Method for disassembling closed breakdown mill roller

A billet rolling mill and closed-end technology, applied in the field of roll disassembly of closed billet mills, can solve the problems of troublesome roll disassembly and replacement, large manpower and time consumption, and the inability to use cranes, etc., so as to shorten disassembly time, improve labor efficiency, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

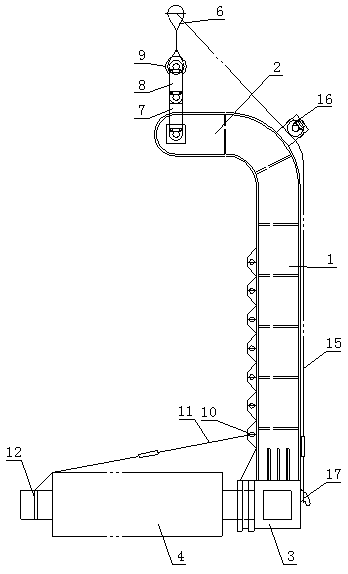

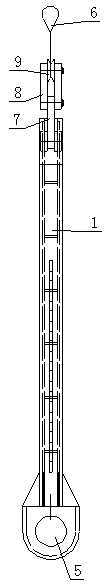

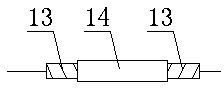

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0026] In specific implementation, such as Figure 1-Figure 3 As shown, a method for dismounting rolls of a closed billet rolling mill specifically comprises the following steps:

[0027] (1) First obtain the spreader with the following structure: including the elongated spreader main body 1, the overall length of the spreader main body 1 is greater than the height distance from the top of the shell of the closed billet rolling mill to the lowest roller in the shell, The upper end of the main body 1 of the spreader has an elbow 2 that bends at 90 degrees, and the lower end is provided with a connecting head 3. The side of the connecting head 3 that is in the same direction as the elbow 2 is provided with a shaft matching the 4 end shafts of the closed billet rolling mill rolls. The roll end shaft installation hole 5, the elbow 2 has an upwardly arranged hook...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com