Multi-axis linkage numerical-control burr and flashing cutting machine tool

A multi-axis linkage and stab cutting technology, which is applied in the field of machine tools, can solve the problems of inability to meet the labor protection requirements of workers, difficulty in adapting to large batches, shapes, and follow-up dimensions of blank damage, etc., to achieve wide processing range, easy operation, and consistent size good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to better understand the present invention, the content of the present invention will be further clarified below in conjunction with specific embodiments and accompanying drawings, but the content of the present invention is not limited to the following embodiments.

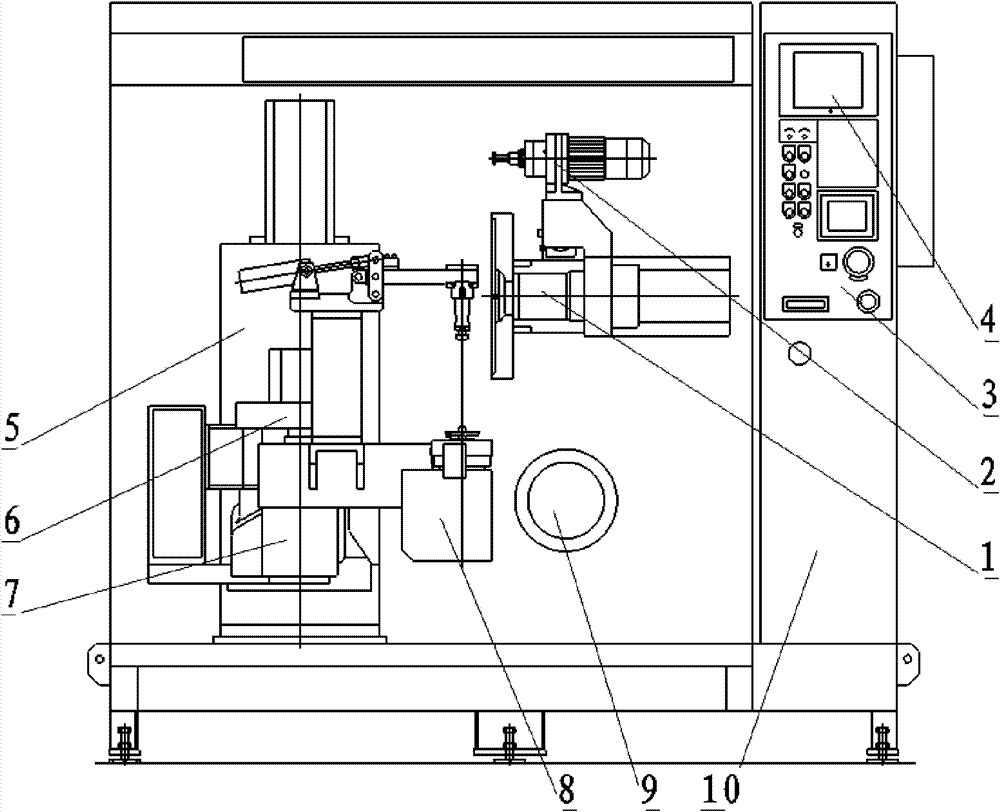

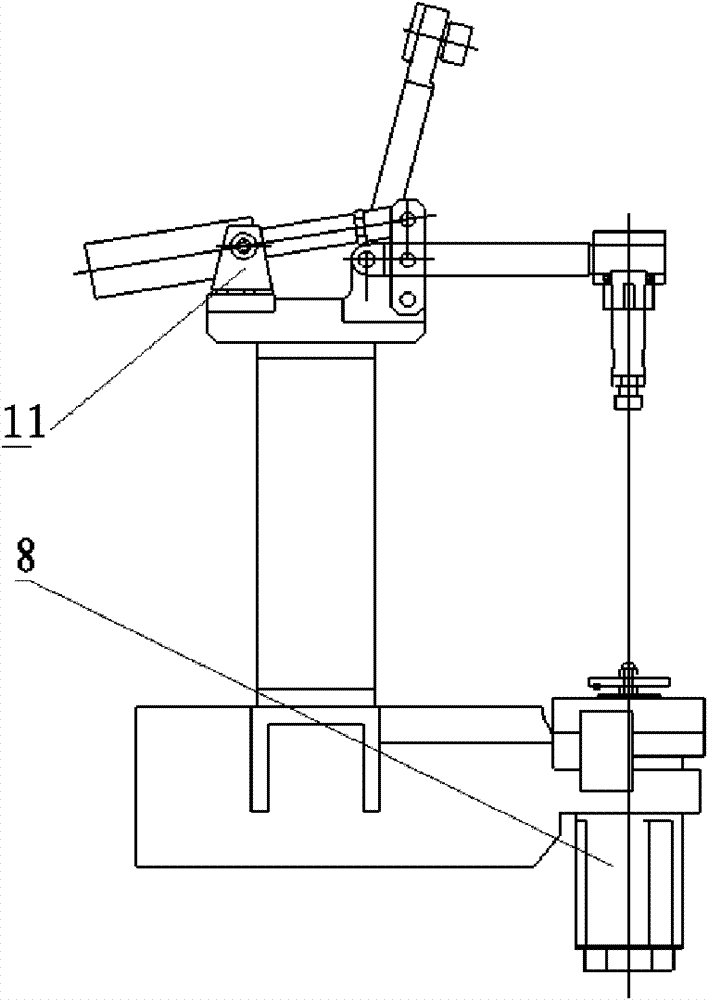

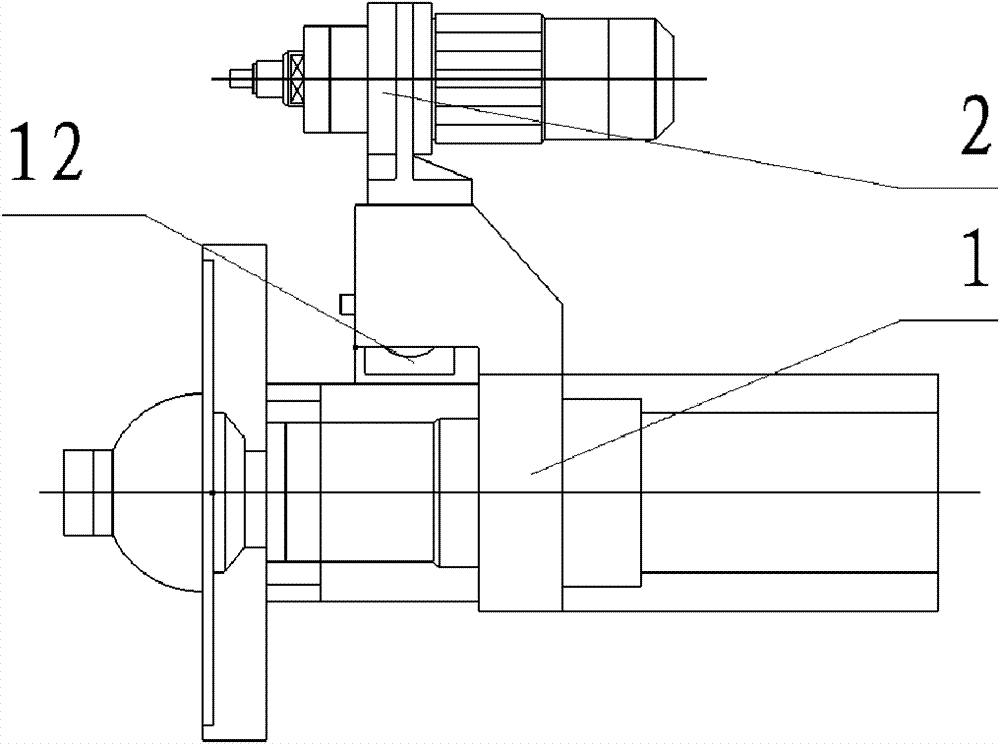

[0026] The multi-axis linkage CNC flash burr cutting machine tool provided by the present invention has a structure such as figure 1 , figure 2 , image 3 As shown, there are main grinding tool 1, auxiliary grinding tool 2, operation control panel 3, numerical control system 4, Z-axis device 5, X-axis device 6, Y-axis device 7, A-axis device 8, dust collection port 9 , a closed bed 10, a pneumatic clamp 11 and a B-axis rotary device 12. Among them: the Z-axis device 5 , the X-axis device 6 , the Y-axis device 7 and the A-axis device 8 are 4-axis linkage servo drive devices under the control of the numerical control system 4 . Z-axis device 5 drives X-axis device 6, Y-axis device 7 and A-axis d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com