Clamping mechanism of injection molding machine

A technology of injection molding machine and mold clamping, which is applied in the field of mold clamping mechanism of injection molding machine, can solve the problems of low processing precision, uneven clamping force, complex structure, etc., and achieve the effect of high processing precision, balanced force and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

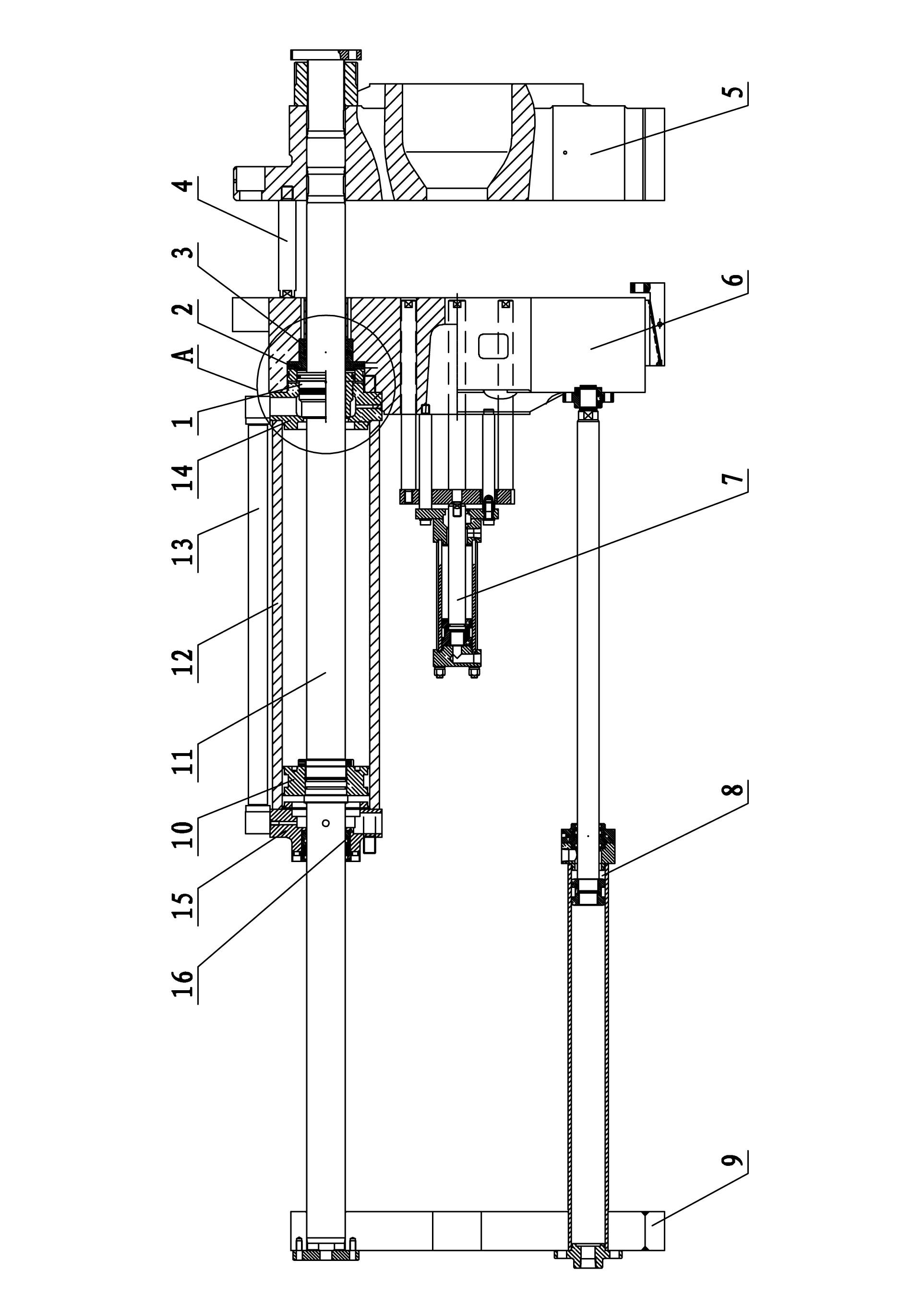

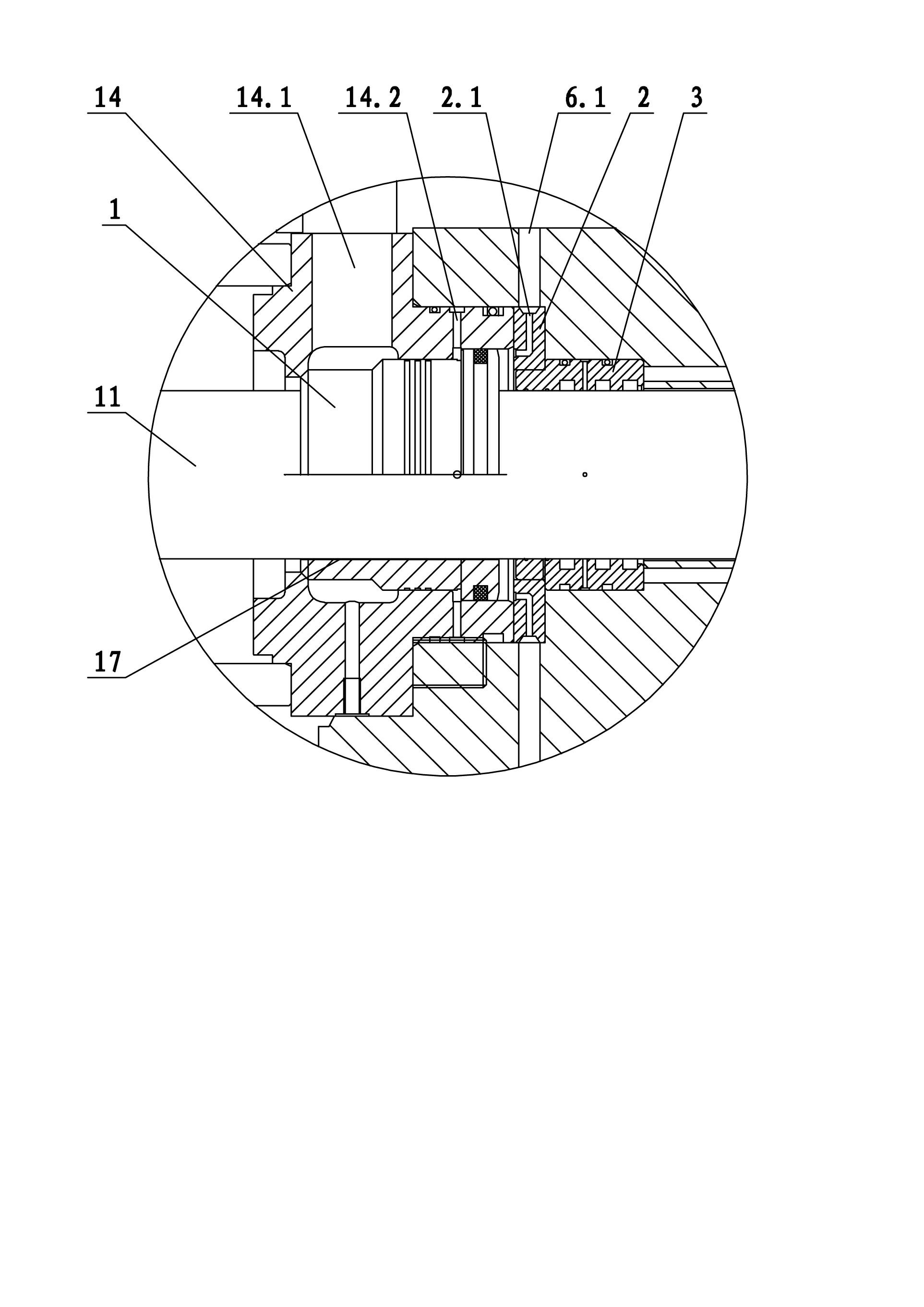

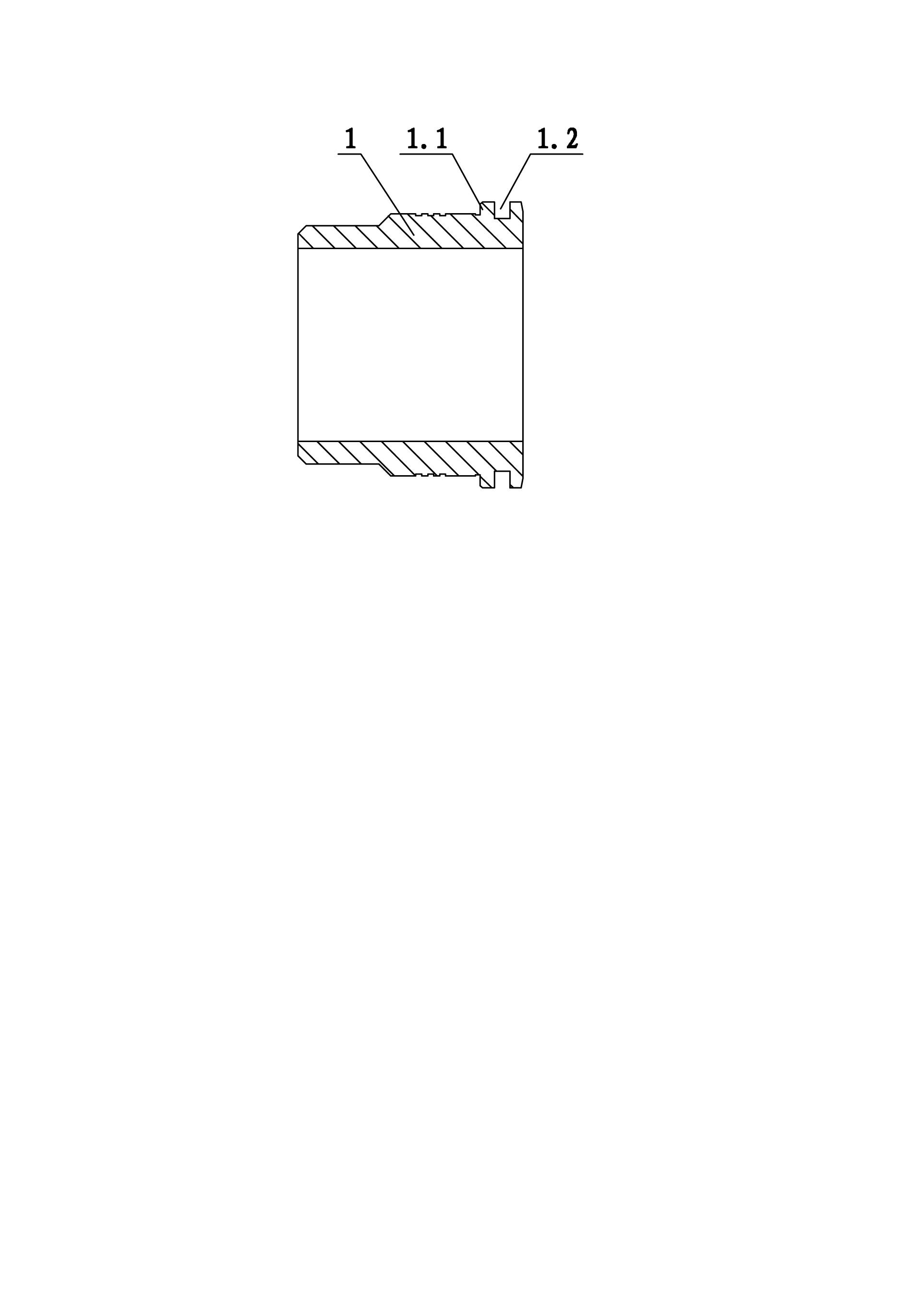

[0026] Embodiment one, such as Figure 1 to Figure 8 As shown, the clamping mechanism of the injection molding machine includes a clamping oil cylinder arranged on the movable template 6, the movable template 6 is slidably arranged on the Gelin column 11, and the front and rear ends of the Gelin column 11 are respectively fixedly connected with the fixed template 5 and the rear Plate 9; the clamping oil cylinder includes a cylinder body 12, a piston 10, a front end cover 14 and a rear end cover 15; the cylinder body 12 is set outside the Corinth column 11, and its front end is fixed to the movable template 6 through the front end cover 14 connection, the rear end is fixedly connected with the rear end cover 15; the piston 10 is set outside the Corinthian column 11 and is located in the cylinder body 12; The front and rear oil passages of the front and rear oil passages are also communicated through the conduction oil pipe 13 outside the cylinder body 12; the front and rear oil...

Embodiment 2

[0038] Embodiment 2 differs from Embodiment 1 in that: the rear plate (support plate) is set in front of the fixed platen, the movable platen is set behind the fixed platen, and the rear plate and the fixed platen are connected by a clamping oil cylinder. The piston rod (Colin column) of the clamping cylinder passes through the fixed template and is connected with the movable template, which is not shown in the figure. For other structures of this clamping cylinder, please refer to Embodiment 1. Compared with the traditional four-cylinder full hydraulic injection molding machine, it has made a major improvement in the overall structure. The clamping cylinder is in front, and the four cylinders are fixed on the fixed platen. The number of moving parts on the moving template is reduced, the energy consumption is low, and the motion inertia is small, thereby effectively reducing a certain amount of energy consumption and improving control accuracy. In addition, the reduction of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com