Steel pipe cutting and blanking device

A steel pipe and blanking technology, applied in welding equipment, metal processing equipment, plasma welding equipment, etc., can solve the problems of not being able to use anytime, anywhere, inconvenient for practical use, and not suitable for moving, etc., and to solve the limitation of blanking size and blanking position. problems, convenient cutting, and the effect of improving cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The invention will be described in detail below in conjunction with the accompanying drawings.

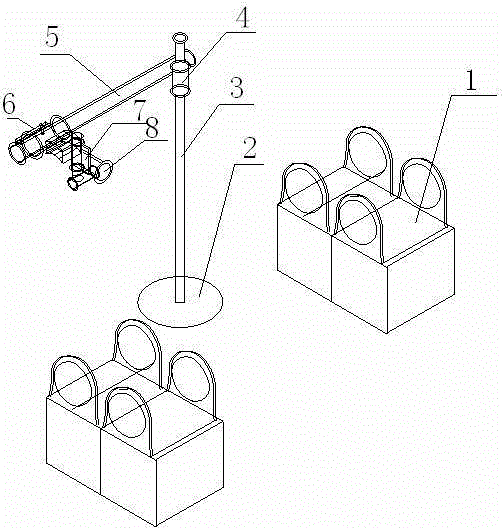

[0016] figure 1 It is a structural schematic diagram of the working state of the steel pipe cutting and blanking device created by the present invention;

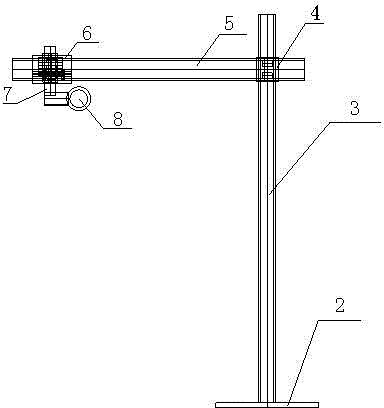

[0017] figure 2 It is a schematic structural diagram of the front view of the steel pipe cutting and blanking device created by the present invention;

[0018] In the figure, a roller frame 1, a base 2, a blanking support 3, an adjustment ring 4, a circumferential support 5, an axial adjustment control ring 6, a local height control ring 7, and a cutting gun fixing port 8.

[0019] The steel pipe cutting and blanking device created by the present invention includes the device mainly including a blanking bracket 3, wherein the lower end of the blanking bracket 3 has a base 2, and the upper end is provided with a hoop bracket 5, and the hoop bracket 5 passes through the bracket 3. The adjustment ring 4 adjusts the relat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com