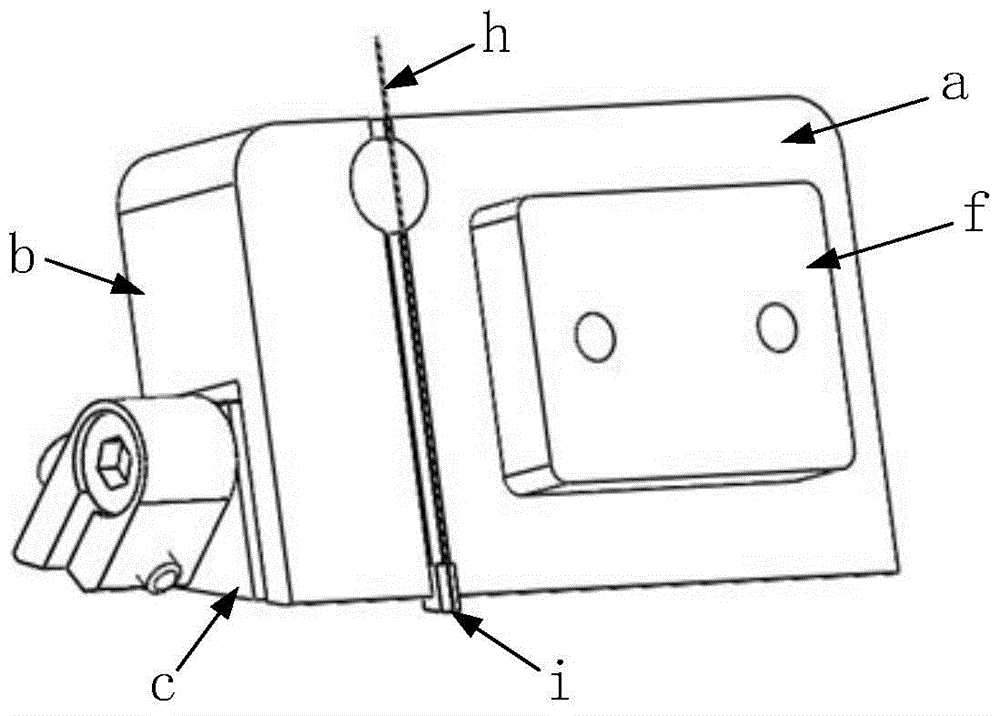

Pneumatic pressure grinding mechanism and grinding method for optical fiber and lithium niobate wafer

A technology of pneumatic pressurization and grinding mechanism, which is used in grinding machine tools, grinding devices, metal processing equipment, etc., to achieve stable and reliable adjustment, ensure grinding pressure, and read the display easily.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with accompanying drawing.

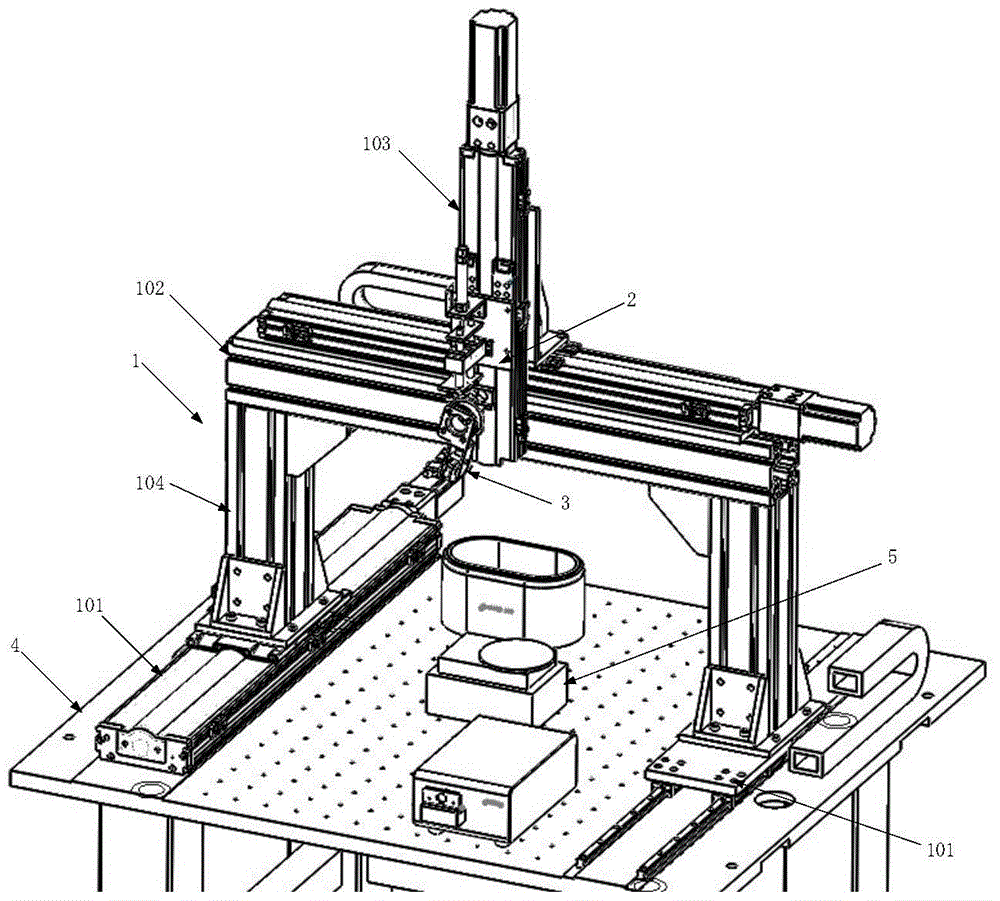

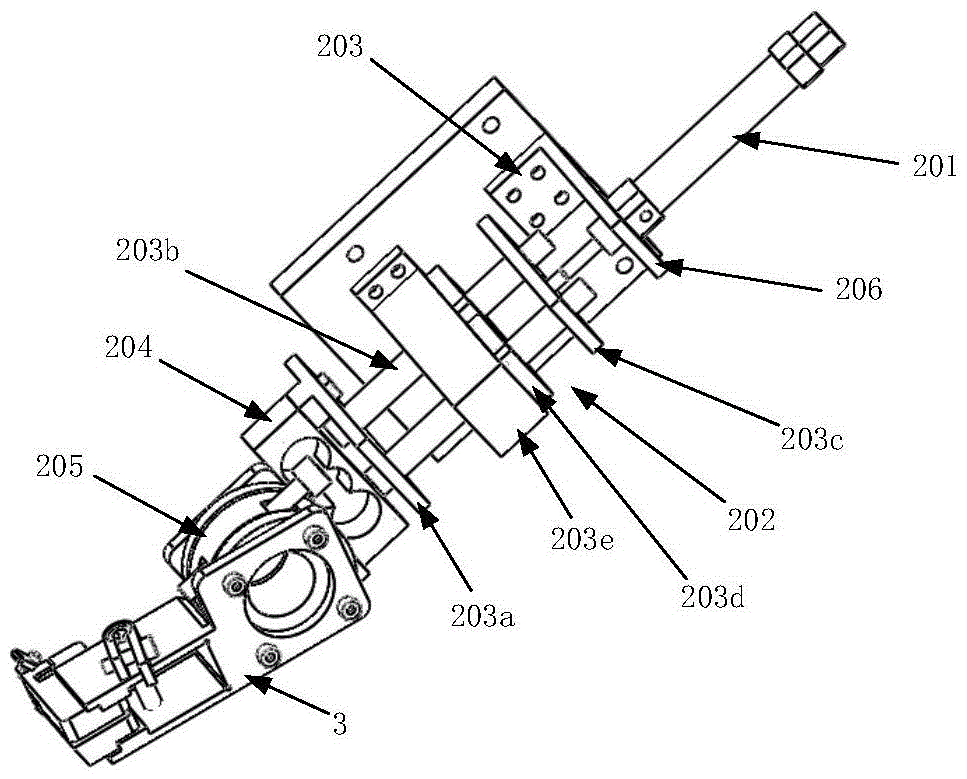

[0056] The optical fiber and lithium niobate wafer pneumatic pressure grinding mechanism of the present invention includes a three-dimensional space positioning device 1, a pneumatic device 2 and a clamping mechanism 3, such as figure 1 shown.

[0057]The three-dimensional spatial positioning device 1 is set on the grinding platform 4 and adopts a door-shaped design, including two sets of x-axis moving mechanisms 101 , one set of y-axis moving mechanisms 102 , one set of z-axis moving mechanisms 103 and two pillars 104 . The x-axis moving mechanism 101 and the y-axis moving mechanism 102 are structurally the same as the z-axis moving mechanism 103, and are composed of a mounting table, a slide rail, a slide table, a ball screw and a driving motor. Wherein, two slide rails parallel to each other are installed on the mounting table. The screw in the ball screw is set in par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com