Patents

Literature

36results about How to "Good wear resistance and antifriction performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

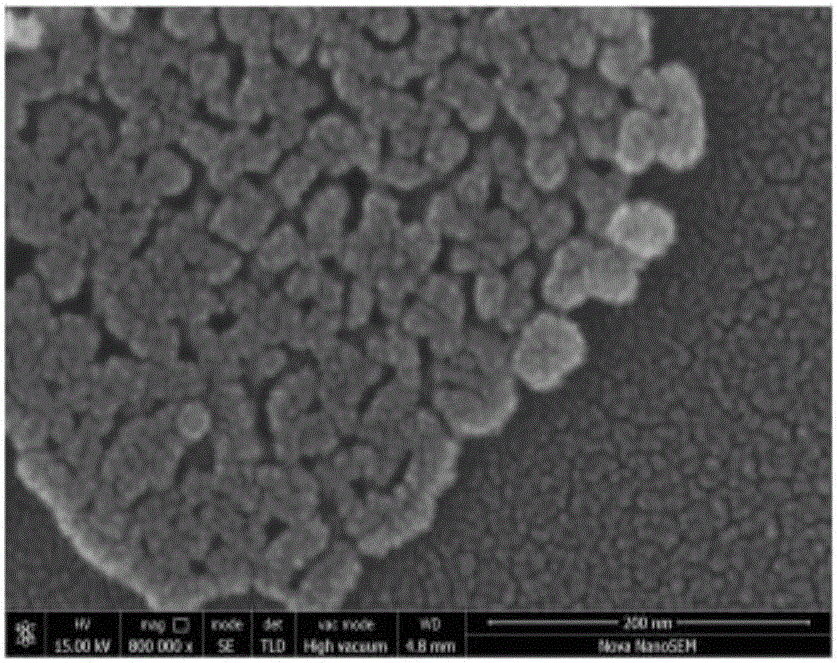

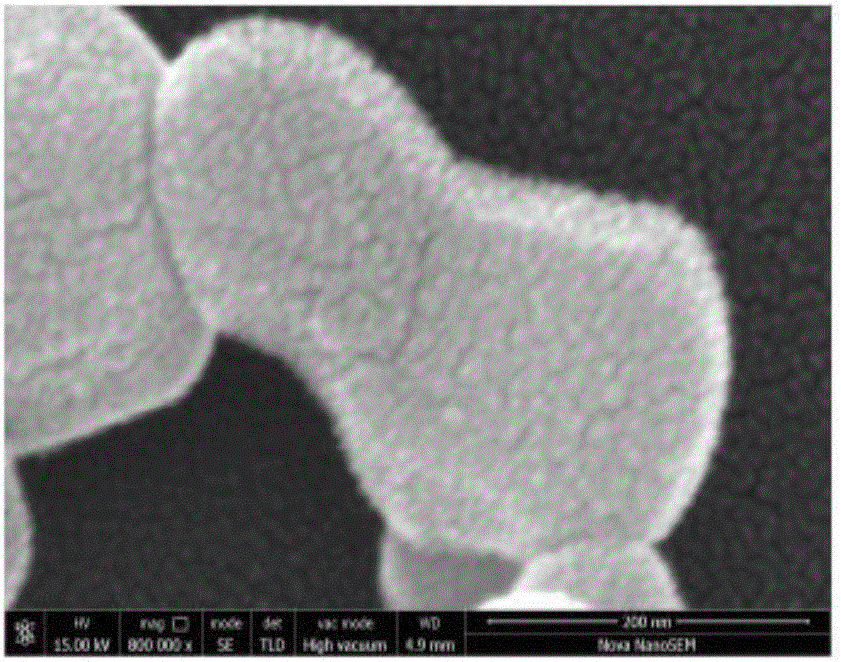

Nanoparticle/graphene oxide composite modified high polymer material and preparation thereof

ActiveCN107880484AImprove mechanical propertiesImprove tribological propertiesPolymer scienceOxide composite

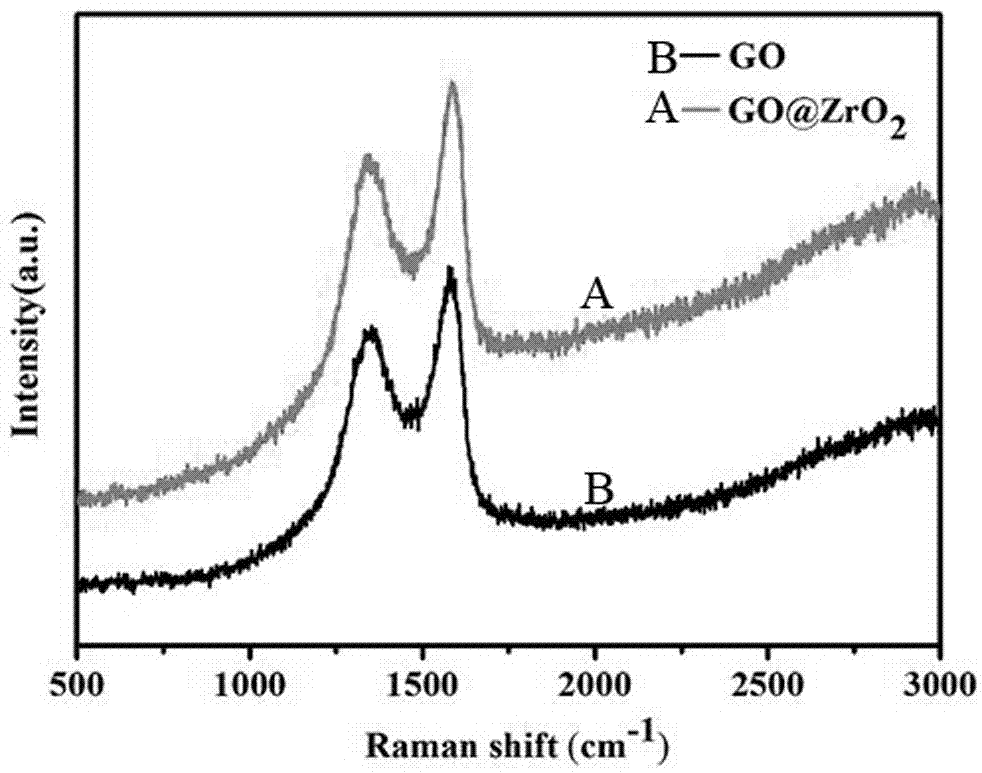

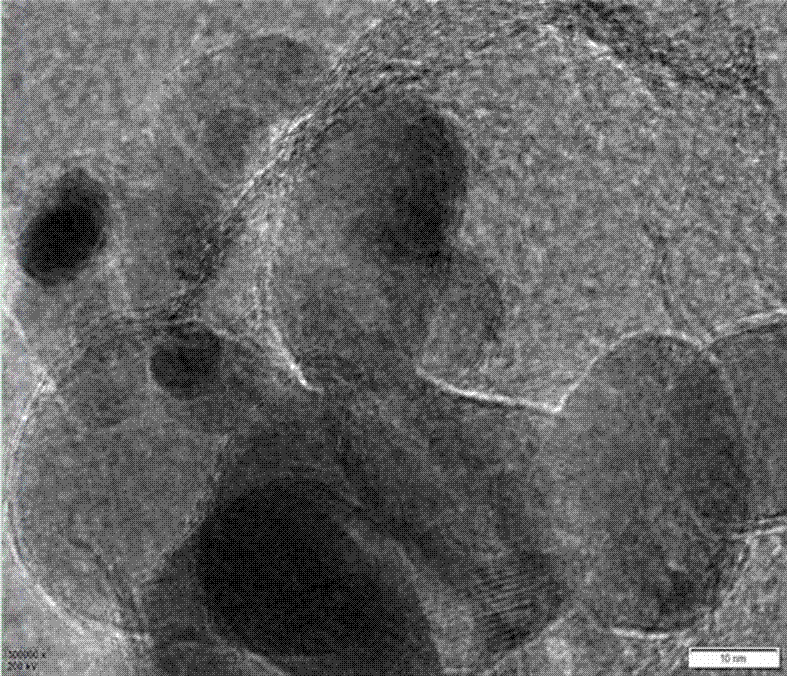

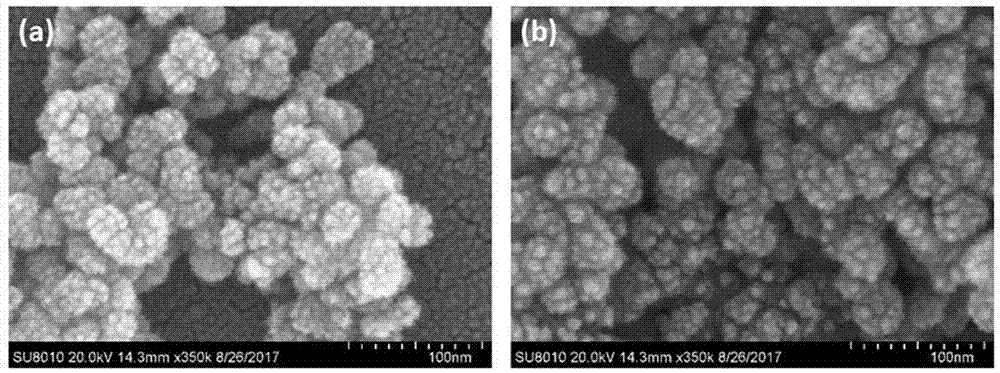

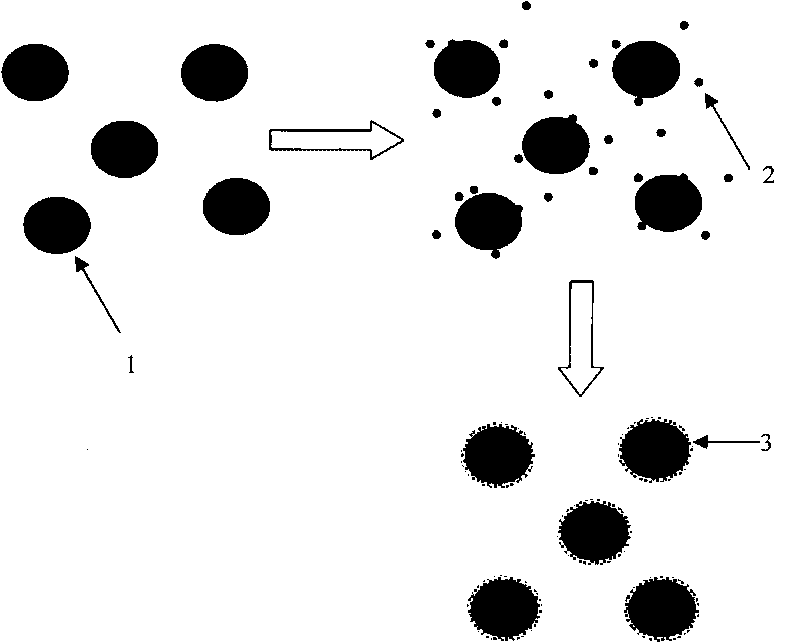

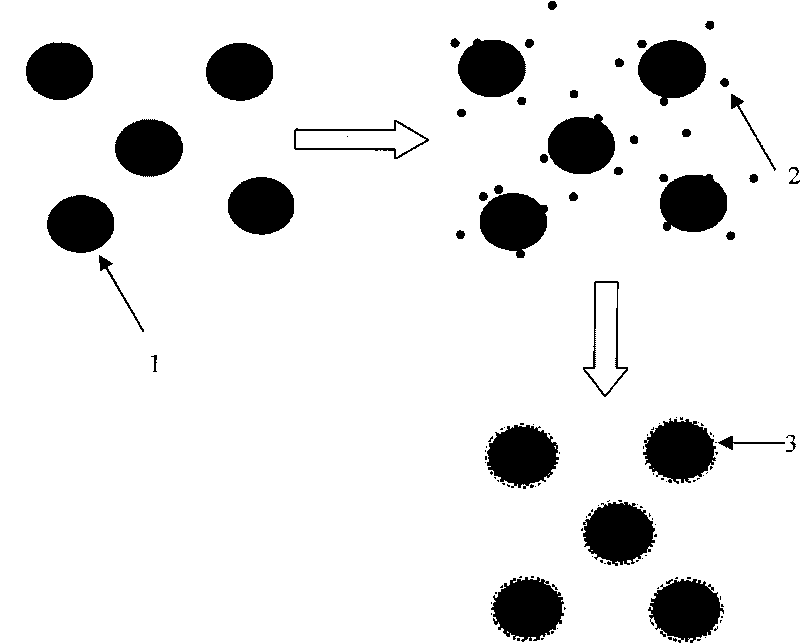

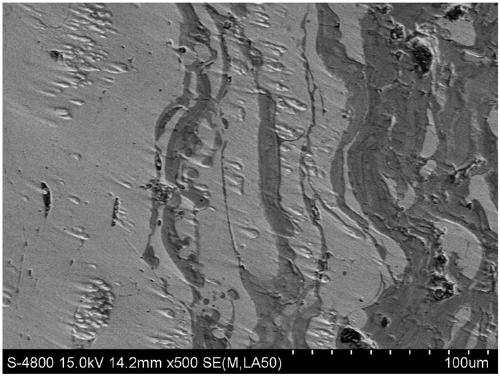

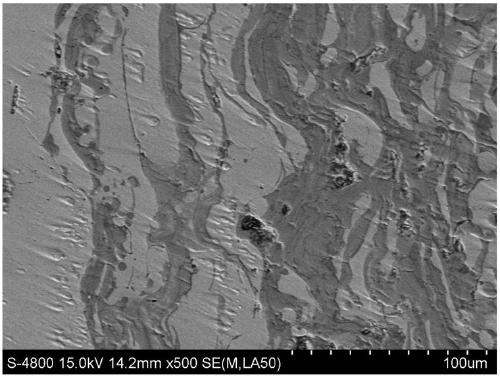

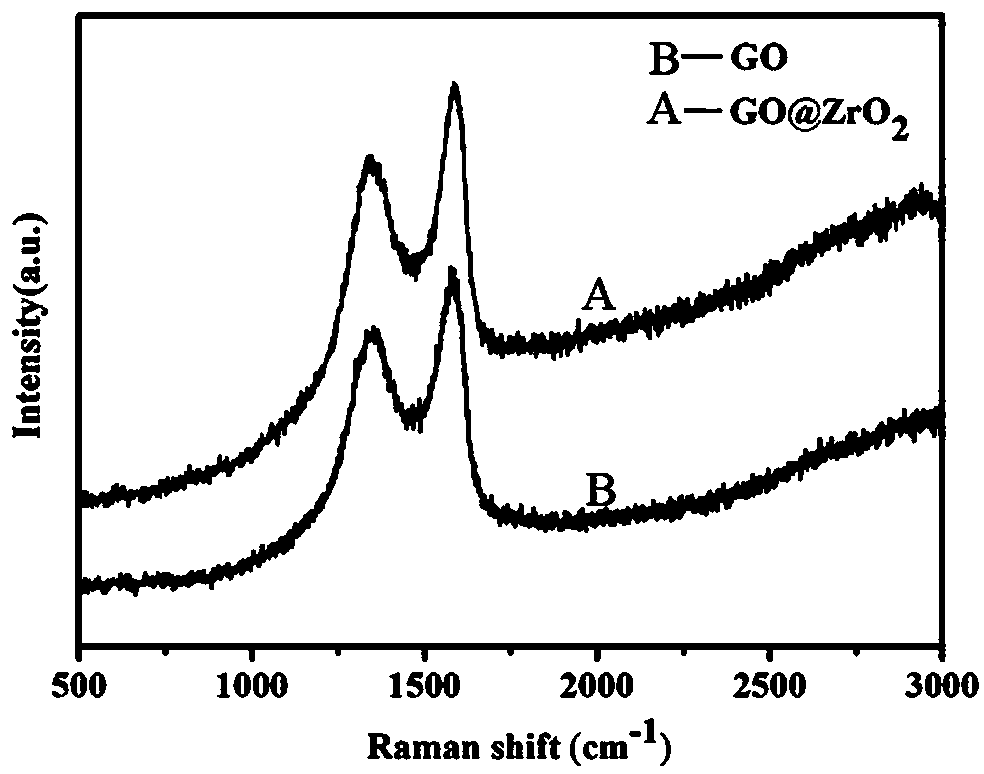

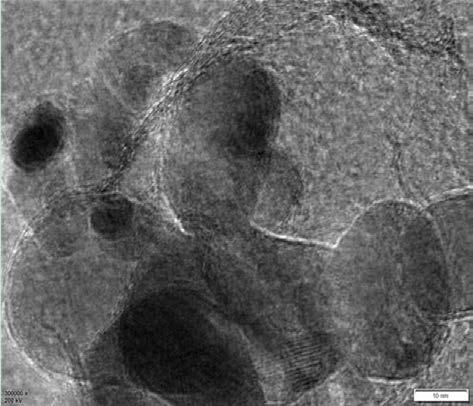

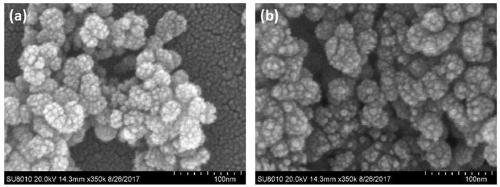

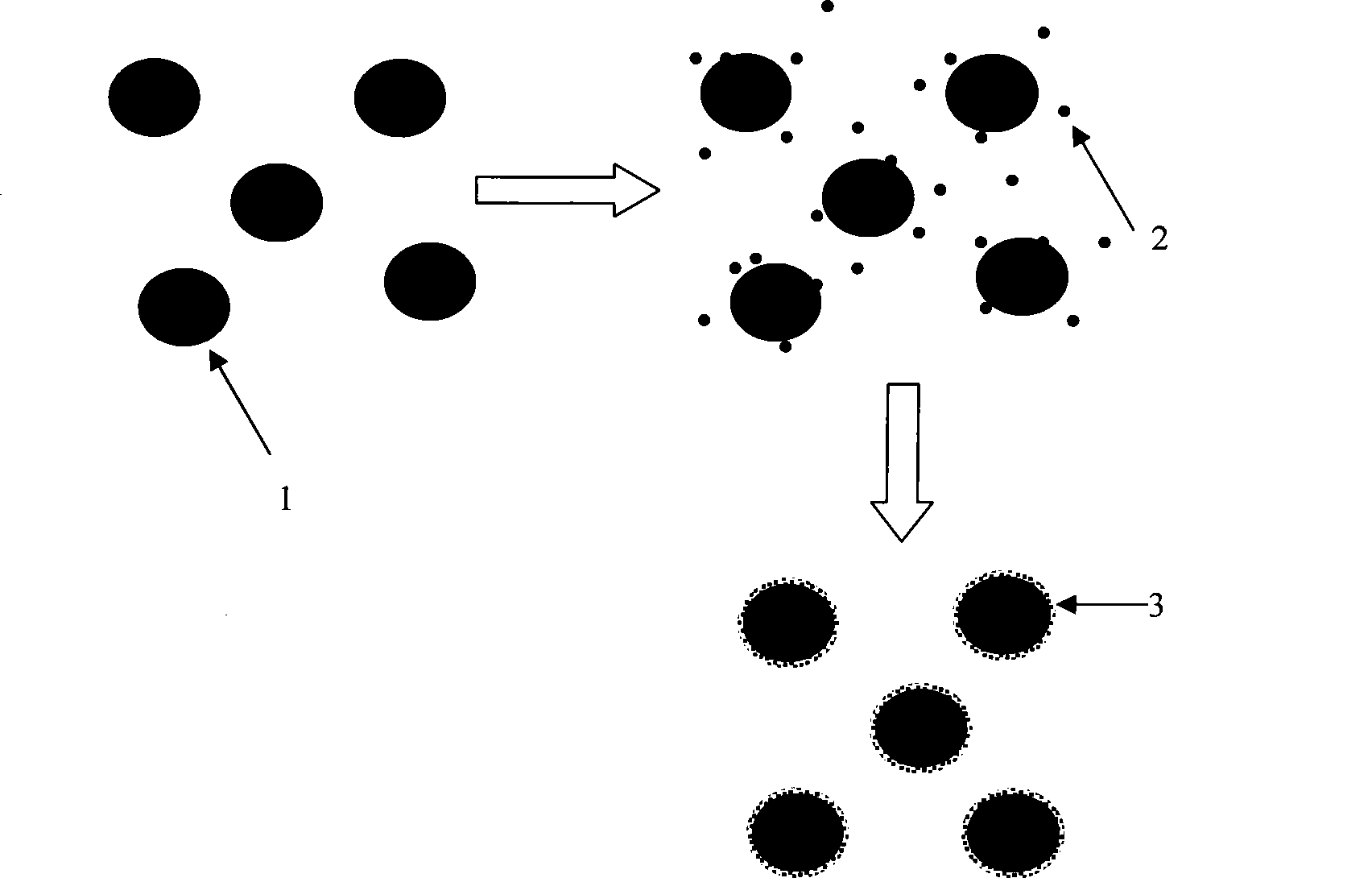

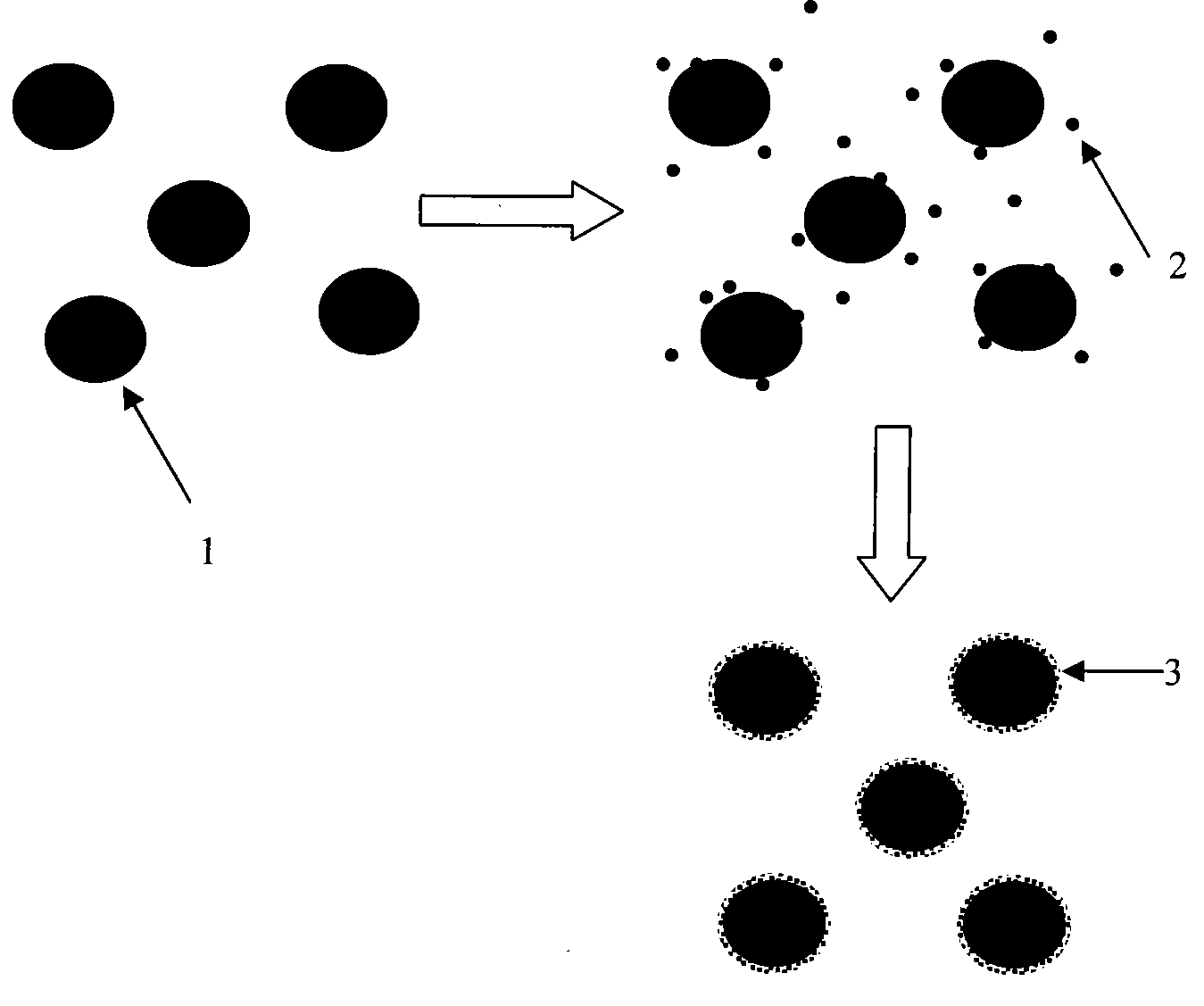

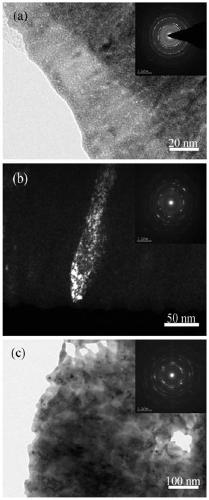

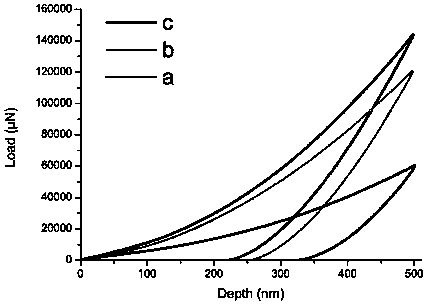

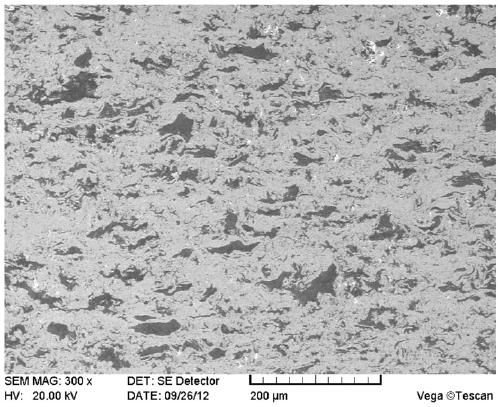

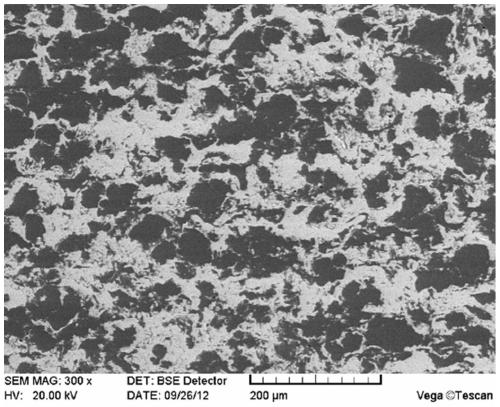

The invention belongs to the field of high polymer composites and particularly relates to a nanoparticle / graphene oxide composite modified high polymer material and a preparation method thereof. The composite is prepared from nanoparticle / graphene oxide composite particles and a macromolecular polymer matrix, wherein the nanoparticle / graphene oxide composite particles are synthesized with an electrostatic self-assembly method, that is, an amino modified nanoparticle dispersion liquid is ionized to have positive charges while graphene oxide contains a large quantity of carboxyls and hydroxyls and is ionized to have negative charges, particles with positive and negative charges are sufficiently contacted, and electrostatically self-assembled nanoparticle and graphene oxide composite particles are obtained. The prepared nanoparticle / graphene oxide composite modified high polymer material has excellent mechanical and tribological performance, is simple and efficient to prepare and has goodapplication prospects in automobiles, aerospace, electronic and electrical engineering, machinery, weapons and other fields.

Owner:ZHONGBEI UNIV

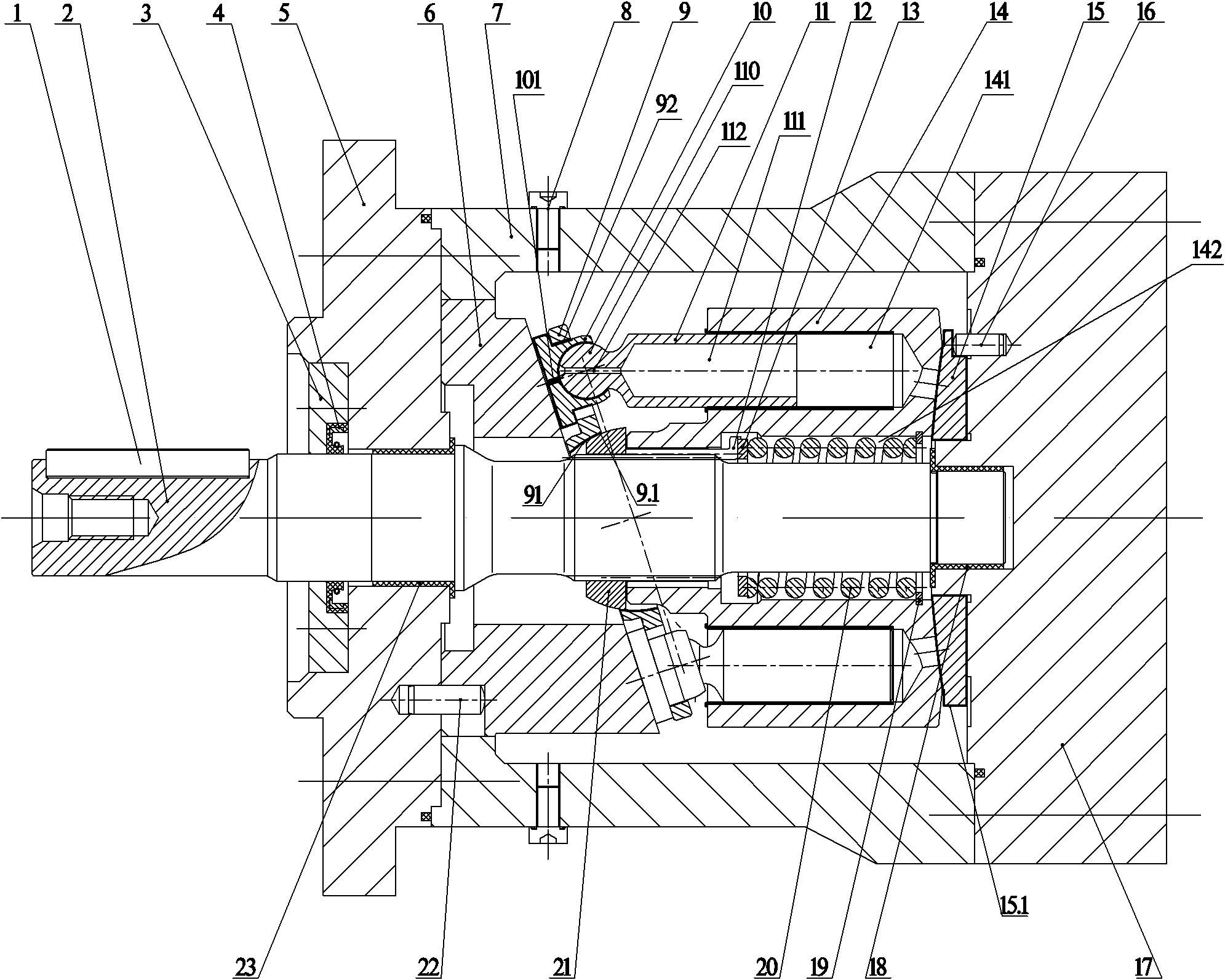

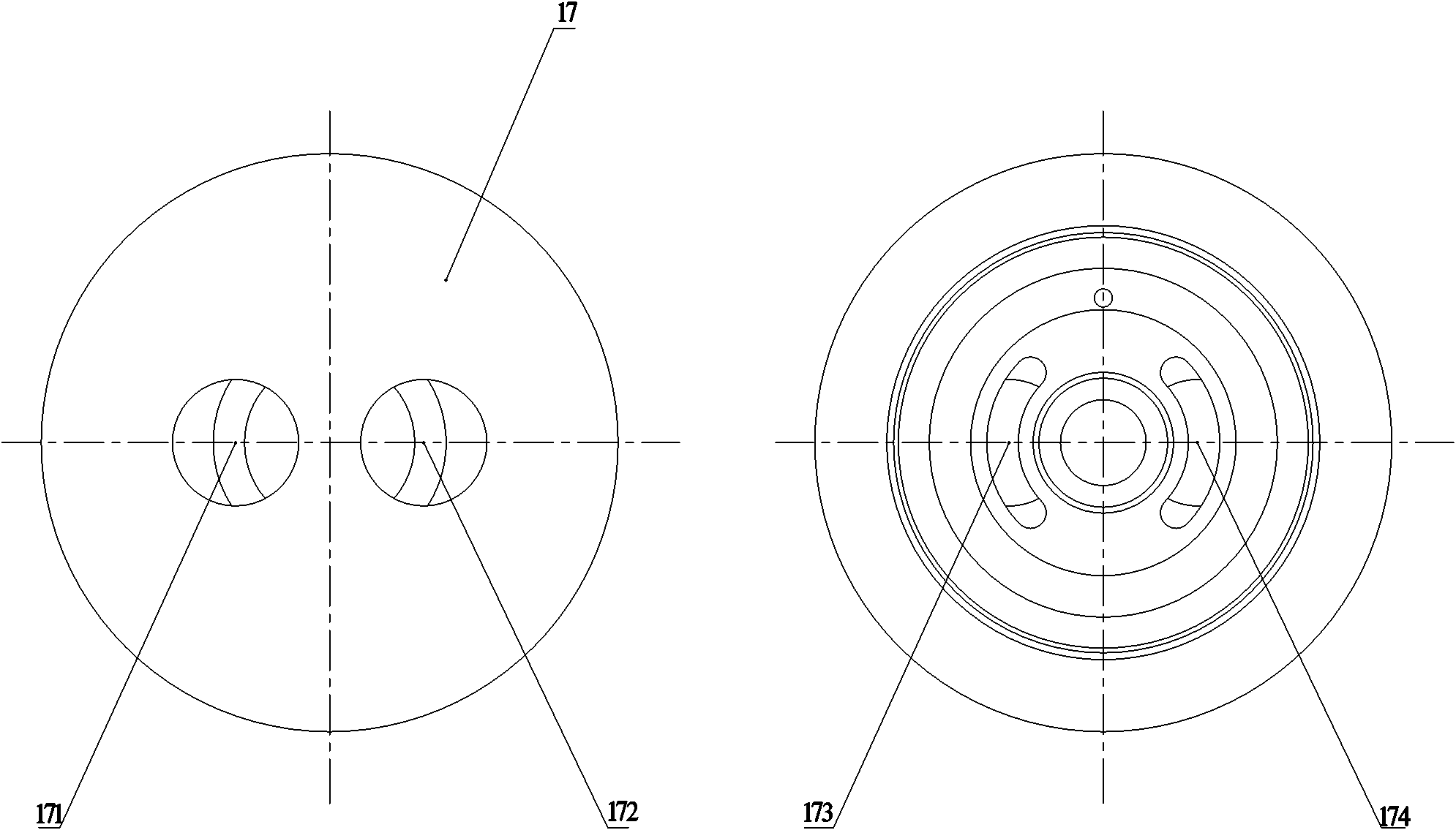

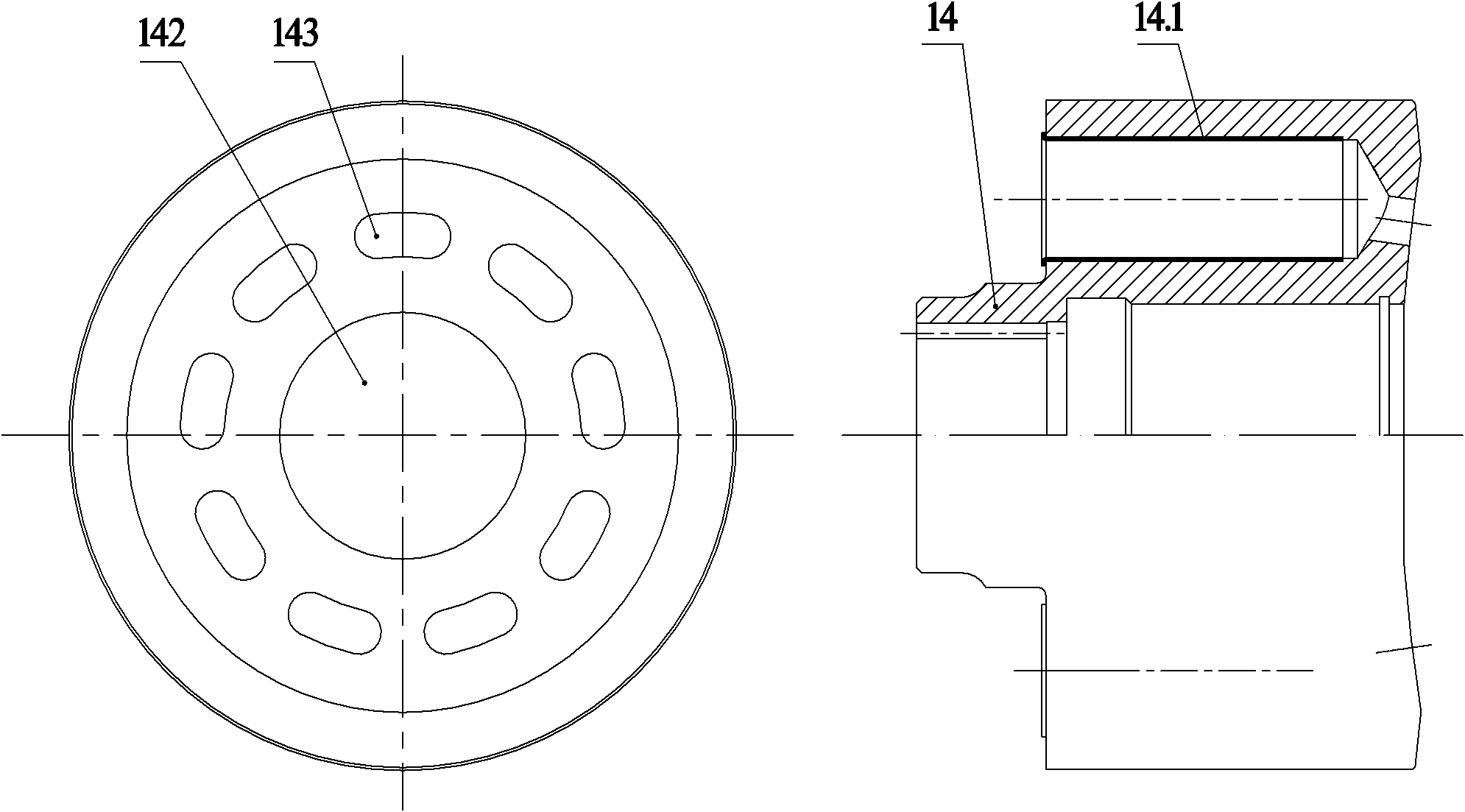

Pure water hydraulic through-shaft type spherical distribution axial plunger pump

InactiveCN102155370ASimple structureReduce the number of partsPositive-displacement liquid enginesMulti-cylinder pumpsPlunger pumpEngineering

The invention discloses a pure water hydraulic through-shaft type spherical distribution axial plunger pump which comprises a housing, wherein a through shaft type structure is adopted, a drive main shaft is connected with a cylinder body through a spline, and the cylinder body is provided with odd plunger holes; a plunger ball head and a slipper ball socket in each plunger-slipper assembly form a slipper spherical hinge pair, and plungers are respectively arranged in the plunger holes of the cylinder body to form a plunger pair; one end of a spring arranged in a center hole of the cylinder body is used for pressing the cylinder body on a distribution plate through a blocking ring, the distribution plate is positioned on a rear end cover through the center hole and a positioning pin, and the end face of the cylinder body and the distribution plate form a distribution pair; and the other end of the spring is used for pressing a slipper in each plunger-slipper assembly on a tilting tray through a pressing rod and the like, the end face of the slipper and the surface of the tilting tray form a slipper pair, and the outer spherical surface of a spherical hinge and the inner ball socket surface of a return tray form a center spherical hinge pair. When the main shaft is driven to rotate, the pure water hydraulic through-shaft type spherical distribution axial plunger pump can ensure that the plungers reciprocate along the plunger holes of the cylinder body and realize suction and discharge processes of sea water through the action of the distribution plate.

Owner:ZHEJIANG UNIV

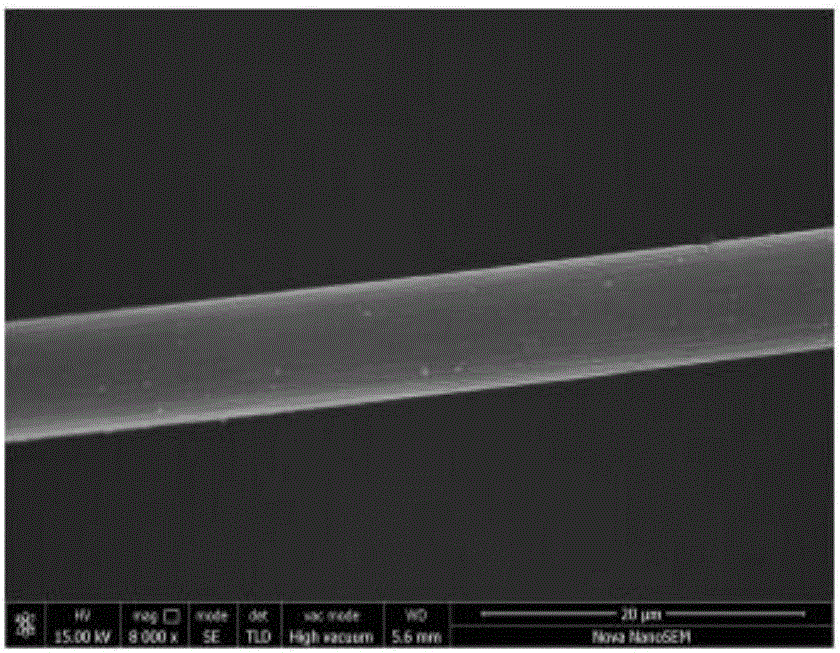

Polyether-ether-ketone/nanometer zinc oxide/carbon fiber wear-resistant composite material and preparation method thereof, and application of composite material to mechanical polishing of retaining rings

The invention provides a polyether-ether-ketone / nanometer zinc oxide / carbon fiber wear-resistant composite material and a preparation method thereof, and application of the composite material to mechanical polishing of retaining rings, belonging to the technical field of polymer-based composite materials. The composite material is composed of, by mass, 75 to 90% of polyether-ether-ketone resin, 5 to 20% of carbon fibers coated by polyethersulfone and 2.5 to 7.5% of nanometer zinc oxide modified by a coupling agent, summing to 100%. To improve dispersibility of zinc oxide nanoparticles and reduce the agglomeration degree of the zinc oxide nanoparticles, the coupling agent is employed for surface modification of the zinc oxide nanoparticles; and polyethersulfone is used for physical coating of the surfaces of the carbon fibers so as to improve compatibility between the carbon fibers and polyether-ether-ketone. Compared with a polyether-ether-ketone composite material without any treatment, the wear-resistant composite material provided by the invention has more excellent strength, wear resistance and antifriction performance, is low in processing cost and is applicable to mechanical polishing of retaining rings.

Owner:JILIN UNIV

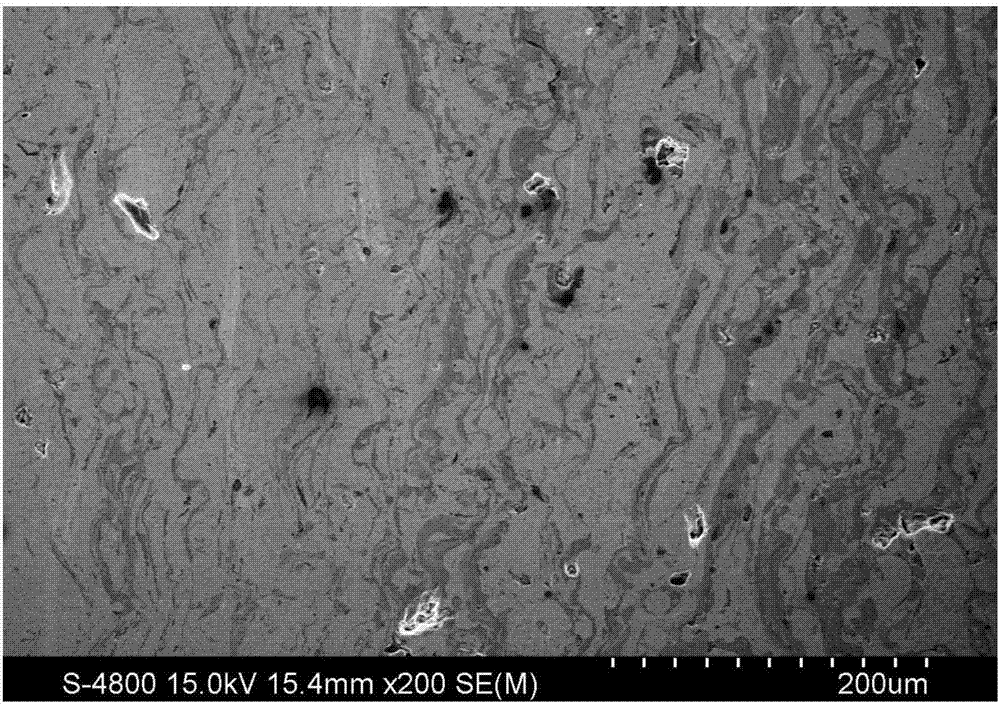

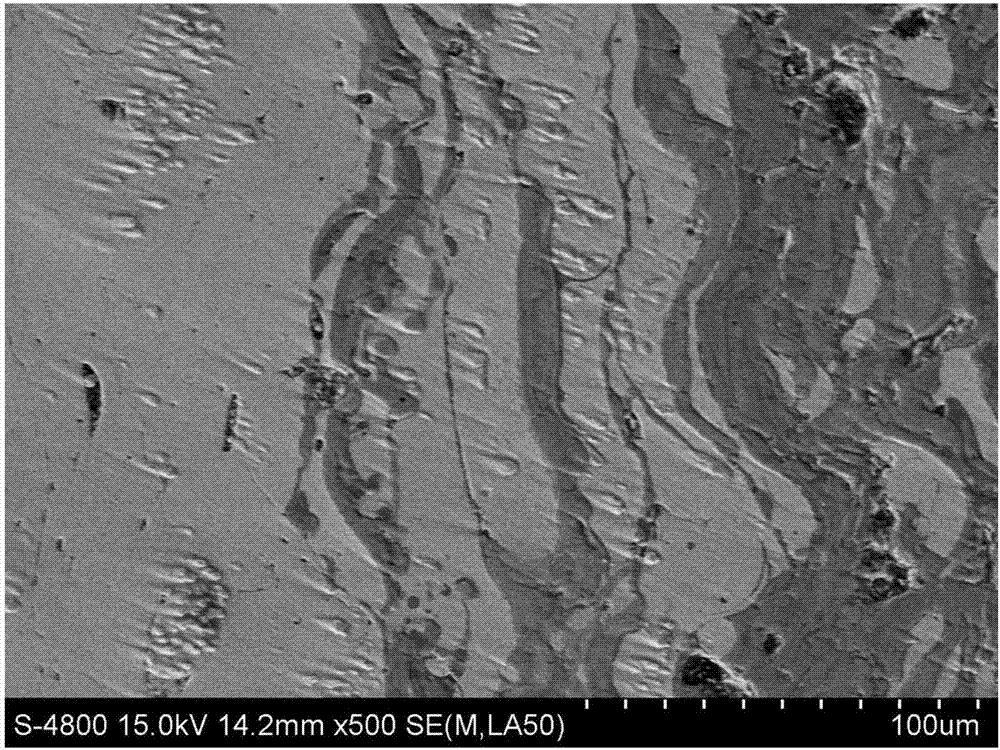

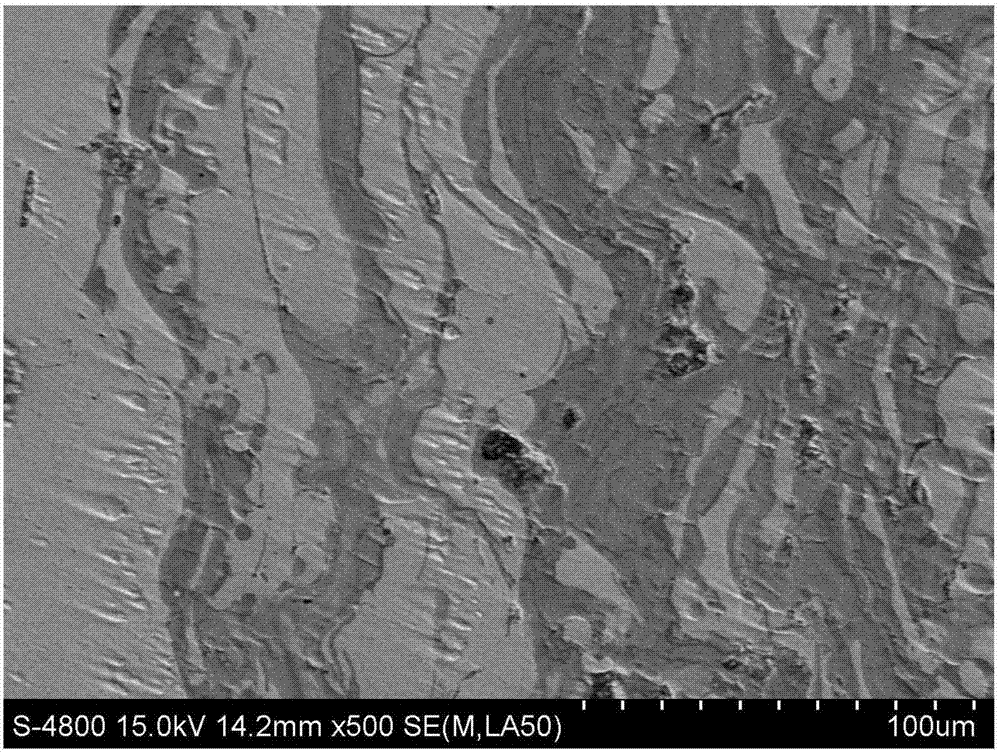

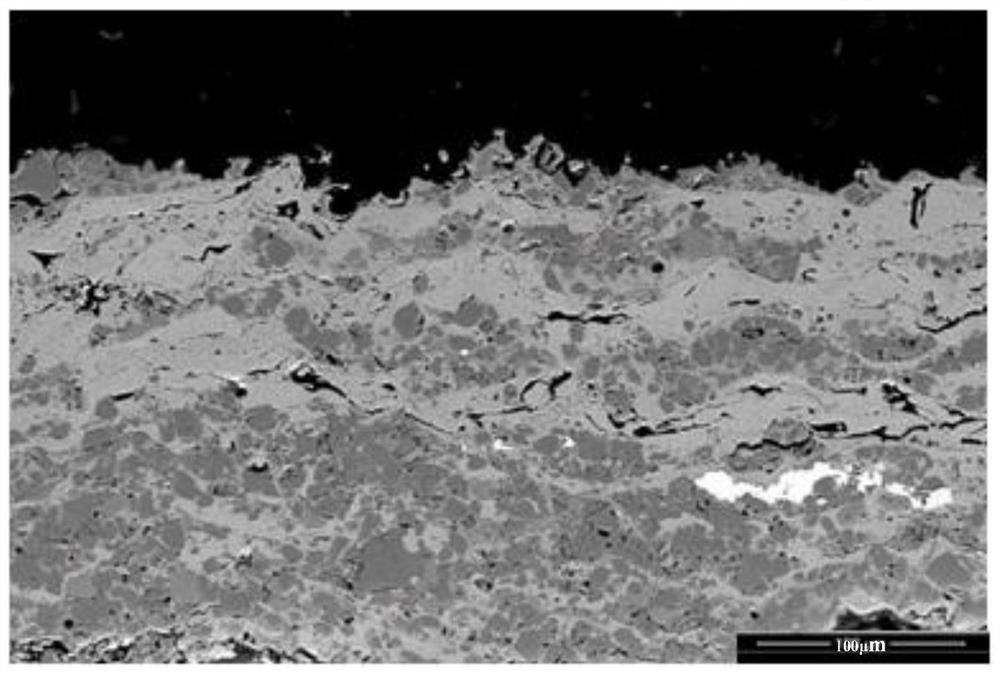

Method for preparing NiCrBSi-TiN gradient composite coating abrasion-resistant belt on the surface of drill rod joint

ActiveCN107267908AHigh strengthExtend the life cycleMolten spray coatingOxidation resistantPlasma sprayed

The invention discloses a method for preparing a NiCrBSi-TiN gradient composite coating abrasion-resistant belt on the surface of a drill rod joint. The method includes the following steps that (1) surface pre-treatment of a base material is performed; (2) a gradient coating is prepared, specifically, mixed powder of each layer is prepared according to the proportions of NiCrBSi powder and Ti powder in each layer in a composite gradient coating shown as follows, the mixed powder of each layer is put in a grinding miller to be mixed, the powder is dried for 0.7-1.2 hours at the temperature of 100 DEG C to 110 DEG C before spraying, and then plasma spraying of each layer is performed in sequence; and (3) induction remelting aftertreatment of the coating is performed, specifically, the drill rod joint is coated with a high-temperature antioxidant coating material with the thickness being 0.2-0.3 mm after being subjected to composite gradient spraying, and then induction melting treatment is performed through high-frequency induction heating equipment. According to the method, the process operation is simple, the feasibility is high, the abrasion resistance is remarkably improved, and abrasion to the abrasion-resistant material is small.

Owner:HEBEI UNIV OF TECH

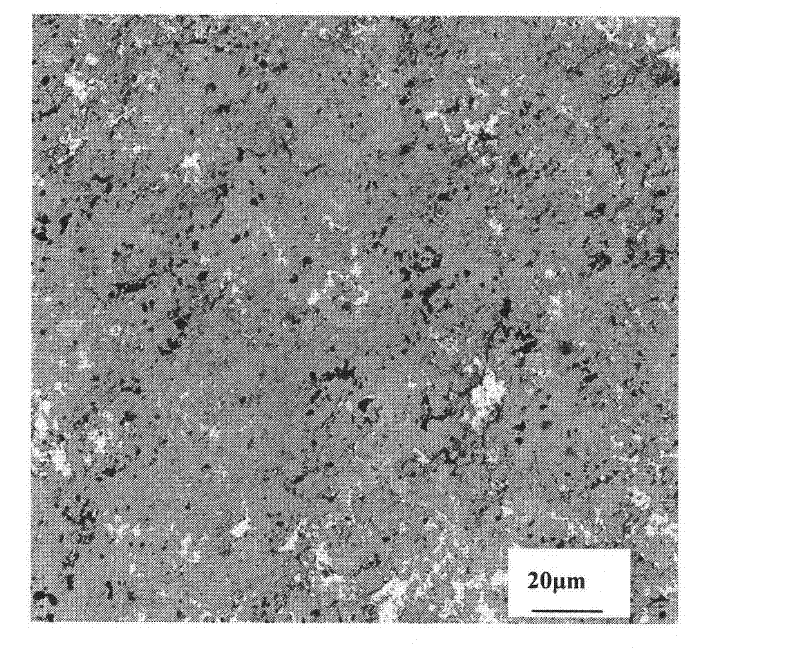

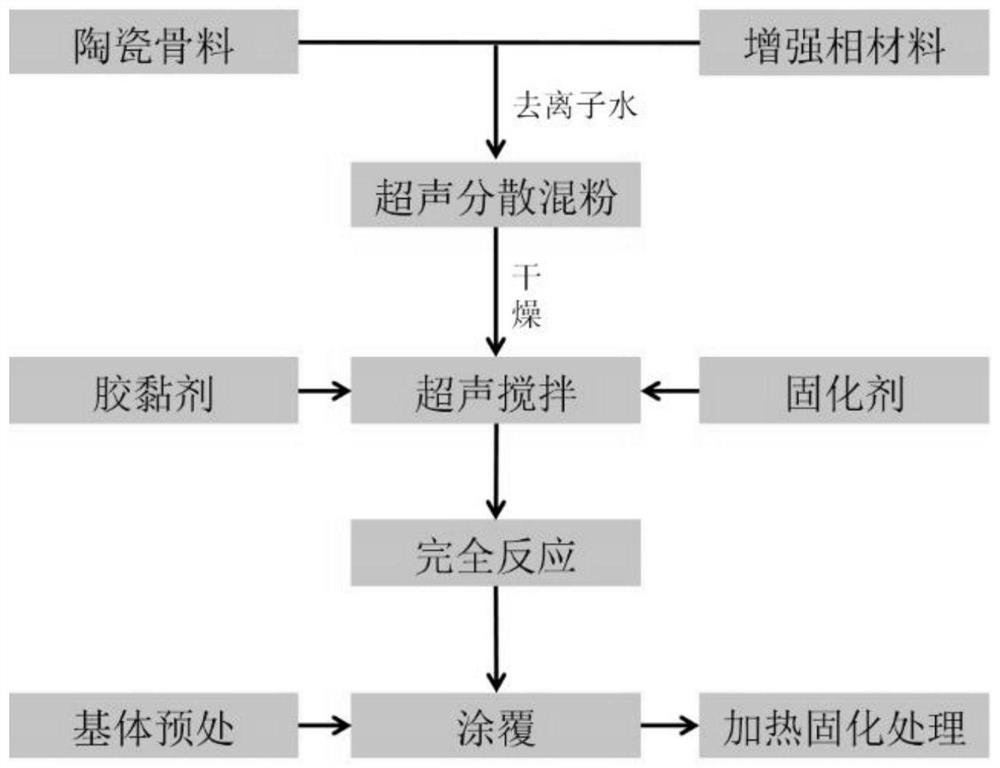

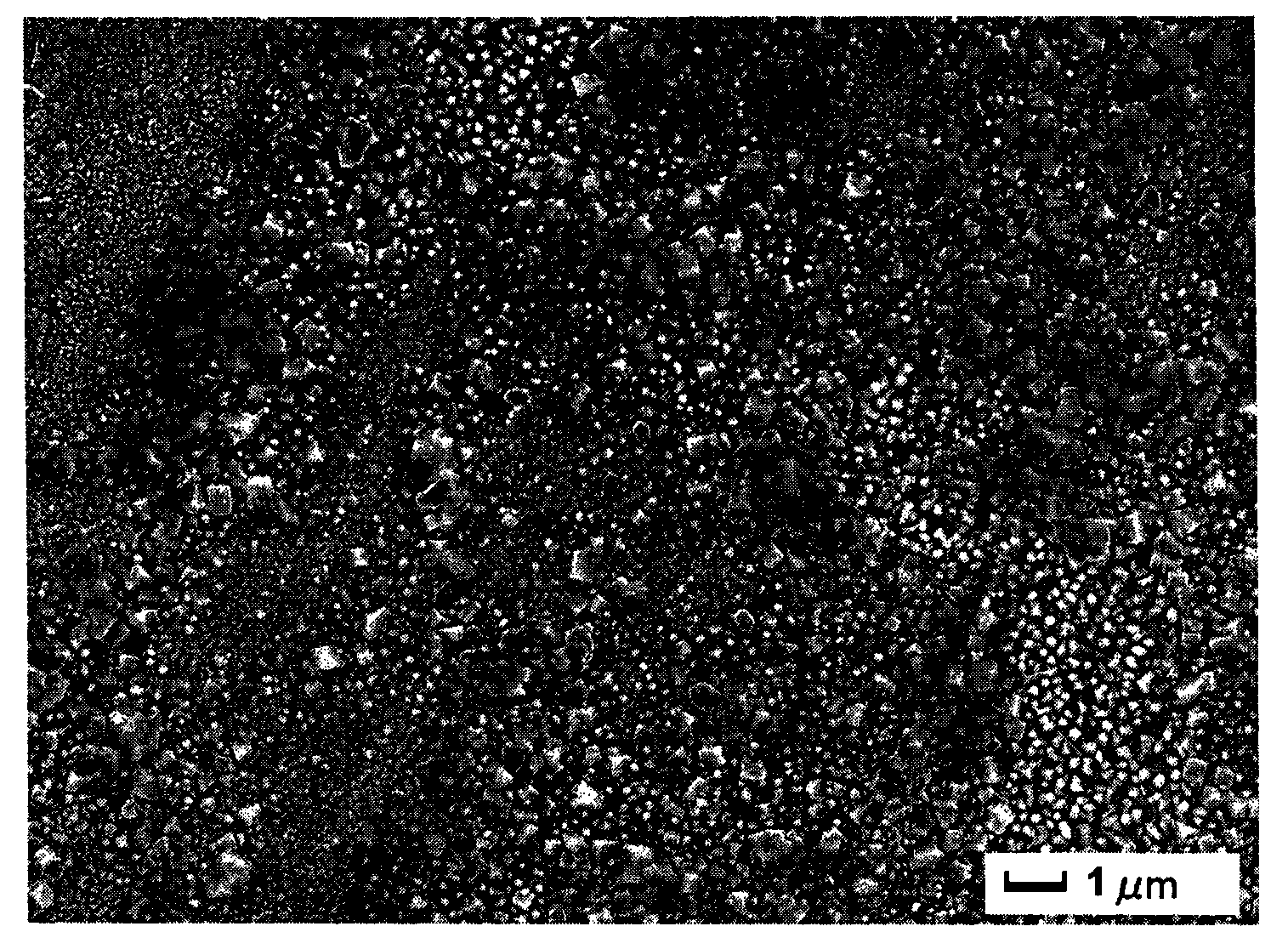

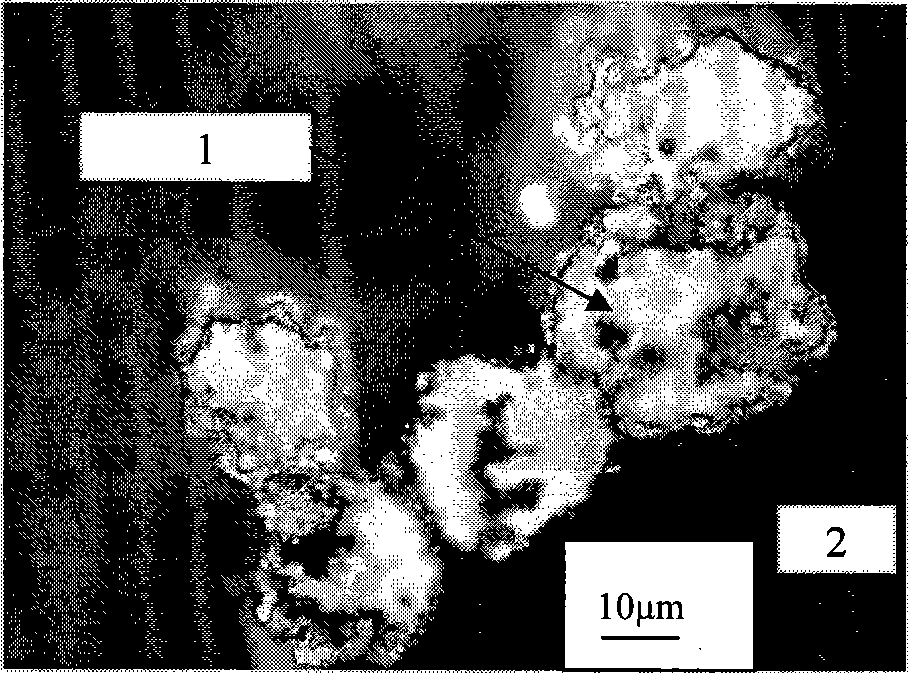

Method for preparing compound powder used for abrasion-resistant self-lubricating coating

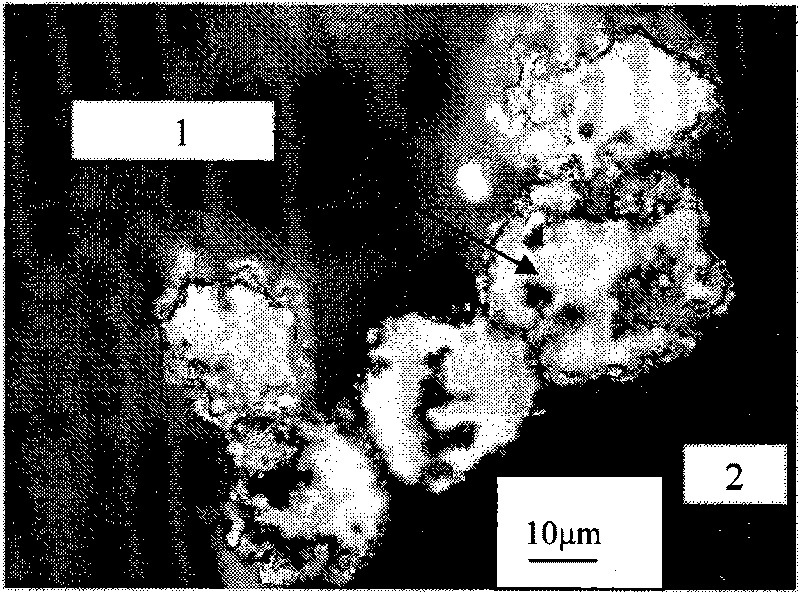

InactiveCN101717928AEvenly distributedGood wear resistance and antifriction performanceLiquid/solution decomposition chemical coatingMaterials preparationDistilled water

The invention discloses a method for preparing a compound powder used for an abrasion-resistant self-lubricating coating, belonging to the technical field of material preparation and comprising the following steps of: adopting a chemical plating process to coat Ag on the surface of a WC-12Co powder; putting the powder to hot alkali liquor to remove oil; carrying out sensitizing treatment on the powder by an SnCl2 solution; carrying out activating treatment on the powder by using a PdCl2 solution; adding the powder to a reducing solution; then adding a silver-ammonia solution; stirring and mixing; regulating the pH value of the mixed solution by using ammonia water; taking out the powder after 5-60min; and washing clean with distilled water; and drying into the powder to obtain the compound powder used for the abrasion-resistant self-lubricating coating. The amount of Ag coated on the surface of the powder is changed through regulating the concentration of the silver-ammonia solution, the concentration of the reducing solution and the deposition time. The Ag / WC-12Co compound powder the Ag layer of which is even and compact can be prepared by utilizing the invention, thereby enabling the lubricating phase distribution in the prepared coating to be even and the abrasion resistance and anti-friction property to be excellent.

Owner:GRIPM ADVANCED MATERIALS CO LTD

Copper alloy composite material containing nano-particles

InactiveCN1603449AImprove flexural strengthHigh compressive strengthChemical compositionNanoparticle

The invention belongs to the metallurgy material domain, specially involves uses in to make east the hydraulic pump to seal contains a nanometer pellet which the static link uses the copper alloy compound material. The compound material chemical composition ingredient (weight %) is: The graphite 1-5%, the particle size for is smaller than 70 microns; Nanometer nickel 1-5%, average grain diameter 40-60nm; The aluminum oxide 1-5%, average grain diameter 140-160nm, in which is smaller than 100nm to occupy 15-17%; The remainder is 6-6-3 copper alloy, the particle size for is smaller than 70 microns. The invention and the existing technology compare has the machinery mildly high, the wear-resisting anti-friction nature good, the seal effect is good, life long merit. Moves with this invention material manufacture hydraulic pressure pump spindle tail seals the static link, the acceleration length-of-life test 130 hours, its average spillage for is not bigger than 0.0076ml / h, after the test run decomposes pumps the inspection, the static link packing surface not visual obviously wears, with soaks the copper graphite material compared to, enhances in a time of situation in the practical work ability, the average spillage reduces nearly 20 times.

Owner:CENT IRON & STEEL RES INST

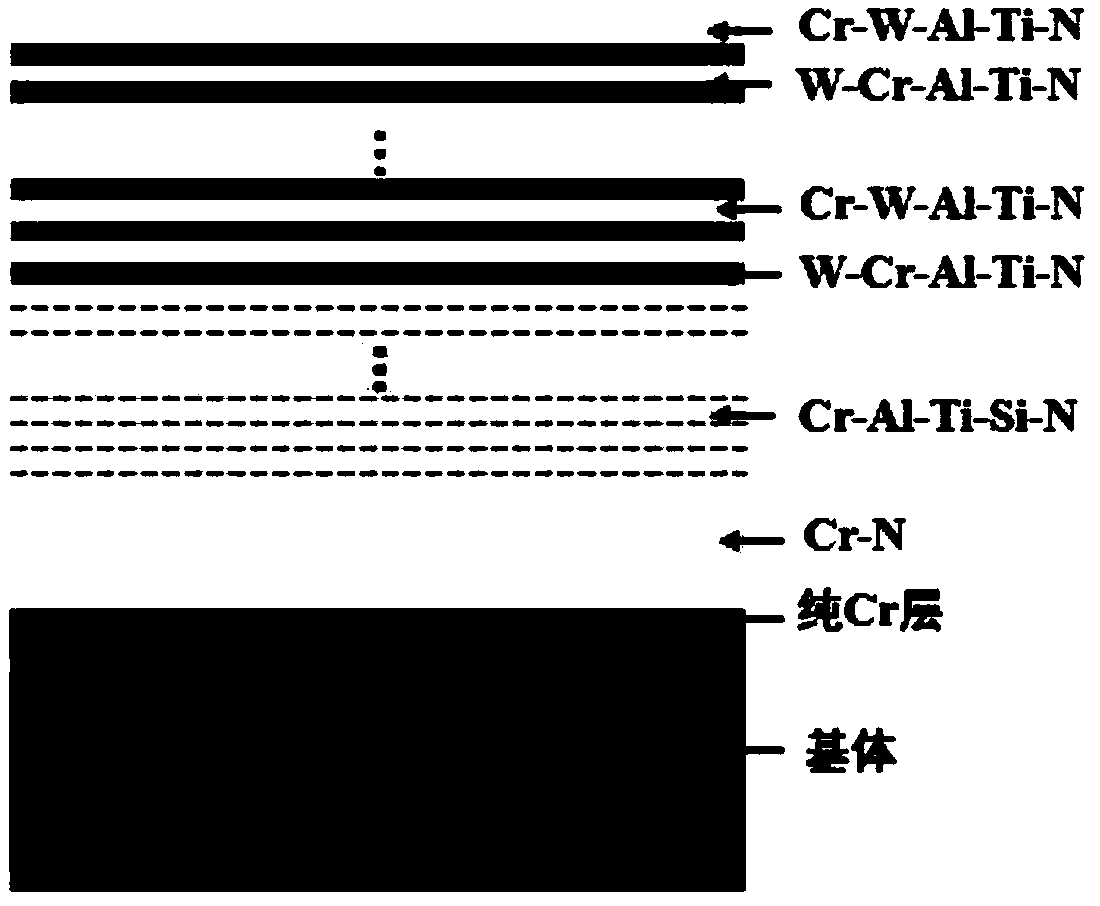

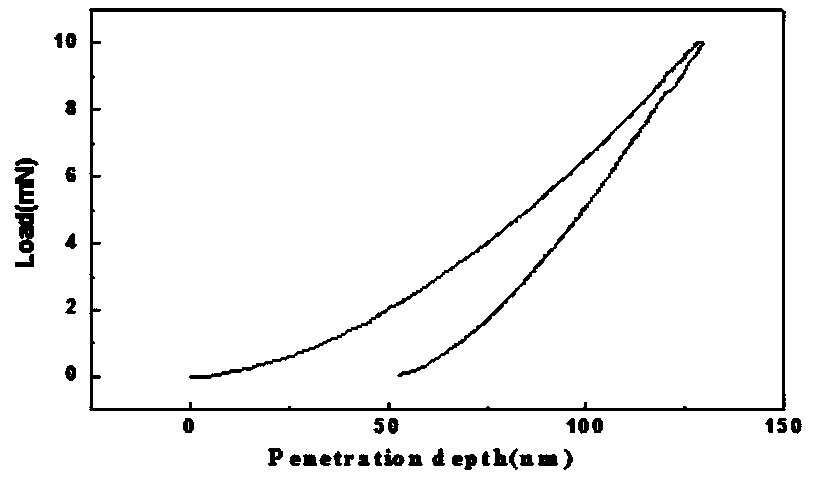

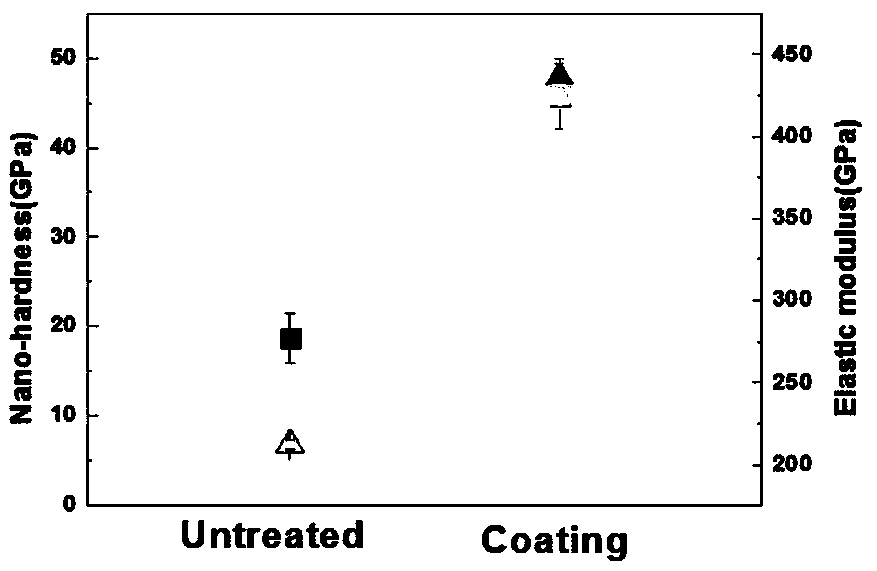

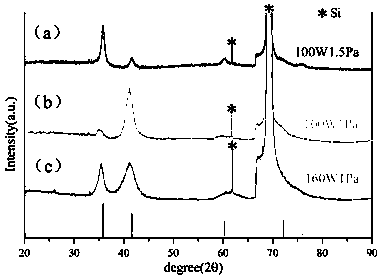

Ultra-hard W-Cr-Al-Ti-N nano gradient multilayer film material and preparation method thereof

ActiveCN109097743AHardness exceedsImprove toughnessVacuum evaporation coatingSputtering coatingHardnessFilm material

The invention provides an ultra-hard W-Cr-Al-Ti-N nano gradient multilayer film material and a preparation method thereof. Multi-arc ion plating technology is adopted in the preparation method, a tungsten element is introduced into a multilayer film, and NH3 and N2 are adopted as reaction gases together to prepare the nano gradient multilayer film material, so that the bonding force between film layers is strengthened, and the hardness of the film layers is greatly improved.

Owner:YANTAI UNIV

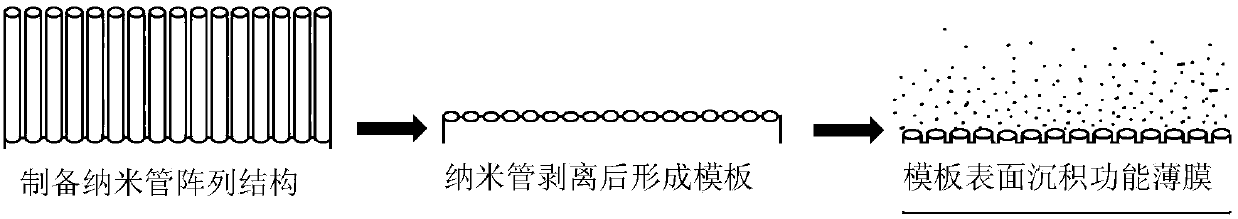

Method for preparing patterned functional film based on template deposition

InactiveCN107904556AGood absorption and utilization efficiencyEasy to produceAnodisationVacuum evaporation coatingNano structuringGas phase

The invention relates to a method for preparing a patterned functional film based on a template deposition, and aims to solve the technical problem that degradation efficiency and light absorbance utilization efficiency are relatively poor as a film prepared by existing similar methods is relatively difficult to realize stored oil lubrication in surface pits, is relatively poor in wear resistanceand anti-friction quality, is relatively small in specific surface area and is relatively difficult to realize selective absorption and reflection of visible light. The key point is that the method comprises the following steps of: preparing a surface nano structure with a nano tube array structure on metal surfaces such as a titanium surface and an aluminum surface through an anode oxidization technology; removing the surface nano tube structure through a chemical or mechanical method, and leaving a patterned template structure on a metal matrix surface; and conducting depositing on a metal patterned surface through a physical gas-phase deposition technology to prepare a functional film. The functional film deposited by the method has a patterned morphology, can improve binding force between the film and matrix, can increase a specific surface area of the film, and is beneficial for bringing functional effects such as photocatalysis of the film into play.

Owner:NINGBO DAHONGYING UNIV

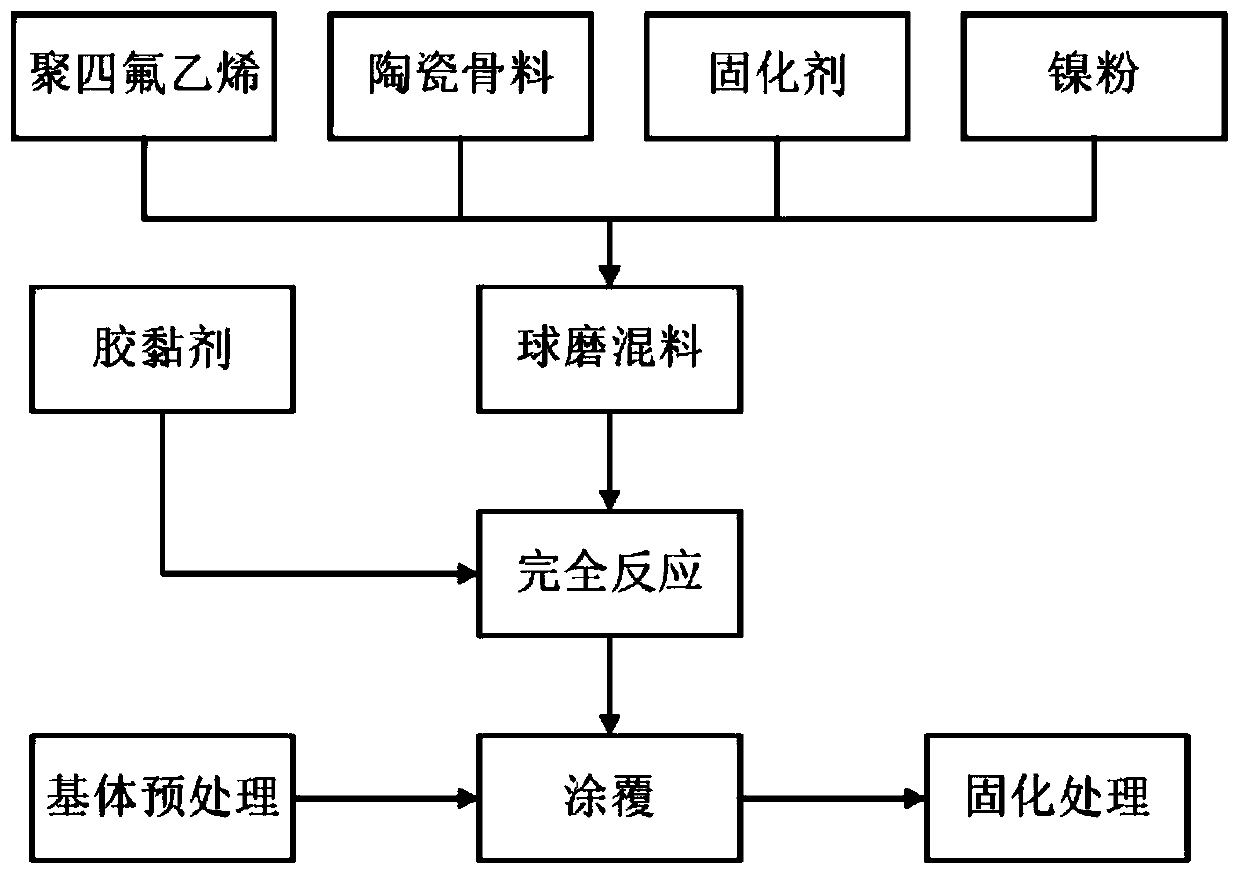

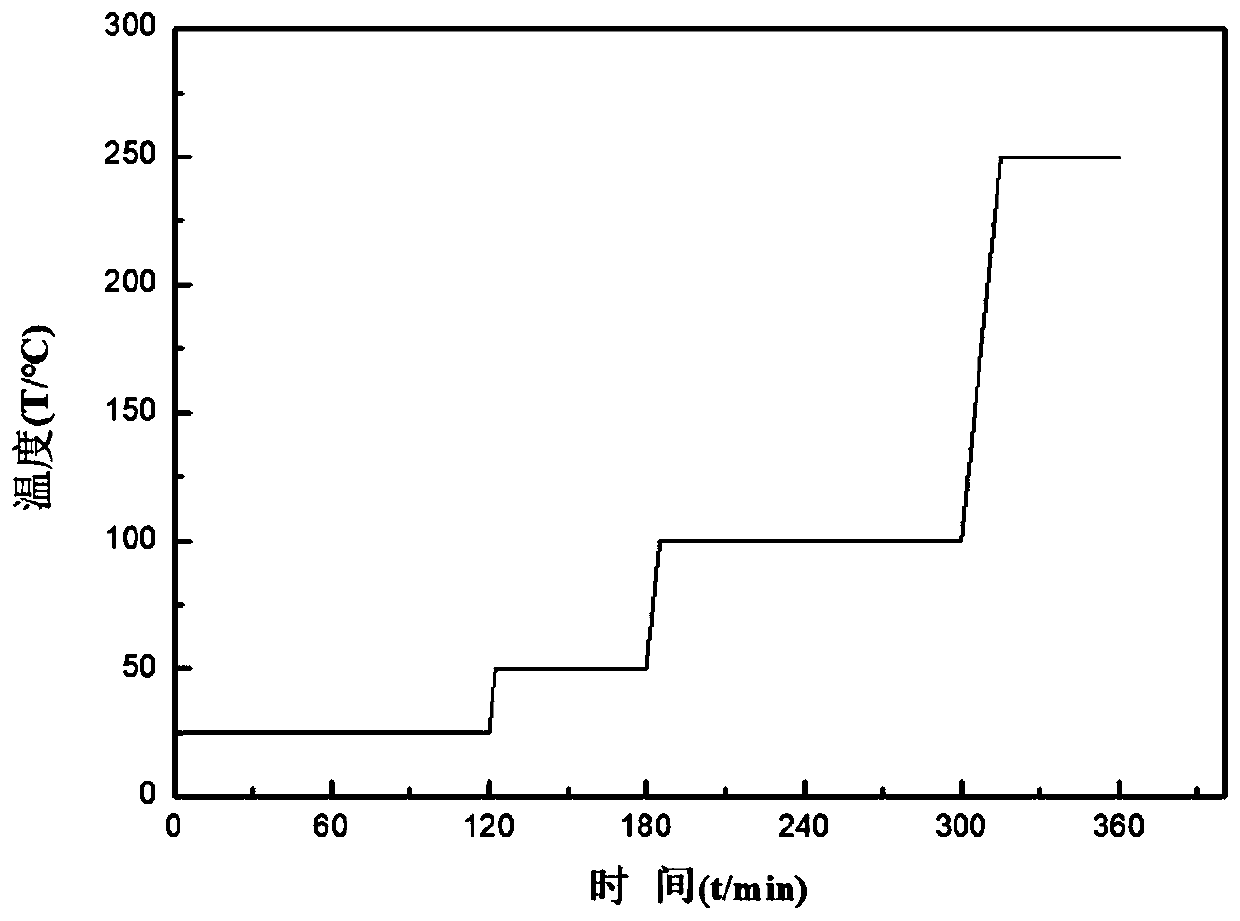

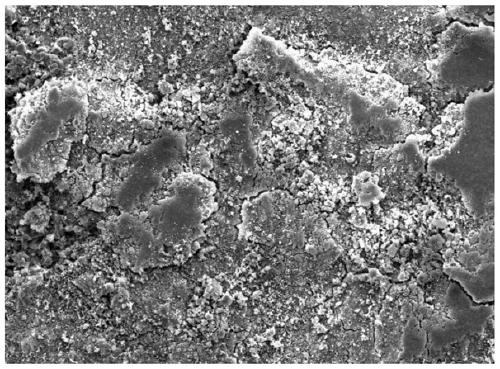

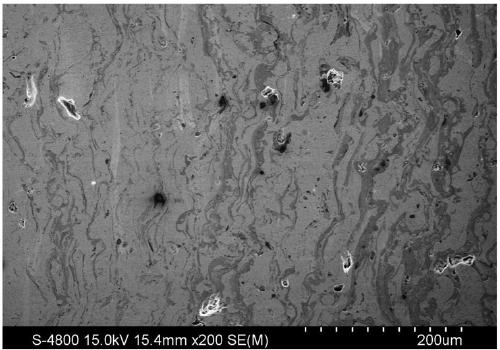

Polytetrafluoroethylene-reinforced adhesion ceramic coating and preparation method thereof

InactiveCN110451920ASimple preparation processLow costPretreated surfacesCoatingsNano zinc oxideSol-gel

The invention discloses a polytetrafluoroethylene-reinforced adhesion ceramic coating material. The polytetrafluoroethylene-reinforced adhesion ceramic coating material includes the following components: by weight, 57.4-58.4% of micron alumina, 0.5-1.5% of nano zinc oxide, 0.4-0.8% of nickel powder, 0.2-1% of polytetrafluoroethylene and 30-50% of aluminum dihydrogen phosphate. The invention also provides an adhesion ceramic coating prepared from the ceramic coating material and a preparation method of the adhesion ceramic coating. The polytetrafluoroethylene-reinforced adhesion ceramic coatingis prepared by using a sol-gel method, the preparation process is simple, no complicated-structure and precise coating equipment is needed, and the cost is low.

Owner:SUZHOU UNIV

Method for preparing nickel phosphorus/expanded graphite-polyester resin/polytetrafluoroethylene composite material

The invention provides a method for preparing a nickel phosphorus / expanded graphite-polyester resin / polytetrafluoroethylene composite material. The method comprises the following steps: firstly, preparing expanded graphite of which the surface is coated by a chemical nickel phosphorus cladding layer, secondly, filling a foamed nickel support with the expanded graphite, preparing an unsaturated polyester resin / polytetrafluoroethylene mixed solution, sufficiently filling pores of foamed nickel filled with the expanded graphite with the unsaturated polyester resin / polytetrafluoroethylene mixed solution, and finally conducting room-temperature polymerization and later polishing and grinding, so as to obtain the nickel phosphorus / expanded graphite-polyester resin / polytetrafluoroethylene composite material. In the preparation process of the nickel phosphorus / expanded graphite-polyester resin / polytetrafluoroethylene composite material, sufficient contact of the polyester resin and the expanded graphite of which the surface is coated by the nickel phosphorus cladding layer with polytetrafluoroethylene is ensured, so aggregation of the polytetrafluoroethylene and the expanded graphite is effectively avoided, furthermore, the wearing resistance of the polytetrafluoroethylene is greatly improved, the prepared composite material is small in friction coefficient, high in hardness, high in pressure resistance and good in wearing resistance, and has wide application prospects under high-frequency friction working conditions.

Owner:YANSHAN UNIV

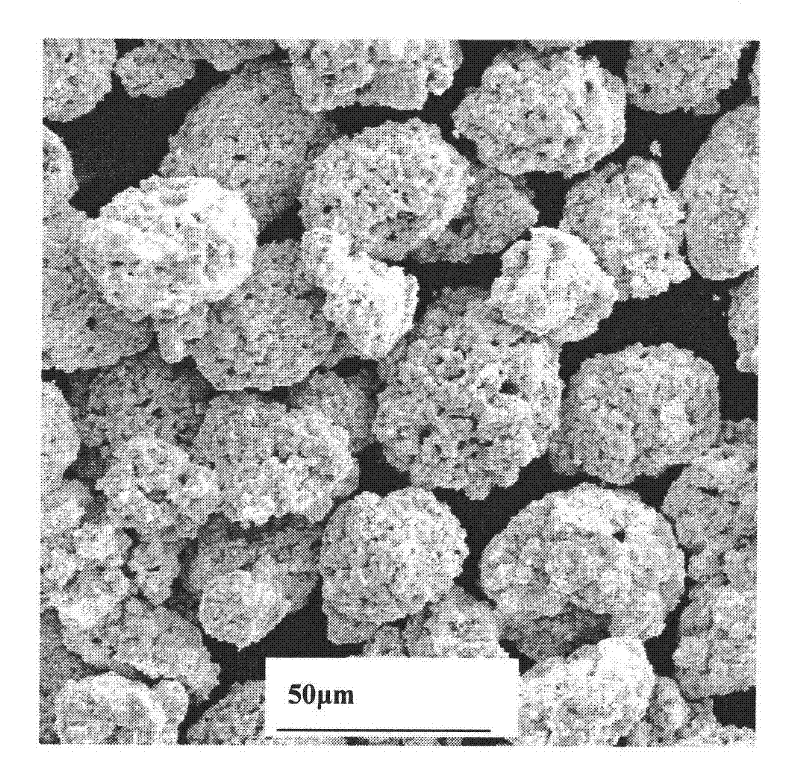

Powder metallurgy circular spline and preparation method thereof

ActiveCN109868422AUniform compositionComposition controllablePortable liftingGearing elementsReducerMaterials processing

The invention discloses a powder metallurgy circular spline which adopts less machining / free-of-machining, can be self-lubricated in the working process and is used for a harmonic reducer, and a preparation method of the powder metallurgy circular spline. The preparation method adopts a powder metallurgy method and comprises the procedures of preparation of powder with high composition uniformity,pressing, sintering, aftertreatment and the like. The powder metallurgy circular spline prepared from the preparation method has the advantages of being uniform in composition, good in abrasion resistance and anti-friction property, low in noise, long in life, less in machining / free of machining, low in cost and the like, and can replace a circular spline currently machined and prepared from materials such as steel and cast iron.

Owner:GRIPM ADVANCED MATERIALS CO LTD

A method for preparing a wear-resistant band of nicrbsi-tin gradient composite coating on the surface of a drill pipe joint

The invention discloses a method for preparing a NiCrBSi-TiN gradient composite coating abrasion-resistant belt on the surface of a drill rod joint. The method includes the following steps that (1) surface pre-treatment of a base material is performed; (2) a gradient coating is prepared, specifically, mixed powder of each layer is prepared according to the proportions of NiCrBSi powder and Ti powder in each layer in a composite gradient coating shown as follows, the mixed powder of each layer is put in a grinding miller to be mixed, the powder is dried for 0.7-1.2 hours at the temperature of 100 DEG C to 110 DEG C before spraying, and then plasma spraying of each layer is performed in sequence; and (3) induction remelting aftertreatment of the coating is performed, specifically, the drill rod joint is coated with a high-temperature antioxidant coating material with the thickness being 0.2-0.3 mm after being subjected to composite gradient spraying, and then induction melting treatment is performed through high-frequency induction heating equipment. According to the method, the process operation is simple, the feasibility is high, the abrasion resistance is remarkably improved, and abrasion to the abrasion-resistant material is small.

Owner:HEBEI UNIV OF TECH

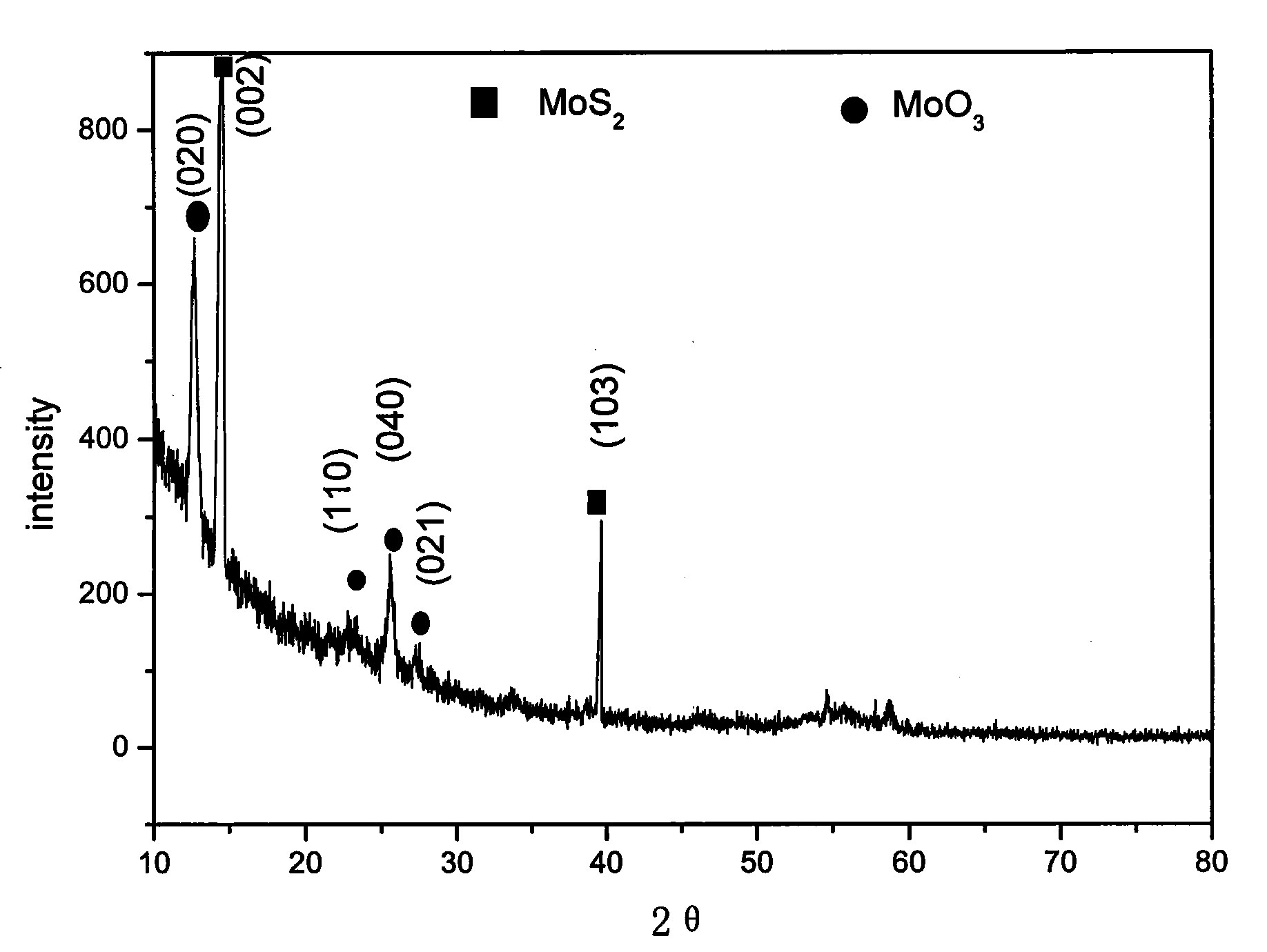

Preparation method of molybdenum disulfide-nickel phosphorus-polytetrafluoroethylene composite material

The invention belongs to the technical field of self-lubricating materials, and relates to a preparation method of a molybdenum disulfide-nickel phosphorus-polytetrafluoroethylene composite material,and the method comprises the following steps: S1, performing plasma treatment on polytetrafluoroethylene powder, and after irradiation for 60-120 seconds, putting the polytetrafluoroethylene powder for standing for 15-30 minutes in air; S2, performing sensitization and activation treatment on the polytetrafluoroethylene powder, to be more specific, after wetting of the polytetrafluoroethylene powder treated by plasma with absolute ethanol, respectively performing sensitization and activation on the polytetrafluoroethylene powder; S3, preparing a nickel phosphorus-polytetrafluoroethylene composite and performing amination treatment, to be more specific, a chemical nickel phosphorus-plating solution is prepared for plating the sensitized and activated polytetrafluoroethylene powder to obtainnickel phosphorus-polytetrafluoroethylene composite powder, and the obtained nickel phosphorus-polytetrafluoroethylene composite powder is aminated; and S4, preparing the molybdenum disulfide-nickelphosphorus-polytetrafluoroethylene composite material, to be more specific, first, molybdenum disulfide-nickel phosphorus-polytetrafluoroethylene composite material powder is prepared, and the molybdenum disulfide-nickel phosphorus-polytetrafluoroethylene composite material powder is molded to obtain the wear resistant and antifriction molybdenum disulfide-nickel phosphorus-polytetrafluoroethylenecomposite material.

Owner:YANSHAN UNIV

A nanoparticle/graphene oxide composite modified polymer material and its preparation

ActiveCN107880484BImprove mechanical propertiesImprove tribological propertiesOxide compositeNanoparticles dispersion

The invention belongs to the field of high polymer composites and particularly relates to a nanoparticle / graphene oxide composite modified high polymer material and a preparation method thereof. The composite is prepared from nanoparticle / graphene oxide composite particles and a macromolecular polymer matrix, wherein the nanoparticle / graphene oxide composite particles are synthesized with an electrostatic self-assembly method, that is, an amino modified nanoparticle dispersion liquid is ionized to have positive charges while graphene oxide contains a large quantity of carboxyls and hydroxyls and is ionized to have negative charges, particles with positive and negative charges are sufficiently contacted, and electrostatically self-assembled nanoparticle and graphene oxide composite particles are obtained. The prepared nanoparticle / graphene oxide composite modified high polymer material has excellent mechanical and tribological performance, is simple and efficient to prepare and has goodapplication prospects in automobiles, aerospace, electronic and electrical engineering, machinery, weapons and other fields.

Owner:ZHONGBEI UNIV

Modified polyurethane elastomer, and preparation method and application thereof

The invention belongs to the technical field of polyurethane sealing elements, and particularly relates to a modified polyurethane elastomer, and a preparation method and application thereof. The modified polyurethane elastomer is prepared from, by mass, 85 to 110 parts of polytetrahydrofuran polyol, 10 to 20 parts of modified polytetrafluoroethylene micro powder, 30 to 40 parts of toluene diisocynate, 6 to 10 parts of polyvinyl alcohol, 10 to 15 parts of a plasticizer, 12 to 18 parts of a chain extender and 0.05 to 0.15 part of a catalyst. According to the modified polyurethane elastomer provided by the invention, the corrosion resistance, the wear resistance and the solvent resistance of the product are remarkably improved, the friction coefficient is greatly reduced, and the special requirements of the product on the performance in some special environments are met. The modified polyurethane elastomer provided by the invention has excellent mechanical properties, corrosion resistance and good wear resistance and friction reduction performance, and is particularly suitable for being applied to hydraulic sealing elements.

Owner:XUZHOU JIULONG SEAL TECH CO LTD

Environment-friendly flame-retardant straw board for buildings, and preparation method thereof

PendingCN111909532AImprove environmental performanceSave resourcesPolytetrafluoroethyleneResin composite

The invention discloses an environment-friendly flame-retardant straw board for a building. The environment-friendly flame-retardant straw board comprises the following components in parts by weight:20-35 parts of straw; 10-16 parts of nano WEP high-fiber resin powder; 5-12 parts of carbon fiber resin composite material powder; 8-14 parts of sisal hemp; 6-10 parts of flame-retardant fibers; 3-5 parts of an environment-friendly bactericide; 2-3 parts of an adhesive; 1-2 parts of a waterproof agent; and 1-3 parts of a flame-retardant agent, wherein the carbon fiber resin composite material powder comprises the following components in parts by weight: 35-40 parts of carbon fibers, 12-20 parts of epoxy resin, 20-32 parts of phenolic resin, and 6-13 parts of polytetrafluoroethylene, the environment-friendly bactericide is nano-silver, and the flame-retardant fibers are polybenzimidazole fibers. According to the invention, waste materials are reasonably utilized to prepare the board throughsimple processing procedures, so that not only are the resources saved and the cost reduced, but also the board has good glossiness and certain air purification capacity, and the board has the advantages of higher flame retardancy, high fatigue strength, high impact toughness, water resistance and antibacterial property, thereby prolonging the service life of the board.

Owner:CHANGSHA CHUANGYUAN ENVIRONMENTAL PROTECTION TECH

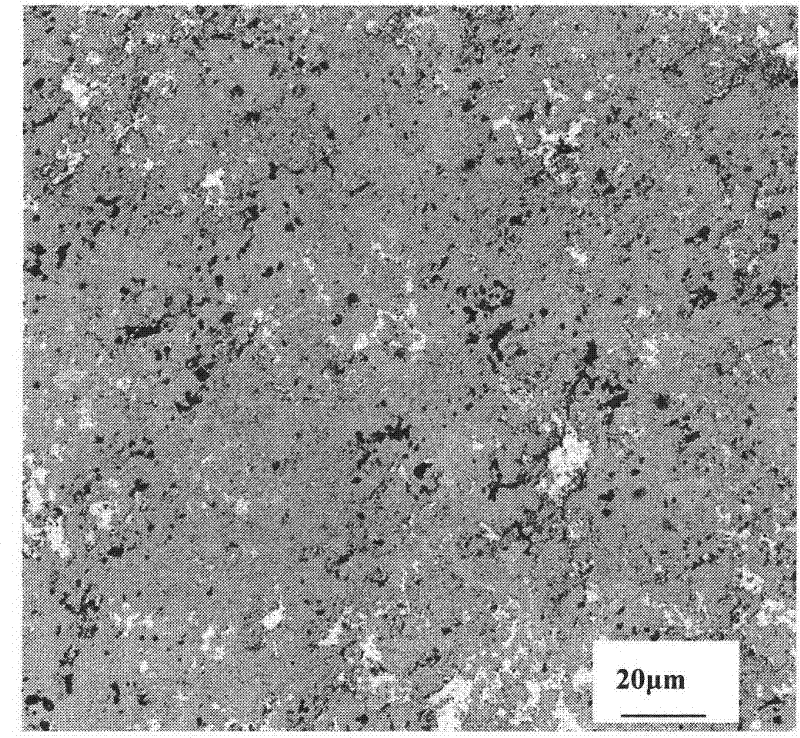

Wear resistant self-lubricating coating for brush type sealed track and preparation method thereof

InactiveCN101735680BImprove wear resistanceImprove impact resistanceMolten spray coatingWear resistantRoom temperature

The invention discloses a wear resistant self-lubricating coating for a brush type sealed track and a preparation method thereof, belonging to the technical field of a coating for a rotor track in a brush type sealed structure, and a preparation method thereof. The coating of the invention comprises the following components in weight percent: 10-20% of Ag, 9-11% of Co, 3.8-6% of C and the balanceW. The preparation method taking WC-12Co powder and Ag powder as raw materials comprises the following steps, preparing the raw materials into composite powder by a spray prilling process, screening out the composite powder with the particle size of 15-45 mu m, and spraying the composite powder on the surface of the brush type sealed track by supersonic speed flame spray coating, thereby preparing the wear resistant self-lubricating coating on the brush type sealed track, wherein the weight of the Ag powder in the raw materials accounts for 10-20% of the total weight of the WC-12Co powder andthe Ag powder. The coating has moderate microhardness, good bonding strength, and good wear resistant anti-friction performance within the temperature range from room temperature to 600 DEG C.

Owner:GRIPM ADVANCED MATERIALS CO LTD

MXene reinforced silicate adhesive ceramic coating and preparation method thereof

ActiveCN113337145ASimple preparation processLow curing temperatureAlkali metal silicate coatingsChemical industryCeramic coatingAdhesive

The invention relates to the technical field of metal surface materials, in particular to an MXene reinforced silicate adhesive ceramic coating and a preparation method thereof. The MXene reinforced silicate adhesive ceramic coating is prepared from aluminum oxide, silicon phosphate, MXene and a silicate adhesive; the chemical formula of the MXene is Ti3C2. The coating disclosed by the invention has relatively low shear strength and self-lubricating capacity, relatively high mechanical strength and a layer-by-layer stacked structure; the preparation process is relatively simple, the curing temperature is relatively low, the time is relatively short, and is very suitable for industrial production equipment and places which are not resistant to high temperature; the preparation process is low in energy consumption, does not need precise coating equipment with a complex structure, and is green and pollution-free.

Owner:SUZHOU UNIV

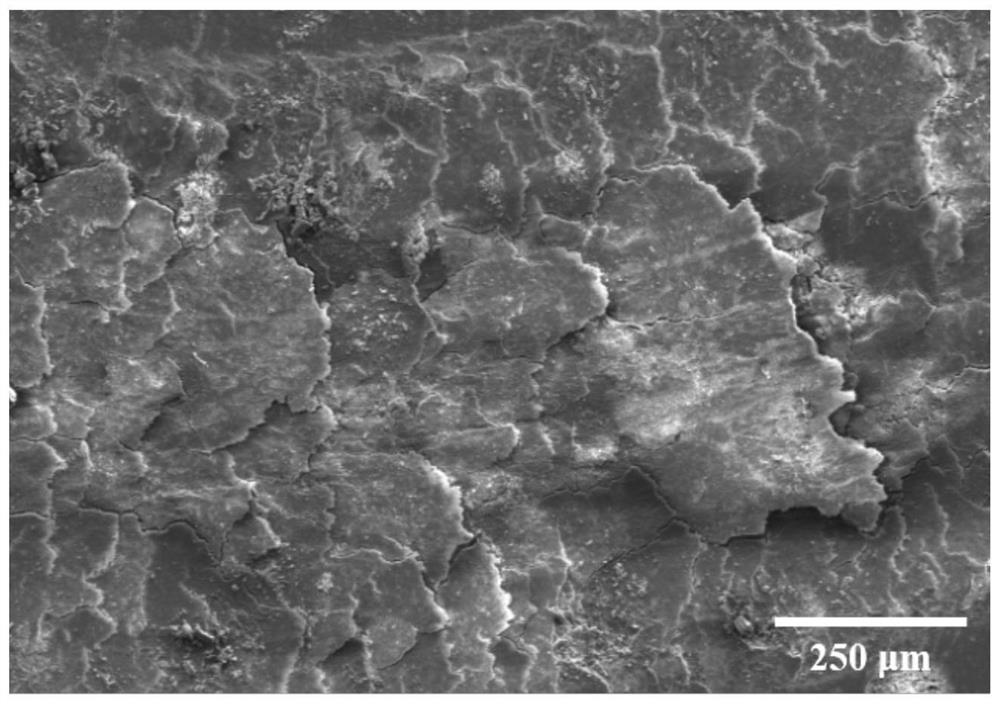

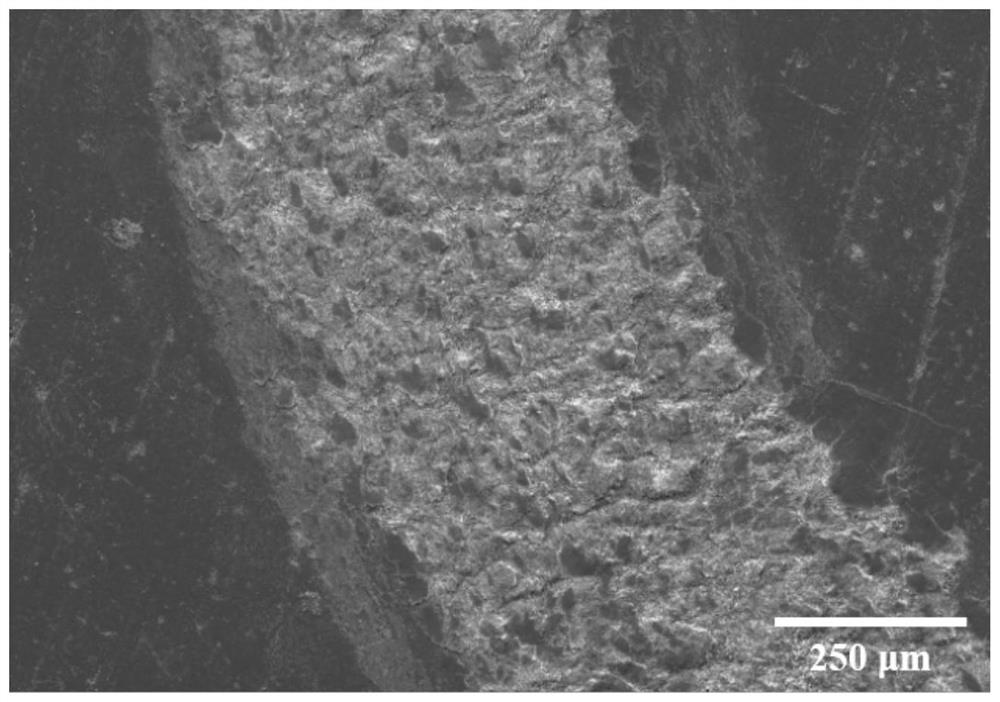

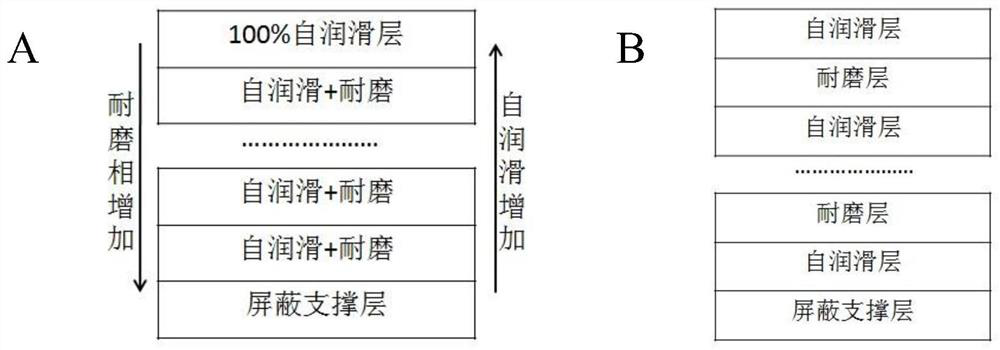

A self-lubricating wear-resistant composite coating and its preparation method and application

ActiveCN110158007BPrevent heat burnImprove wettabilityMolten spray coatingCeramic compositeHigh density

The invention relates to the field of surface coatings, in particular to a self-lubricating and wear-resistant composite coating, a preparation method and application thereof. The self-lubricating wear-resistant composite coating includes a shielding support layer and a functional composite layer, wherein the shielding support layer is prepared from wear-resistant materials composed of hard ceramic particles and nickel-based alloys as raw materials, and belongs to cermet composite coatings. It has high hardness, high density, and plays the role of shielding corrosion and hard surface support; the functional composite layer is composed of wear-resistant materials and self-lubricating materials with gradient structure or alternating structure. This structure has both wear-resistant and friction-reducing self-lubricating properties. characteristics, while also ensuring the long-term release of solid self-lubricating materials in the composite coating. The composite coating provided by the invention can improve the antifriction and wear resistance of moving parts such as shafts and rollers under dry friction, and has good application prospects.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

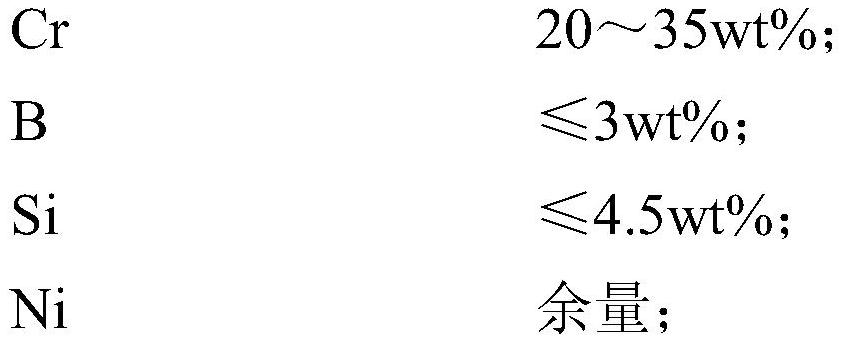

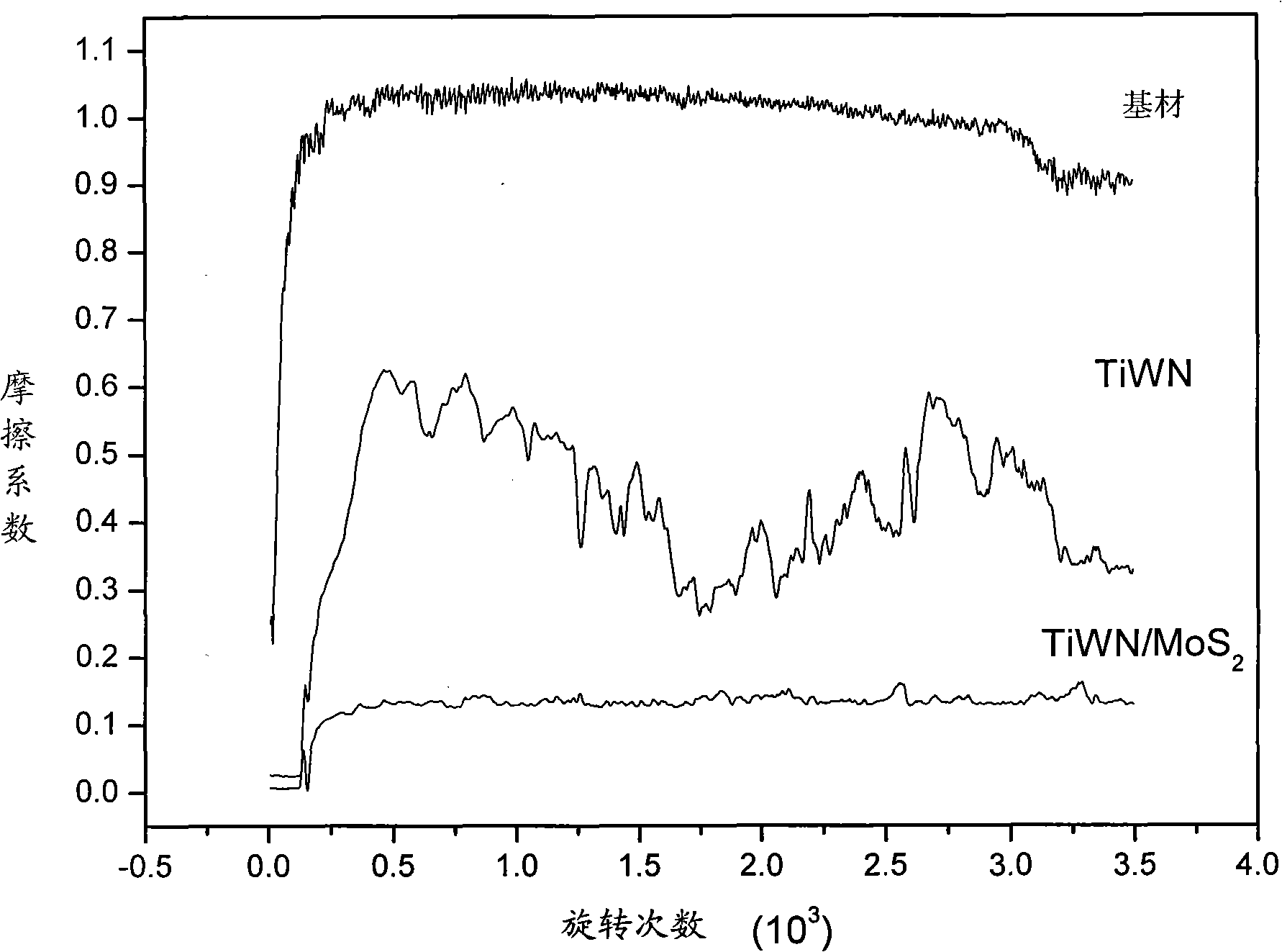

Method for preparing TiWN/MoS2 composite film

InactiveCN102094172BHas lubricating and antifriction effectGood wear resistance and antifriction performanceVacuum evaporation coatingSputtering coatingSputteringComposite film

The invention discloses a method for preparing a TiWN / MoS2 composite film, which comprises the following steps of: with a Ti target, a W target and a MoS2 target as raw materials, under the protection of nitrogen and / or argon, sequentially sputtering on a base material after surface finishing and cleaning with a magnetron sputtering method to obtain a TiWN film and a MoS2 film, thereby obtaining a TiWN / MoS2 composite film, wherein the TiWN film is a hard film, and the MoS2 film is a soft film for protecting the hard film. The composite film has good properties of antifriction and wear resistance and can be used as a protective coating of a machinery part to play roles in increasing the mechanical property and prolonging the service life. Moreover, the requirements for production conditions are low, the process is simple, the cost is low, the yield is high, and the composite film is suitable for large-scale industrial production.

Owner:无锡润鹏复合新材料有限公司

Method for preparing compound powder used for abrasion-resistant self-lubricating coating

InactiveCN101717928BEvenly distributedGood wear resistance and antifriction performanceLiquid/solution decomposition chemical coatingChemical platingMetallurgy

The invention discloses a method for preparing a compound powder used for an abrasion-resistant self-lubricating coating, belonging to the technical field of material preparation and comprising the following steps of: adopting a chemical plating process to coat Ag on the surface of a WC-12Co powder; putting the powder to hot alkali liquor to remove oil; carrying out sensitizing treatment on the powder by an SnCl2 solution; carrying out activating treatment on the powder by using a PdCl2 solution; adding the powder to a reducing solution; then adding a silver-ammonia solution; stirring and mixing; regulating the pH value of the mixed solution by using ammonia water; taking out the powder after 5-60min; and washing clean with distilled water; and drying into the powder to obtain the compound powder used for the abrasion-resistant self-lubricating coating. The amount of Ag coated on the surface of the powder is changed through regulating the concentration of the silver-ammonia solution, the concentration of the reducing solution and the deposition time. The Ag / WC-12Co compound powder the Ag layer of which is even and compact can be prepared by utilizing the invention, thereby enabling the lubricating phase distribution in the prepared coating to be even and the abrasion resistance and anti-friction property to be excellent.

Owner:GRIPM ADVANCED MATERIALS CO LTD

Preparation method of nickel phosphorus/expanded graphite-polyester resin/polytetrafluoroethylene composite material

The invention provides a method for preparing a nickel phosphorus / expanded graphite-polyester resin / polytetrafluoroethylene composite material. The method comprises the following steps: firstly, preparing expanded graphite of which the surface is coated by a chemical nickel phosphorus cladding layer, secondly, filling a foamed nickel support with the expanded graphite, preparing an unsaturated polyester resin / polytetrafluoroethylene mixed solution, sufficiently filling pores of foamed nickel filled with the expanded graphite with the unsaturated polyester resin / polytetrafluoroethylene mixed solution, and finally conducting room-temperature polymerization and later polishing and grinding, so as to obtain the nickel phosphorus / expanded graphite-polyester resin / polytetrafluoroethylene composite material. In the preparation process of the nickel phosphorus / expanded graphite-polyester resin / polytetrafluoroethylene composite material, sufficient contact of the polyester resin and the expanded graphite of which the surface is coated by the nickel phosphorus cladding layer with polytetrafluoroethylene is ensured, so aggregation of the polytetrafluoroethylene and the expanded graphite is effectively avoided, furthermore, the wearing resistance of the polytetrafluoroethylene is greatly improved, the prepared composite material is small in friction coefficient, high in hardness, high in pressure resistance and good in wearing resistance, and has wide application prospects under high-frequency friction working conditions.

Owner:YANSHAN UNIV

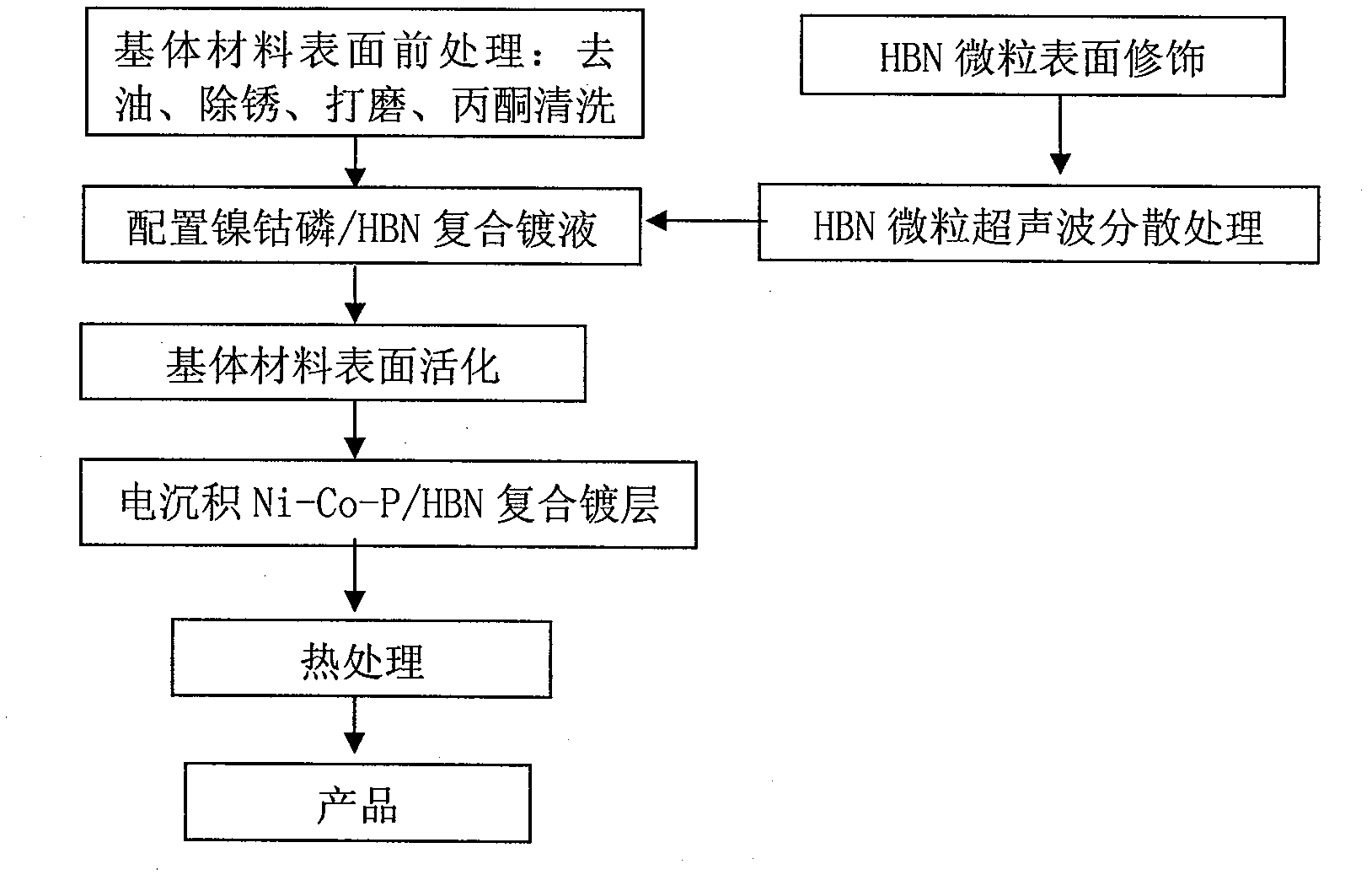

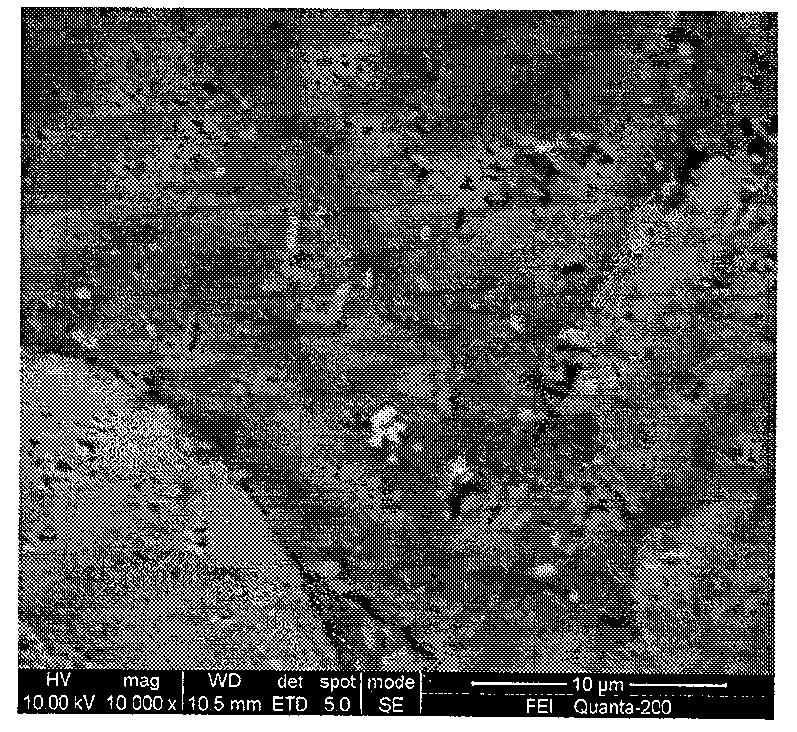

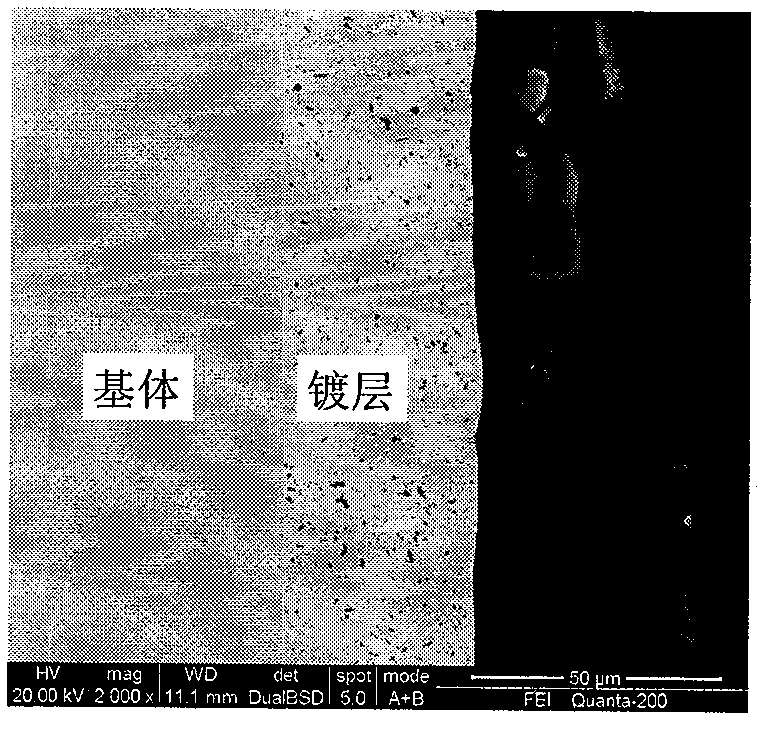

Pulse electrodeposited ni-co-p/hbn composite coating and its preparation method

InactiveCN102534732BImprove electrodeposition efficiencyEasy to useElectrolytic coatingsChemical industryPolyvinyl alcohol

A pulse electrodeposited Ni-Co-P / HBN composite coating and a preparation method thereof, which uses a metal material as a substrate, first pre-treats the surface of the substrate, and then mixes it with nickel sulfate, cobalt chloride, sodium hypophosphite, and citric acid , trisodium citrate, boric acid, and polyvinyl alcohol as the main components, and hexagonal boron nitride HBN powder as the dispersed phase of the composite plating solution. The HBN particles are surface-modified and dispersed with surfactants and ultrasonic vibrations. Through reasonable settings Pulse electrodeposition parameters, fully stirred to make HBN particles evenly dispersed in the plating solution, HBN particles and matrix metal nickel-cobalt-phosphorus co-deposition and heat treatment under the state of applying pulse current to obtain corrosion-resistant, wear-resistant and anti-friction pulse electrodeposited Ni- Co-P / HBN composite coating; it overcomes the shortcomings of existing composite coatings such as relatively single components, coarse coating grains, low interface bonding strength with the substrate, and unsatisfactory comprehensive performance of corrosion resistance, wear resistance and friction reduction; it is suitable for use as Wear-resistant and anti-friction and corrosion-resistant surface coatings for frictional motion parts in machinery, metallurgy, and chemical industries.

Owner:HUNAN UNIV OF SCI & TECH

Preparation method of molybdenum disulfide-nickel phosphorus-polytetrafluoroethylene composite material

Owner:YANSHAN UNIV

Preparation method of molybdenum disulfide-graphite oxide-nickel phosphorus-polytetrafluoroethylene composite material

The invention belongs to the technical field of self-lubricating materials, and relates to a preparation method of a molybdenum disulfide-graphite oxide-nickel phosphorus-polytetrafluoroethylene composite material, and the method comprises the following steps: S1, performing plasma treatment on polytetrafluoroethylene powder, and after irradiation for 60-120 seconds, putting the polytetrafluoroethylene powder for standing for 15-30 minutes in air; S2, performing pretreatment on graphite powder, S3, performing sensitization and activation treatment on the polytetrafluoroethylene powder, to be more specific, after wetting of the polytetrafluoroethylene powder treated by plasma with absolute ethanol, respectively performing sensitization and activation on the polytetrafluoroethylene powder; S4, preparing graphite-nickel phosphorus-polytetrafluoroethylene composite powder, S5, preparing graphite oxide-nickel phosphorus-polytetrafluoroethylene composite material powder, and S6, preparing the molybdenum disulfide-graphite oxide-nickel phosphorus-polytetrafluoroethylene composite material, to be more specific, first, molybdenum disulfide-graphite oxide-nickel phosphorus-polytetrafluoroethylene composite material powder is prepared, and the molybdenum disulfide-graphite oxide-nickel phosphorus-polytetrafluoroethylene composite material powder is molded to obtain the wear resistant andantifriction molybdenum disulfide-graphite oxide-nickel phosphorus-polytetrafluoroethylene composite material.

Owner:YANSHAN UNIV

A kind of wear-resistant delta-tan thin film and its preparation method and application

ActiveCN108977767BReduce control difficultyIncrease profitVacuum evaporation coatingSputtering coatingNitrogen gasRadio frequency

The invention relates to a wear-resistant delta-TaN film, and a preparation method and application thereof, and belongs to the technical field of wear-resistant material design and preparation. A texture coefficient I(200) / [I(200) + I(111)] of the delta-TaN film is 0.2 to 0.8; the crystal structure of the film is delta-TaN of an NaCl crystal form. In the film, an atomic ratio of Ta / N is about 0.72 to 1.33. The preparation method comprises the following steps: using radio frequency reactive magnetron sputtering, using nitrogen and argon as working gases, using a tantalum target as a tantalumsource, and fixing a flow ratio of nitrogen and argon; adjusting a grain texture coefficient of the film by changing working pressure and / or tantalum target power. The application of the resulting filmincludes use as a cutting device, a diffusion impervious layer for electronic packaging, and the like. The invention opens up a new method for controlling the grain texture coefficient of the film; an obtained product is excellent in performance and is convenient for high-precision and large-scale generation and application.

Owner:HUNAN UNIV

Galvanic deposit composite plating method and plating solution for oil casing coupling screw thread

The invention relates to an electro-deposition composite plating method of oil-sleeve collar-joint screw-threads and a plating solution thereof. The method includes the following steps: a composite plating solution comprises surfactant mixed solution and alkalescence plating solution with the usage ratio of 10g to 60g:1L, wherein the surfactant mixed solution comprises fatty alcohol-polyxyethylene ether and polytetrafluoroethylene latex with the weight ratio of 1: 20 to 1: 50. Self-lubricating composite plating obtained on the screw surface of the nickel-base alloy oil-sleeve collar-joint by the method and the plating solution of the invention has good wear resistance and antifriction performance and can improve the pick resistance of the oil-sleeve collar-joint.

Owner:BAOSHAN IRON & STEEL CO LTD

Galvanic deposit composite plating method and plating solution for oil casing coupling screw thread

ActiveCN101353808AUniform particle distributionGood wear resistance and antifriction performanceChemistryEther

The invention relates to an electro-deposition composite plating method of oil-sleeve collar-joint screw-threads and a plating solution thereof. The method includes the following steps: a composite plating solution comprises surfactant mixed solution and alkalescence plating solution with the usage ratio of 10g to 60g:1L, wherein the surfactant mixed solution comprises fatty alcohol-polyxyethylene ether and polytetrafluoroethylene latex with the weight ratio of 1: 20 to 1: 50. Self-lubricating composite plating obtained on the screw surface of the nickel-base alloy oil-sleeve collar-joint by the method and the plating solution of the invention has good wear resistance and antifriction performance and can improve the pick resistance of the oil-sleeve collar-joint.

Owner:BAOSHAN IRON & STEEL CO LTD

A kind of powder metallurgy diamond wheel and its preparation method

ActiveCN109868422BUniform compositionComposition controllablePortable liftingGearing elementsReducerMaterials processing

The invention discloses a powder metallurgy circular spline which adopts less machining / free-of-machining, can be self-lubricated in the working process and is used for a harmonic reducer, and a preparation method of the powder metallurgy circular spline. The preparation method adopts a powder metallurgy method and comprises the procedures of preparation of powder with high composition uniformity,pressing, sintering, aftertreatment and the like. The powder metallurgy circular spline prepared from the preparation method has the advantages of being uniform in composition, good in abrasion resistance and anti-friction property, low in noise, long in life, less in machining / free of machining, low in cost and the like, and can replace a circular spline currently machined and prepared from materials such as steel and cast iron.

Owner:GRIPM ADVANCED MATERIALS CO LTD

Preparation method of wear-resistant and anti-friction coating with highly dispersed lubricating phase

ActiveCN109457211BReduce porosityHigh hardnessMolten spray coatingThermal sprayingPhysical chemistry

The invention relates to a preparation method of a wear-resistant anti-friction coating with a highly dispersed and distributed lubricating phase. According to the preparation method, powder such as Ni-C, AlSi-polyphenyl ester and NiCr-BN-MoS2 which have the self-lubricating property is used as a raw material, and an internal powder feeding high-energy plasma spraying method is adopted for formingthe wear-resistant anti-friction coating on a metal substrate. According to the preparation method, through reasonable thermal spraying process parameters, the spraying technological process is strictly controlled, the porosity of the coating is reduced, the hardness and the bonding force are improved, the comprehensive mechanical properties are greatly improved, the wear-resisting anti-frictionperformance is obviously optimized, and the work service life of turbomachinery is effectively prolonged.

Owner:XI AN JIAOTONG UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com