Method for preparing compound powder used for abrasion-resistant self-lubricating coating

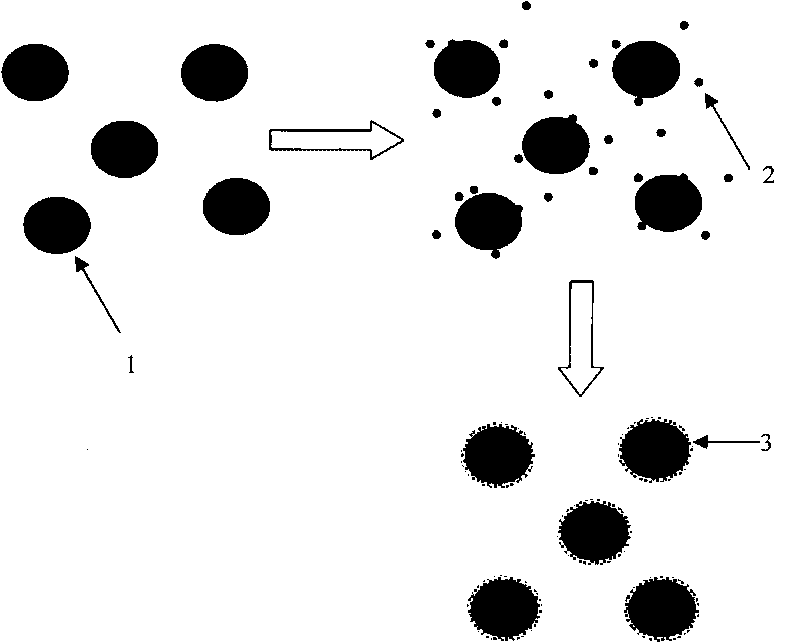

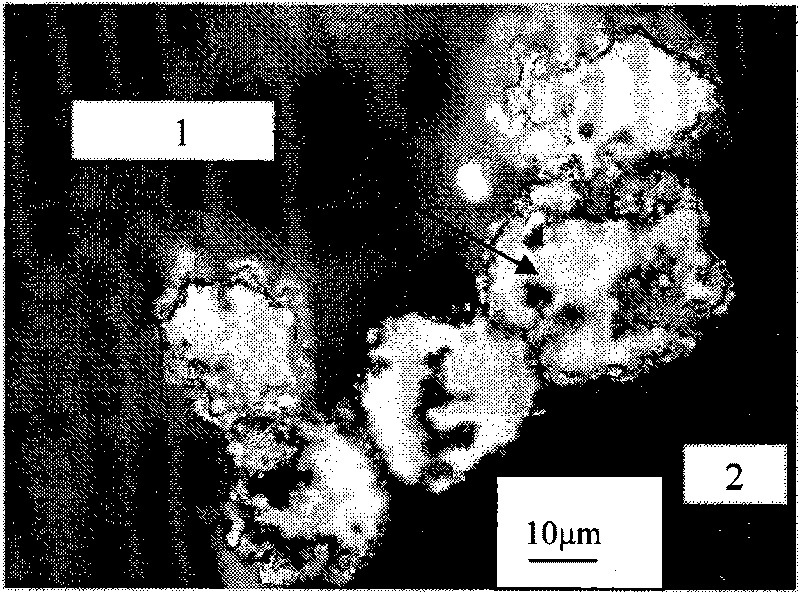

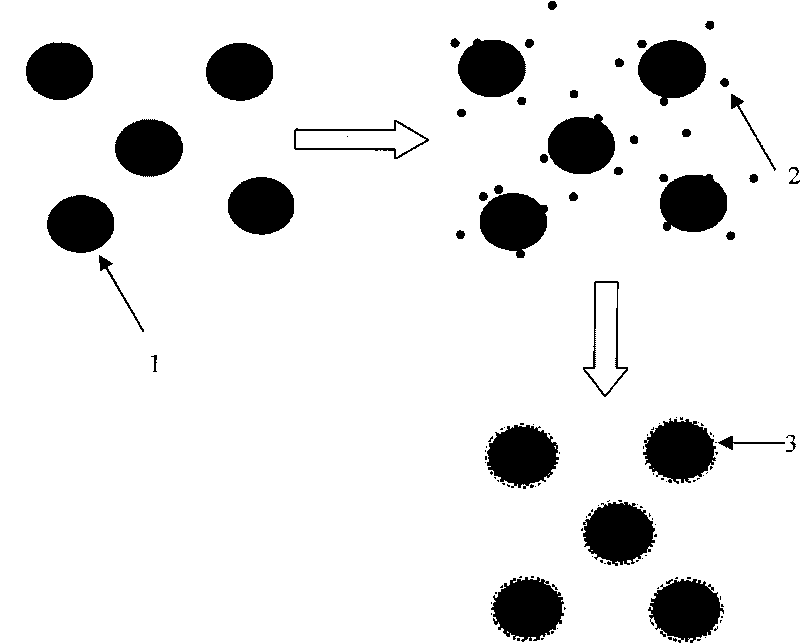

A self-lubricating coating, composite powder technology, applied in the coating, metal material coating process, liquid chemical plating and other directions, can solve the problems of increasing difficulty, difficult temperature control, inability to mix, etc., to achieve wear resistance and friction reduction Excellent performance and uniform distribution of lubricating phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation method of a composite powder for wear-resistant self-lubricating coating, adopting an electroless plating process to coat Ag on the surface of WC-12Co powder, the preparation method is as follows:

[0028] (1) Weigh 40 g of spray granulated WC-12Co powder with a particle size of 20 to 40 microns, and wash it with distilled water for 3 to 4 times;

[0029] (2) Preparation of lye, with NaOH, Na 2 CO 3 、Na 3 PO 4 and distilled water as raw materials, NaOH: 10g, Na 2 CO 3 : 15g and Na 3 PO4 : Put 15g into a beaker, add distilled water to 500ml to prepare lye, then heat the lye to 60-70°C, pour WC-12Co powder into the lye, stir, cook for 20 minutes to remove oil, and wash with distilled water Powder 5-6 times, wash clean;

[0030] (3) Prepare the sensitization solution, with concentrated hydrochloric acid, SnCl 2 With distilled water as raw material, 40ml of concentrated hydrochloric acid with a concentration of 37% is dropped into a beaker, and 15g of ...

Embodiment 2

[0037] A preparation method of a composite powder for wear-resistant self-lubricating coating, adopting an electroless plating process to coat Ag on the surface of WC-12Co powder, the preparation method is as follows:

[0038] (1) Weigh 40 g of spray granulated WC-12Co powder with a particle size of 20 to 40 microns, and wash it with distilled water for 3 to 4 times;

[0039] (2) Preparation of lye, with NaOH, Na 2 CO 3 、Na 3 PO 4 And distilled water as raw material, NaOH: l 0g, Na 2 CO 3 : 15g and Na 3 PO 4 : Put 15g into a beaker, add distilled water to 500ml to prepare lye, then heat the lye to 60-70°C, pour WC-12Co powder into the lye, stir, cook for 20 minutes to remove oil, and wash with distilled water Clean the powder 5-6 times;

[0040] (3) Prepare the sensitization solution, with concentrated hydrochloric acid, SnCl 2 With distilled water as raw material, 40ml of concentrated hydrochloric acid with a concentration of 37% is dropped into a beaker, and 15g of ...

Embodiment 3

[0047] A preparation method of a composite powder for wear-resistant self-lubricating coating, adopting an electroless plating process to coat Ag on the surface of WC-12Co powder, the preparation method is as follows:

[0048] (1) Weigh 40 g of spray granulated WC-12Co powder with a particle size of 20 to 40 microns, and wash it with distilled water for 3 to 4 times;

[0049] (2) Preparation of lye, with NaOH, Na 2 CO 3 、Na 3 PO 4 and distilled water as raw materials, NaOH: 10g, Na 2 CO 3 : 15g and Na 3 PO 4 : Put 15g into a beaker, add distilled water to 500ml to prepare lye, then heat the lye to 60-70°C, pour WC-12Co powder into the lye, stir, cook for 20 minutes to remove oil, and wash with distilled water Clean the powder 5-6 times;

[0050] (3) Prepare the sensitization solution, with concentrated hydrochloric acid, SnCl 2 With distilled water as raw material, 40ml of concentrated hydrochloric acid with a concentration of 37% is dropped into a beaker, and 15g of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com