A kind of wear-resistant delta-tan thin film and its preparation method and application

A thin film, sample technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

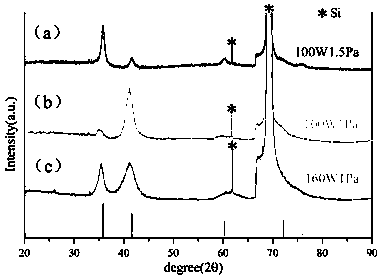

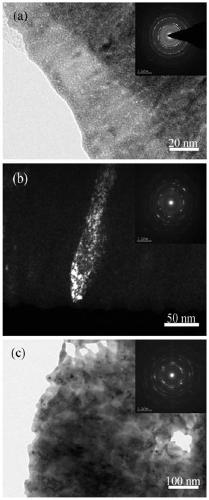

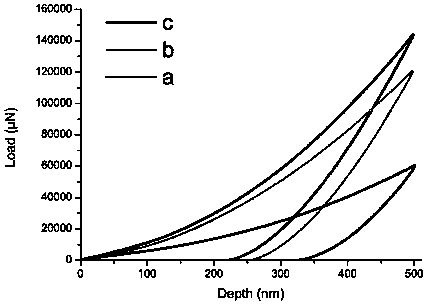

[0045] Place the cleaned WC-Co substrate on the sample stage, the sample stage is passed through cooling water, each sample is located in a concentric circle equiaxially from the center of the sample stage, the distance between the fixed target and the sample surface is 80 mm, and the Ta target is adjusted The power is 130W, the nitrogen / argon flow ratio is fixed at 0.2, that is, the nitrogen gas intake is 10 sccm, the argon gas intake is 50 sccm, and the deposition time is 2 hours. Adjust the working pressure from 0.2Pa to 1.5Pa to obtain TaN films with different orientations. Carry out XRD analysis to the sample, its structure diagram is as follows figure 1 As shown in a, the film has a crystal structure of NaCl crystal form, with a strong (111) preferred orientation; its texture coefficient I (200) / [I (200)+ I (111) ] is 0.26. The samples were analyzed by transmission electron microscopy, figure 2 a is the TEM topography of the cross-section of the δ-TaN film, and th...

Embodiment 2

[0047] Place the cleaned WC-Co substrate on the sample stage, the sample stage is passed through cooling water, each sample is located in a concentric circle equiaxially from the center of the sample stage, the distance between the fixed target and the sample surface is 80mm, and the working pressure is 1Pa, the fixed nitrogen / argon flow ratio is 0.2, that is, the nitrogen gas intake is 10 sccm, the argon gas intake is 50 sccm, and the deposition time is 2 hours. Adjust the carbon target power from 60W to 260W to obtain different Ta / N atomic ratios; when the tantalum target power is 80W, the Ta / N atomic ratio is 0.85; when the tantalum target power is 210W, the Ta / N atomic ratio is 1.12.

Embodiment 3

[0049] Place the cleaned WC-Co substrate on the sample stage, the sample stage is passed through cooling water, each sample is located in a concentric circle equiaxially from the center of the sample stage, the distance between the fixed target and the sample surface is 80 mm, and the Ta target is adjusted The power is 100W, the working pressure is 1Pa, the fixed nitrogen / argon flow ratio is 0.2, that is, the nitrogen gas intake is 10sccm, the argon gas intake is 50sccm, the deposition time is 2.5 hours, and the thickness of the film is about 2.7μm. XRD analysis, its structure diagram is as follows figure 1 As shown in b, the prepared δ-TaN film has a strong (200) preferred orientation, and its texture coefficient I (200) / [I (200)+ I (111) ] is 0.8. The samples were analyzed by transmission electron microscopy, figure 2 b is the dark field image of the δ-TaN film, which shows that the film grows in the form of columnar crystals, and the diameter of the columnar crystals ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com