Preparation method of wear-resistant and anti-friction coating with highly dispersed lubricating phase

A dispersion distribution and anti-friction coating technology, which is applied in the coating, metal material coating process, fusion spraying, etc., can solve the problem of low coating strength and bonding strength, which cannot meet the requirements of turbomachinery. Affect the anti-friction and wear resistance of the coating, etc., to achieve the effect of optimizing the anti-friction performance, excellent bonding strength, and improving the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of the wear-resistant anti-friction coating with highly dispersed lubricating phase of the present invention includes the following steps:

[0032] 1) Pre-treat the surface of the substrate before spraying.

[0033] 2) Pre-heat treatment of the pre-treated substrate.

[0034] 3) Adopting internal powder feeding high-energy plasma spraying method to spray raw materials on the surface of the preheated substrate to prepare anti-friction and wear-resistant coating.

[0035] 4) Machining and polishing the surface of the metal parts after spraying.

[0036] The specific process of the pre-treatment in the step 1) is: firstly perform degreasing and decontamination and grinding and rust removal, then use acetone ultrasonic cleaning, after cleaning, put it in a drying box for drying, and finally use white corundum (#24) Sandblasting.

[0037] In the step 2), the spray gun is used for preheating, and the temperature is controlled at about 80-100°C.

[0038] The proces...

Embodiment 1

[0041] This embodiment uses Q235 carbon structural steel as the matrix, the size is 45×20×5mm, and the mass percentage is: ≤0.22% of C, ≤1.0% of Si, ≤1.4% of Mn, ≤0.044% of P, ≤0.35 % Si, ≤0.05% S, and the balance is Fe.

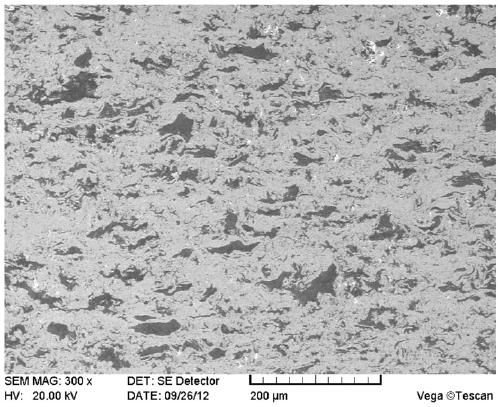

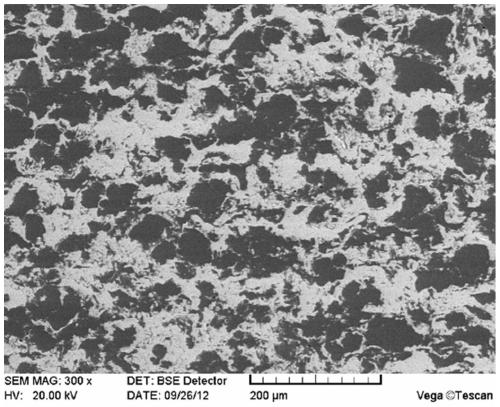

[0042] The coating is a high wear-resistant coating with a thickness of 1.6mm on the substrate surface, and the coating material is nickel-coated graphite powder.

[0043] The particle size of the Ni-C powder (nickel-coated graphite powder) ranges from 30 to 150 μm; in terms of weight percentage, the Ni content is 75 wt%, and the C content is 25 wt%.

[0044] The specific implementation steps for preparing a wear-resistant anti-friction coating with a highly dispersed lubricating phase are as follows:

[0045] 1) Pretreatment of substrate surface

[0046] The surface of the Q235 carbon structural steel used as the base material is first degreasing, decontamination, sanding and rust removal, and then ultrasonically cleaned with acetone. After cleaning, it is placed in...

Embodiment 2

[0052] This embodiment uses Q235 carbon structural steel as the matrix, the size is 45×20×5mm, and the mass percentage is: ≤0.22% of C, ≤1.0% of Si, ≤1.4% of Mn, ≤0.044% of P, ≤0.35 % Si, ≤0.05% S, and the balance is Fe.

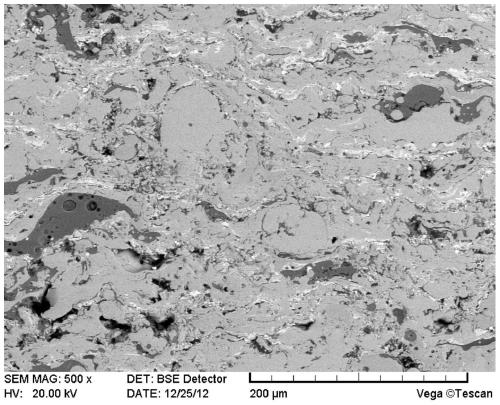

[0053] The coating is a high wear-resistant coating with a thickness of 1.8mm on the substrate surface, and the coating material is AlSi and polyphenylene resin composite powder.

[0054] The particle size of the AlSi and polyphenylene resin composite powder (AlSi-polyphenylene resin powder) ranges from 20 to 100 μm; in terms of weight percentage, the AlSi content is 60wt%, and the polyphenylene resin content is 40wt%.

[0055] The specific implementation steps for preparing a wear-resistant anti-friction coating with a highly dispersed lubricating phase are as follows:

[0056] 1) Pretreatment of substrate surface

[0057] The surface of the Q235 carbon structural steel sheet as the base material is first degreasing, decontamination and grinding and derusting, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com