A single crystal silicon rod cutting machine

A single crystal silicon rod and cutting machine technology, which is applied in the direction of manufacturing tools, stone processing equipment, fine working devices, etc., can solve the problems of reduced work efficiency, large errors, single crystal silicon rod defects, etc., to achieve automatic operation, Adjust the effect of improving efficiency and improving cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

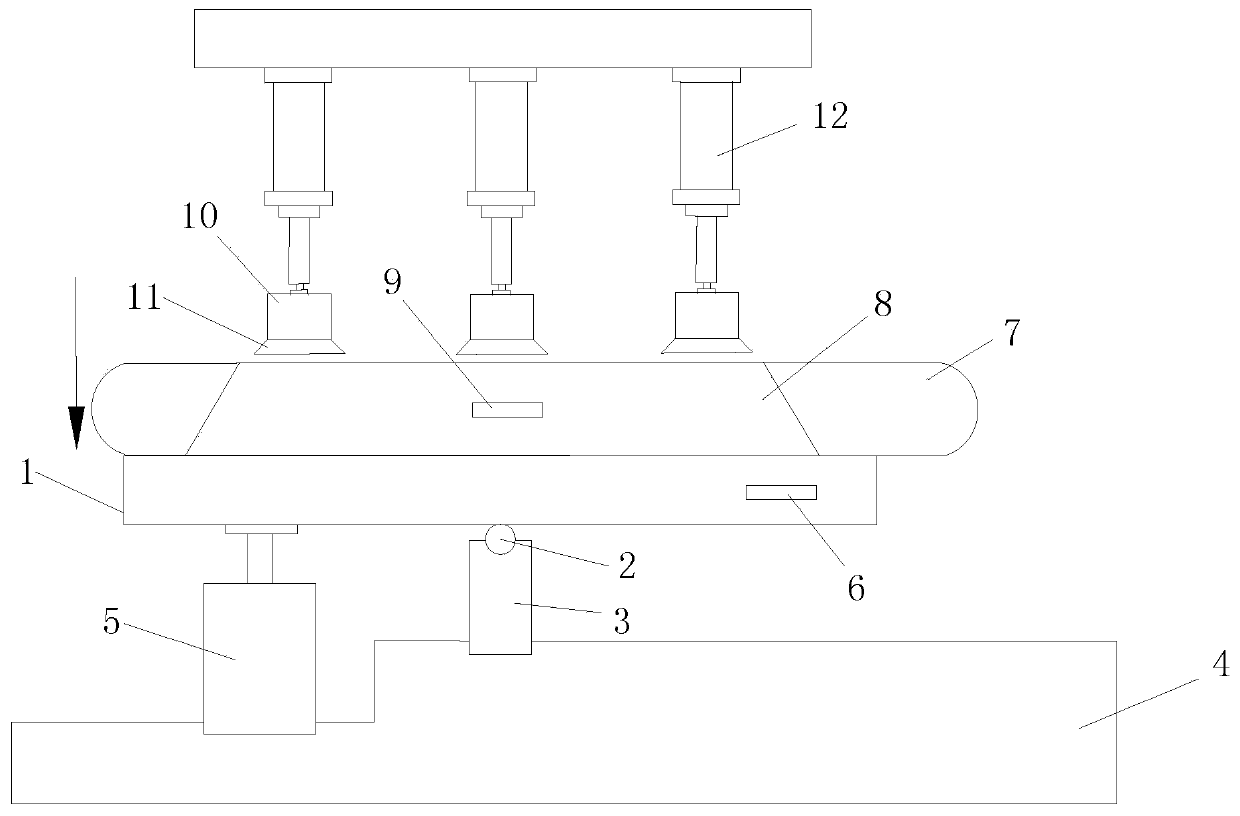

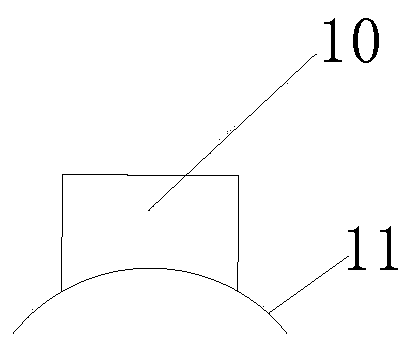

[0035] Such as Figure 1 to Figure 3 As shown, a single crystal silicon rod cutting machine includes a workbench 1 for supporting the single crystal silicon rod 7 . The cutter also includes a control unit.

[0036] The cutting machine also includes a position detection unit for detecting the inclination between the axial direction of the single crystal silicon rod 7 and the cutting direction of the saw blade of the cutting machine, wherein figure 1 The direction of the arrow in shows the cutting direction of the saw blade of the cutter. Preferably, the position detection unit is a biaxial inclination sensor, and the biaxial inclination sensor is arranged on the workbench 1 at a position capable of contacting the single crystal silicon rod 7 . The two-axis inclination sensor is connected in communication with the control unit.

[0037] The cutting machine also includes an adjustment unit, which is used to adjust the horizontal position and the height position of the workbenc...

Embodiment 2

[0053] The structure and principle of this embodiment and embodiment 1 are basically the same, the difference is:

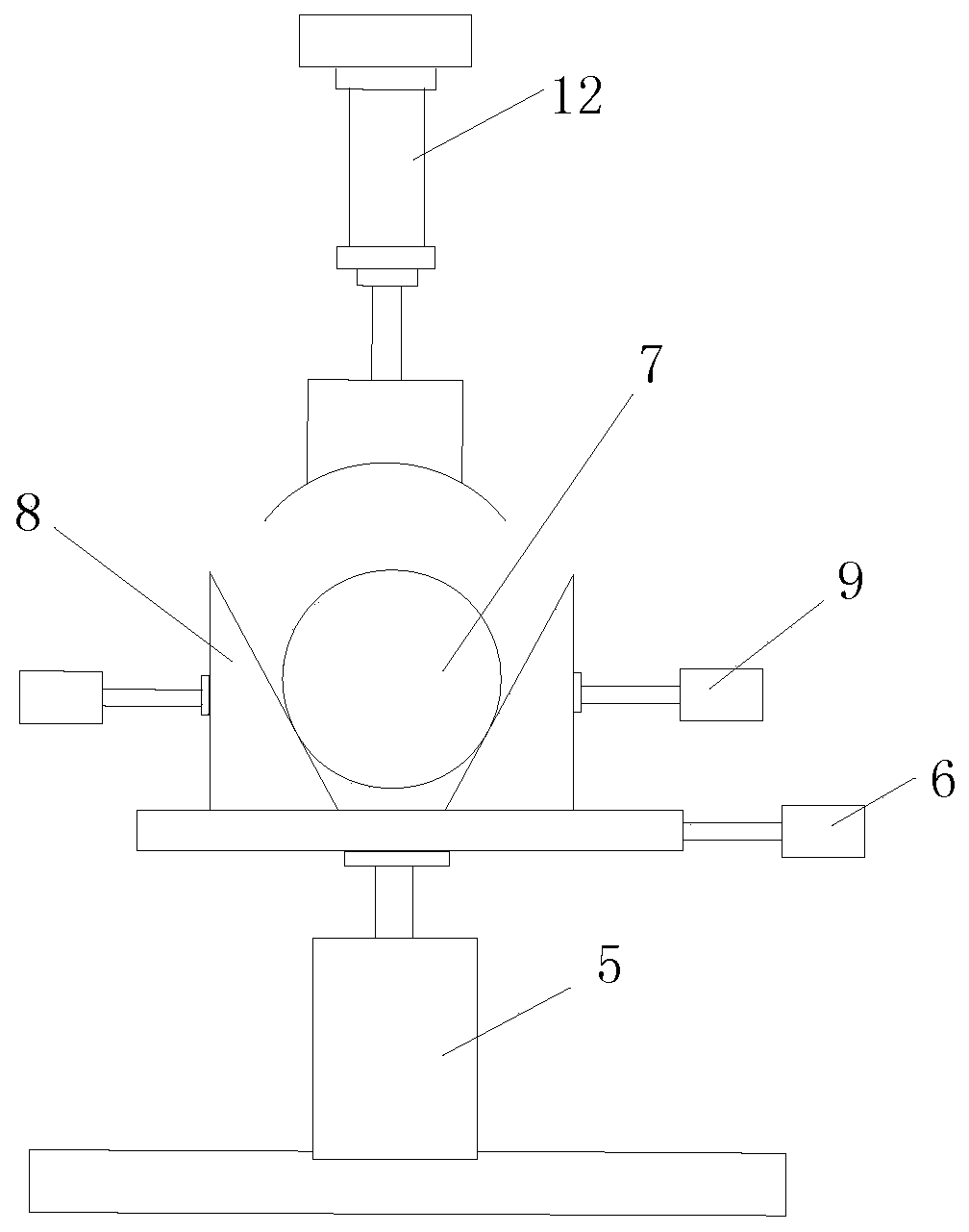

[0054] Such as Figure 4 with Figure 5 As shown, in this embodiment, there are two workbench lifting adjustment mechanisms 5, which are respectively arranged under the front and rear of the workbench 1, and the workbench horizontal displacement adjustment mechanism 6 has two Two, which are respectively arranged on one side of the front and rear of the workbench 1 (the "side" refers to the left or right side of the workbench), so as to achieve faster adjustment.

[0055] Parts not mentioned in this application can be realized by adopting or referring to existing technologies.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com