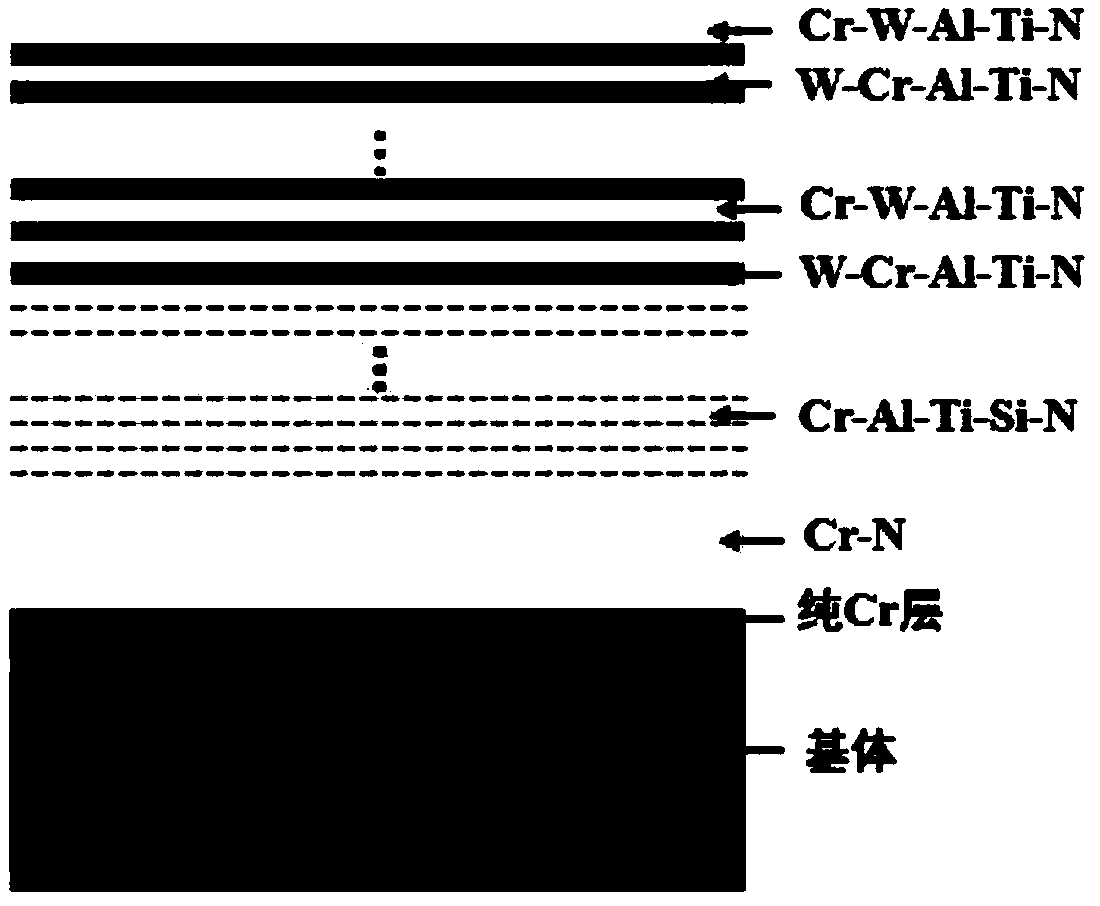

Ultra-hard W-Cr-Al-Ti-N nano gradient multilayer film material and preparation method thereof

An al-ti-si, multi-layer film technology, applied in the field of metal surface coating, can solve the problems of low hardness, poor coating toughness, weak film-base bonding force, etc., to improve the hardness and improve the film-base bonding force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A preparation method of a superhard W-Cr-Al-Ti-N nanometer gradient multilayer film material, which comprises the following steps:

[0036] (1) Sample treatment: After rough grinding, fine grinding, rough polishing, and fine polishing of the metal matrix sample on metallographic sandpaper, it was cleaned ultrasonically in acetone for 10 minutes, and then ultrasonically cleaned twice with ethanol. Take out and dry;

[0037] (2) Equipment preparation: a multi-arc ion coating machine is used, and the target materials are 3 W simple substance targets with a purity of 99.99%, 3 Cr simple substance targets with a purity of 99.99%, 1 Al-Ti alloy target and 1 Al-Ti-Si alloy target, the working gas is Ar gas with a purity of 99.99%. After loading the sample treated in step (1) into the furnace, adjust the rotation speed of the sample holder to 3rpm, heat the temperature of the deposition chamber to 450°C, and pump Vacuum to ≤4×10 -3 After Pa, pass Ar gas and carry out ion bomb...

Embodiment 2

[0045] A preparation method of a superhard W-Cr-Al-Ti-N nanometer gradient multilayer film material, which comprises the following steps:

[0046] (1) Sample treatment: After rough grinding, fine grinding, rough polishing, and fine polishing of the metal matrix sample on metallographic sandpaper, it was cleaned ultrasonically in acetone for 10 minutes, and then ultrasonically cleaned twice with ethanol. Take out and dry;

[0047] (2) Equipment preparation: a multi-arc ion coating machine is used, and the target materials are 3 W simple substance targets with a purity of 99.99%, 3 Cr simple substance targets with a purity of 99.99%, 1 Al-Ti alloy target and 1 Al-Ti-Si alloy target, the working gas is Ar gas with a purity of 99.99%. After loading the sample treated in step (1) into the furnace, adjust the rotation speed of the sample holder to 3rpm, heat the temperature of the deposition chamber to 450°C, and pump Vacuum to ≤4×10 -3 After Pa, pass Ar gas and carry out ion bomb...

Embodiment 3

[0054] A preparation method of a superhard W-Cr-Al-Ti-N nanometer gradient multilayer film material, which comprises the following steps:

[0055] (1) Sample treatment: After rough grinding, fine grinding, rough polishing, and fine polishing of the metal matrix sample on metallographic sandpaper, it was cleaned ultrasonically in acetone for 10 minutes, and then ultrasonically cleaned twice with ethanol. Take out and dry;

[0056] (2) Equipment preparation: a multi-arc ion coating machine is used, and the target materials are 3 W simple substance targets with a purity of 99.99%, 3 Cr simple substance targets with a purity of 99.99%, 1 Al-Ti alloy target and 1 Al-Ti-Si alloy target, the working gas is Ar gas with a purity of 99.99%. After loading the sample treated in step (1) into the furnace, adjust the rotation speed of the sample holder to 3rpm, heat the temperature of the deposition chamber to 450°C, and pump Vacuum to ≤4×10 -3 After Pa, pass Ar gas and carry out ion bomb...

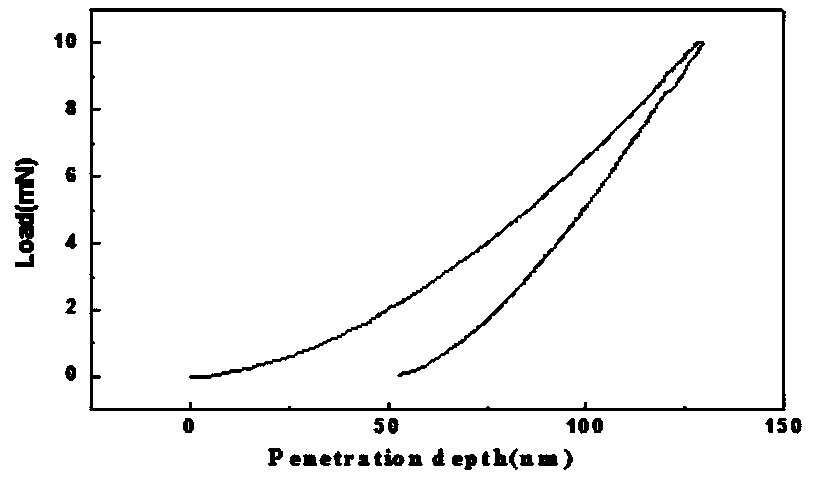

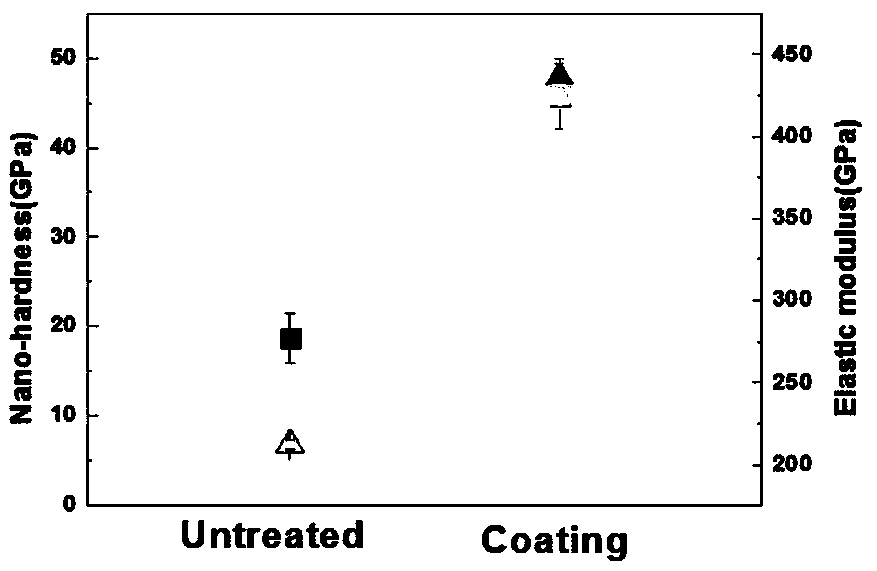

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| elasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com