Laser cutting machine

A laser cutting machine and laser cutting technology, applied in the laser field, can solve the problems of high processing cost, increased product processing cost, cumbersome operation, etc., to improve the time for clamping or taking out the workpiece, good laser cutting effect, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

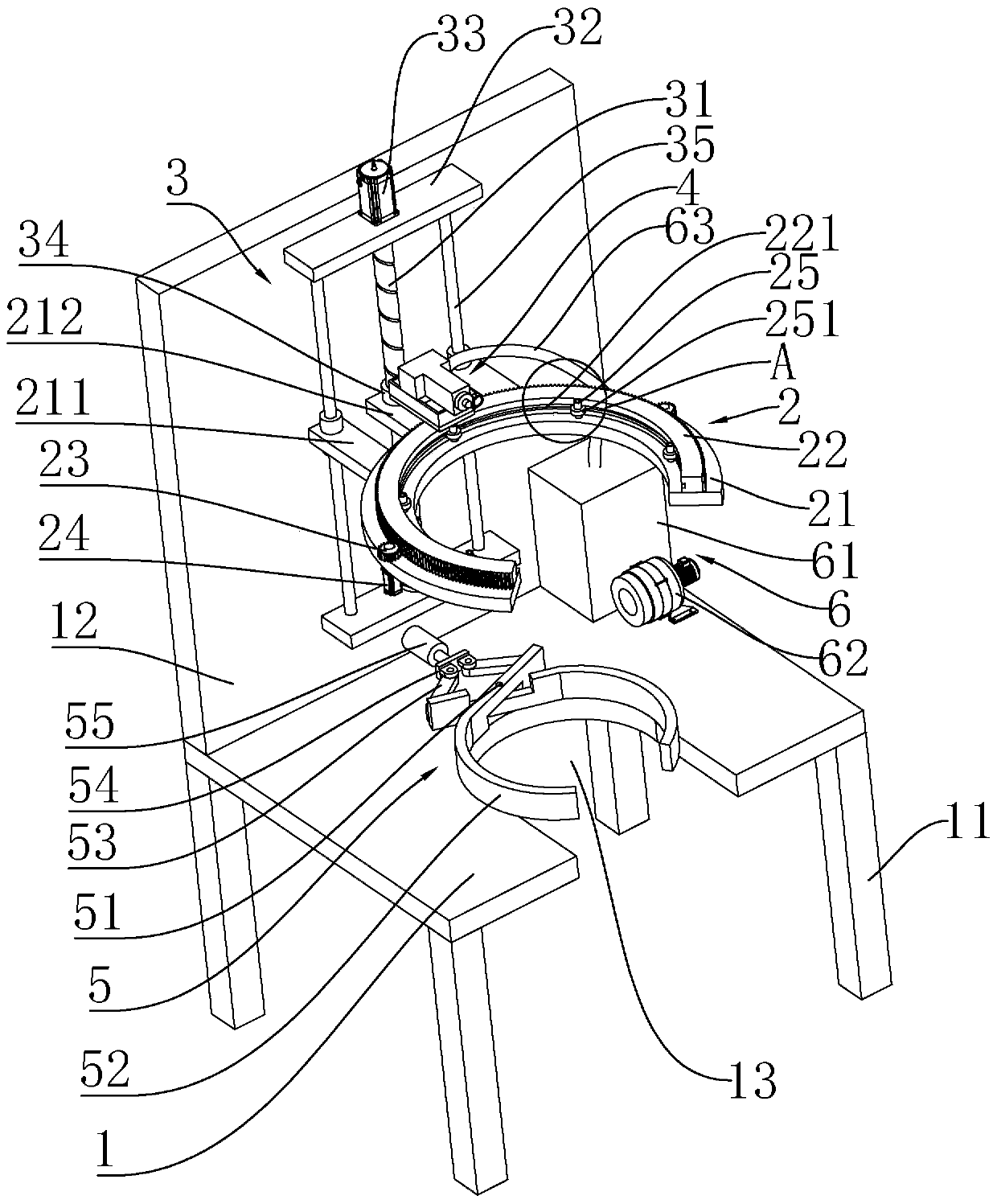

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

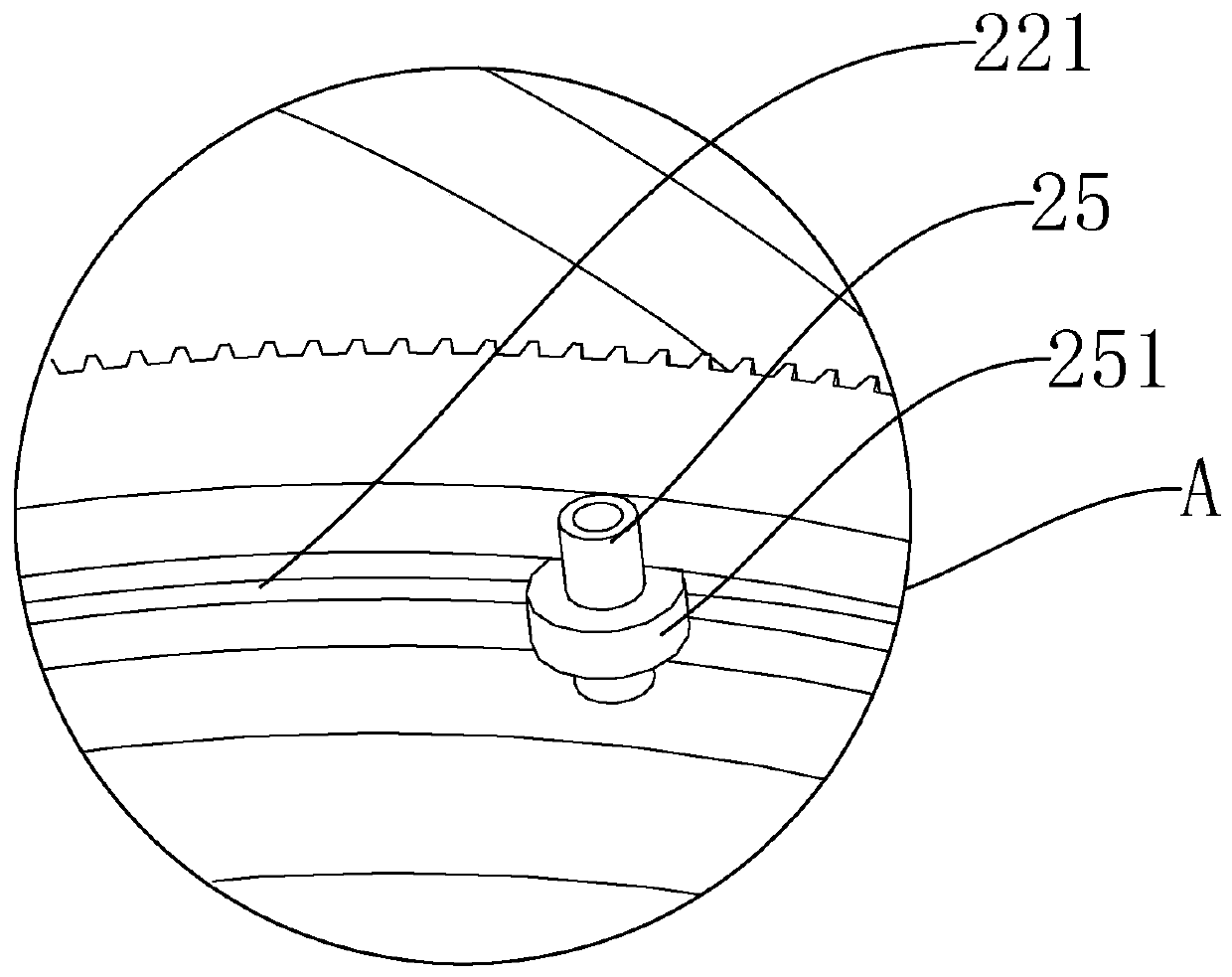

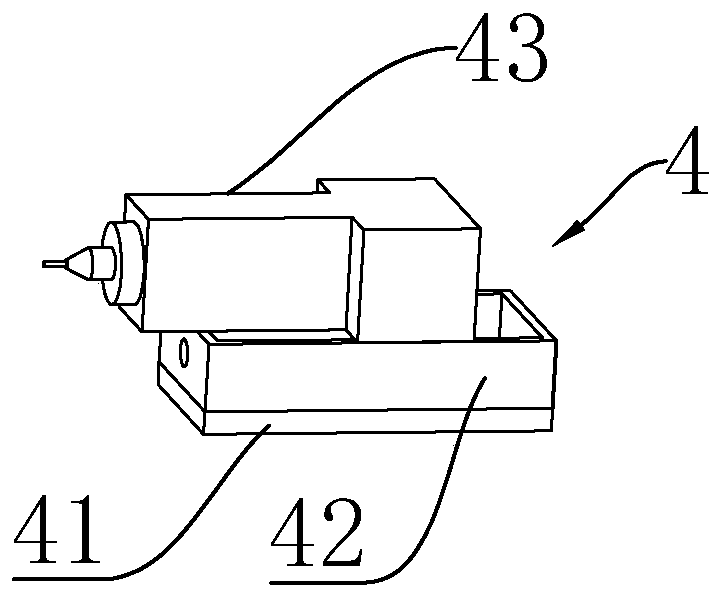

[0033] Such as figure 1 As shown, a laser cutting machine includes a platform 1, a support rod 11 is provided under the platform 1, a vertical plate 12 is provided on the rear side of the platform 1, and a vertical plate 12 is provided on the vertical plate 12 to drive the rotary cutting platform 2 to move up and down. The lifting mechanism 3, the rotary cutting platform 2 includes an annular supporting plate 21 with an open front side, the upper end of the supporting plate 21 is provided with an annular ring gear 22 with an opening, and the ring gear 22 is provided with a ring gear 22 along its circumferential direction. The gears 23 that are meshed and arranged oppositely, each gear 23 is respectively connected with the first driving motor 24 fixed below the supporting plate 21, the other side of the ring gear 22 is arranged at intervals along its circumfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com