One-step method for preparing black titanium oxide/alumina composite ceramic coating

A technology of composite ceramics and titanium oxide, applied in coating, anodizing, surface reaction electrolytic coating, etc., to achieve the effects of low cost, simple process and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of black titanium oxide / alumina composite ceramic coating of the present invention is as follows:

[0028] The first step is to use Ti6Al4V titanium alloy as the base material and process it into a round bar-shaped part by machining means, then ultrasonically clean it with acetone, absolute ethanol and distilled water for 10 minutes, and dry it for later use;

[0029] The second step is to configure the electrolyte for micro-arc oxidation treatment, using 6g / L Na 2 SiO 3 , 5g / L (NaPO 3 ) 6 , 3g / L NaAlO 2 and 3g / L NH 4 VO 3 , and use NaOH to adjust the pH value of the electrolyte to 8-11, form the electrolyte for micro-arc oxidation and pour it into the micro-arc oxidation electrolytic cell;

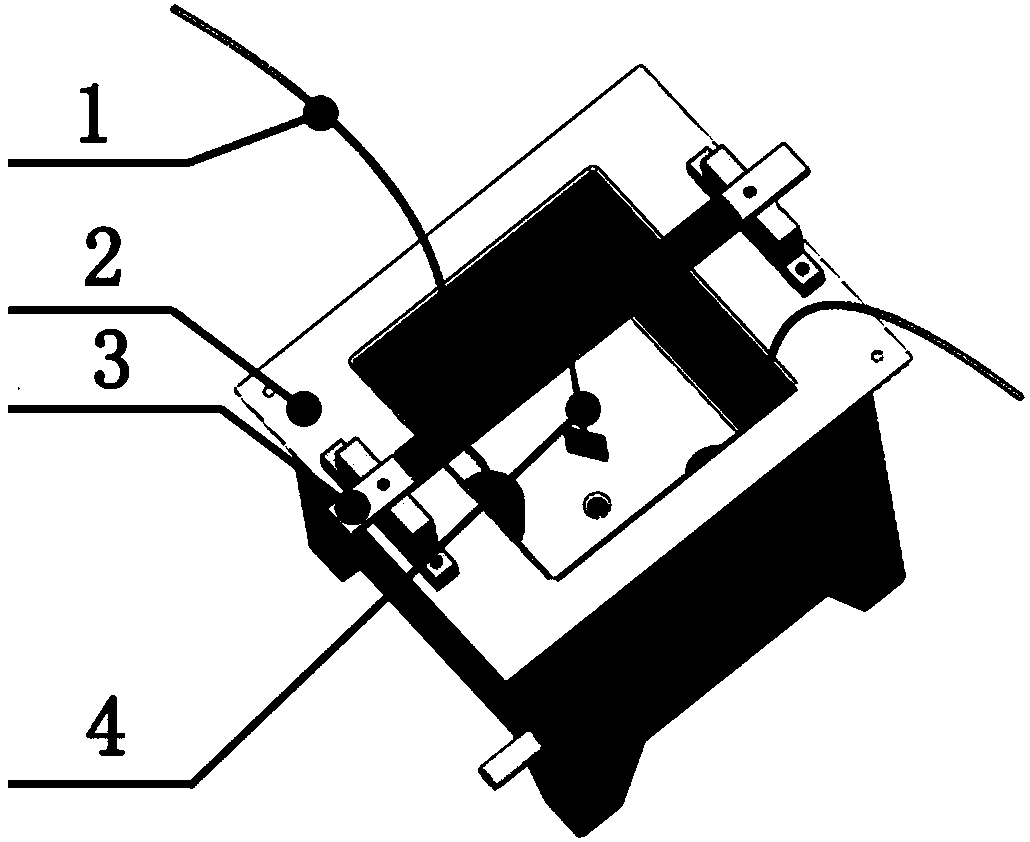

[0030] The third step is to hang the cleaned titanium alloy rod-shaped parts in the micro-arc oxidation electrolytic cell, connect the workpiece to the anode of the micro-arc oxidation power supply, connect the stainless steel electrolytic cell to the c...

Embodiment 2

[0033] The preparation method of black titanium oxide / alumina composite ceramic coating of the present invention is as follows:

[0034]The first step is to use Ti6Al4V titanium alloy as the base material and process it into a round bar-shaped part by machining means, then ultrasonically clean it with acetone, absolute ethanol and distilled water for 10 minutes, and dry it for later use;

[0035] The second step is to configure the electrolyte for micro-arc oxidation treatment, using 8g / L Na 2 SiO 3 , 10g / L (NaPO 3 ) 6 , 5g / L NaAlO 2 and 6g / L NH 4 VO 3 , and use NaOH to adjust the pH value of the electrolyte to 8-11, form the electrolyte for micro-arc oxidation and pour it into the micro-arc oxidation electrolytic cell;

[0036] The third step is to hang the cleaned titanium alloy rod-shaped parts in the micro-arc oxidation electrolytic cell, connect the workpiece to the anode of the micro-arc oxidation power supply, connect the stainless steel electrolytic cell to the c...

Embodiment 3

[0038] The preparation method of black titanium oxide / alumina composite ceramic coating of the present invention is as follows:

[0039] The first step is to use Ti6Al4V titanium alloy as the base material and process it into a round bar-shaped part by machining means, then ultrasonically clean it with acetone, absolute ethanol and distilled water for 10 minutes, and dry it for later use;

[0040] The second step is to configure the electrolyte for micro-arc oxidation treatment, using 5g / L Na 2 SiO 3 , 3g / L (NaPO 3 ) 6 , 8g / L NaAlO 2 and 8g / L NH 4 VO 3 , and use NaOH to adjust the pH value of the electrolyte to 8-11, form the electrolyte for micro-arc oxidation and pour it into the micro-arc oxidation electrolytic cell;

[0041] The third step is to hang the cleaned titanium alloy rod-shaped parts in the micro-arc oxidation electrolytic cell, connect the workpiece to the anode of the micro-arc oxidation power supply, connect the stainless steel electrolytic cell to the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com