A mechanical processing equipment for the production of auto parts

A technology for auto parts and mechanical processing, applied in metal processing equipment, grinding machine parts, grinding/polishing equipment, etc., can solve the problems of poor adjustment accuracy, low efficiency, slow speed, etc., and achieve high safety , high efficiency, fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

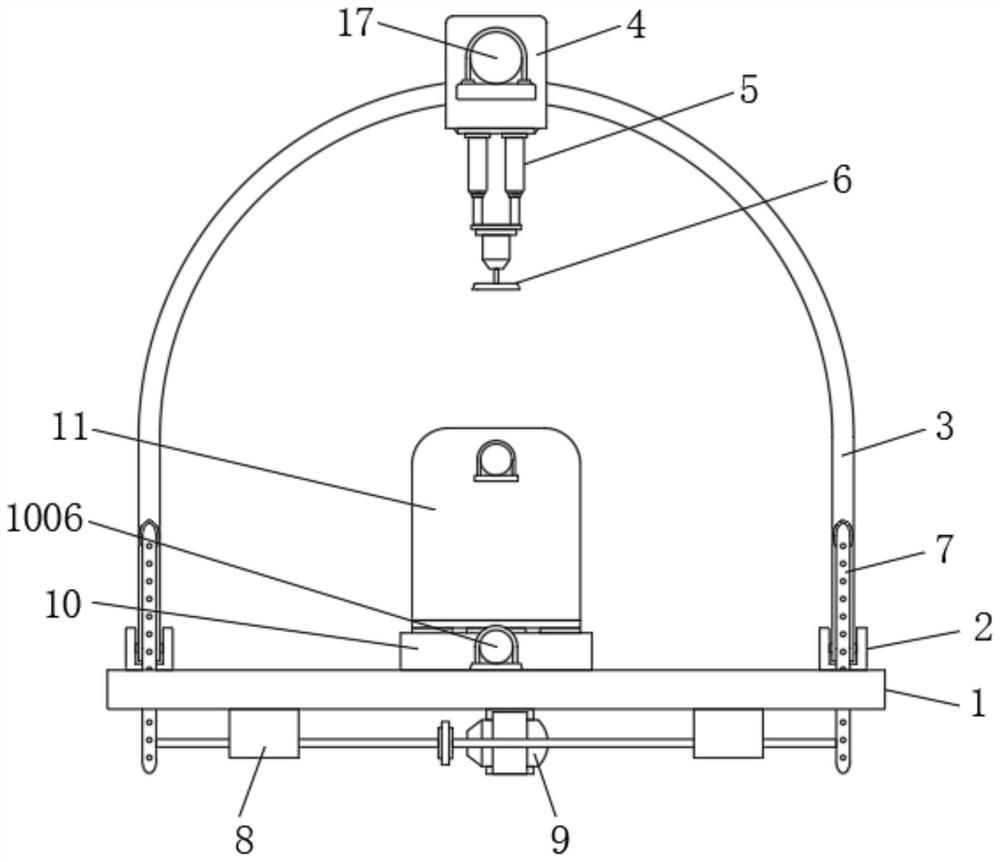

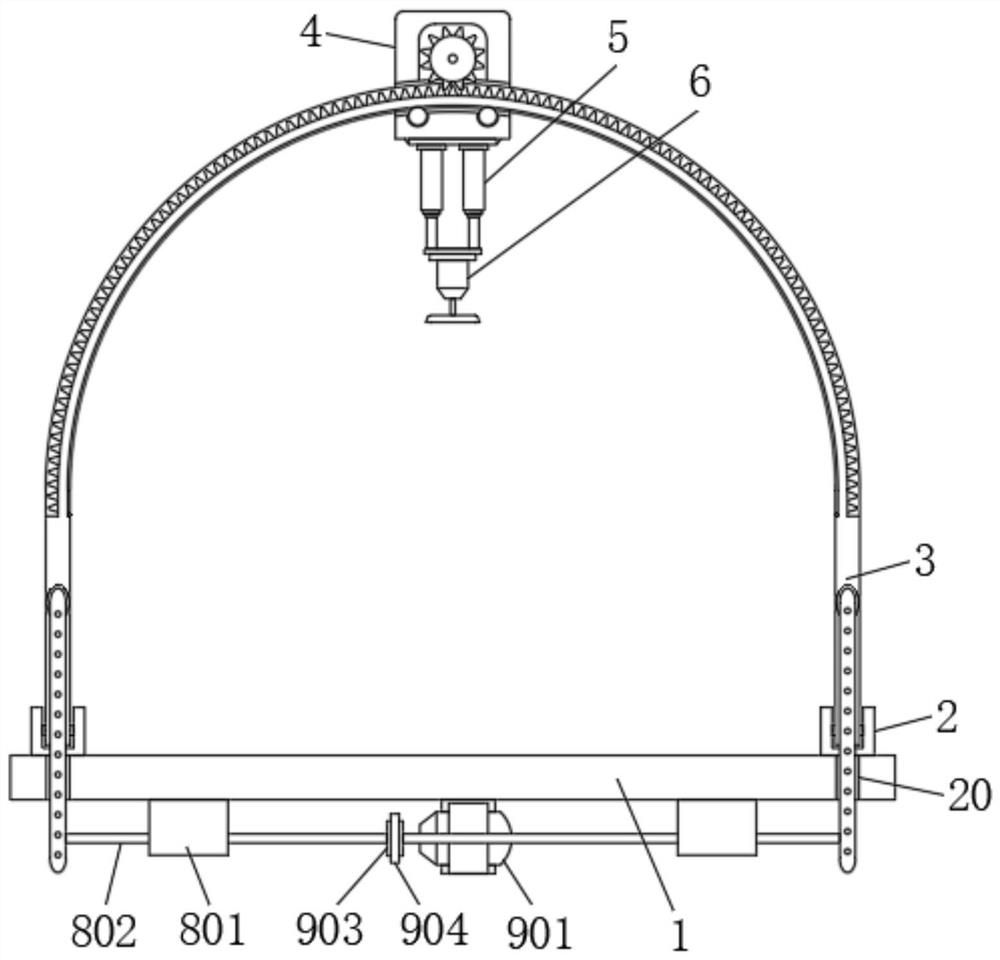

[0030] First embodiment, the Figure 1 to 6Are given, the present invention comprises a base 1, both ends of the top side of the chassis 1 are connected to base 2 is fixedly mounted, two connecting base 2 rotatably mounted between the arcuate inner rotating lever 3, is provided by connecting the base 2, rotating lever 3 so that the arc can be effectively installed and rotated, the arcuate bottom central rotation shaft 3 is mounted, the bottom of the moving block 4 of the moving block 4 are mounted two hydraulic telescopic cylinders 5, two hydraulic telescopic cylinder 5 of between the grinding machine 6 is mounted, the arcuated ends between the rod 3 and the base ends are attached to a fixed circle 7, the bottom of the base 1 is attached to both ends of the two drive rods 8, two drive rod 8 are respectively connected to two gear 7 fixed circle, and the bottom of the base 1 is positioned between the transmission lever 8 is mounted has two adjustable power end 9, the central base is ...

Embodiment 2

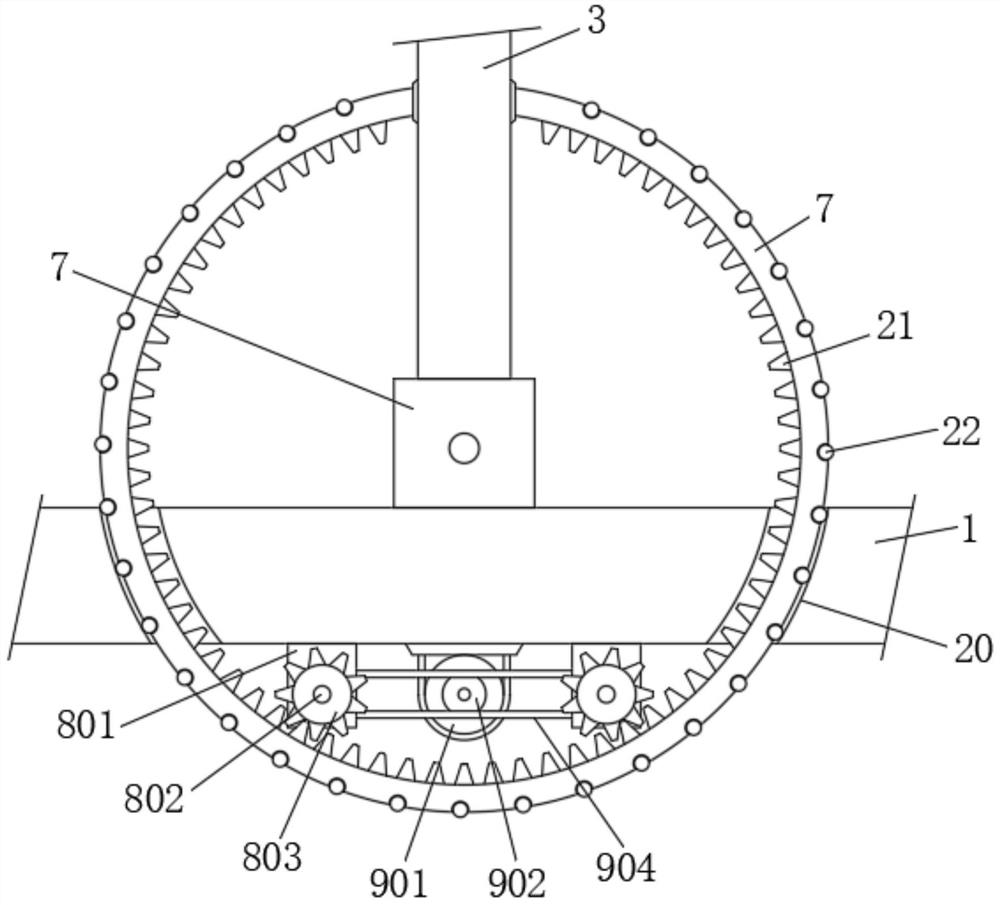

[0032] According to the second embodiment, on the basis of the first embodiment, the Figure 4 Given arc of rotation of the lever 3 intrados defines two ball grooves 18, on both sides of the central arcuate through slot 14 are mounted on the first two balls 19, 19 is fixed to the movable first ball in the ball detent grooves interior 18, so that the movement of the moving block 4 can be stabilized.

Embodiment 3

[0033] The third embodiment, on the basis of the first embodiment, the image 3 Given, both sides of the base 1 defines two arcuate grooves 20 on both ends 7 of the fixed circle rotating lever 3 connected by two stationary arcuate slot 20 and through the arcuate, fixed inside two circles 7 equalization is mounted from a second fixing teeth 21, two outer circles uniformly fixed distance 7 is mounted a second ball 22, by providing the second ball 22, with the mounting circle 7 can be rotated easily adjusted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com