Multifunctional production line and production method for level A2, level B1 and three-dimensional core layer composite boards

A composite board, multi-functional technology, applied in chemical instruments and methods, layered products, lamination, etc., can solve problems such as increasing equipment investment costs, and achieve the effect of fast sawing, reducing floor space, and simplifying equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be described in further detail below through specific examples.

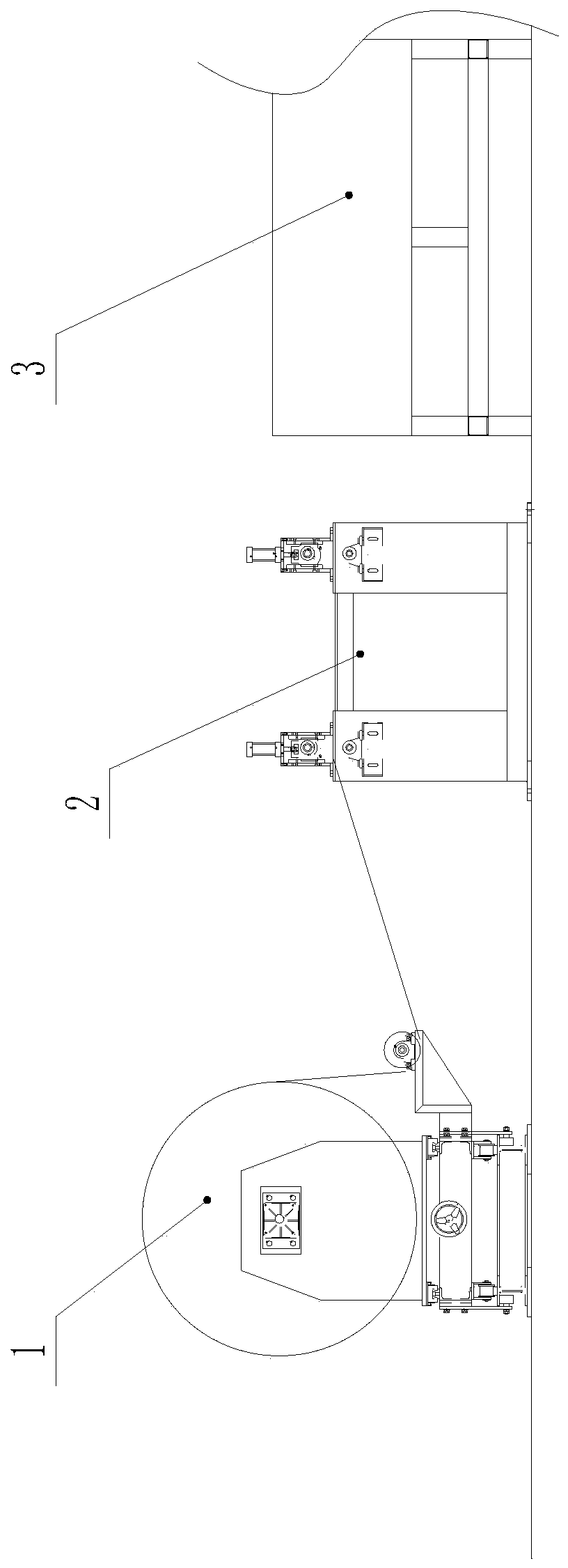

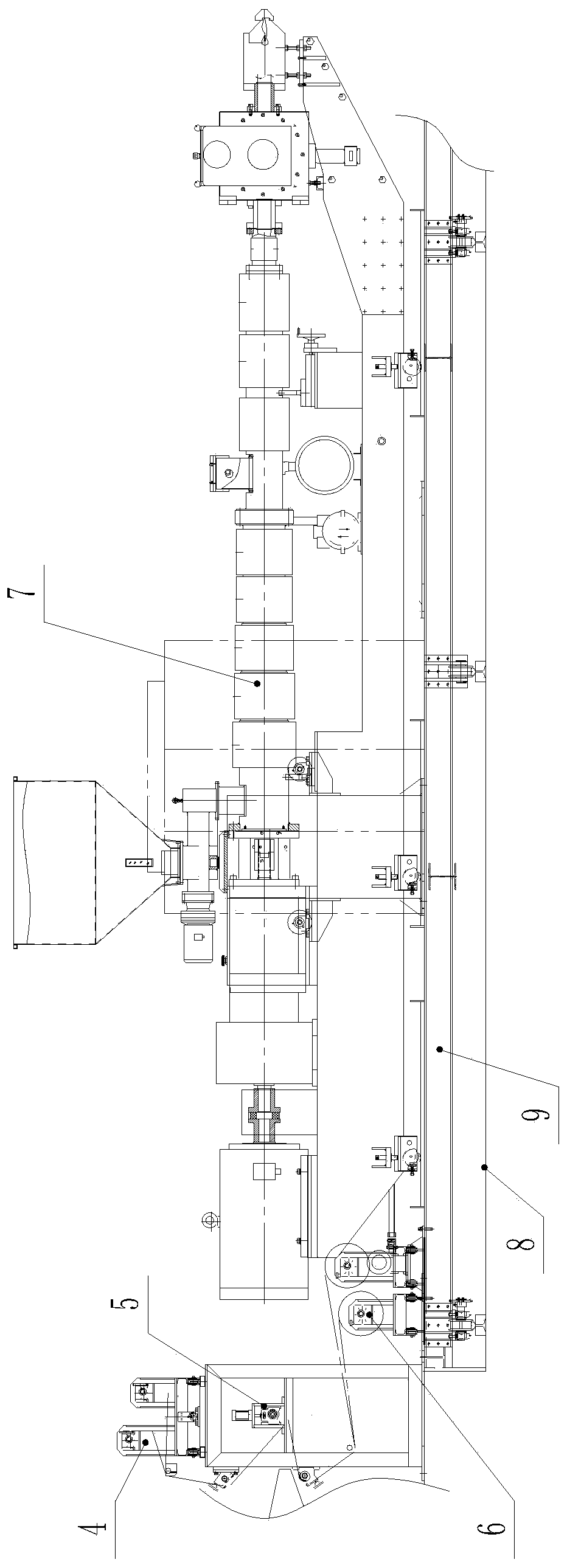

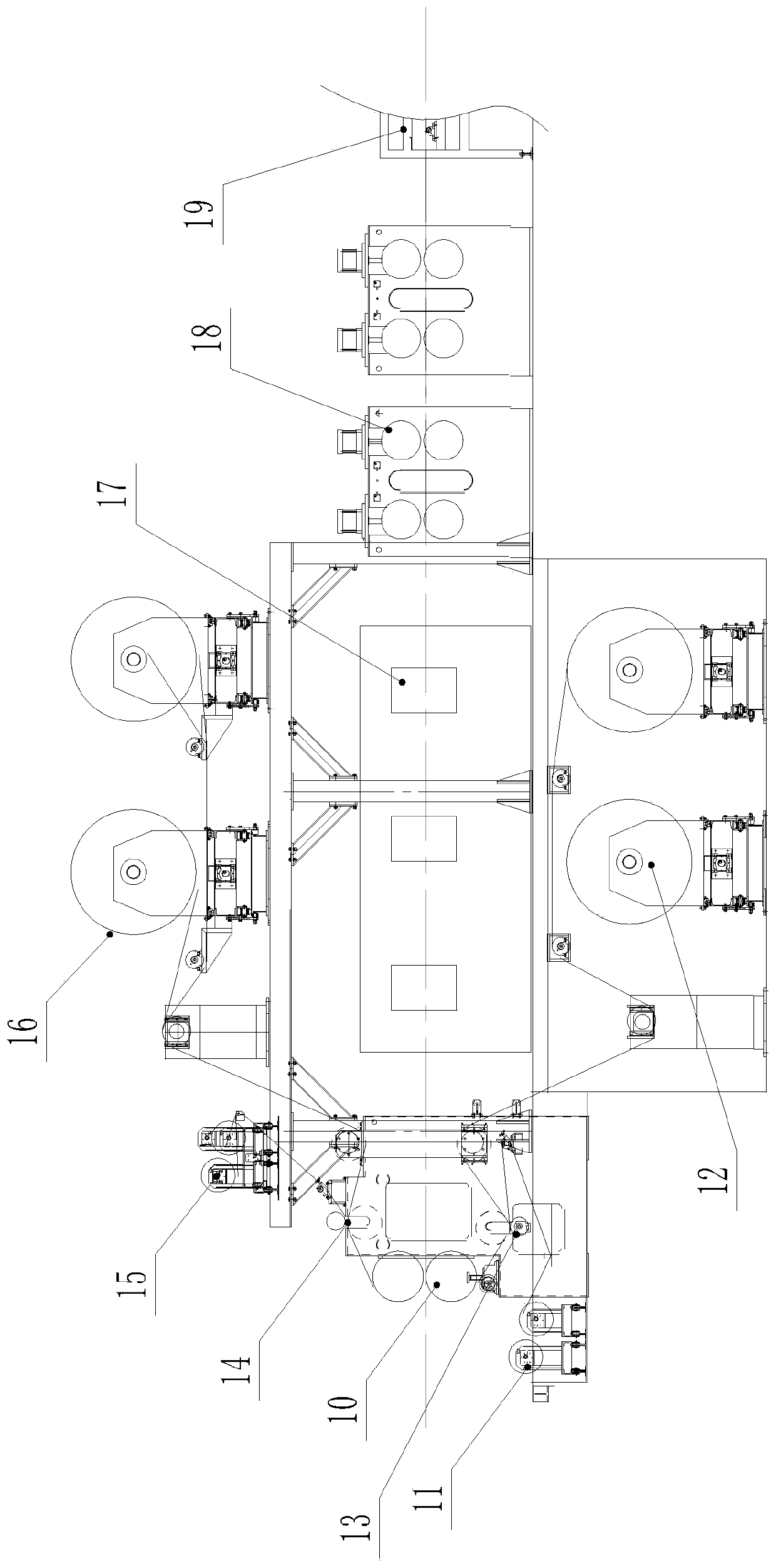

[0058] like Figure 1 to Figure 7 As shown, A2 grade, B1 grade and three-dimensional core composite board multifunctional production line, including

[0059] The core layer unwinder 1 is used to unwind the core layer board. The downstream of the core layer unwinder 1 is provided with a joint machine 2, which is used to facilitate the jointing of the core layer unwinder 1. In the production of A2 fireproof composite When producing three-dimensional core layer composite boards, the core layer unwinder 1 unwinds A2 fireproof core layer coils; and when producing three-dimensional core layer composite boards, the core layer unwinder 1 unwinds metal core layer boards;

[0060] The first preheating oven 3 arranged downstream of the core layer unwinding machine 1 is used for preheating the core layer board;

[0061] The first laminating machine 5 arranged downstream of the first prehe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com