Ceramic composite material as well as preparation method and application thereof

A ceramic composite material and raw material technology, applied in the field of material processing, can solve problems such as low efficiency, reduced processing efficiency, and poor temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1 proposes a ceramic composite material, including the following raw materials in parts by weight: 80 parts of silicon nitride, 12 parts of yttrium oxide, 3 parts of aluminum oxide, 3 parts of titanium carbide and 0.5 part of ytterbium nitride.

[0026] The preparation method of the ceramic composite material of embodiment 1, comprises the steps:

[0027] (1) The raw materials are mixed and ball milled for 44 hours, then dried and passed through a 200-mesh sieve.

[0028] (2) Preparing the raw material processed in step (1) according to the preset size to prepare a green mold.

[0029] (3) Prepare a graphite mold according to a predetermined size, and then put the green blank mold into the graphite mold.

[0030] (4) Put the graphite mold processed in the step (3) into a hot-press sintering furnace, first raise the temperature to 980°C at a heating rate of 10°C / min, and then increase the temperature at a heating rate of 7°C / min The temperature was raised to 15...

Embodiment 2

[0033] Example 2 proposes a ceramic composite material, including the following raw materials in parts by weight: 90 parts of silicon nitride, 8 parts of yttrium oxide, 5 parts of aluminum oxide, 1 part of titanium carbide and 1.5 parts of ytterbium nitride.

[0034] The preparation method of the ceramic composite material of embodiment 2, comprises the steps:

[0035] (1) The raw materials are mixed and ball milled for 50 hours, then dried and passed through a 300-mesh sieve.

[0036] (2) Preparing the raw material processed in step (1) according to the preset size to prepare a green mold.

[0037] (3) Prepare a graphite mold according to a predetermined size, and then put the green blank mold into the graphite mold.

[0038] (4) Put the graphite mold processed in the step (3) into a hot press sintering furnace, first raise the temperature to 1200°C at a heating rate of 6°C / min, and then at a heating rate of 3°C / min The temperature was raised to 1620°C, and at the same time...

Embodiment 3

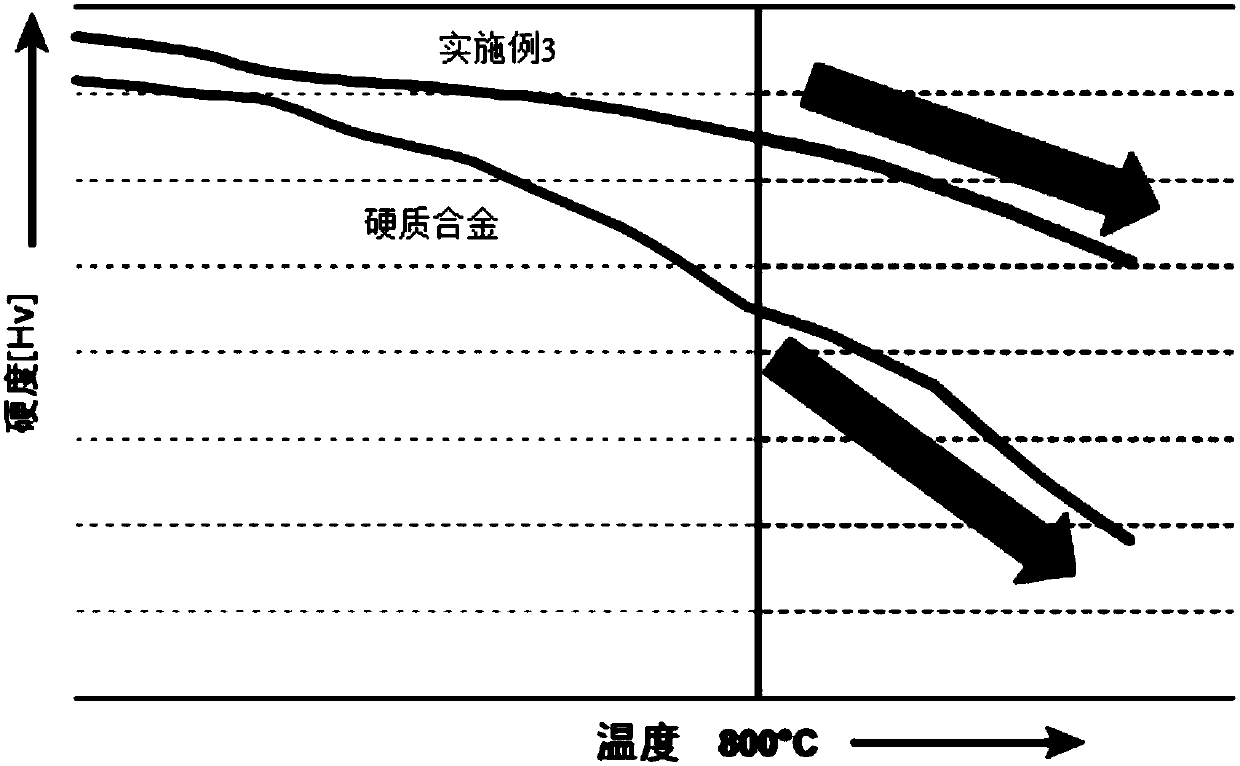

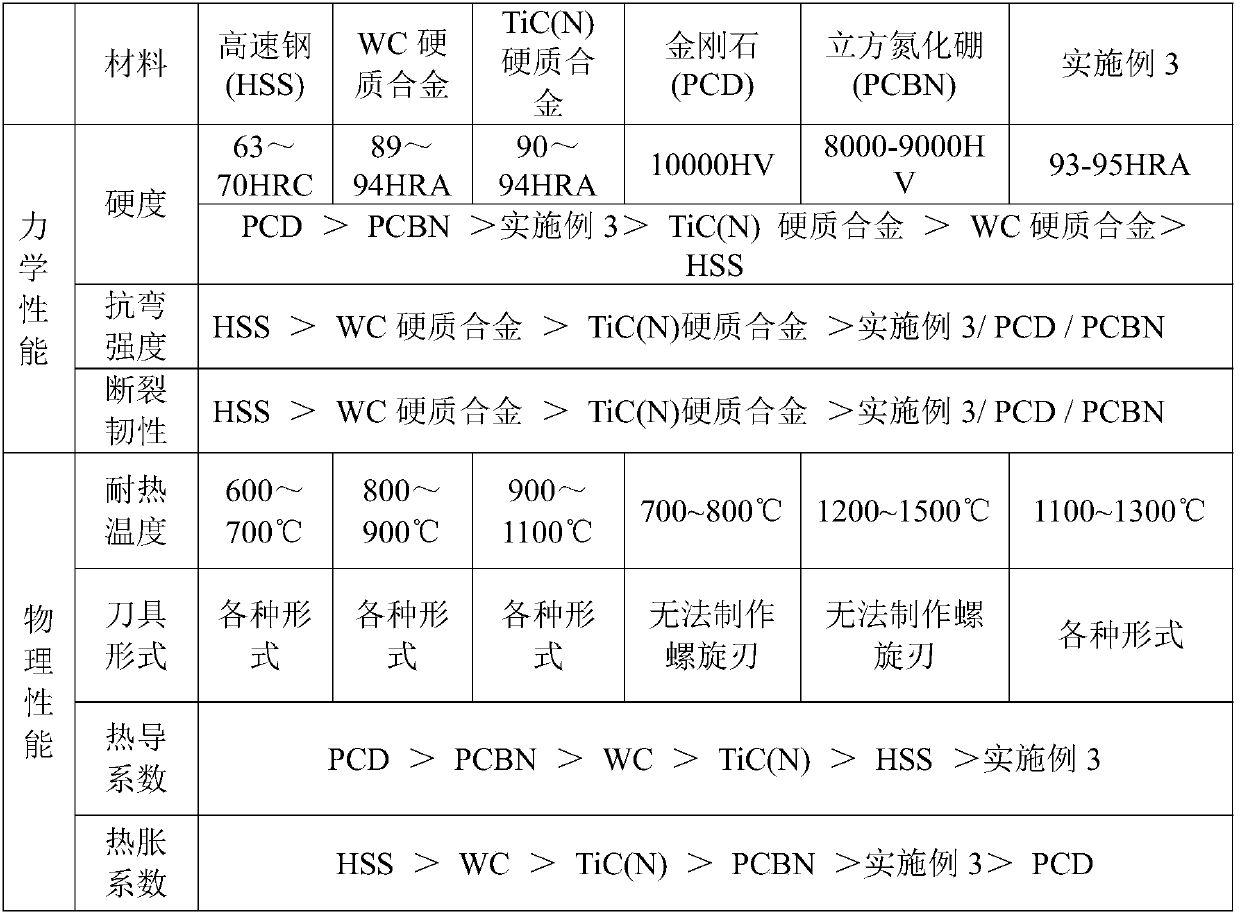

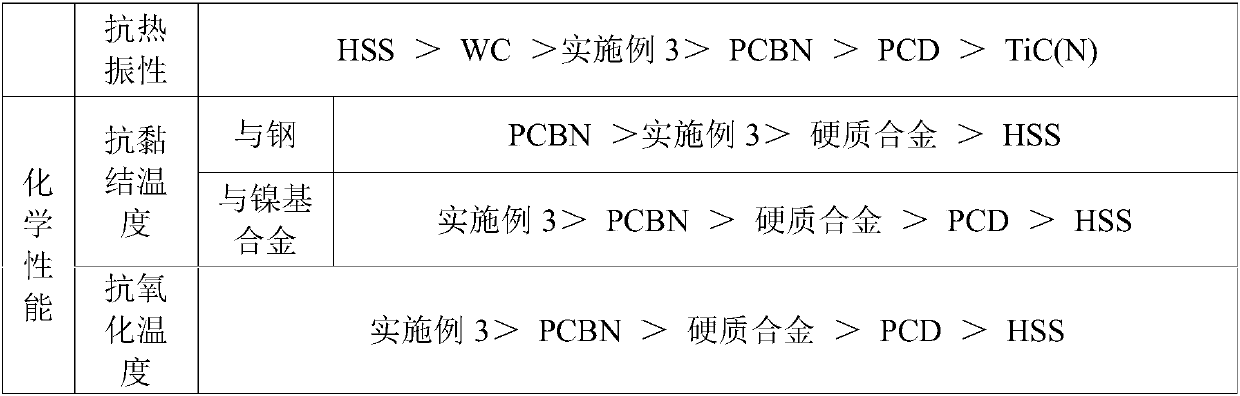

[0041] Example 3 proposes a ceramic composite material, including the following raw materials in parts by weight: 85 parts of silicon nitride, 10 parts of yttrium oxide, 4 parts of aluminum oxide, 2 parts of titanium carbide and 1 part of ytterbium nitride.

[0042] The preparation method of the ceramic composite material of embodiment 3, comprises the steps:

[0043] (1) The raw materials are mixed and ball milled for 48 hours, then dried and passed through a 250-mesh sieve.

[0044] (2) Preparing the raw material processed in step (1) according to the preset size to prepare a green mold.

[0045] (3) Prepare a graphite mold according to a predetermined size, and then put the green blank mold into the graphite mold.

[0046] (4) Put the graphite mold processed in the step (3) into a hot press sintering furnace, first raise the temperature to 1000°C at a heating rate of 8°C / min, and then increase the temperature at a heating rate of 5°C / min The temperature was raised to 1600...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com