Nut removal equipment

A nut and equipment technology, applied in the field of prefabricated component production equipment, can solve the problems that different pipe piles cannot be used in common, inaccurate positioning of nut sleeves and nuts, complicated processing and installation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

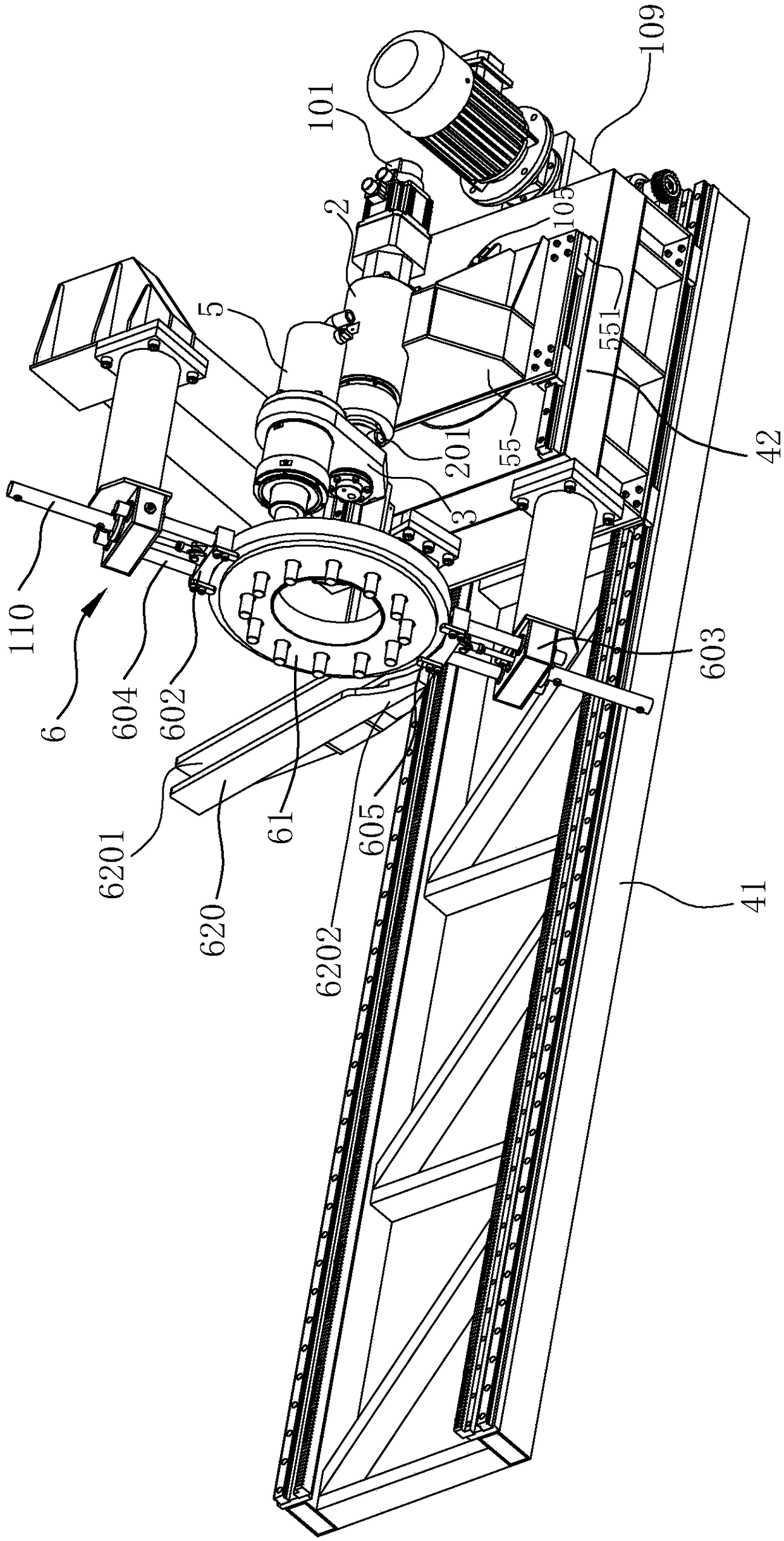

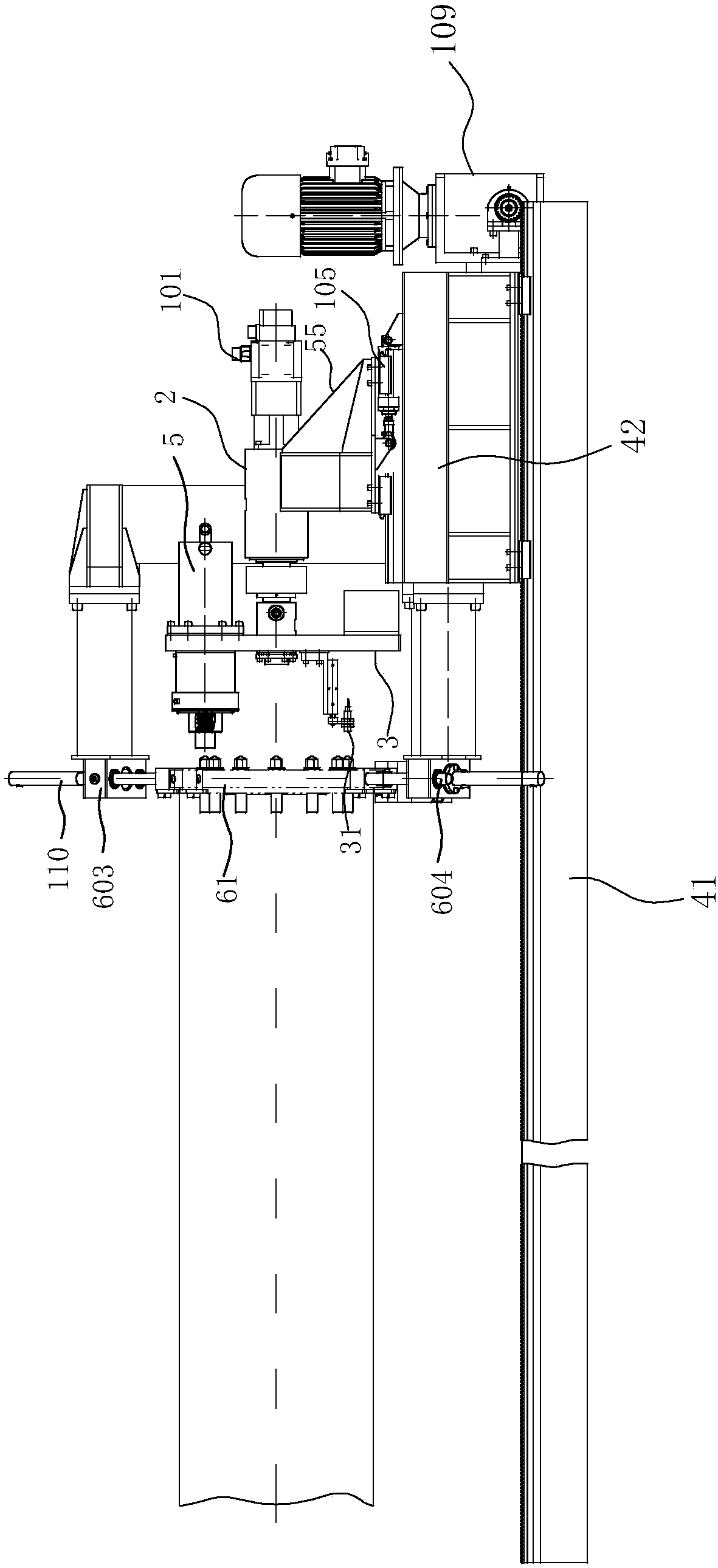

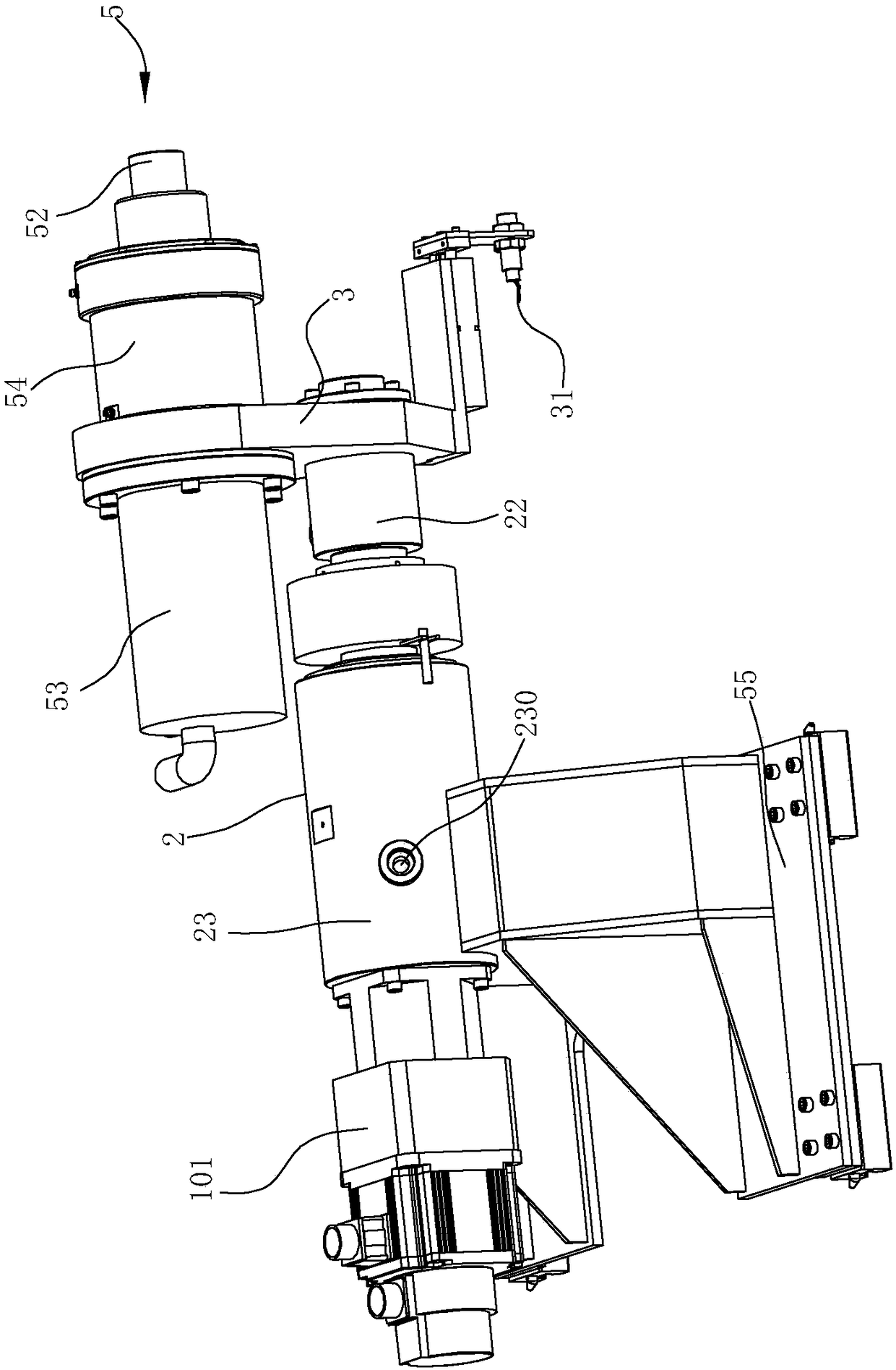

[0088] like Figure 1-8 As shown, the nut removal equipment in this preferred embodiment includes a machine table 41, a first frame 42, a nut removal assembly 5, a first driving mechanism 101 that drives the nut removal assembly 5 to rotate in the circumferential direction of the end plate 61, and is used for clamping. The clamp 6 holding the end plate 61, the delivery device that can remove the end plate 61.

[0089] In this embodiment, the first driving mechanism 101 is a motor, the power output end of the motor is connected to the connecting body 2, and the connecting body 2 is fixedly connected to the nut removal assembly 5 through the connecting piece 3, and the connecting piece 3 is provided with a sensor for sensing the nut. The sensing mechanism 31 is electrically connected to the controller, and the controller controls the action of the first driving mechanism 101 and the second driving mechanism 53 of the nut removal assembly 5 . The nut removal assembly 5 and the i...

Embodiment 2

[0110] like Figures 9 to 17 As shown, the difference between embodiment 2 and embodiment 1 is:

[0111] (1) Embodiment 2 is not provided with conveying device;

[0112] (2) The present embodiment is provided with a positioning mechanism, which enables the rotation center of the nut removal assembly 5 to rotate circumferentially around the central axis of the end plate 61 to quickly and accurately align with the center of the end plate 61:

[0113] like Figures 9 to 13 As shown, the positioning mechanism includes a frame body and an induction assembly 46, and the frame body includes a second frame 43 and a third frame 44, and the nut removal assembly 5 can be mounted on the first frame 42, the second frame 43, the third frame Driven by the frame 44, it moves back and forth, left and right, and up and down, so as to locate quickly and accurately in the three-dimensional direction of space.

[0114] The third frame 44 is located above the second frame 43 and can move with th...

Embodiment 3

[0136] like Figures 18-23 As shown, the difference between embodiment 3 and embodiment 2 is:

[0137] (1) The structure of fixture 6 is different:

[0138] like Figure 18 , 19 As shown, the fourth frame 47 is provided with two opposite jaws 602, and each jaw 602 is correspondingly driven by a sixteenth drive mechanism 116 installed on the fourth frame 47, and the jaws 602 are The sixteenth driving mechanism 116 moves toward the end plate 61 to clamp the end plate 61 , or moves in the opposite direction (a direction away from the end plate 61 ) to release the end plate 61 . Each jaw 602 is correspondingly connected with a second guide rod 614 slidably installed on the fourth frame 47 , and the moving track of the jaw 602 is guided by the second guide rod 614 .

[0139] (2) The induction mechanism 31 is connected with the connector 3 through the cylinder 306:

[0140] like Figure 20-22 As shown, a cylinder 306 is provided at the bottom of the connecting member 3 , the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com