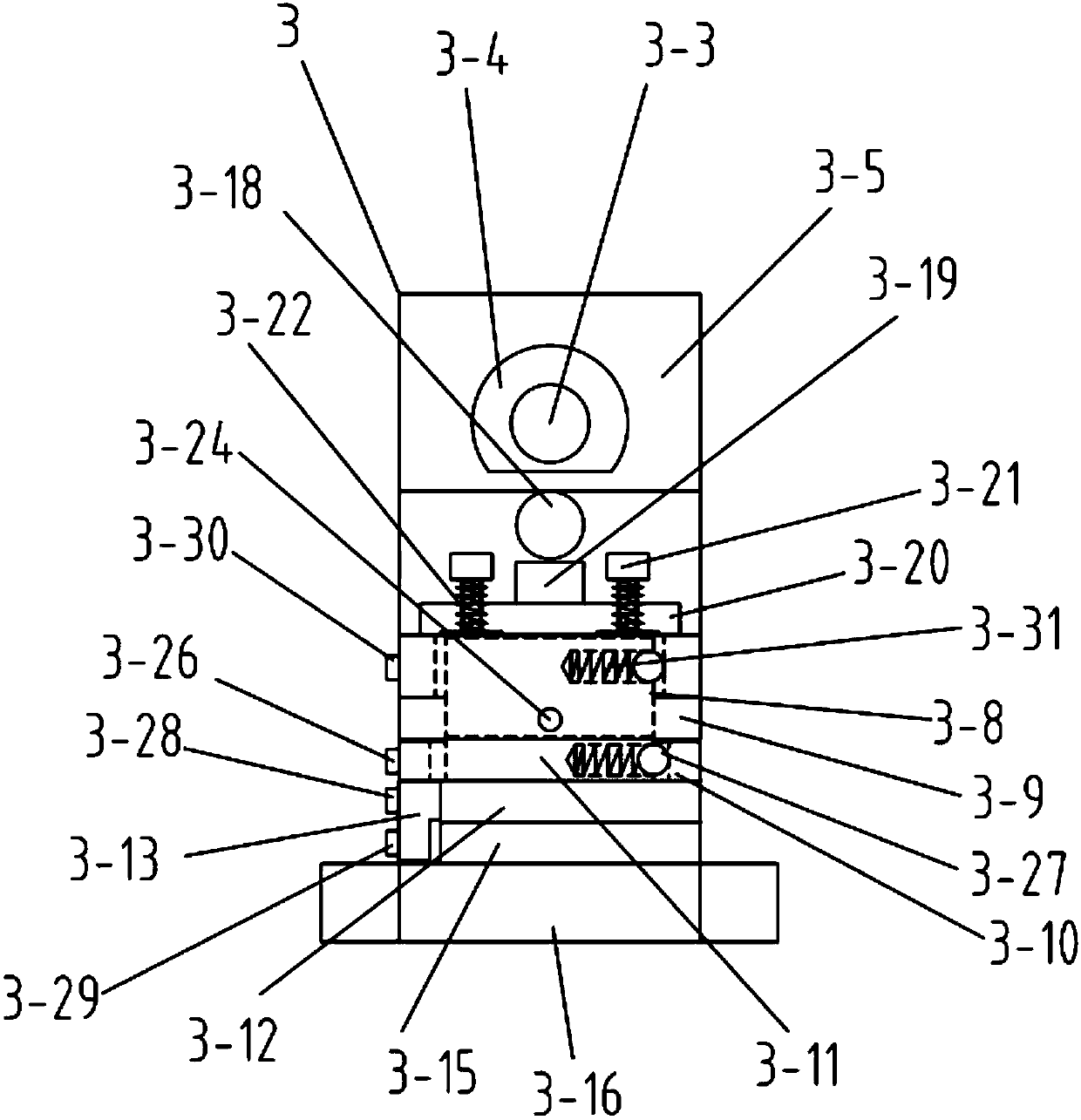

Compound hydraulic hinging and locking die mechanism

The invention discloses a compound hydraulic hinging and locking die mechanism which comprises a conventional template hinging and locking die component, a mold adjusting and mold locking composite oil cylinder body and a mold locking pull rod; by the characteristic that the hinging mechanism is capable of quickly opening and clamping a die, the die can be quickly opened and clamped; the adjustment die and mold locking compound oil cylinder body has a function of finishing direct pressure die locking force at high pressure; and the size of the die locking force is in direct proportion to pressure of hydraulic oil. Due to direct pressure die locking, the parallelism of a template is extremely high; the stress on the mold locking pull rod is completely balanced; die adjustment is also finished by the adjustment die and mold locking compound oil cylinder body; and the mechanism has the high-speed and high-efficiency characteristics of the hinging mechanism and the high-precision characteristic of a hydraulic direct pressing machine or a hydraulic two-plate machine.

Owner:叶廷璧

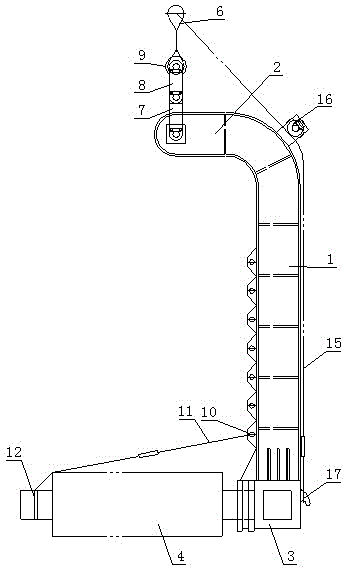

A method for dismantling rolls of a closed billet rolling mill

InactiveCN103832919BEasy to adjustSmooth and reliable adjustmentLoad-engaging elementsIndustrial engineering

Owner:CHONGQING IRON & STEEL (GRP) CO LTD

Method for disassembling closed breakdown mill roller

InactiveCN103832919AEasy to adjustSmooth and reliable adjustmentLoad-engaging elementsIndustrial engineeringRolling mill

Owner:CHONGQING IRON & STEEL (GRP) CO LTD

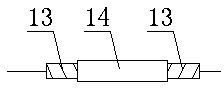

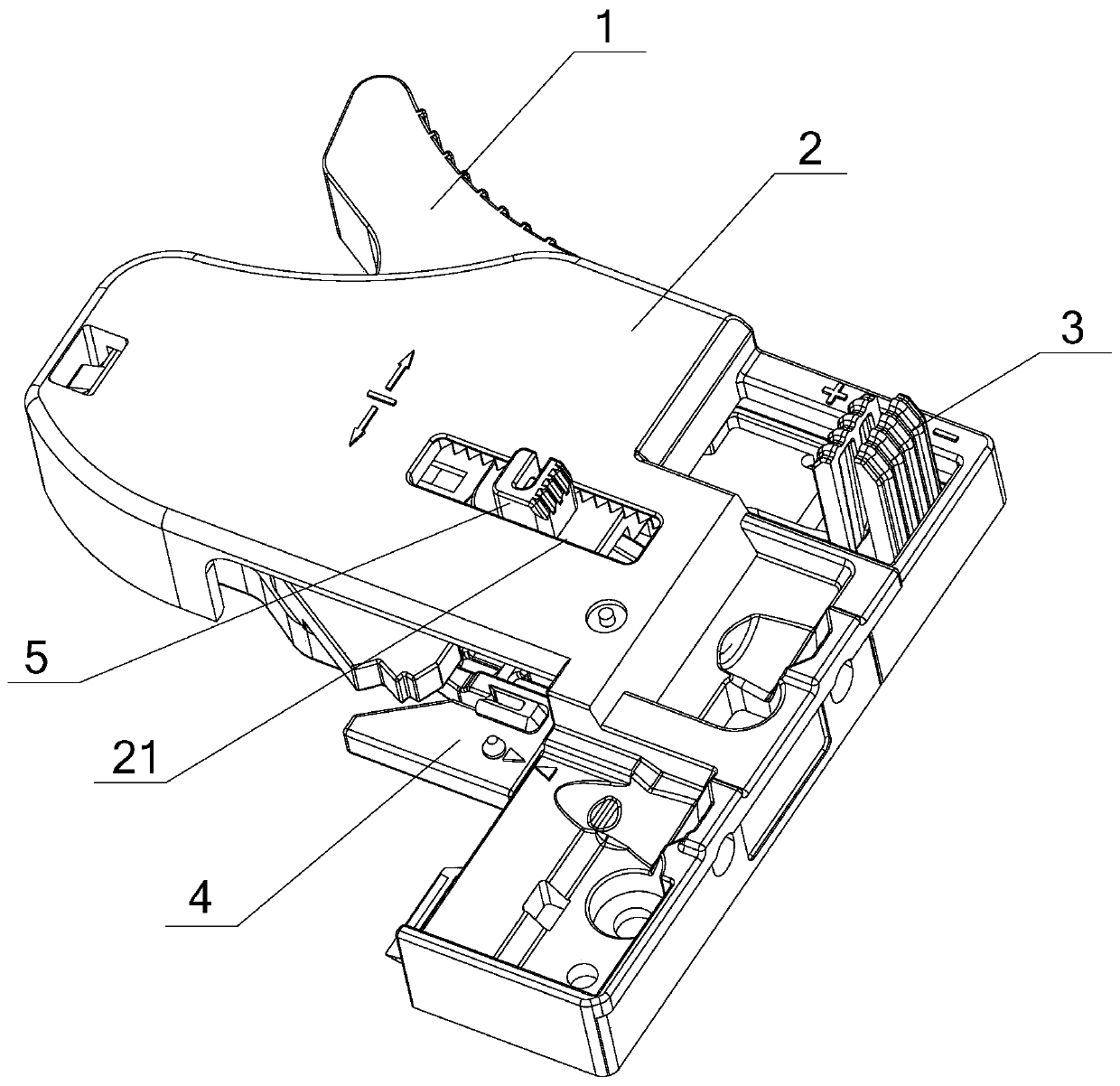

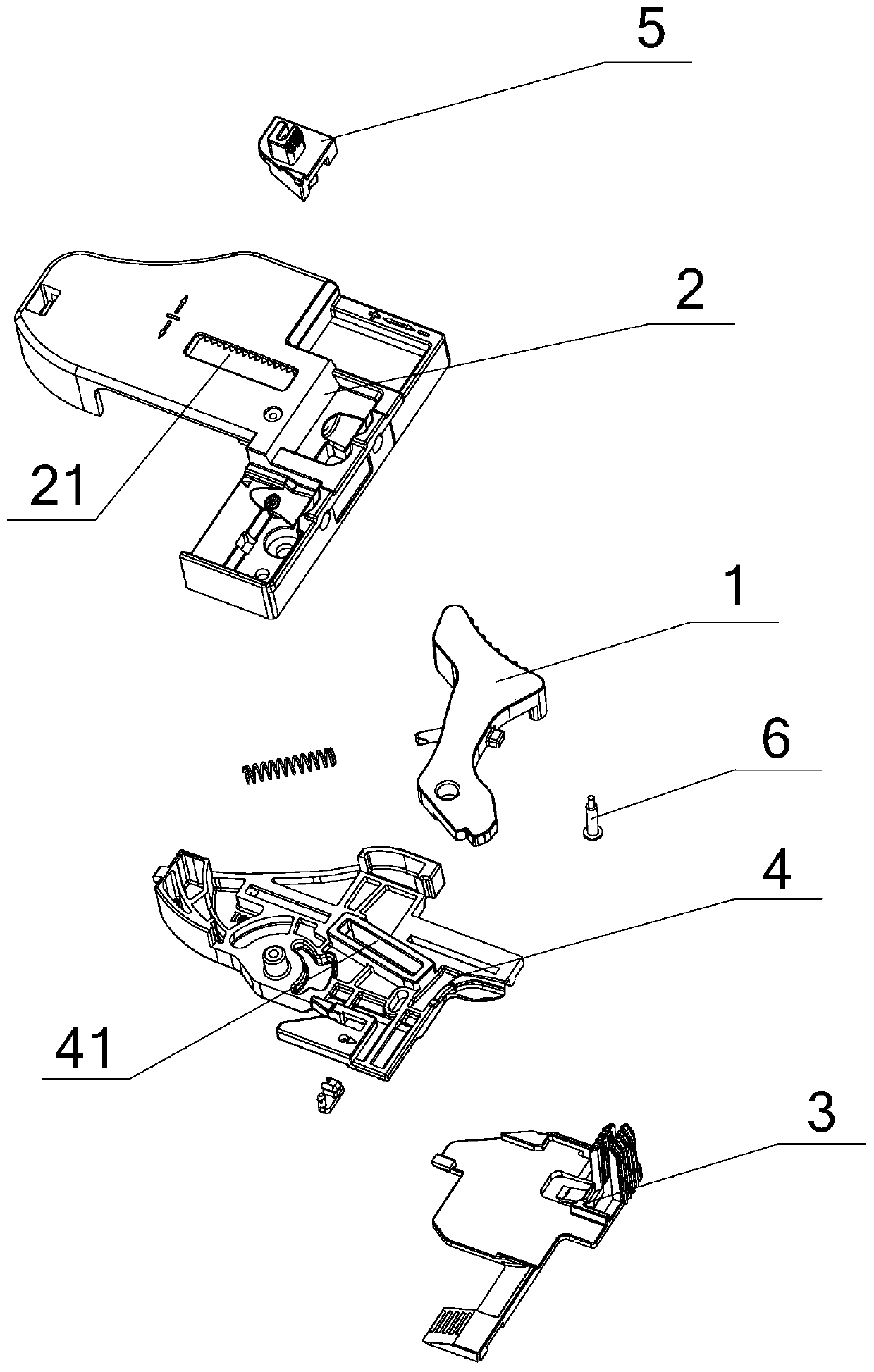

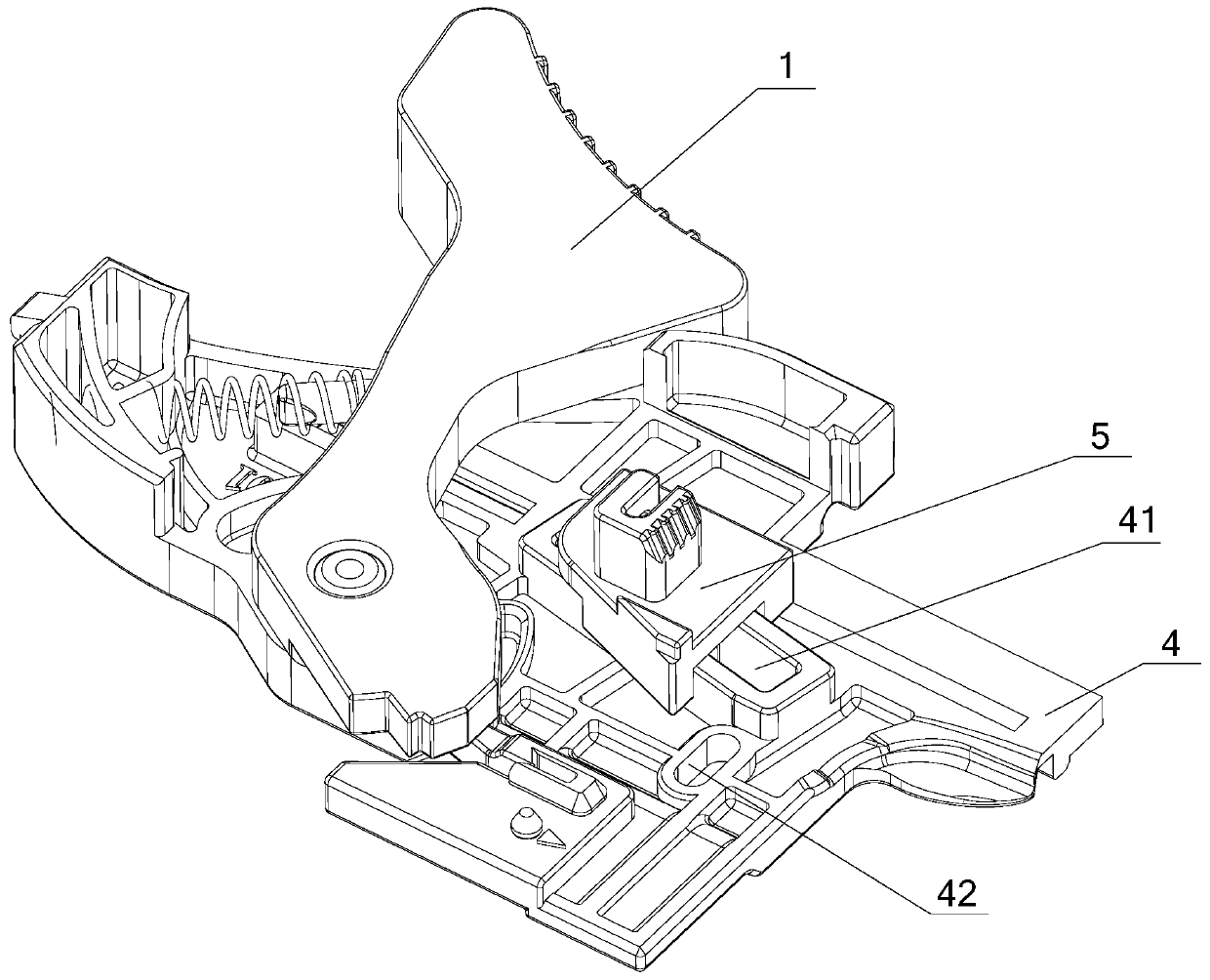

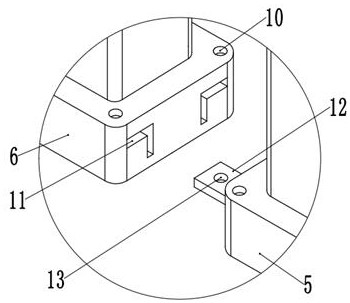

Locking and adjusting device of drawer and drawer

PendingCN110141058AThere will be no stuck problemSmooth and reliable adjustmentDrawersEngineeringContact mode

The invention discloses a locking and adjusting device of a drawer and the drawer. The locking and adjusting device comprises a bottom plate, a left and right adjusting plate and an adjusting pushingblock; the bottom plate is used for being fixed to a drawer box, and a first guiding hole is formed in the bottom plate; the left and right adjusting plate is used for being connected with movable rails, the left and right adjusting plate is movably connected to the bottom plate in the left-right direction of the drawer box, a guiding structure is arranged on the left and right adjusting plate, and an included angle exists between the guiding direction of the guiding structure and the guiding direction of the first guiding hole; and the adjusting pushing block is movably arranged in the firstguiding hole, and the pushing end of the adjusting pushing block is matched with the guiding structure in a contact guiding mode. During adjustment, the adjusting pushing block is pushed, the pushingend of the adjusting pushing block acts on the guiding structure of the left and right adjusting plate in a contact mode, due to the fact that the included angle exists between the guiding direction of the first guiding hole and the guiding direction of the guiding structure, the adjusting pushing block pushes the left and right adjusting plate to move relative to the bottom plate in the left-right direction, and smooth and reliable adjustment of the drawer box relative to the movable rails in the left-right direction is realized.

Owner:GUANGDONG TAIMING METAL PROD

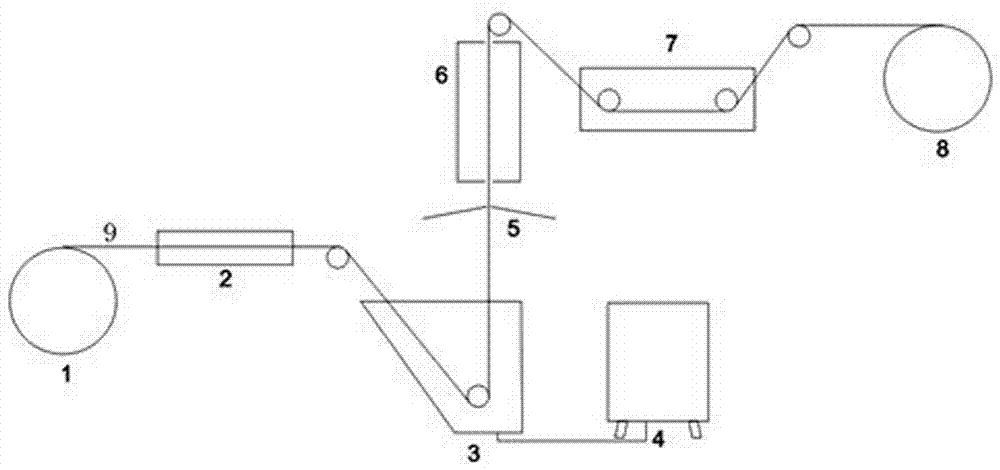

Preparation method and preparation system of enhanced hollow fiber micro-filtration membrane

PendingCN107970791AReduce labor intensityDoes not seriously affect qualitySemi-permeable membranesFiberHollow fibre

The invention discloses a preparation method and a preparation system of an enhanced hollow fiber micro-filtration membrane. The preparation method comprises the following steps: firstly, removing pollutants and moisture on the surface of a braided tube; towing the braided tube into a casting membrane solution for impregnation, and then towing the braided tube impregnated with the casting membranesolution vertically upwards; introducing the braided tube coated with the casting membrane solution into a steam bath, splitting phases of a membrane surface of the braided tube to form a micro-porous membrane, and introducing the micro-porous membrane into a coagulating bath for further solidification to form an enhanced hollow fiber micro-filtration membrane; and rinsing the enhanced hollow fiber micro-filtration membrane in pure water for 12 to 24 hours, finally drying the membrane after soaking the membrane in a protective solution for 8 to 24 hours. The preparation method provided by theinvention can ensure the uniformity of a coating layer on the surface of the braided tube, and can quickly adjust the thickness of the coating layer and the bonding strength between the membrane andthe braided tube. The production process is stable and reliable, the production is convenient to operate and control, and the membrane wire quality will not be seriously influenced. The preparation system saves the cost of a spinneret and saves the cost; and the work of adjusting and cleaning the spinneret is omitted, the labor intensity of workers is reduced, and the labor cost is saved.

Owner:深圳市君脉膜科技有限公司

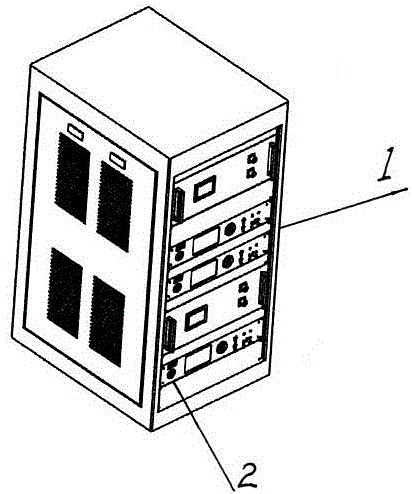

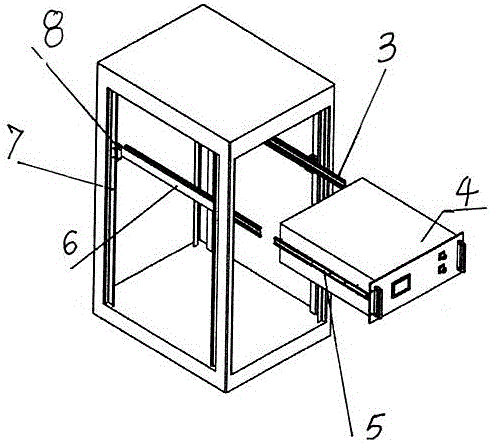

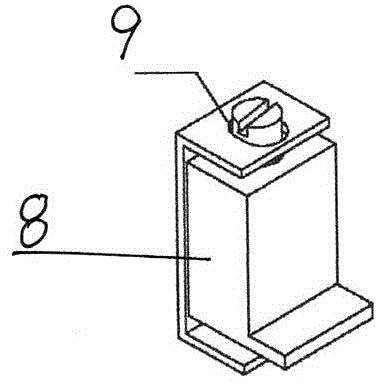

Gap adjustment mechanism between devices in cabinet

InactiveCN106211696AEasy to adjustSmooth and reliable adjustmentServersData center roomsFixed frameArchitectural engineering

The invention discloses a gap adjustment mechanism between devices in a cabinet. The gap adjustment mechanism comprises the cabinet and the devices. The gap adjustment mechanism between the devices is composed of adjustment units, stand columns, support plates and drawable guide rail parts, wherein each adjustment unit is composed of oblong holes, a fixed frame, an adjustment screw rod and an adjustment screw block; the oblong holes are formed in the upper part and the bottom of the fixed frame; the adjustment screw block is assembled on the adjustment screw rod; the upper and lower ends of the adjustment screw rod penetrate the oblong holes; the adjustment block is located in the fixed frame and fixed through the adjustment screw rod; the bottom of the adjustment screw block extends outwards to form a support surface; the drawable guide rail is supported and fixed on the support surface; the adjustment units are fixed to the front, back, left and right stand columns of the cabinet and connected with the support plates mounted on the left and right sides transversely in the cabinet; the drawable guide rails are fixed to the left and right support plates; and first guide rails are mounted on the left and right sides of each device. According to the technical scheme, the first-pass yield of production assembly is increased; and the number of construction personnel can be changed to two from three due to simple and convenient operation, so that the production cost is reduced.

Owner:CNGC COMM TECH

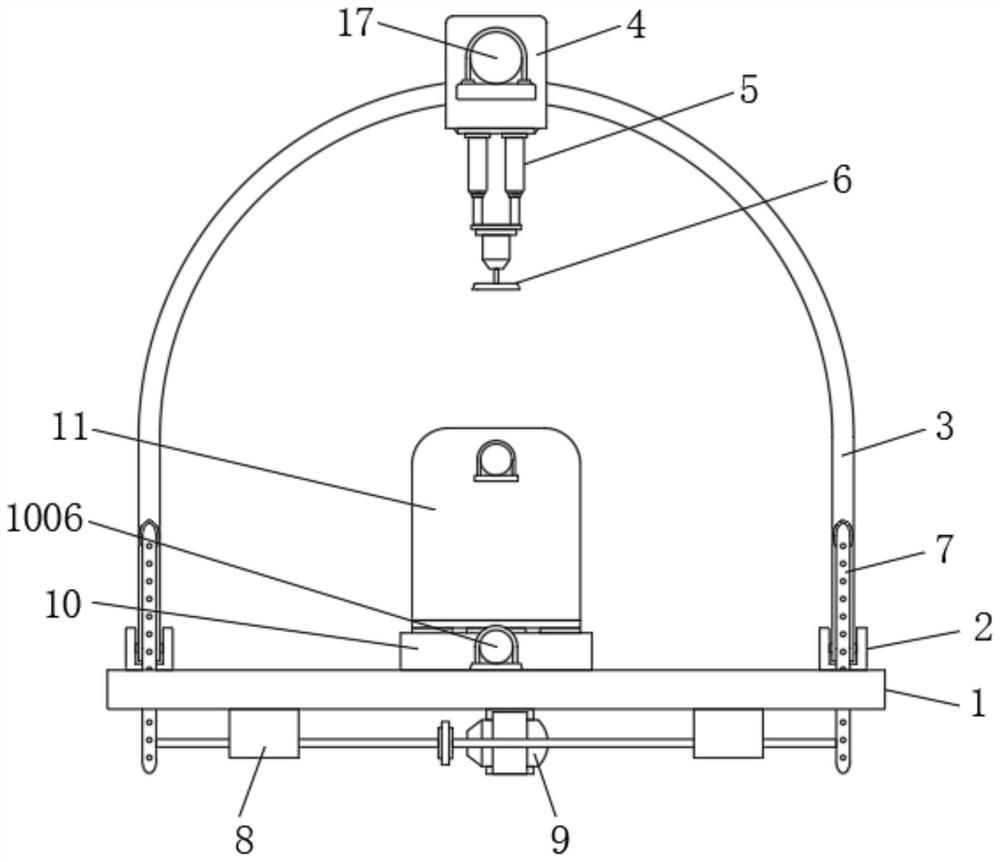

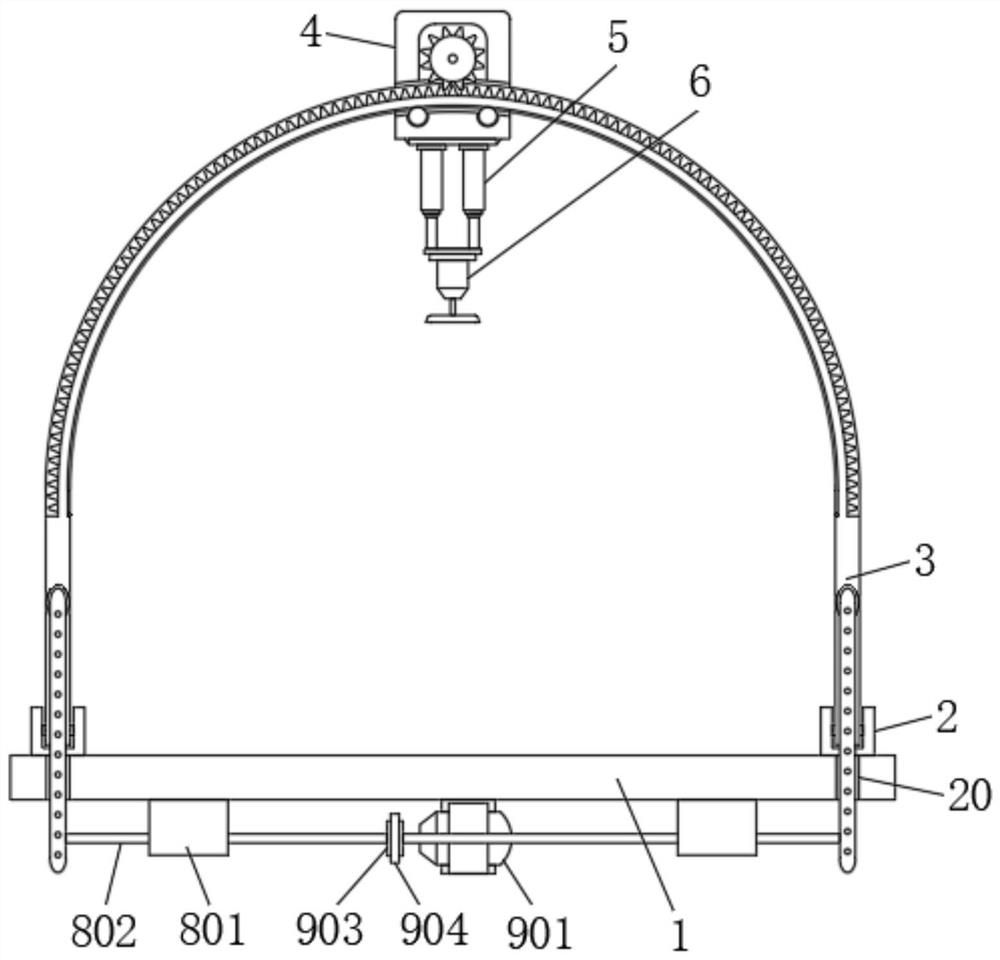

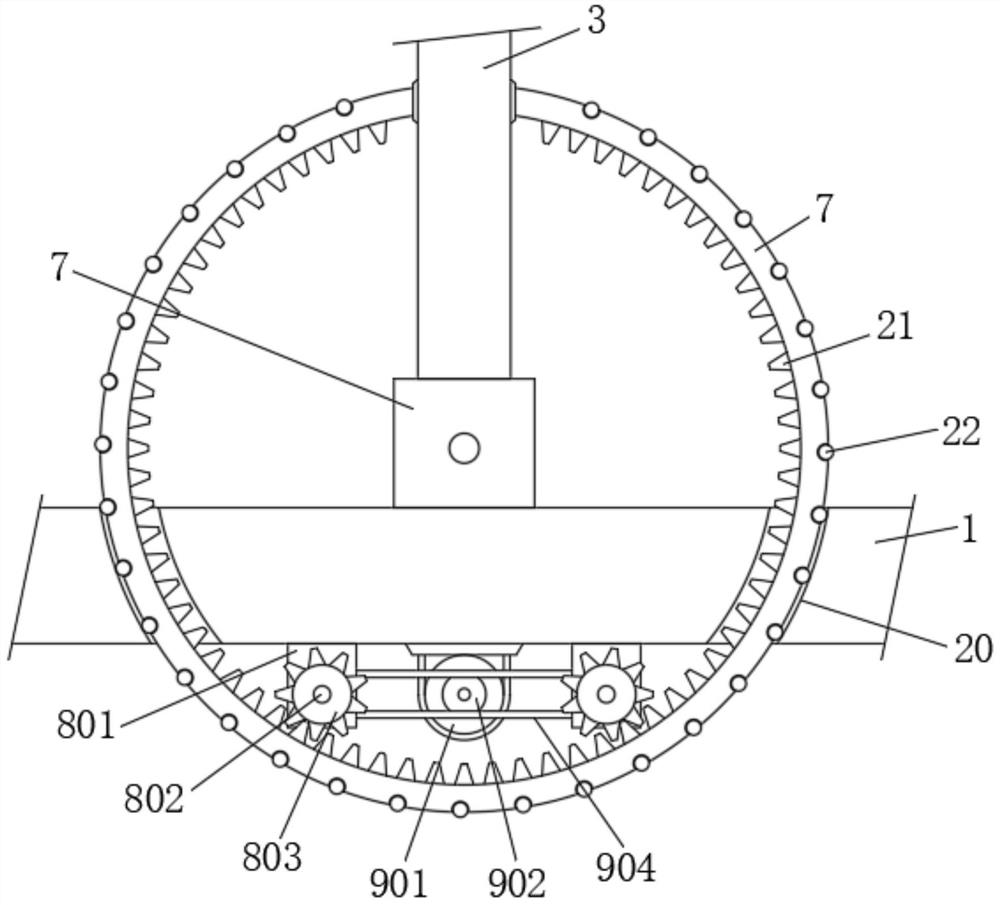

A mechanical processing equipment for the production of auto parts

ActiveCN112692694BMeet the needs of processing and useImprove practicalityGrinding carriagesGrinding drivesMachiningIndustrial engineering

The invention relates to the technical field of mechanical processing equipment for auto parts, and discloses a mechanical processing equipment for producing auto parts, which solves the problem that the angle adjustment of the grinding device requires manual adjustment, which requires slow speed, low efficiency, and adjustment accuracy. Poor problem, which includes the base, the two ends of the top side of the base are fixedly installed with connecting seats, the inner sides of the two connecting seats are rotated and installed with an arc-shaped rotating rod, and the middle part of the arc-shaped rotating rod is installed with a moving block , two hydraulic telescopic cylinders are installed at the bottom of the moving block, a grinder is installed between the bottoms of the two hydraulic telescopic cylinders, and fixed circles are installed between the two ends of the arc-shaped rotating rod and the two ends of the base; The parts machining, polishing and grinding equipment can automatically adjust the angle, and the angle adjustment speed is fast, the efficiency is high, and the adjustment accuracy is high. At the same time, the adjustment process is stable and reliable, and the safety is high, which can meet the processing and use requirements of auto parts.

Owner:江西华盛精诚智能装备有限公司

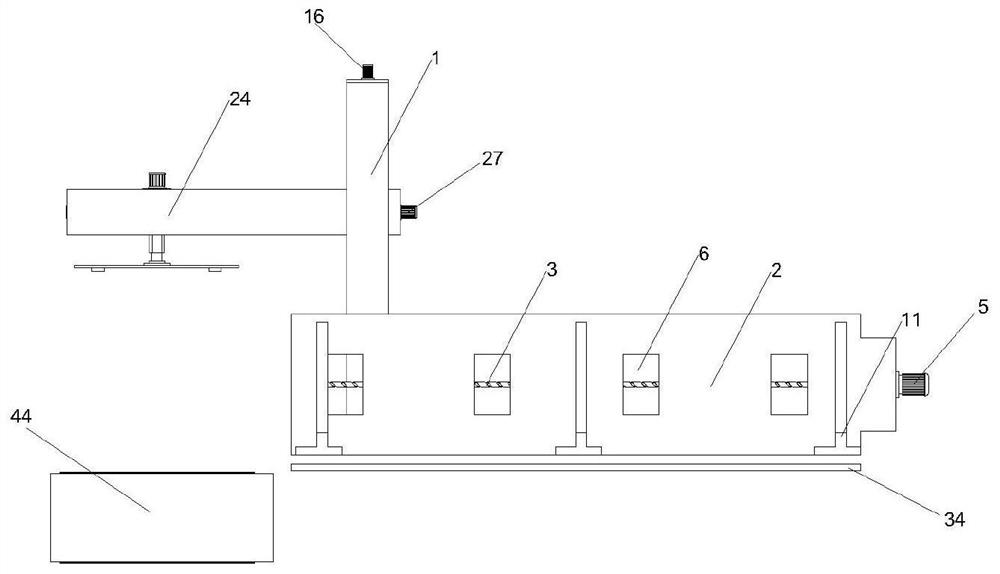

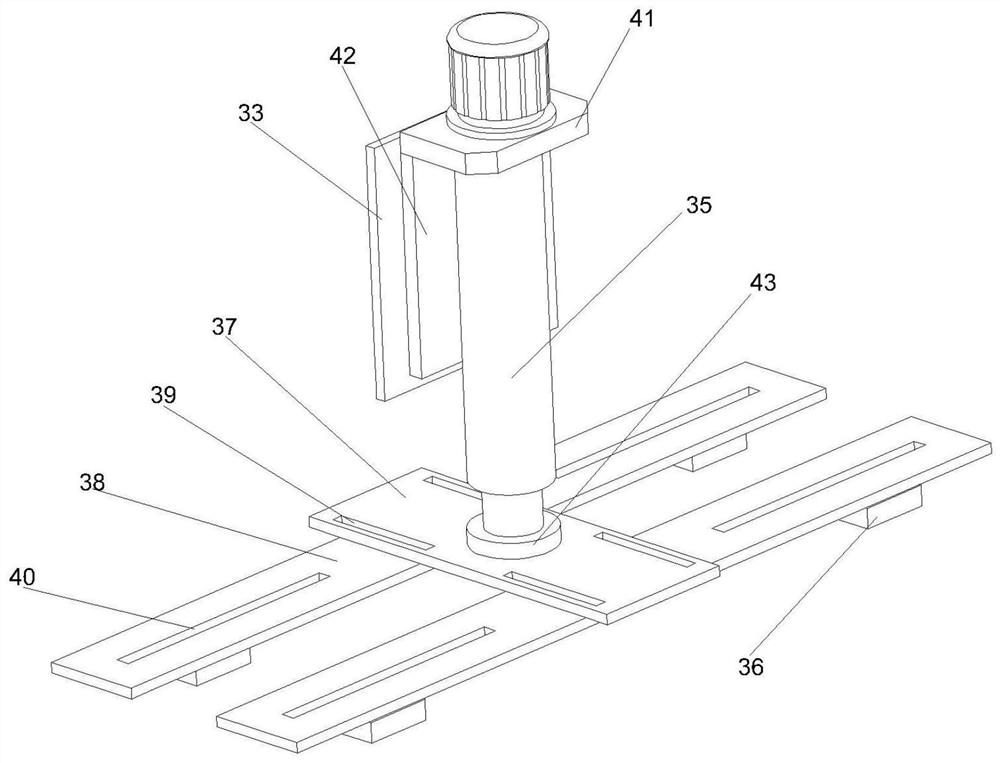

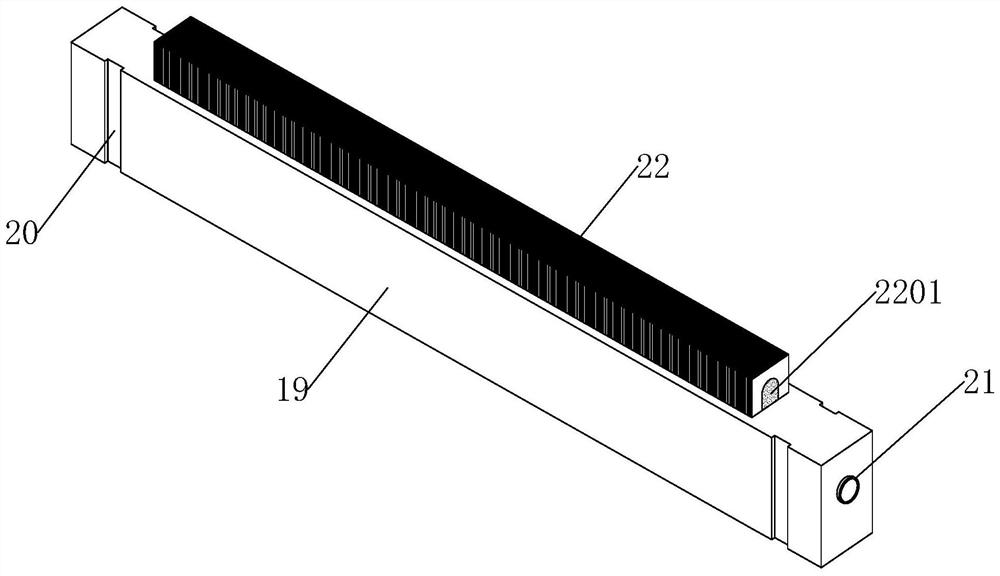

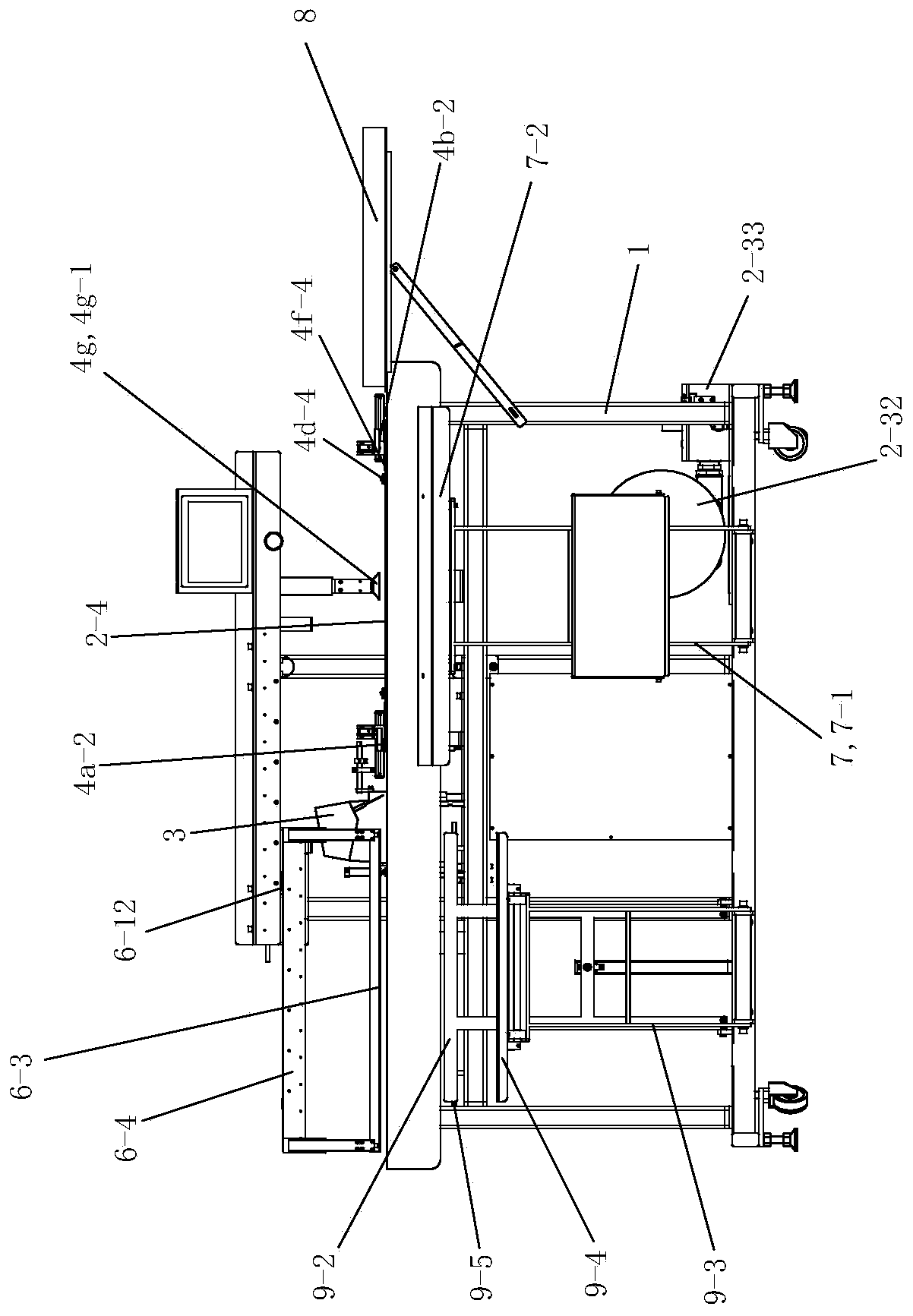

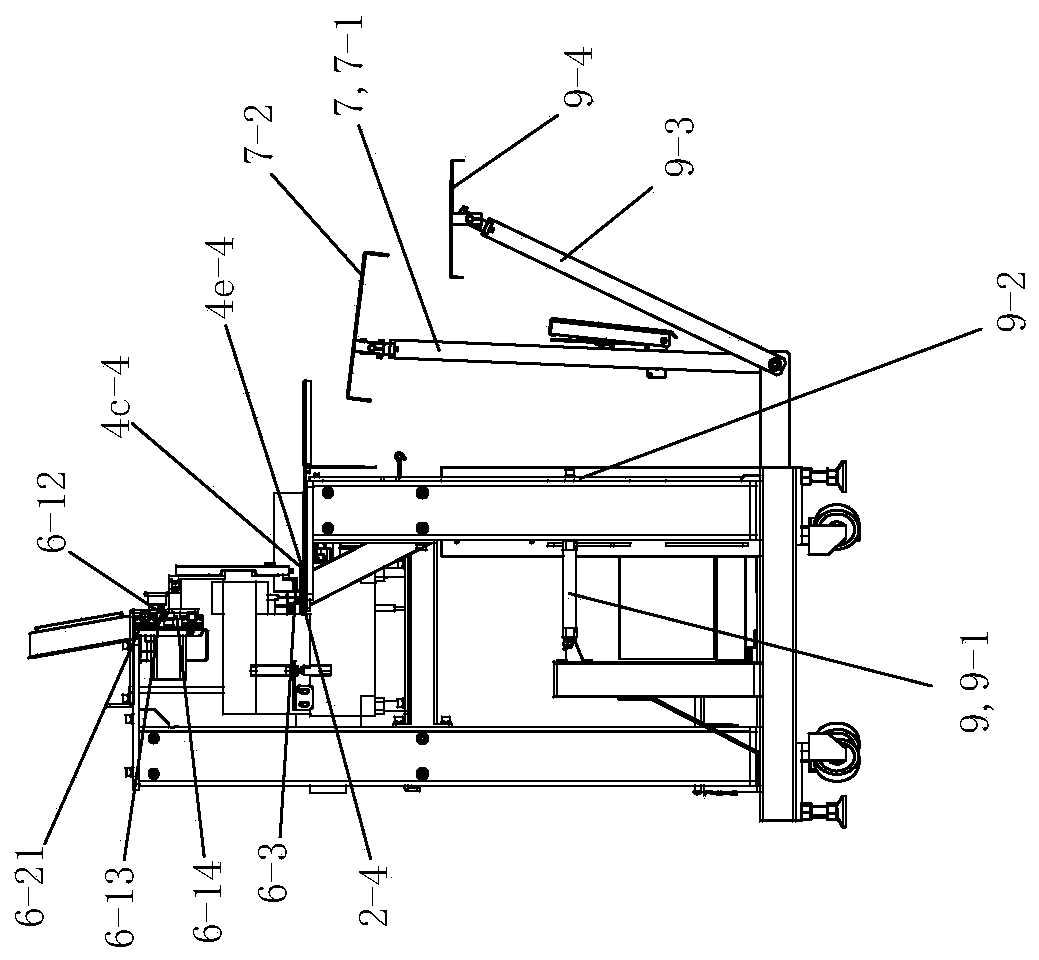

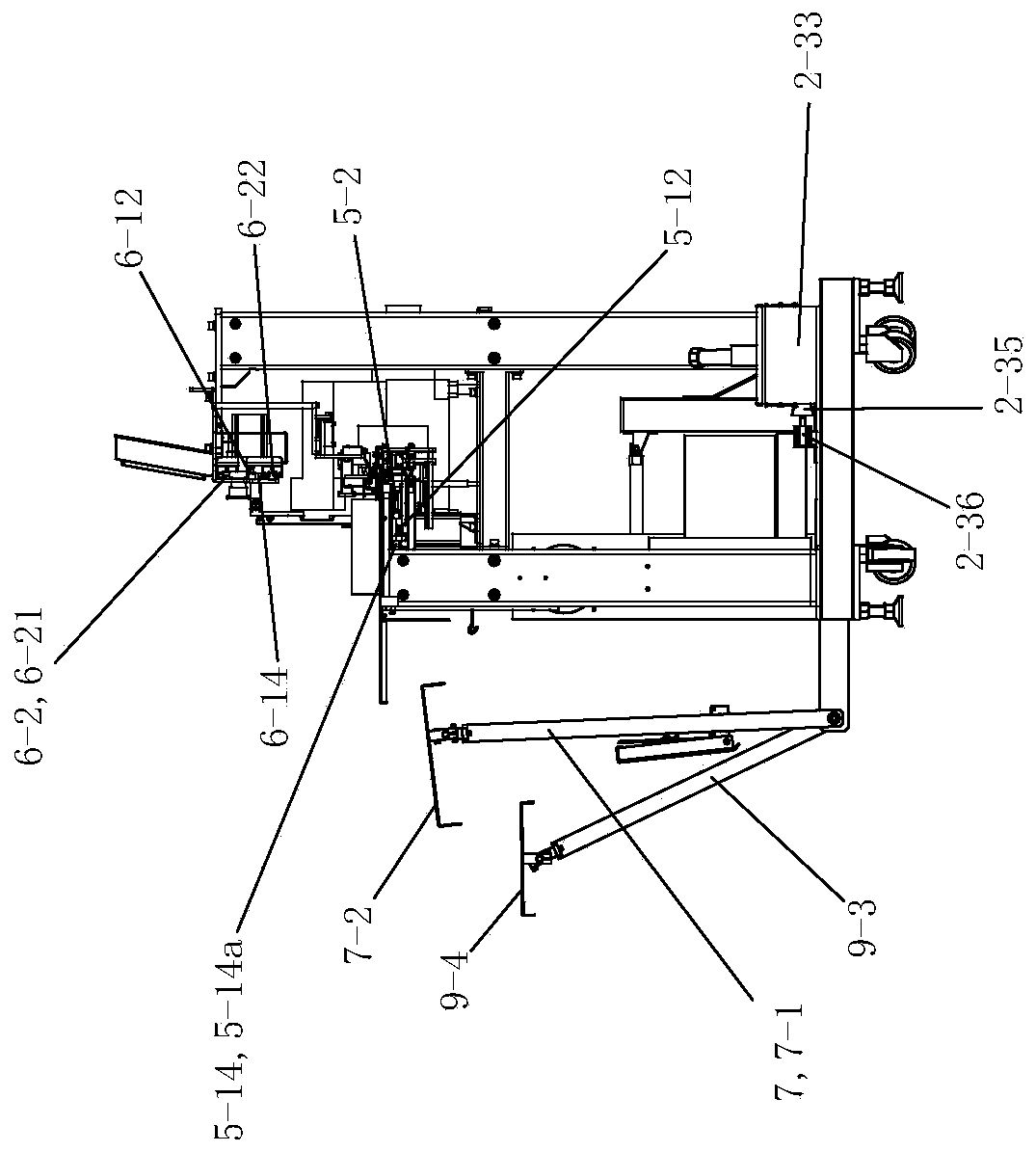

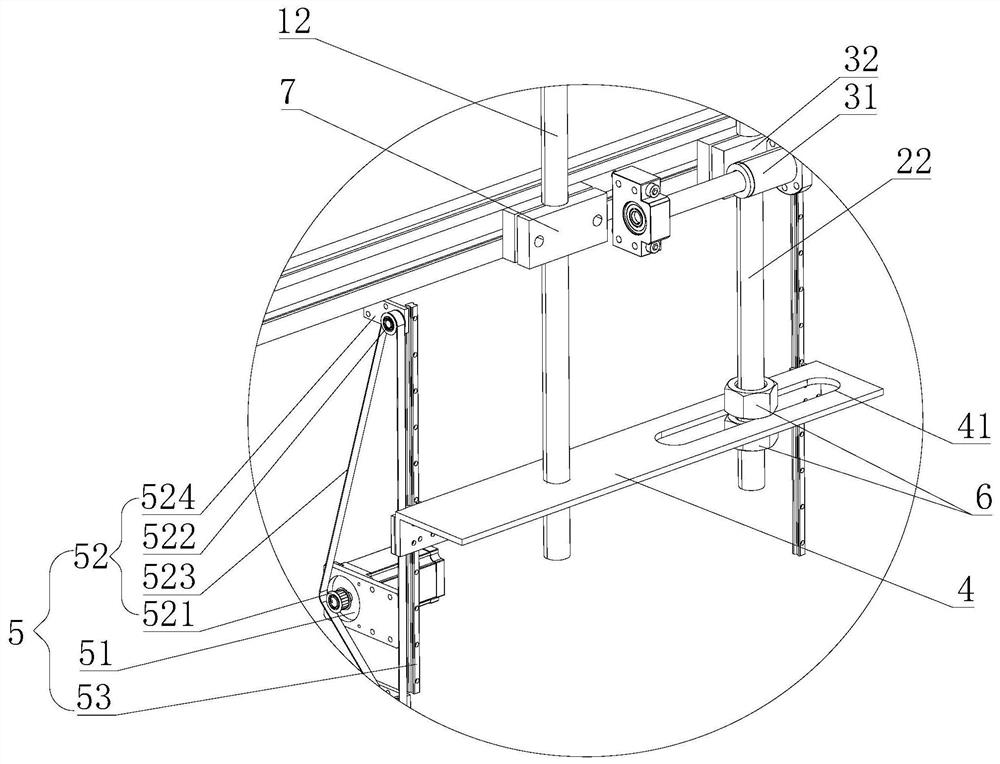

Multidirectional conveying stacking machine

InactiveCN111908141AEasy alignmentImprove stacking efficiencyStacking articlesStructural engineeringMachine

The invention discloses a multidirectional conveying stacking machine. The multidirectional conveying stacking machine comprises a stacking table, a conveying mechanism located on one side of the stacking table and a taking and placing mechanism installed on the conveying mechanism, wherein the conveying mechanism comprises a primary front-back conveying mechanism, an up-down conveying mechanism connected to the primary front-back conveying mechanism in a front-back sliding mode, a left-right conveying mechanism connected to the up-down conveying mechanism in an up-down sliding mode, and a secondary front-back conveying mechanism connected to the left-right conveying mechanism in a left-right sliding mode, and the taking and placing mechanism is connected to the secondary front-back conveying mechanism in a front-back sliding mode. According to the multidirectional conveying stacking machine, multidirectional conveying can be achieved, the distance between the stacking machine and a front conveying belt can be properly adjusted, and the matching flexibility is improved; in addition, the conveying position of the front-back conveying mechanism can well correspond to the stacking position on the stacking table, it is guaranteed that stacked products can be well aligned, and the stacking efficiency is improved; and the multidirectional conveying stacking machine can adjust the suction width and the suction length, is suitable for products with various specifications, can adjust the direction of the products, is convenient and fast in operation, and reduces the stacking cost.

Owner:HANGZHOU XIANZE TECH

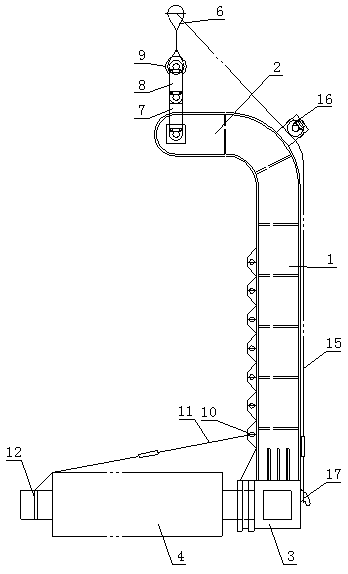

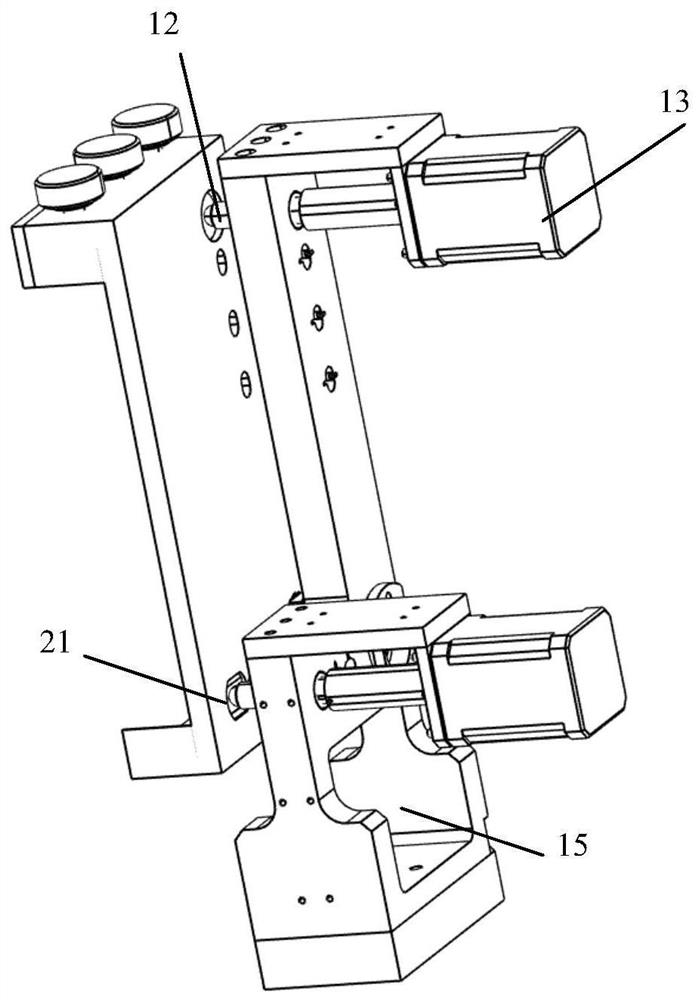

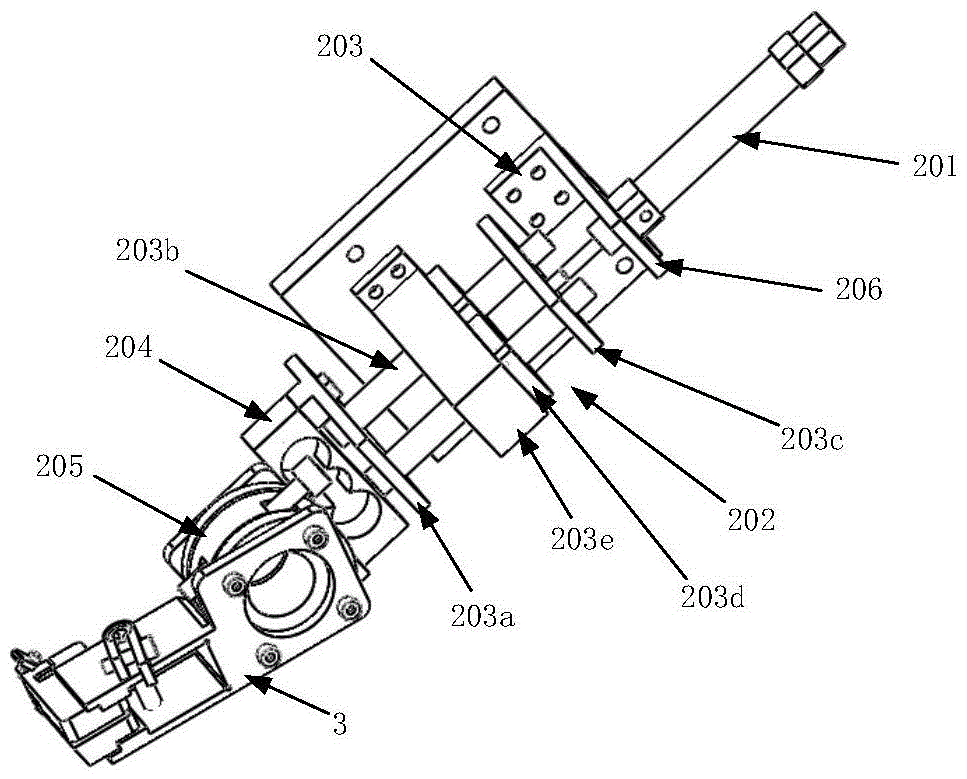

A clamping mechanism for a drop tester

ActiveCN111707435BSmooth and reliable automatic adjustmentEasy to adjust the clamping heightShock testingBall screw driveReciprocating motion

The invention discloses a clamping mechanism for a drop testing machine, belonging to the technical field of drop testing. The nut end of a ball screw drive group is fixedly connected with the slider end of a guide rail slider group, and a first clamping group passes through a mounting beam. The group is fixedly connected to the power output end of the lifting and feeding mechanism, the second clamping group is movably connected to the mounting beam group through the slider end of the guide rail slider group, and the lifting and feeding mechanism can drive the first clamping group through the mounting beam group. And the second clamping group makes up and down reciprocating motion, the ball screw drive group can drive the second clamping group to slide back and forth on the guide rail end of the guide rail slider group through the slider end of the guide rail slider group, so that the second clamping group can move back and forth. The group cooperates with the first clamping group to clamp or release the sample to be tested. The clamping mechanism for a drop testing machine disclosed by the invention not only ensures that the clamping mechanism can realize the clamping or loosening action stably and reliably, but also can be adapted to test prototypes of various sizes and specifications and perform batch drop detection. At the same time, it is easy to adjust the clamping height.

Owner:萍乡伊博智能科技有限公司

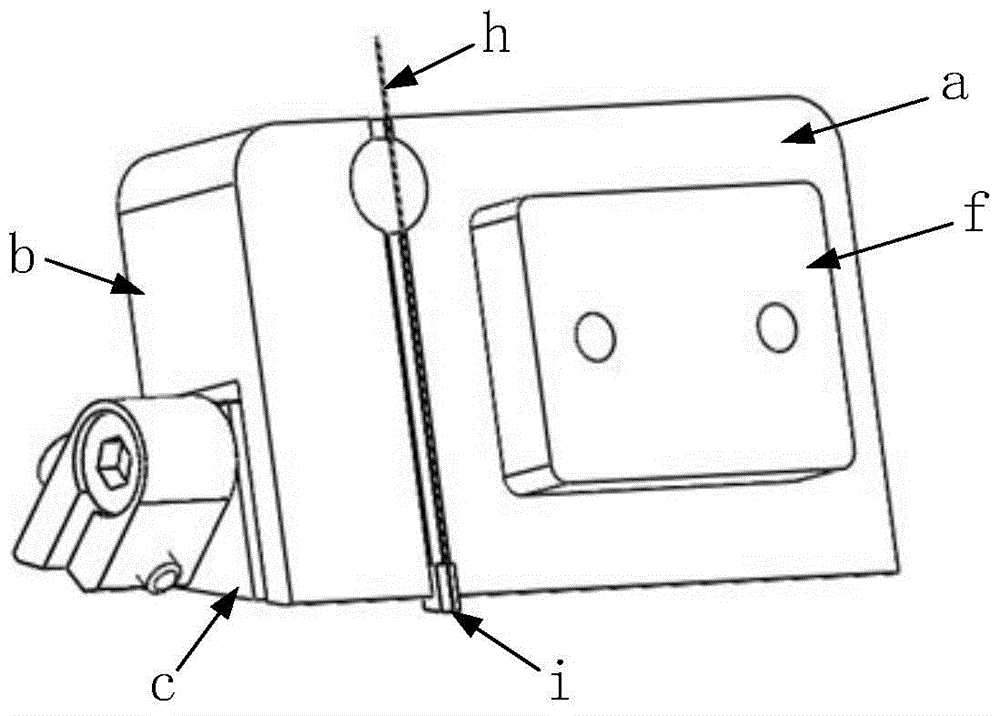

Automatic reflection light path adjusting assembly, adjusting device and using method

PendingCN111965782AThe overall structure is simpleSimple and reliable adjustment processMountingsPhysicsEngineering

The invention discloses an automatic reflection light path adjusting assembly, an adjusting device and a using method. The automatic reflection light path adjusting assembly comprises a base plate andan adjusting plate loaded with a reflecting lens, wherein the adjusting plate is fixed on the base plate and is driven to rotate around a fixed point relative to the base plate, two adjusting ejectorrods which are driven to extend or retract are arranged on the base plate, and a tension spring is arranged between the base plate and the adjusting plate, so that the end parts of the adjusting ejector rods are pressed against the back part of the adjusting plate. According to the automatic reflection light path adjusting assembly, the fixed point and the contact points of the two adjusting ejector rods and the adjusting plate form a triangular structure, the posture of the reflecting lens can be adjusted in a multi-dimensional mode by adjusting the ejector rods, the overall structure is simple, and the stability and reliability of the adjusting process are guaranteed through the design of a limiting guide groove.

Owner:RES INST OF PHYSICAL & CHEM ENG OF NUCLEAR IND

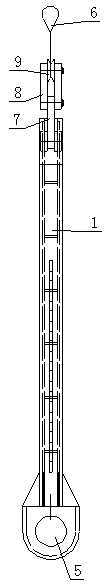

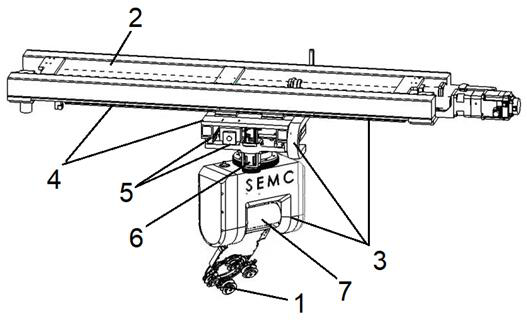

A method and device for changing the attitude and position of the taping head in the air

ActiveCN110601471BLower the altitudeEasy to controlApplying solid insulationClassical mechanicsEngineering

Owner:株洲南方机电制造有限公司

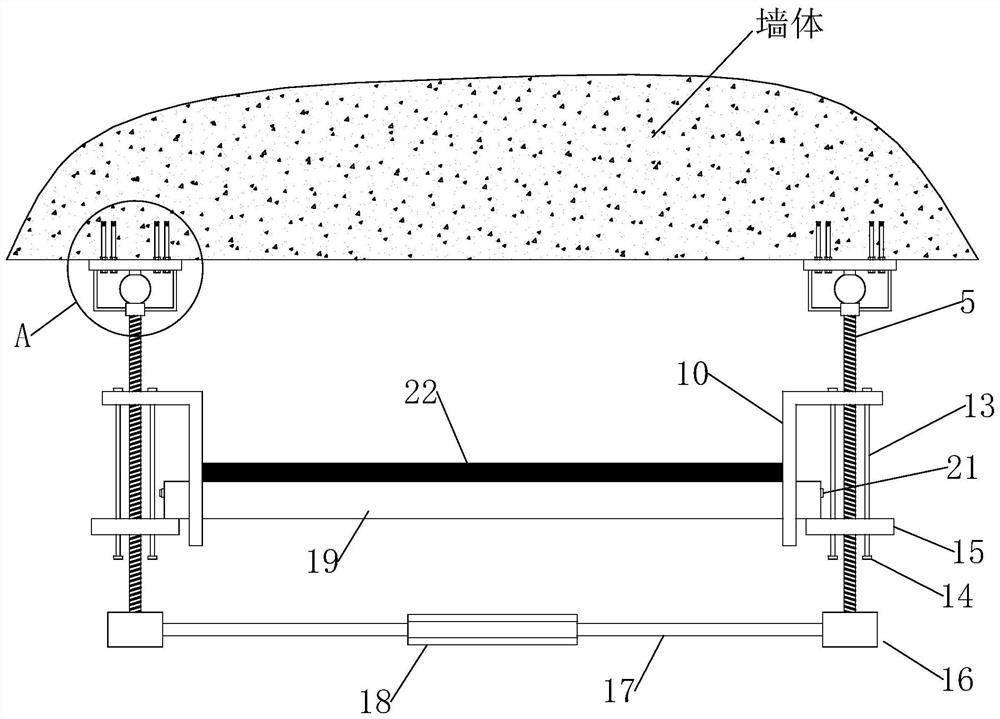

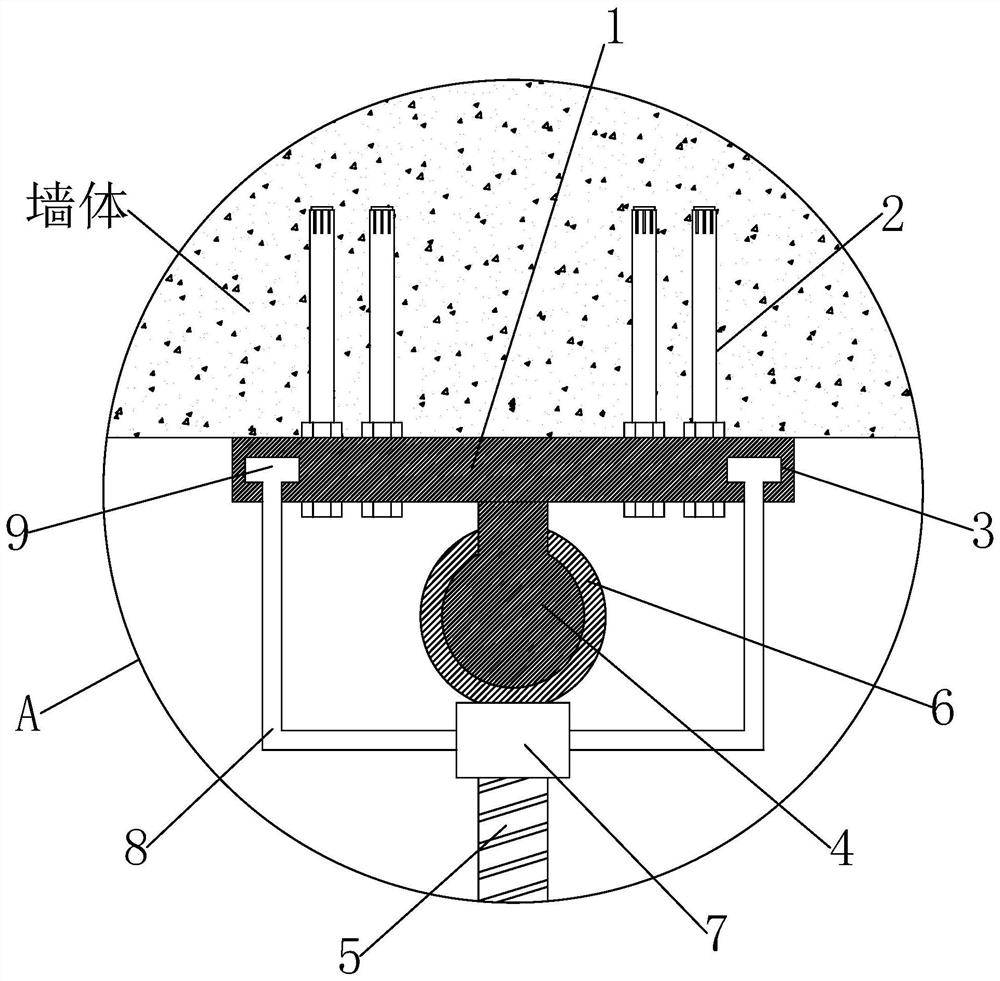

Adjustable building equipment mounting bracket and using method thereof

ActiveCN113074310AImprove general performancePlay a positioning roleCeramic shaping apparatusStands/trestlesHollow coreStructural engineering

The invention discloses an adjustable building equipment mounting bracket and a using method thereof, and belongs to the technical field of building equipment mounting. According to the key points of technical scheme, the adjustable building equipment mounting bracket is characterized by comprising a connecting assembly, a hoisting assembly and a bracket assembly, the hoisting assembly is mounted on a wall through the connecting assembly, the bracket assembly is mounted on the hoisting assembly, and the bracket assembly can be subjected to lifting adjustment by virtue of the hoisting assembly; and the bracket assembly is used for supporting and placing building equipment and comprises a bracket body, and the bracket body is of a hollow shell structure. The adjustable building equipment mounting bracket has very high universality and can adapt to various building equipment of different models and brands, the step of lifting adjustment of the adjustable building equipment mounting bracket is simple and labor-saving, and the firmness of a connecting structure of the adjustable building equipment mounting bracket and a building wall surface is greatly improved; and according to the using method of the adjustable building equipment mounting bracket is convenient to use. a mounting base is prefabricated for a building equipment site, and site customized adjustment of the building equipment mounting bracket is achieved.

Owner:江铃汽车集团江西工程建设有限公司

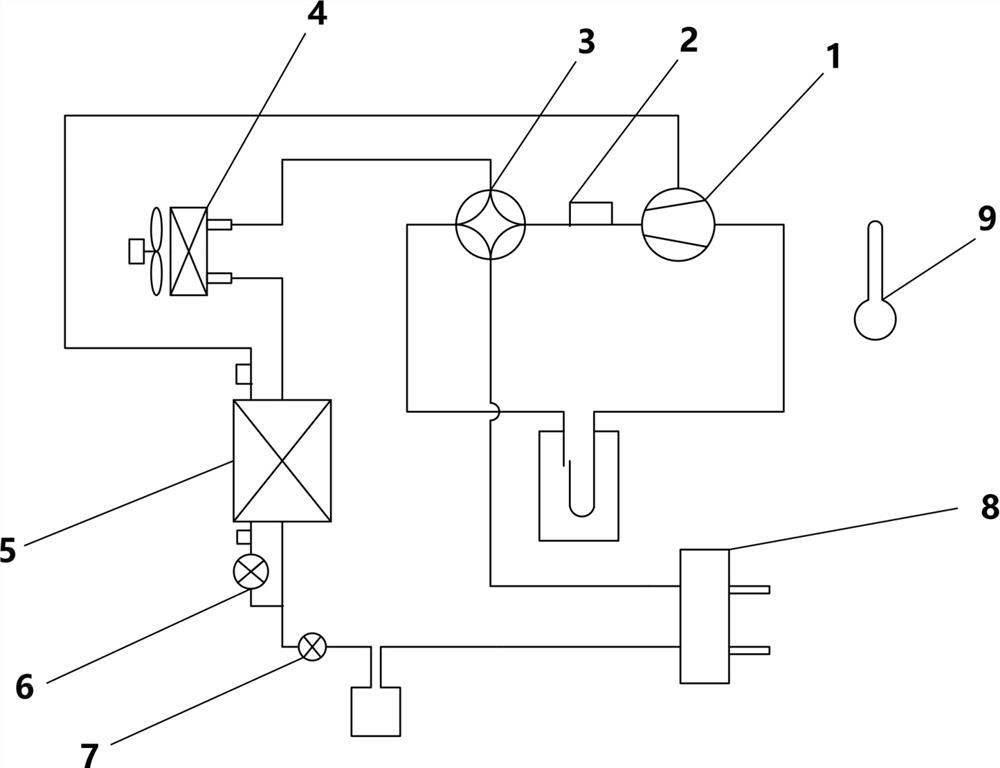

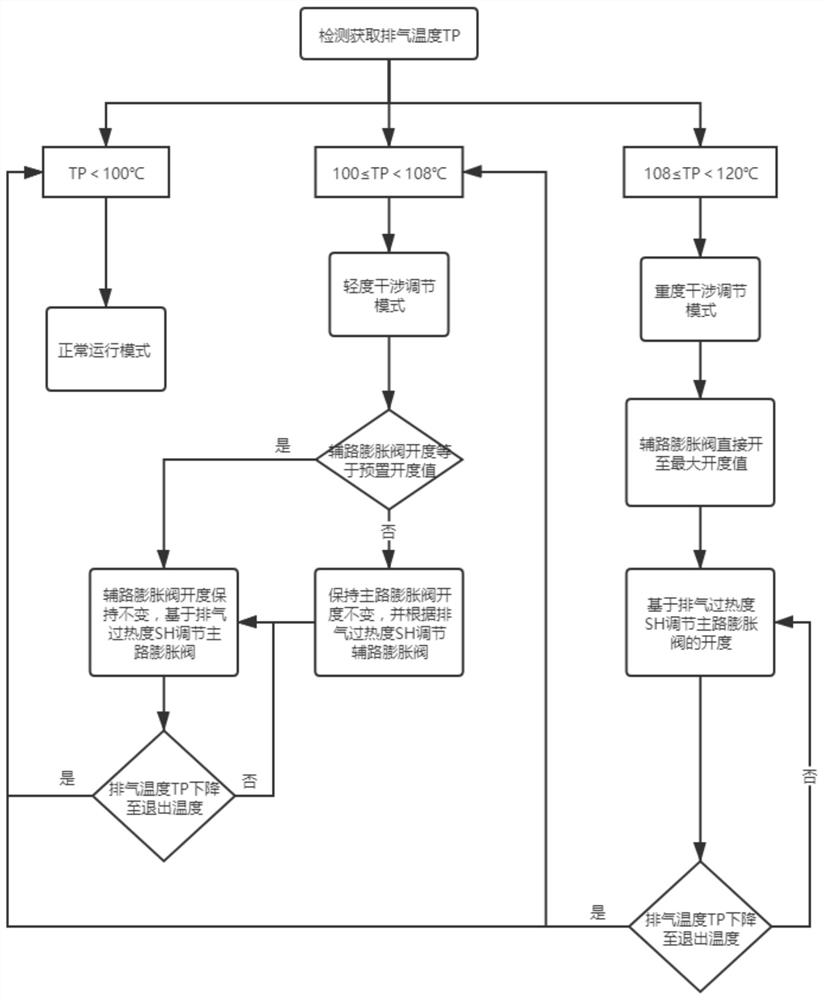

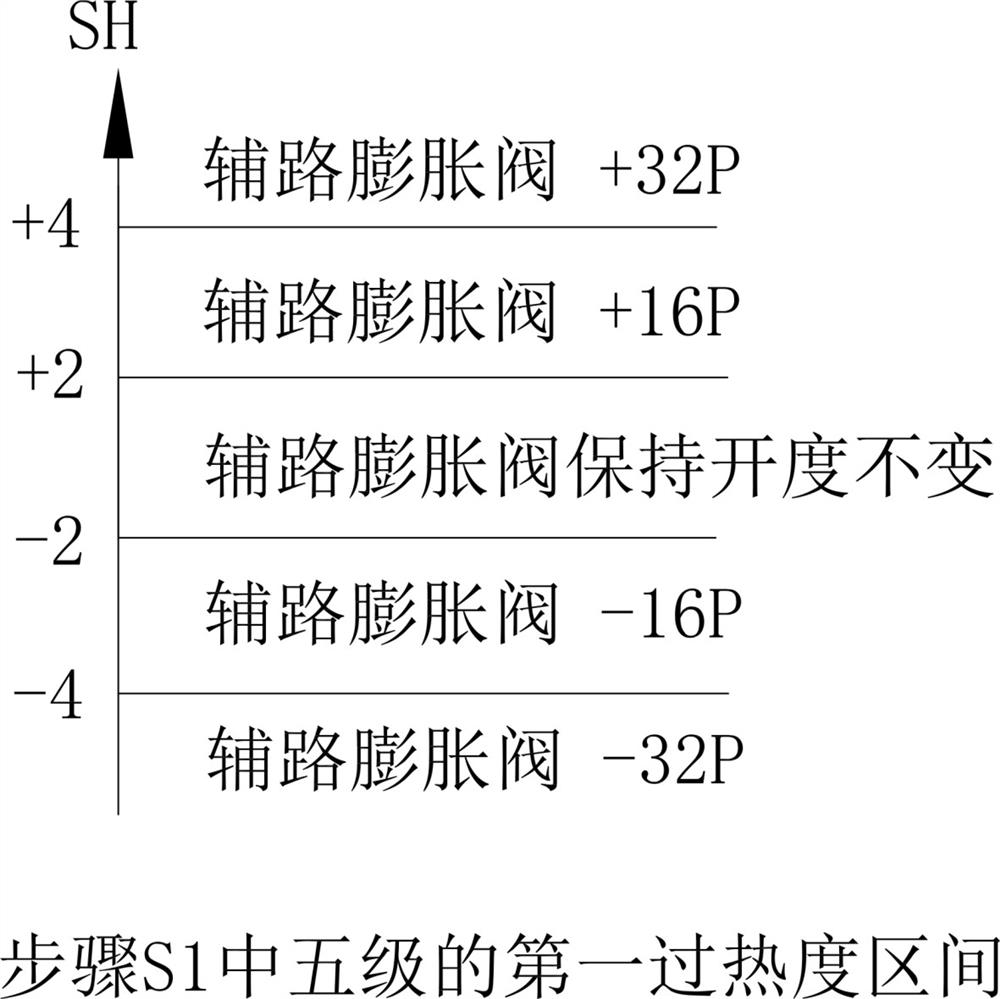

A low-temperature heat pump water jet jet enthalpy increasing system and its control method

ActiveCN112503792BSmooth and reliable adjustmentToggle smallMechanical apparatusHeat pumpsEngineeringMechanical engineering

The invention discloses a jet enthalpy increasing system for a low-temperature heat pump water machine, comprising a compressor, a four-way valve, an indoor heat exchanger, an outdoor heat exchanger and a water side heat exchanger. The outdoor heat exchanger exchanges heat with the water side. The main path expansion valve is arranged on the flow path pipeline between the heat exchangers; it also includes an auxiliary path pipeline, one end of which extends through the outdoor heat exchanger and is bypassed to the flow between the outdoor heat exchanger and the main path expansion valve. The other end of the auxiliary pipeline is connected to the input port of the compressor, and the auxiliary pipeline is provided with an auxiliary expansion valve between the outdoor heat exchanger and the bypass position; An exhaust gas temperature sensor for real-time detection and acquisition of exhaust gas temperature TP is provided on the flow path pipeline between the through valves, so that under low temperature conditions, it is determined whether to perform interference adjustment on the system based on the detected exhaust gas temperature TP. , wherein, when the system needs to be interfered and adjusted, the opening degrees of the main circuit expansion valve and the auxiliary circuit expansion valve are correspondingly adjusted based on the exhaust gas temperature TP obtained by detection and the calculated exhaust gas superheat degree SH.

Owner:GUANDONG GIWEE TECH CO LTD

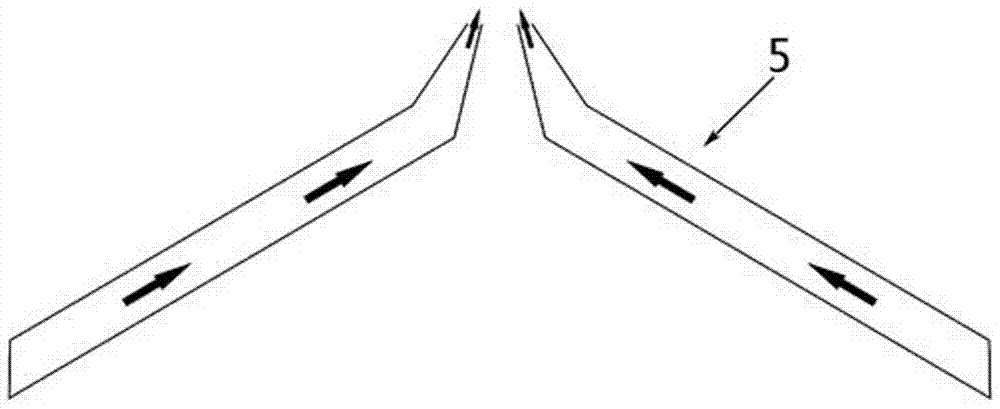

Post-sewing yoke machine

PendingCN111155244ASimple structureImprove sewing qualityWork-feeding meansSewing-machine control devicesStructural engineeringIndustrial engineering

The invention discloses a post-sewing yoke machine. The machine comprises a main frame, a workbench component, a sewing machine head and an edge folding component. The machine is characterized by further comprising an adjustment component and a feeding component. The adjustment component comprises a left-side adjustment base and a right-side adjustment base. The edge folding component comprises aleft-side locating device, a right-side locating device, a left-side folding knife component and a right-side folding knife component. The left-side locating device and the left-side folding knife component are both arranged on the left-side adjustment base. The right-side locating device and the right-side folding knife component are both arranged on the right-side adjustment base. The left-sidelocating device and the right-side locating device are used for locating the pleating width of main cloth. The left-side folding knife component and the right-side folding knife component are used forperforming edge folding and pleating on the main cloth. The distance between the left-side adjustment base and the right-side adjustment base of the adjustment component can be adjusted. The feedingcomponent is used for feeding the pleated main cloth and corresponding yoke cloth jointly to the sewing machine head for sewing.

Owner:CHANGZHOU ZHIGU ELECTROMECHANICAL TECH CO LTD

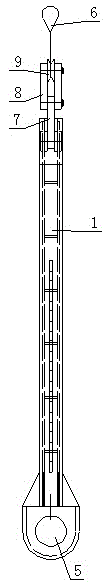

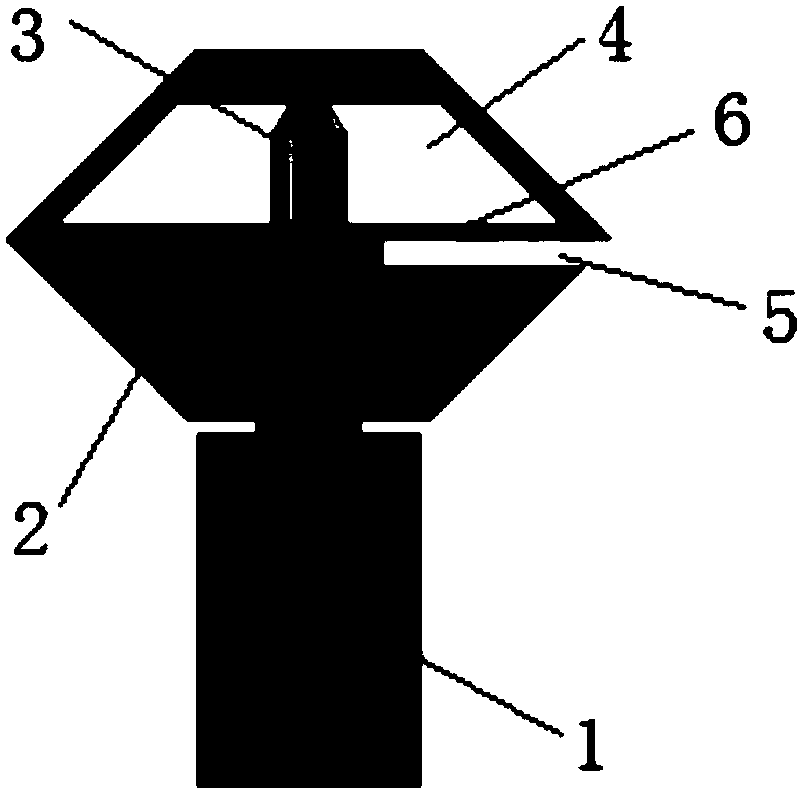

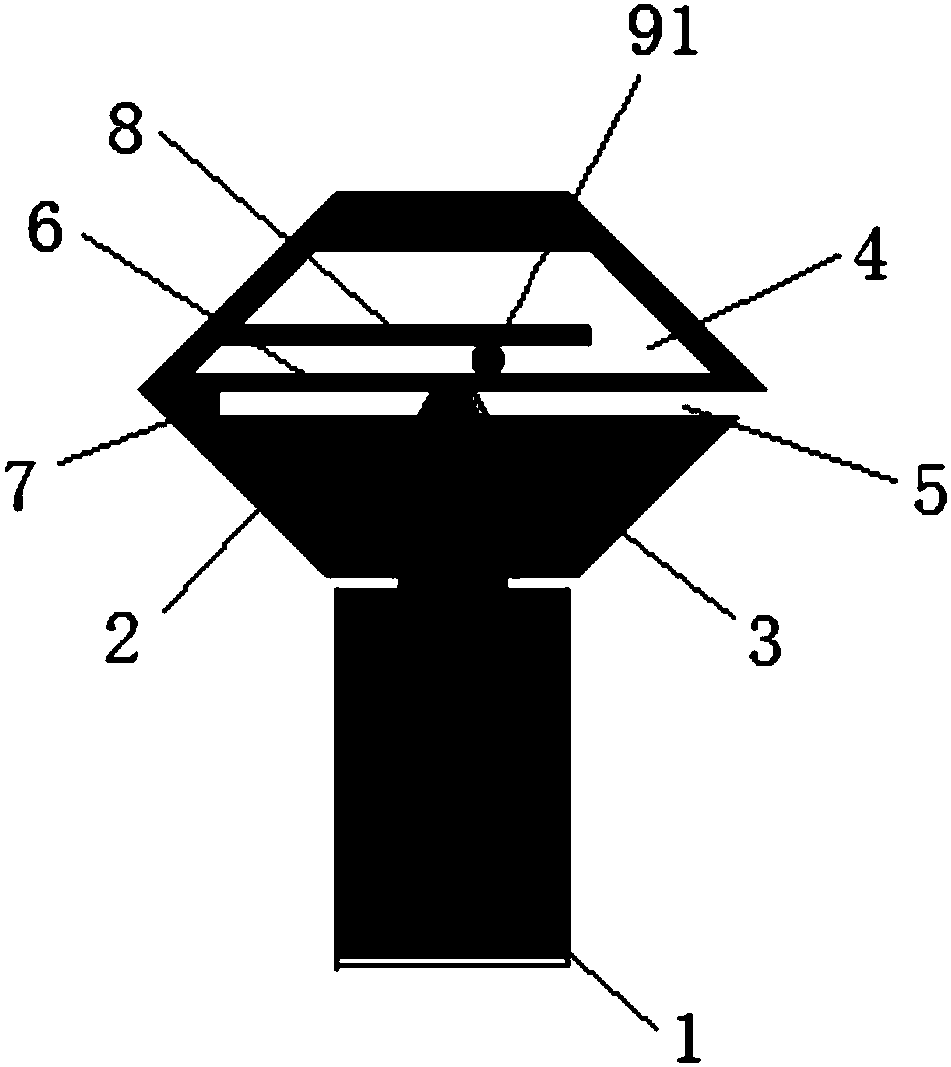

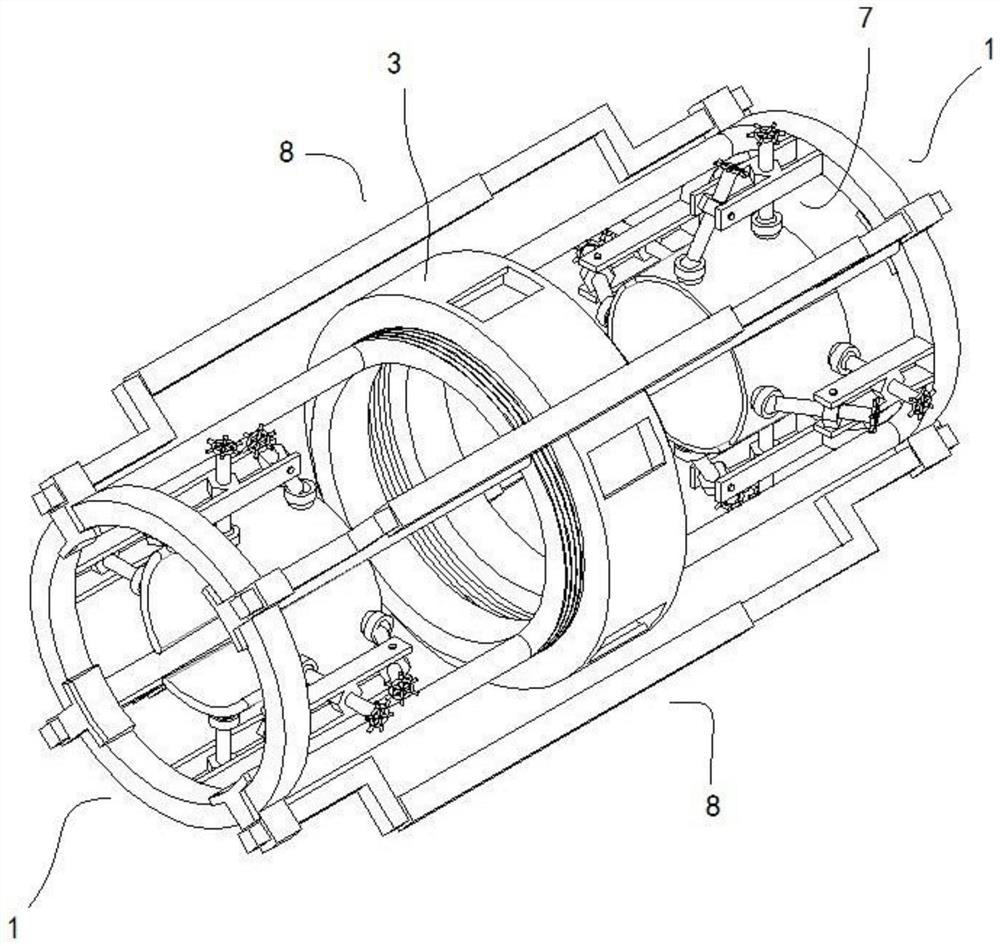

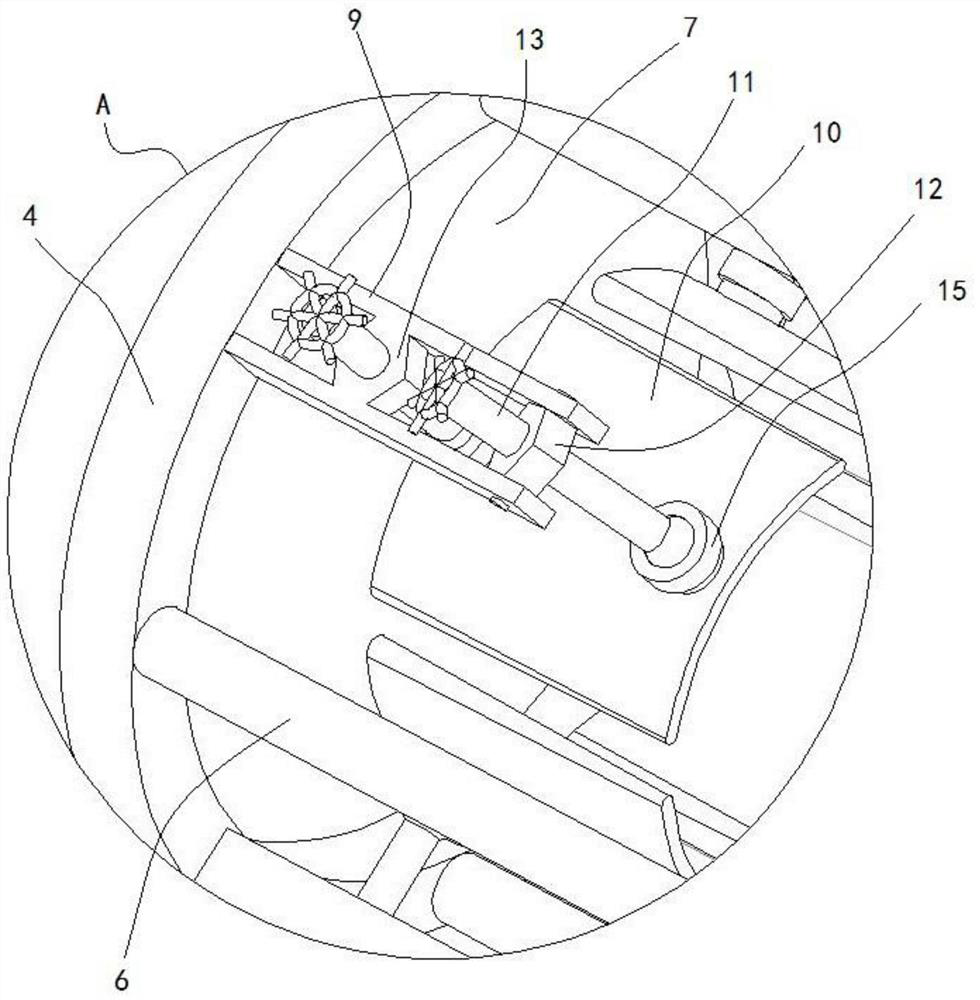

A Closed Elastic Core Adjusting Mechanism

ActiveCN105589134BSolve the problem of fine alignmentSmooth and reliable adjustmentCoupling light guidesElastomerEngineering

The invention discloses a closed type elastic core regulation mechanism which comprises a support, an ejector rod and an elastic body. The elastic body is installed on the top of the support. The closed type elastic core regulation mechanism is characterized in that a deformation cavity and a deformation groove are formed in the elastic body, the deformation cavity is a hollow cavity formed in the upper portion in the elastic body, the deformation groove is formed below the deformation cavity, the deformation cavity and the deformation groove are separated through a supporting wall, the ejector rod is arranged in the elastic body, and the bottom of the elastic body extends upwards and points to the deformation cavity. Compared with the prior art, the closed type elastic core regulation mechanism has the advantages that the problem of fine alignment of a left optical fiber and a right optical fiber which need to be welded is solved, machining is facilitated, the machining difficulty is lowered, and the manufacturing cost is low; meanwhile, the regulation accuracy and amplitude can be taken into consideration for the core regulation mechanism at the same time through the combination of the deformation cavity and the deformation groove, the regulation process is stable and reliable, and stability is good.

Owner:NANJING JILONG OPTICAL COMM

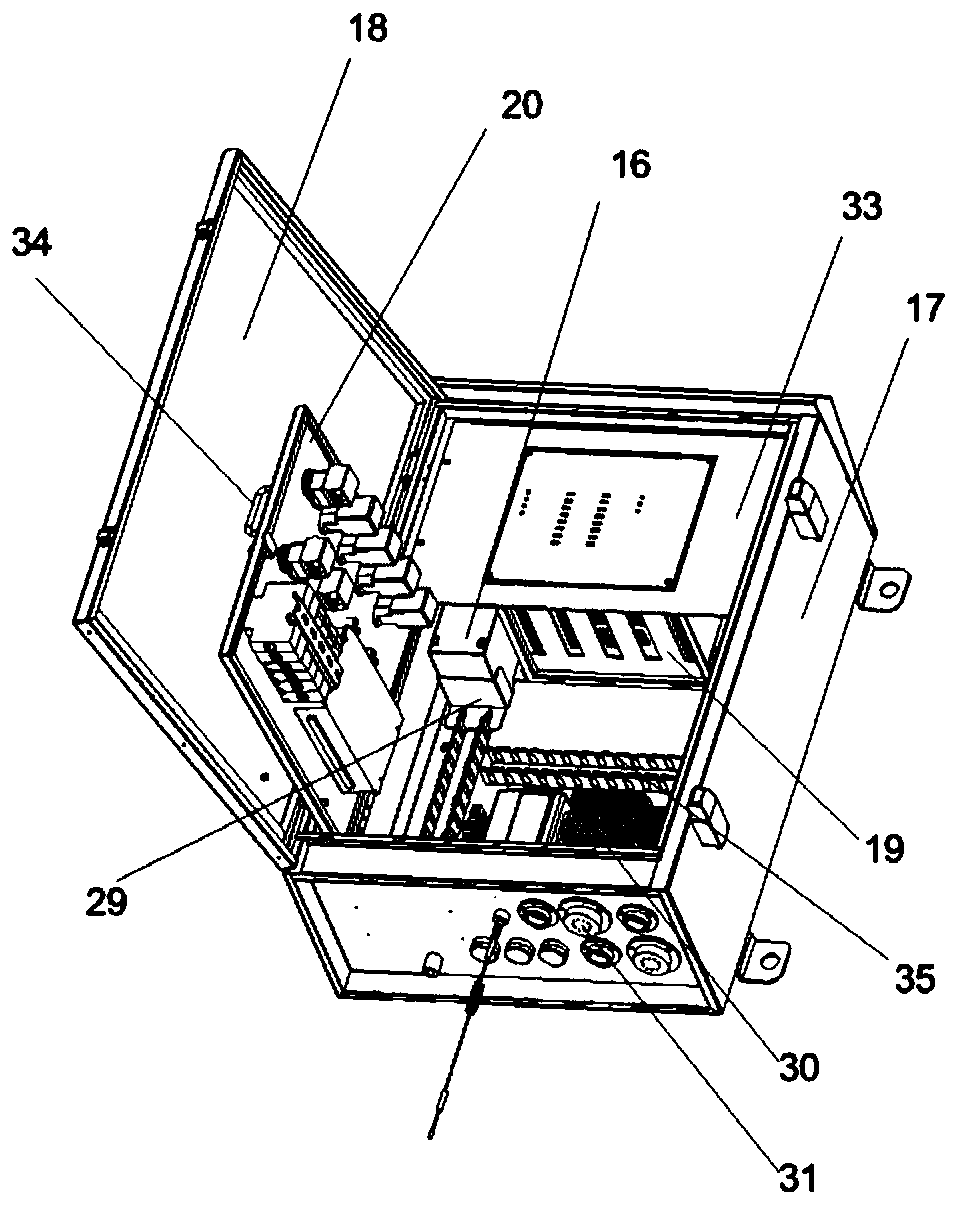

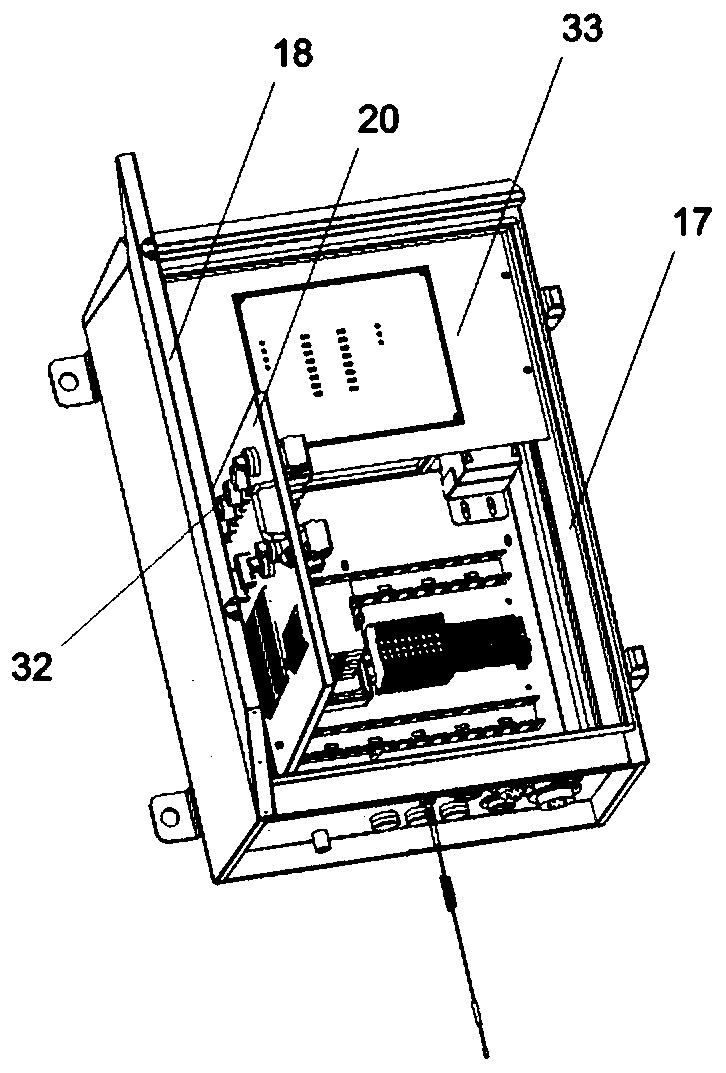

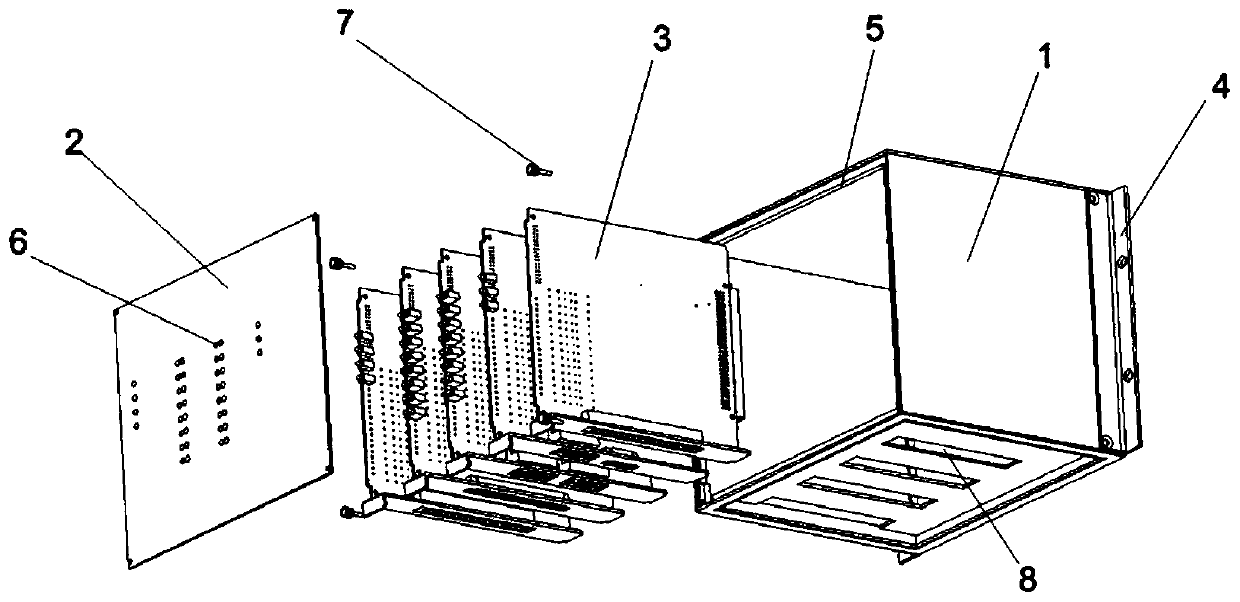

Box-type feeder terminal

PendingCN111431063AMake the most of the interior spaceEasy maintenanceSubstation/switching arrangement detailsCircuit arrangementsInterior spaceFeeder line

The invention discloses a box-type feeder terminal. The computer case comprises comprising a case body, a case cover, a core unit structure, a control panel, a dual-power-supply switching module, a backup power supply, a backup power supply mounting structure, a power supply module, a communication module, an air switch, a line bank, an aviation socket and an indicating lamp, wherein the core unitstructure comprises a casingcase, a cover plate and a circuit board plugging member., the The bottom of the casing case is provided with a plurality of elongated through holes, and the elongated through holes are used for exposing wiring terminals after the circuit board plugging member is installed; the backup power supply mounting structure comprises a mounting bottom plate, a fixed cover and amovable cover, the position of the movable cover corresponds to the position of the fixed cover, an upper covered edge is arranged at the top of the fixed cover, a kidney-shaped adjusting hole is formed in the movable cover, and an adjusting screw matched with the kidney-shaped adjusting hole is arranged on the mounting bottom plate. According to the feeder terminal box, tThe advantages that anyplate can be independently plugged and unplugged and is convenient to maintain are kept, an the operator can easily operate on the rod to achieve replacement of a backup power supply, the structure issimple and compact, and the internal space of the feeder terminal box can be fully utilized.

Owner:浙江安众科技有限公司

A welding process platform with its own scribing device

ActiveCN112247442BSimple structureEasy to assembleFinal product manufactureWelding/cutting auxillary devicesEngineeringLaser assisted

Owner:NUCLEON XINXIANG CRANE

Reset fixing frame for orthopedics department

InactiveCN111743612ASimple and reliable adjustment processEasy to operateExternal osteosynthesisStructural engineeringOrthopedic department

The invention discloses a reset fixing frame for the orthopedics department, and relates to the technical field of medical instruments. The reset fixing frame comprises a first annular frame and a second annular frame which have the same structure and are coaxially arranged; the near ends of the first annular frame and the second annular frame are connected through an internal thread sleeve; and first threads opposite in rotating direction are symmetrically formed in the two ends of the inner wall of each inner threaded sleeve. The first annular frame comprises an outer ring and an inner ring.The outer ring and the inner ring are coaxially arranged, and the opposite surfaces of the outer ring and the inner ring are connected through four fixing round rods which are annularly and evenly arranged. A pressing plate adjusting assembly used for limb connection adjustment is fixed to the side face, opposite to the inner ring, of the outer ring and located in the middle of every two adjacentfixing round rods. Second threads matched with the first threads are formed in the circumferential side face of the inner ring. Through combined use of the first annular frame, the second annular frame, the internal thread sleeves, the pressing plate adjusting assemblies and a guide rod assembly, omnidirectional angle adjustment can be conducted on a limb at the joint.

Owner:合肥三元康泰医疗设备有限公司

Clamping mechanism for drop test machine

ActiveCN111707435ASmooth and reliable automatic adjustmentEasy to adjust the clamping heightShock testingReciprocating motionDrop tests

The invention discloses a clamping mechanism for a drop test machine. The invention belongs to the technical field of drop test. The nut end of a ball screw transmission set is fixedly connected withthe sliding block end of a guide rail sliding block set. A first clamping group is fixedly connected with the power output end of a lifting feeding mechanism through a mounting beam group. A second clamping group penetrates through the sliding block end of the guide rail sliding block set and is movably connected with the mounting beam group. The lifting feeding mechanism can drive the first clamping group and the second clamping group to do lifting reciprocating motion through the mounting beam group. The ball screw transmission set can drive the second clamping group to slide on the guide rail end of the guide rail sliding block set in a reciprocating mode through the sliding block end of the guide rail sliding block set, so that the second clamping group is matched with the first clamping group to clamp or loosen a sample to be tested. According to the clamping mechanism for a drop test machine disclosed by the invention, it is guaranteed that the clamping mechanism can stably and reliably achieve the clamping or loosening action, the clamping mechanism can adapt to to-be-tested sample machines of various sizes and specifications, batch drop detection can be conducted, and meanwhile the clamping height can be conveniently adjusted.

Owner:萍乡伊博智能科技有限公司

Pneumatic pressure grinding mechanism and grinding method for optical fiber and lithium niobate wafer

InactiveCN104959908BEasy to read displayConstant grinding pressureLapping machinesWork carriersFiberEngineering

The invention discloses a fiber and lithium niobate wafer pneumatic pressurized grinding mechanism and grinding method, including a three dimensional positioning device, a pneumatic device, and a clamping mechanism, a z-axis moving mechanism switching board of the three dimensional positioning device is connected with the pneumatic device, and the clamping mechanism is arranged on the pneumatic device. A fiber and lithium niobate wafer is clamped by the clamping mechanism and is connected with a cylinder piston rod through an adjusting slide rod and a beam type force transducer. The three dimensional positioning device can realize the accurate positioning and grinding micro-feeding of a lithium niobate wafer clamping tool, the pneumatic device makes the change of the grinding pressure a gradually changing process, and the lithium niobate wafer clamping tool can stably and rapidly clamp a lithium niobate wafer. The grinding pressure during the grinding of the lithium niobate wafer is constant, and the changing process of the grinding pressure is a gradually changing process, so that the grinded end face quality is guaranteed, and the grinding process is stable and reliable; and meanwhile, the fiber end face of the grinded lithium niobate wafer can be conveniently observed.

Owner:BEIHANG UNIV

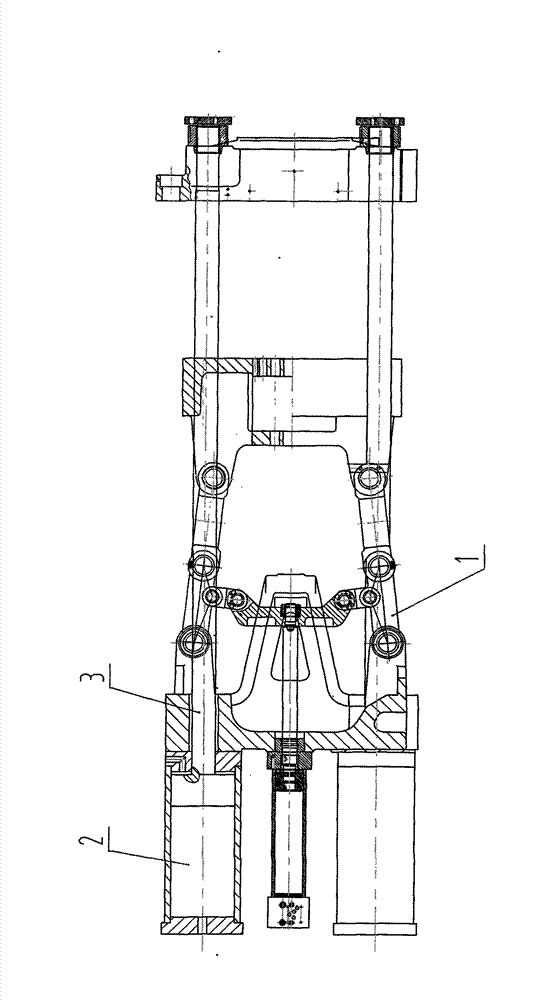

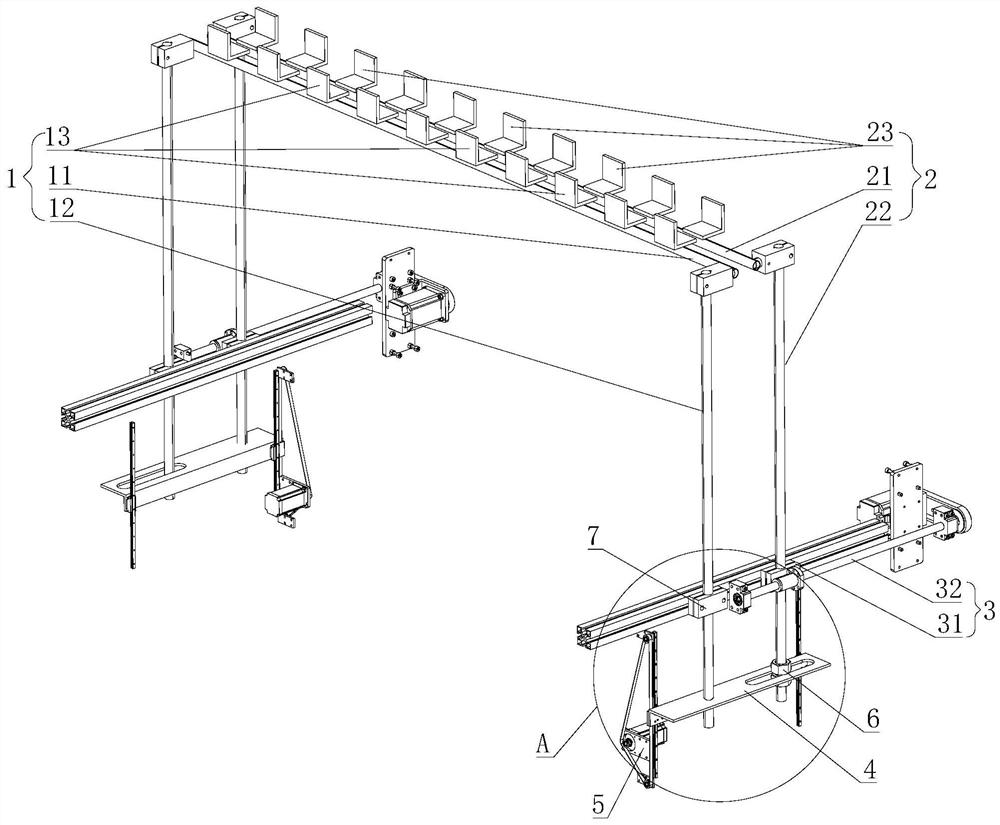

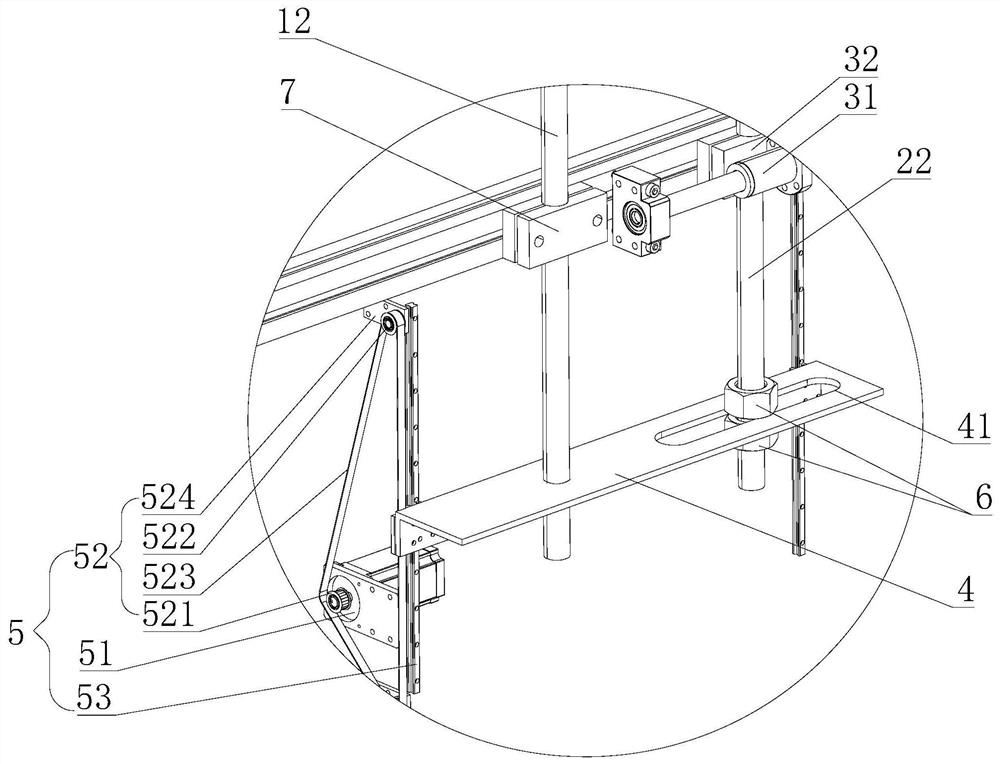

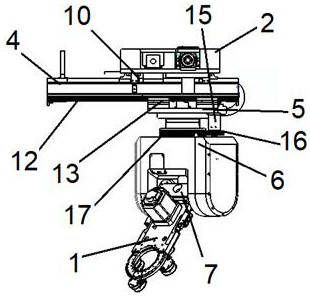

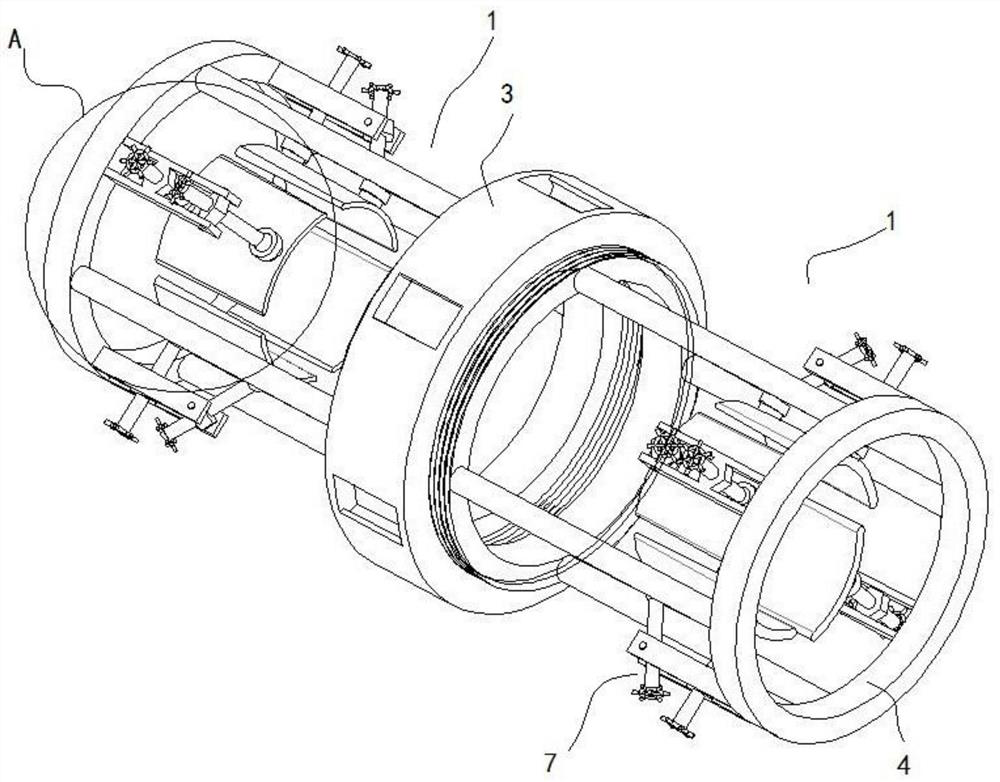

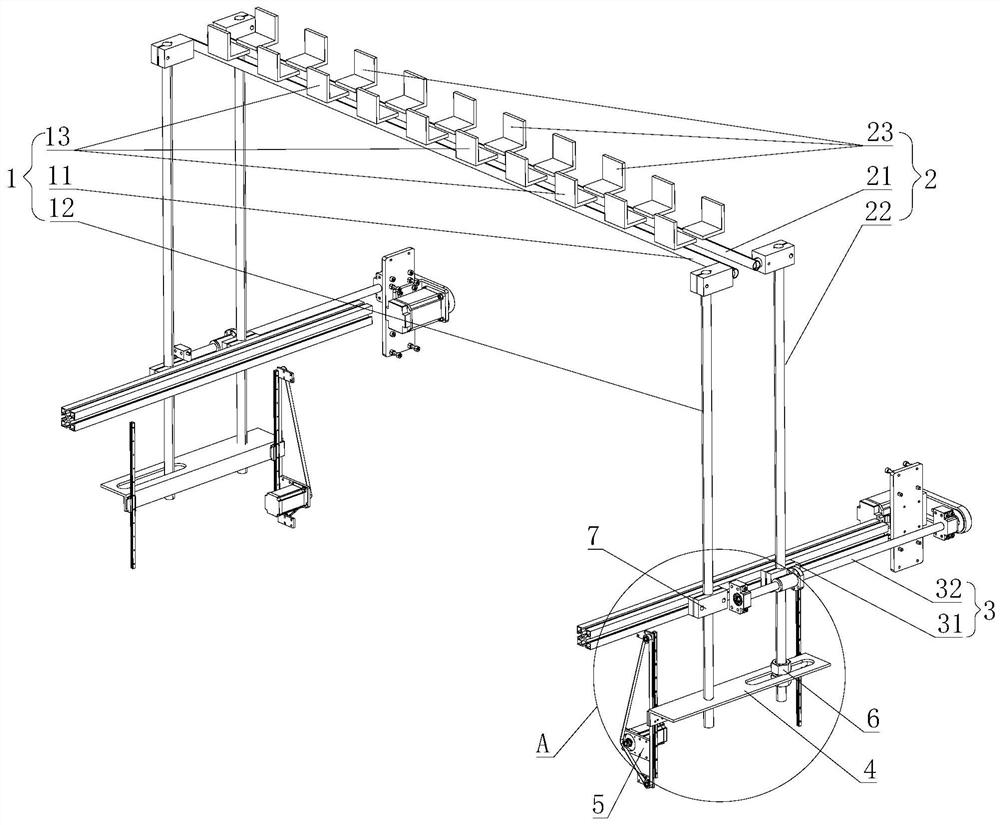

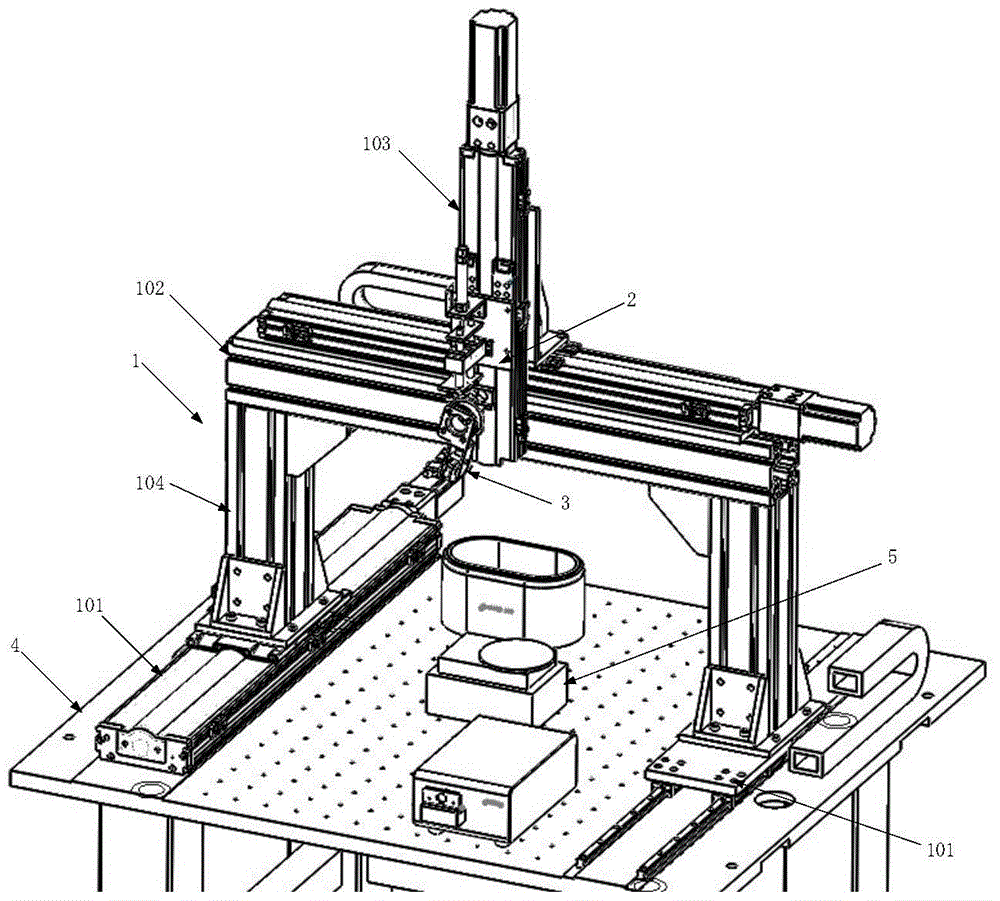

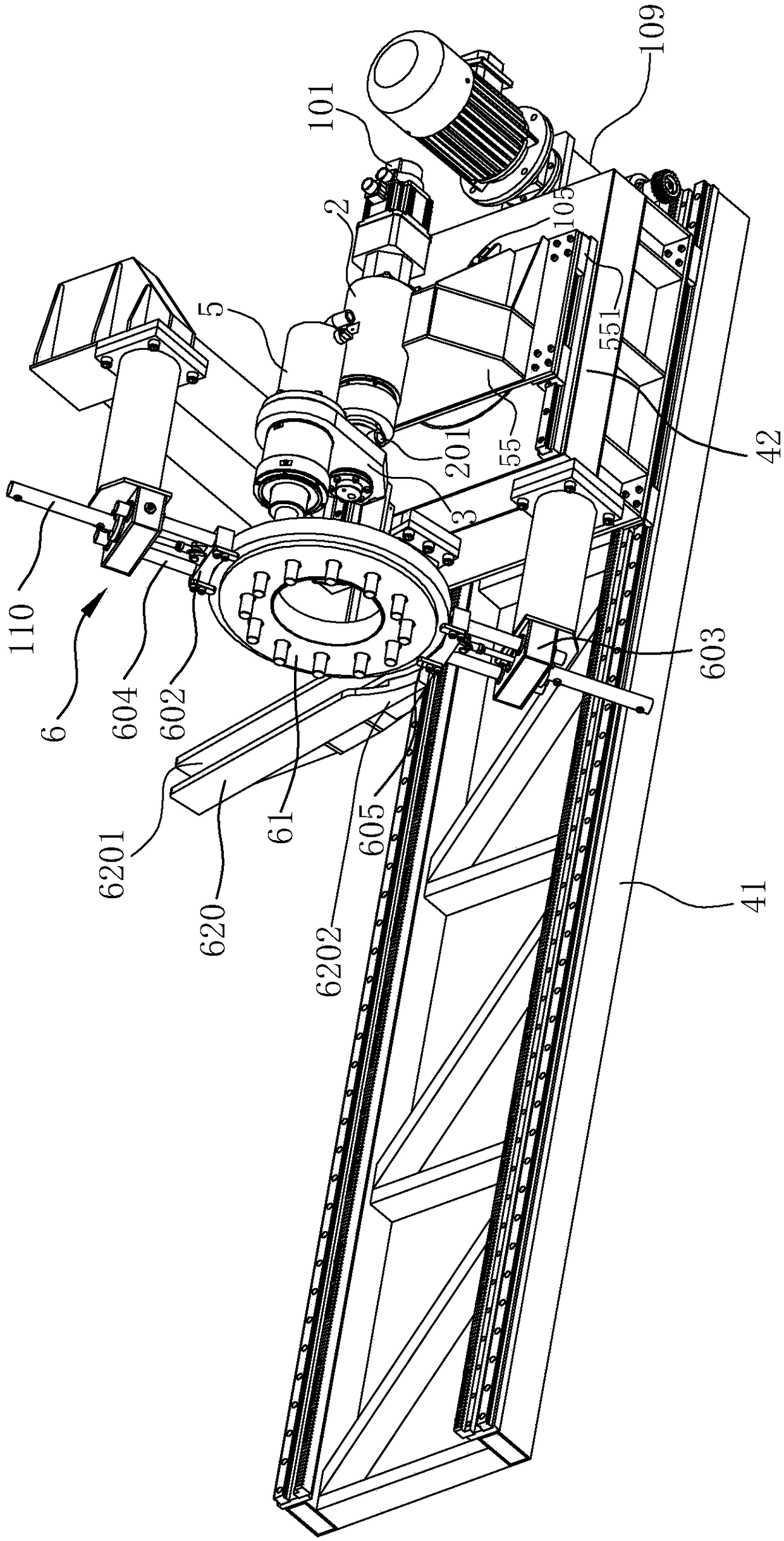

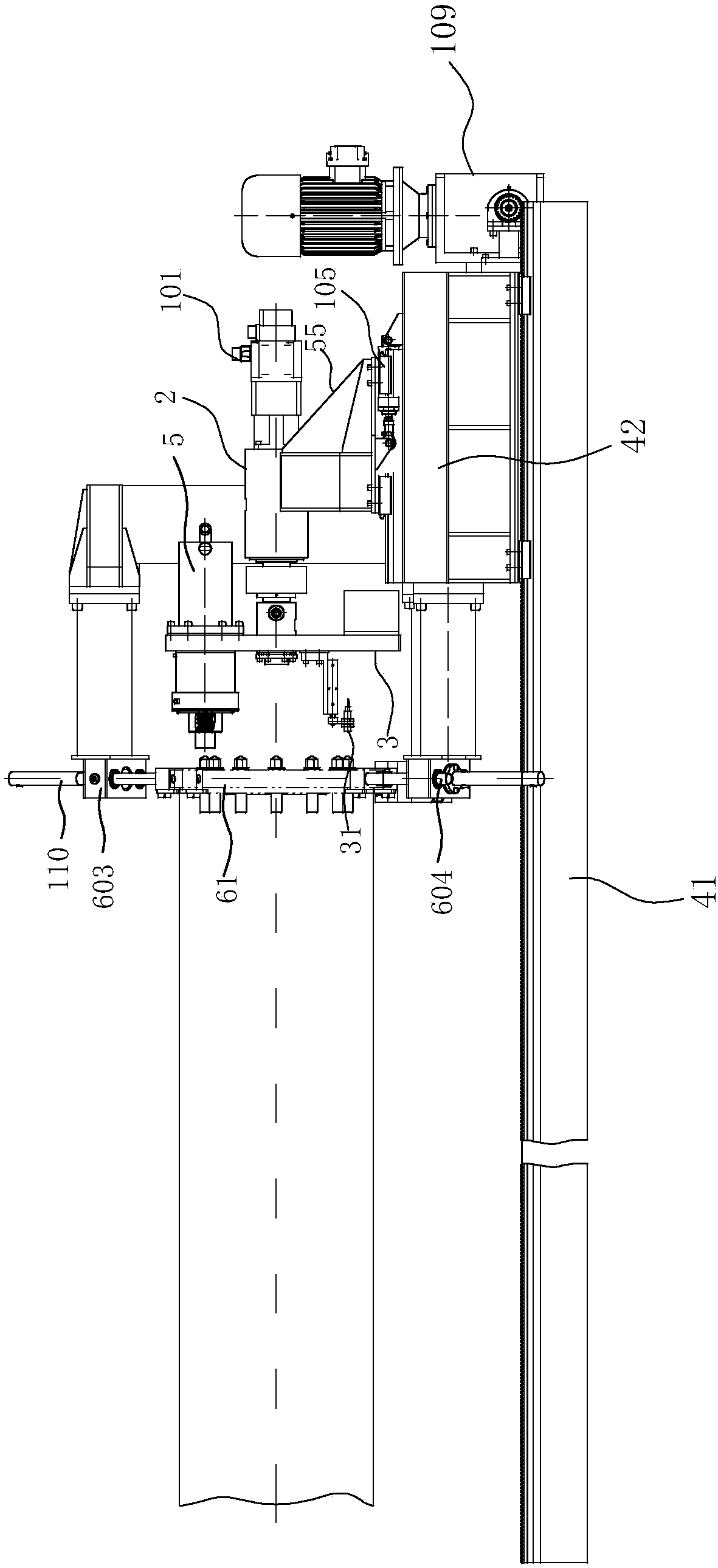

Tape lapping head aerial attitude position change method and device

ActiveCN110601471ALess teaching timeLower the altitudeApplying solid insulationEngineeringChange control

The invention relates to a tape lapping head aerial attitude position change method and device. A tape lapping head is hoisted below a cross beam of a rack, the tape lapping head is driven for aerialattitude change by a four-axis linkage assembly, and wrapping of a coil insulating layer is carried out. The fact that the tape lapping head is driven for aerial attitude change by the four-axis linkage assembly is that the tape lapping head is hoisted below the cross beam of the rack through the four-axis linkage assembly, and aerial attitude change of the tape lapping head is realized through matched movement of the four-axis linkage assembly. The four-axis linkage assembly drives the tape lapping head to realize aerial attitude change, the height of the tape lapping head on the cross beam can be effectively reduced, the height of the whole tape lapping machine is further reduced, the occupied space is reduced, the change control is easier and the accuracy is further improved.

Owner:株洲南方机电制造有限公司

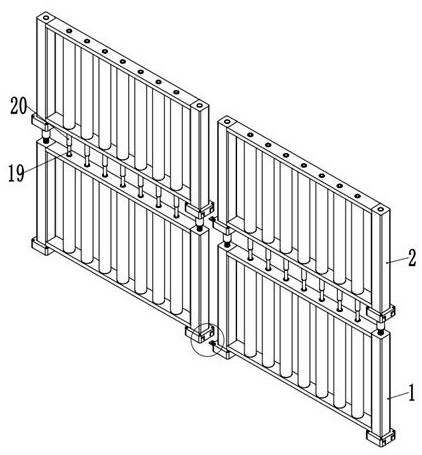

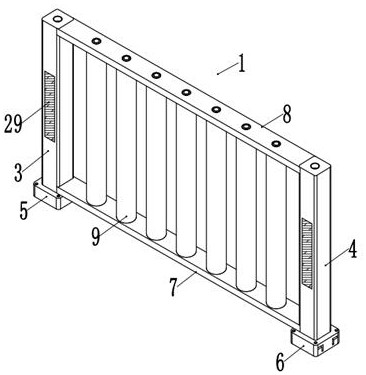

Protective fence with anti-crossing function for municipal engineering

InactiveCN112813883AThe connection is tight and firmImprove skid resistanceRoadway safety arrangementsArchitectural engineeringStructural engineering

The invention relates to the field of municipal engineering, and aims to provide a protective fence with an anti-crossing function for municipal engineering; the protective fence comprises a lower protective fence body and an upper protective fence body, the lower protective fence body comprises a first stand column and a second stand column, a first base is welded to the bottom end of the first stand column, and a second base is welded to the bottom end of the second stand column. The protective fence has the beneficial effects that the lower protective fence body and the upper protective fence body are matched for use, so that the municipal engineering protective fence has a very good anti-crossing function, insertion plates are inserted into insertion grooves, connection between the protective fence bodies is more compact and stable, and through matched use of cylinders, forward threaded rods and reverse threaded rods, the cylinders drive the forward threaded rod and the reverse threaded rod to rotate in the adjusting screw holes, so that the distance between the lower protective fence body and the upper protective fence body can be adjusted according to needs, and the anti-crossing effect of the protective fence is further improved.

Owner:徐雪玲

Nut removal equipment

The invention relates to nut removal equipment which comprises a machine, a first rack and a nut removal component, wherein the nut removal component is used for removing nuts on an end plate; the fist rack is movably arranged on the machine and can move back and force along the machine; and the nut removal component is arranged on the first rack and can move along with the first rack. The nut removal equipment is characterized by also comprising a clamp, an induction mechanism, and a first driving mechanism; the clamp is used for clamping the end plate, and the induction mechanism is used forinducting the nuts; the nut removal component and the induction mechanism are driven by the first driving mechanism to synchronously rotate circumferentially around the center shaft of the end plate,therefore when the induction mechanism inducts one nut on the end plate, the nut removal component can aim at one nut on the end plate and can remove the aimed nuts on the end plate in order. Only bythe matching of one nut removal component and the induction mechanism, the nut removal equipment can remove the nuts of the end plate.

Owner:周兆弟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com