Double-station servo laser cracking-off flat grinding machine

A double-station, flat grinding machine technology, which is applied to machine tools, grinding machines, manufacturing tools, etc., which are suitable for grinding the edge of workpieces, can solve the problems of low efficiency, high site requirements, and large floor space, and achieve operational Convenience, small site requirements, good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments.

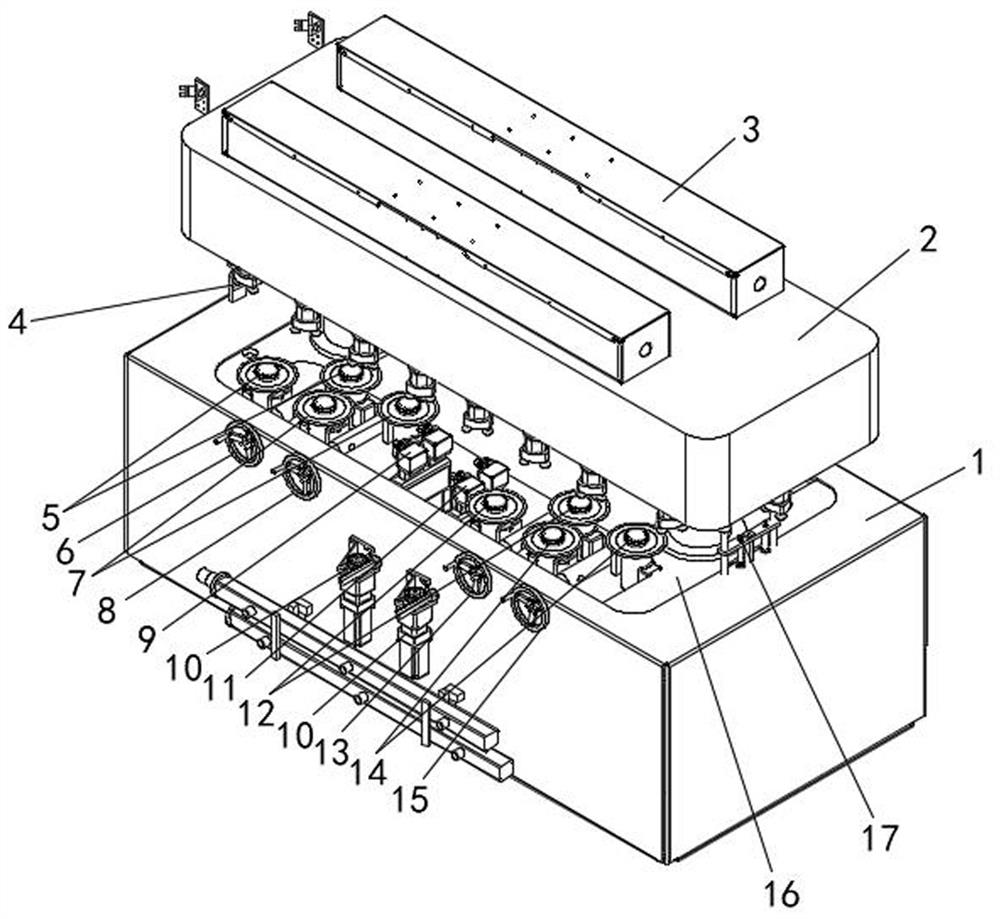

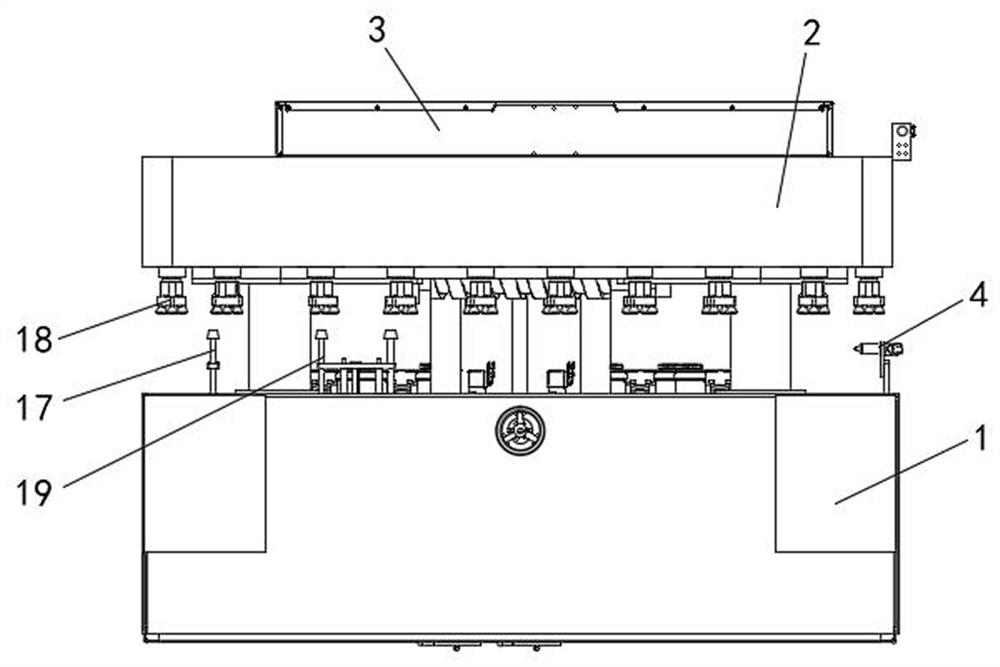

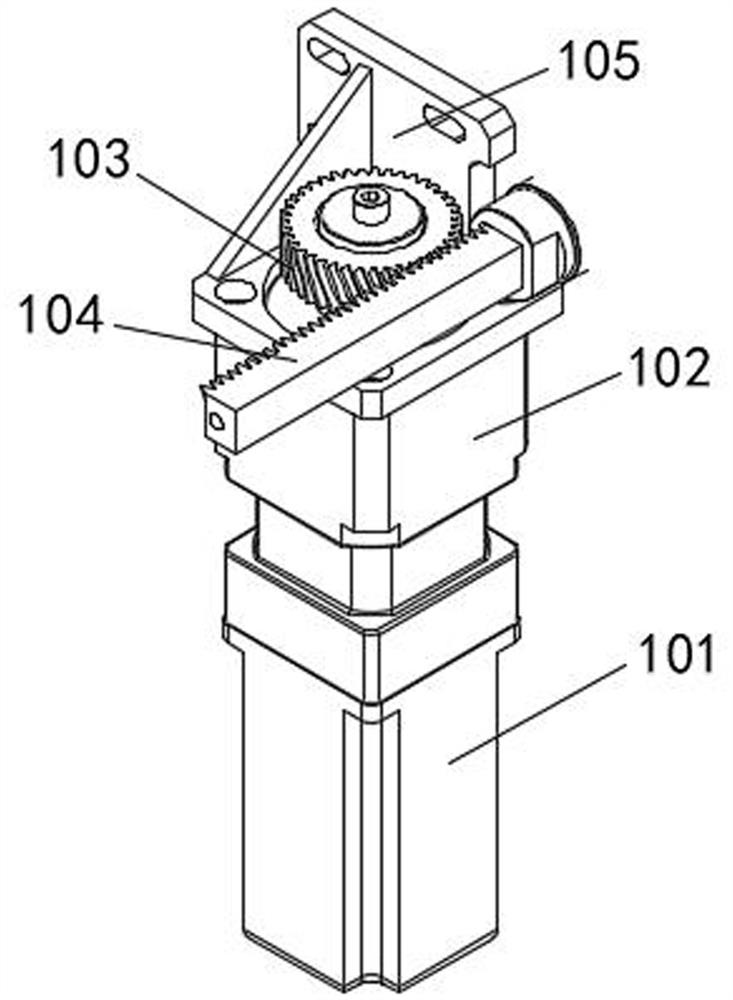

[0023] like Figure 1-3 As shown, a dual station servo laser explosion port is flat mill, including the upper machine 2 and the lowerter table 1, and the upper stage 2 is disposed at the lower stage 1, and the two sets of space is separated. At the bottom of the machine 2, a transfer blocking system 18 includes an electrode mechanism and a mounting mechanism, and the assembly mechanism is used to bond the fixed workpiece, and the transfer mechanism is used to transfer the assembly mechanism. Operation, the top of the upper machine 2 is provided with two laser generators 3, the up and down machine table 1 having a dual station system, which includes sequentially arranged from l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com