Polyether-ether-ketone/nanometer zinc oxide/carbon fiber wear-resistant composite material and preparation method thereof, and application of composite material to mechanical polishing of retaining rings

A technology of nano-zinc oxide and polyetheretherketone, which is applied in the direction of the working carrier, can solve the problems of high friction coefficient of pure polyetheretherketone, flaky particles falling off, thermoplastic deformation, etc., and achieve reduced roughness and low friction coefficient and wear rate, the effect of reducing the friction coefficient and wear rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1: Preparation of 10wt% polyethersulfone-coated carbon fiber / 2.5wt% KH550-ZnO / PEEK wear-resistant composite material

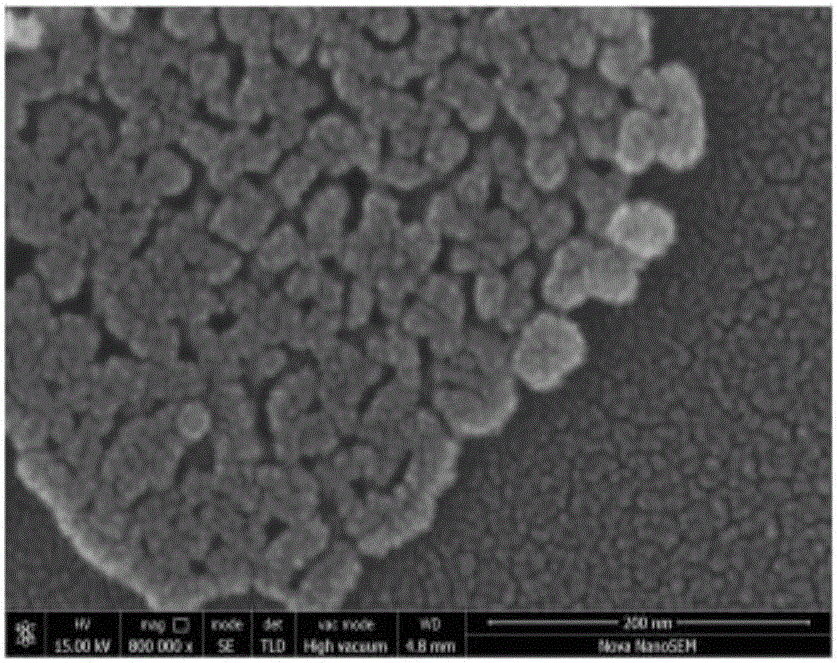

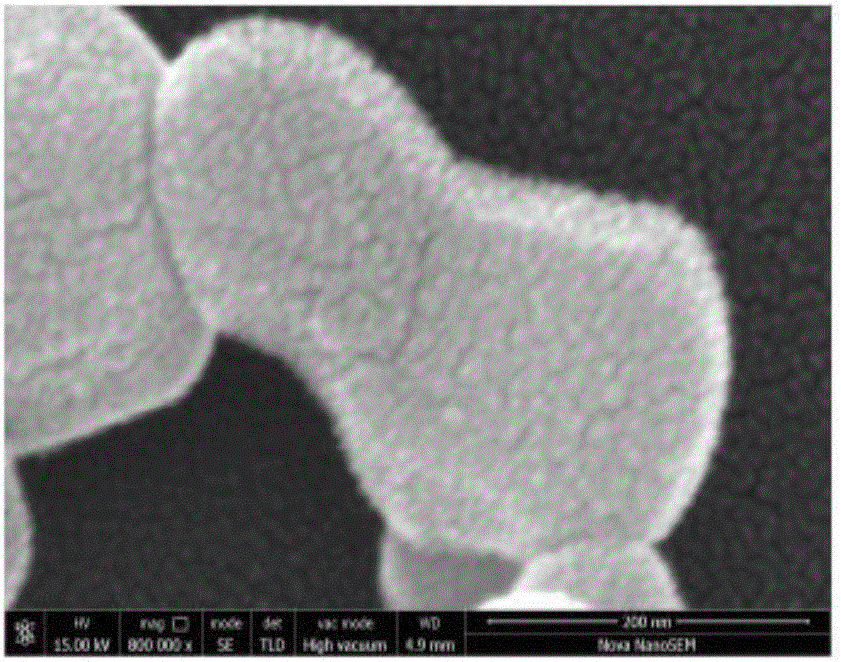

[0032] Add 0.1g of KH550 into 50mL of absolute ethanol, stir mechanically for 5min, then adjust the pH value of the mixture to 6 with acetic acid, add 3g of zinc oxide nanoparticles, ultrasonically disperse for 1h, and then reflux at 78°C for 4.5 hours. Suction filtration, washing 3 times with absolute ethanol, and drying at 70°C to obtain KH550 modified zinc oxide nanoparticles;

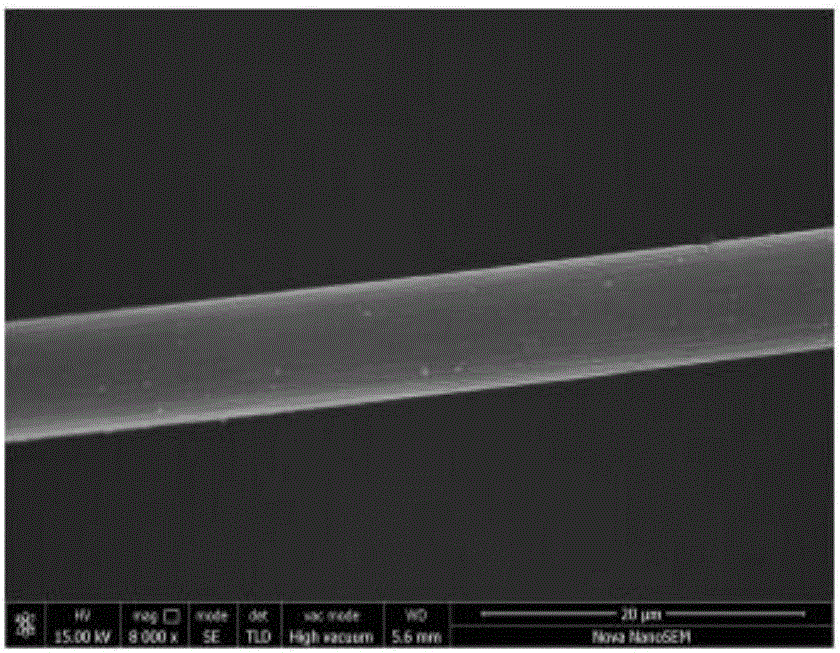

[0033] 0.5g polyethersulfone (viscosity value is 0.38dLg -1 ) into 15mL of N,N-dimethylacetamide, and magnetically stirred until completely dissolved to obtain a mixed solution. Add 10g of carbon fiber into 500mL N,N-dimethylacetamide, stir mechanically for 1h, then pour the above N,N-dimethylacetamide solution dissolved in polyethersulfone, and continue mechanically stirring for 2h. Then the resulting mixture was poured into ethanol, filtered with suction, washed t...

Embodiment 2

[0035] Example 2: Preparation of 10wt% polyethersulfone-coated carbon fiber / 5.0wt% KH550-ZnO / PEEK wear-resistant composite material

[0036] Add 0.2g of KH550 into 90mL of absolute ethanol, stir mechanically for 5min, then adjust the pH value of the mixture to 6 with acetic acid, add 5g of zinc oxide nanoparticles, ultrasonically disperse for 1h, and reflux at 78°C for 4.5 hours. Filter, wash with absolute ethanol, and dry to obtain KH550 modified zinc oxide nanoparticles.

[0037]Add 0.5g of polyethersulfone into 15mL of N,N-dimethylacetamide, and magnetically stir until completely dissolved to obtain a mixed solution. Add 10g of carbon fiber into 500mL N,N-dimethylacetamide, stir mechanically for 1h, then pour the above N,N-dimethylacetamide solution dissolved in polyethersulfone, and continue mechanically stirring for 2h. Then pour the obtained mixed solution into ethanol to obtain polyethersulfone-coated carbon fibers, and after suction filtration, wash with absolute etha...

Embodiment 3

[0039] Example 3: Preparation of 10wt% polyethersulfone-coated carbon fiber / 7.5wt% KH550-ZnO / PEEK wear-resistant composite material

[0040] Add 0.28g of KH550 to 150mL of absolute ethanol, stir mechanically for 5min, then adjust the pH value of the mixture to 6 with acetic acid, add 8g of zinc oxide nanoparticles, ultrasonically disperse for 1h, and reflux at 78°C for 4.5 hours. Filter, wash with absolute ethanol, and dry to obtain KH550 modified zinc oxide nanoparticles.

[0041] Add 0.5g of polyethersulfone into 15mL of N,N-dimethylacetamide, and magnetically stir until completely dissolved to obtain a mixed solution. Add 10g of carbon fiber into 500mL N,N-dimethylacetamide, stir mechanically for 1h, then pour the above N,N-dimethylacetamide solution dissolved in polyethersulfone, and continue mechanically stirring for 2h. Then pour the obtained mixed solution into ethanol to obtain polyethersulfone-coated carbon fibers, and after suction filtration, wash with absolute eth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com