Device and method suitable for cover culvert wall body template moving construction

A technology of wall body and mold shifting, which is applied in the direction of buildings and road floors, etc., can solve problems such as unfavorable promotion, low safety factor, and complicated operation, and achieve the effects of reducing labor intensity of workers, improving work intensity, and ensuring movement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to better understand the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. The described embodiments are only used to illustrate the technical solutions of the present invention, and are not intended to limit the present invention.

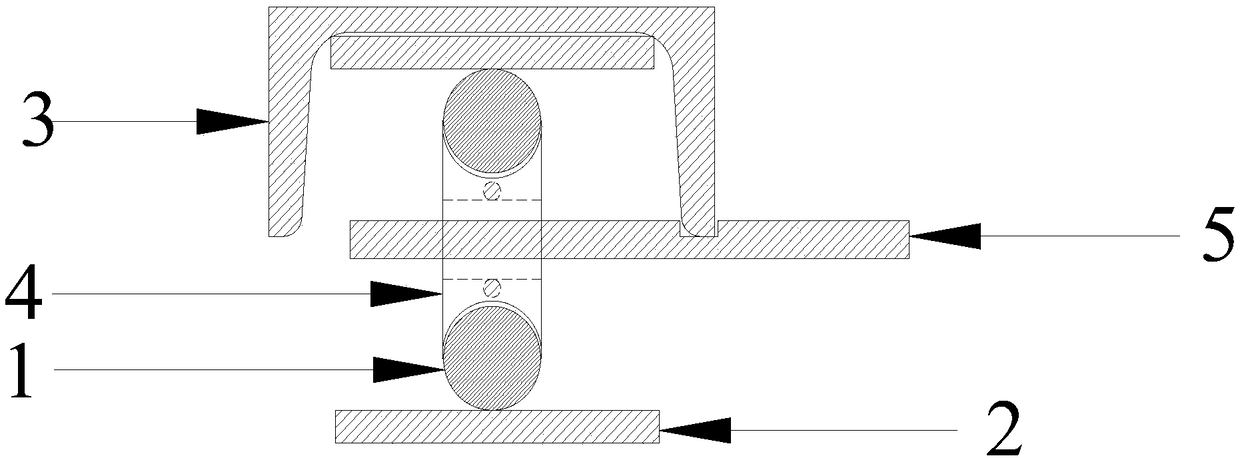

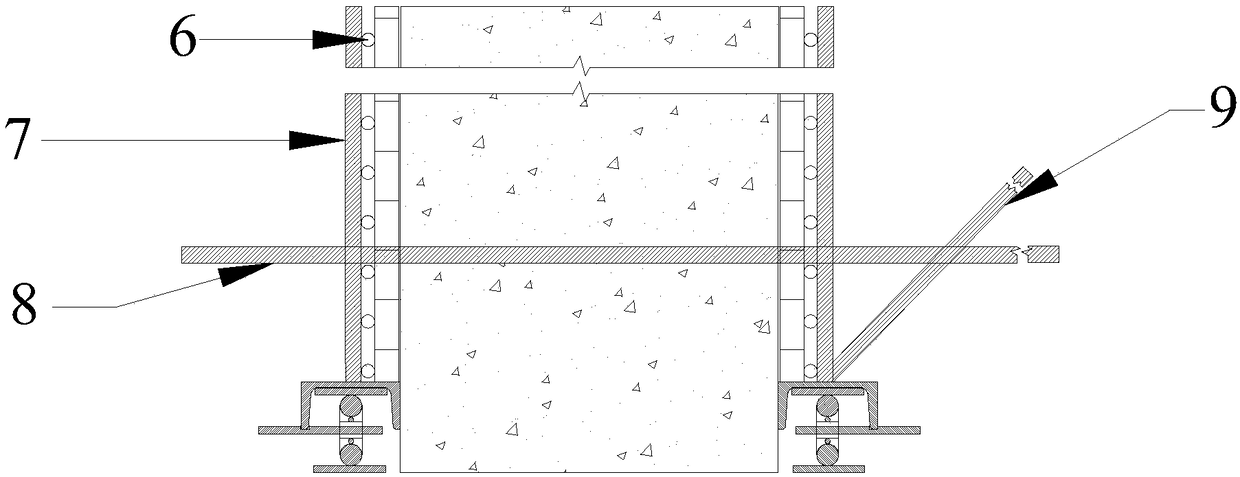

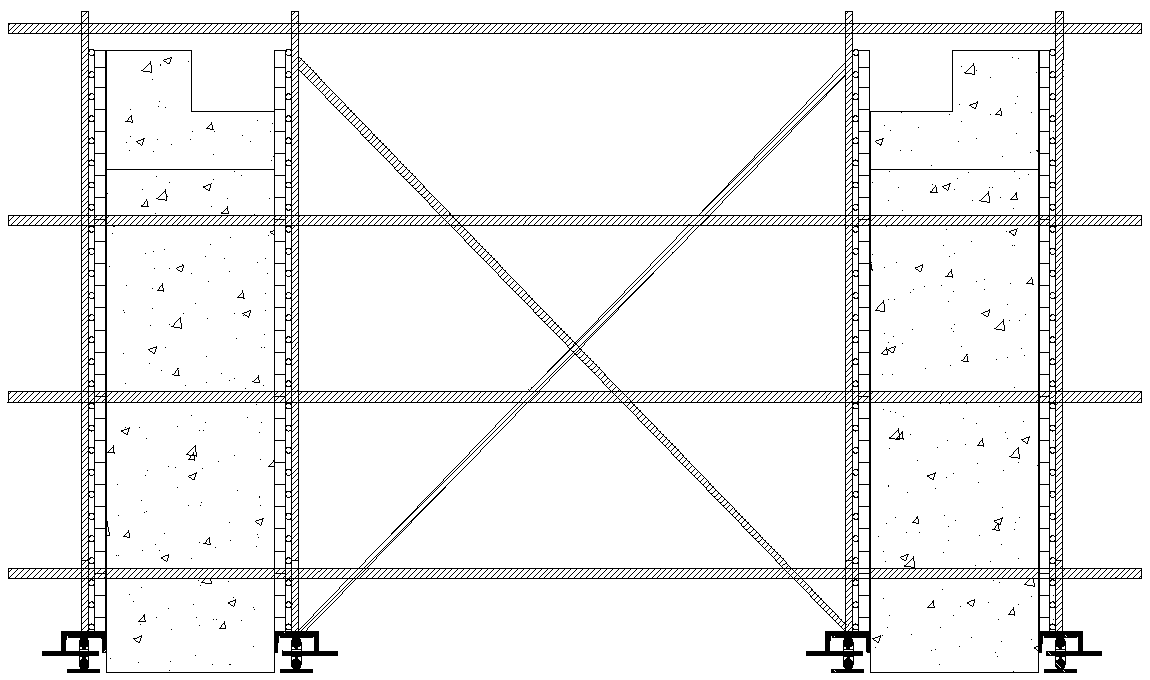

[0029] Such as figure 1 As shown, first, the stainless steel rod 1 and the prefabricated steel plate 2 are welded to form a stable track, and the prefabricated steel plate 2 and the channel steel 3 are welded to form a whole as the upper track of the mold shifting, and then the channel steel 3 and the bottom formwork of the wall are firmly welded and assembled. The remaining formwork on the wall is reinforced with bolts to form a whole; figure 2 As shown, in the assembly process, the horizontal reinforcement steel pipe 6, the vertical reinforcement steel pipe 7, the horizontal horizontal connection steel pipe 8 and the lateral ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com