Compound hydraulic hinging and locking die mechanism

A hydraulic press and mold clamping technology, applied in the field of hinge mold clamping mechanism of compound hydraulic press, can solve the problems of uneven mold adjustment, mold clamping pull rod breakage, long cycle period, etc., and achieves improved machine stability, stable and reliable mold adjustment. , The effect of improving the life of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

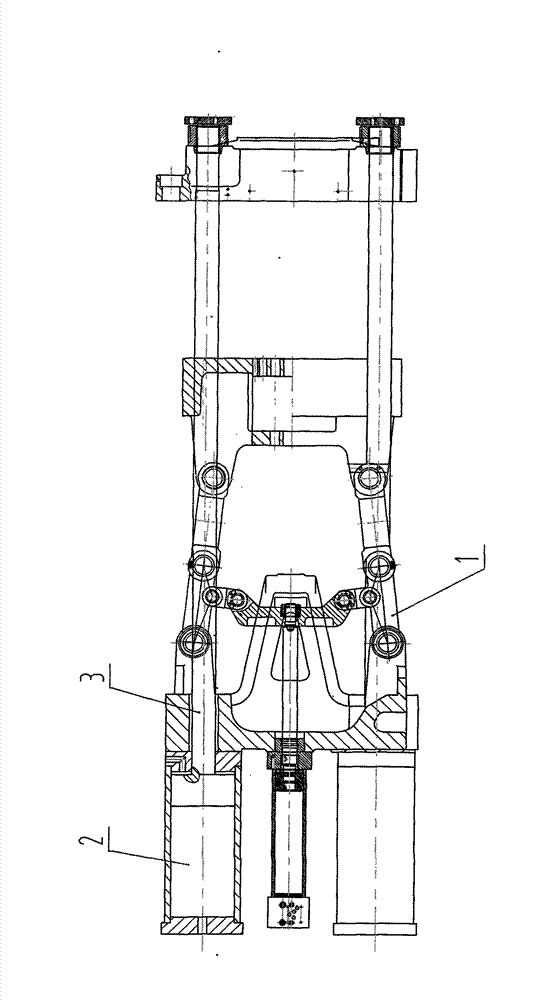

[0011] Such as figure 1 As shown, a compound hydraulic press hinged mold locking mechanism, which includes a traditional formwork machine hinged mold locking assembly (1), a mold adjusting and locking composite oil cylinder body (2), a mold locking pull rod (3), and the mold adjusting lock The mold composite oil cylinder body (2) is fixedly installed on the formwork on one side of the hinged mold lock assembly (1) of the traditional template machine, and one end of the mold lock tie rod (3) is installed on the mold adjustment mold lock composite oil cylinder body (2) In the form of a piston rod, it forms a dynamic fit connection with the mold adjusting and clamping compound oil cylinder body (2), and the other end of the clamping rod (3) is fixed to the template on the other side of the hinge mold clamping assembly (1) of the traditional template machine connect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com