A kind of high-strength tungsten-based alloy and its preparation method

A tungsten-based alloy and high-strength technology, which is applied in the field of high-strength tungsten-based alloys and their preparation, can solve problems such as difficulty in obtaining multi-principal alloys and less dendrite segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028]A high-strength tungsten-based alloy material with a mass fraction of FeNiCoCrAl of 10% was prepared. 1) Prepare FeNiCoCrAl (mole fraction) multi-principal alloy powder. The raw materials are high-purity iron, nickel, cobalt, chromium, aluminum and other bulk metal materials, which are melted into a multi-principal alloy melt at 1500 ° C. The melt is heated in high-purity argon FeNiCoCrAl multi-principal alloy powder (particle size: 10 microns) with a simple solid solution structure was atomized under air. 2) Weigh tungsten powder (with a particle size of 50 microns) and FeNiCoCrAl multi-principal alloy powder according to the mass fraction of 90% W and 10% FeNiCoCrAl multi-principal alloy powder. Time 8h, mix evenly, vacuum dry and sieve after ball milling, prepare W-FeNiCoCrMn x al y The composite powder (with a particle size of 40 microns) was then sintered in a vacuum hot-press sintering furnace at a sintering temperature of 1200° C., a pressure of 50 MPa, and a si...

Embodiment 2

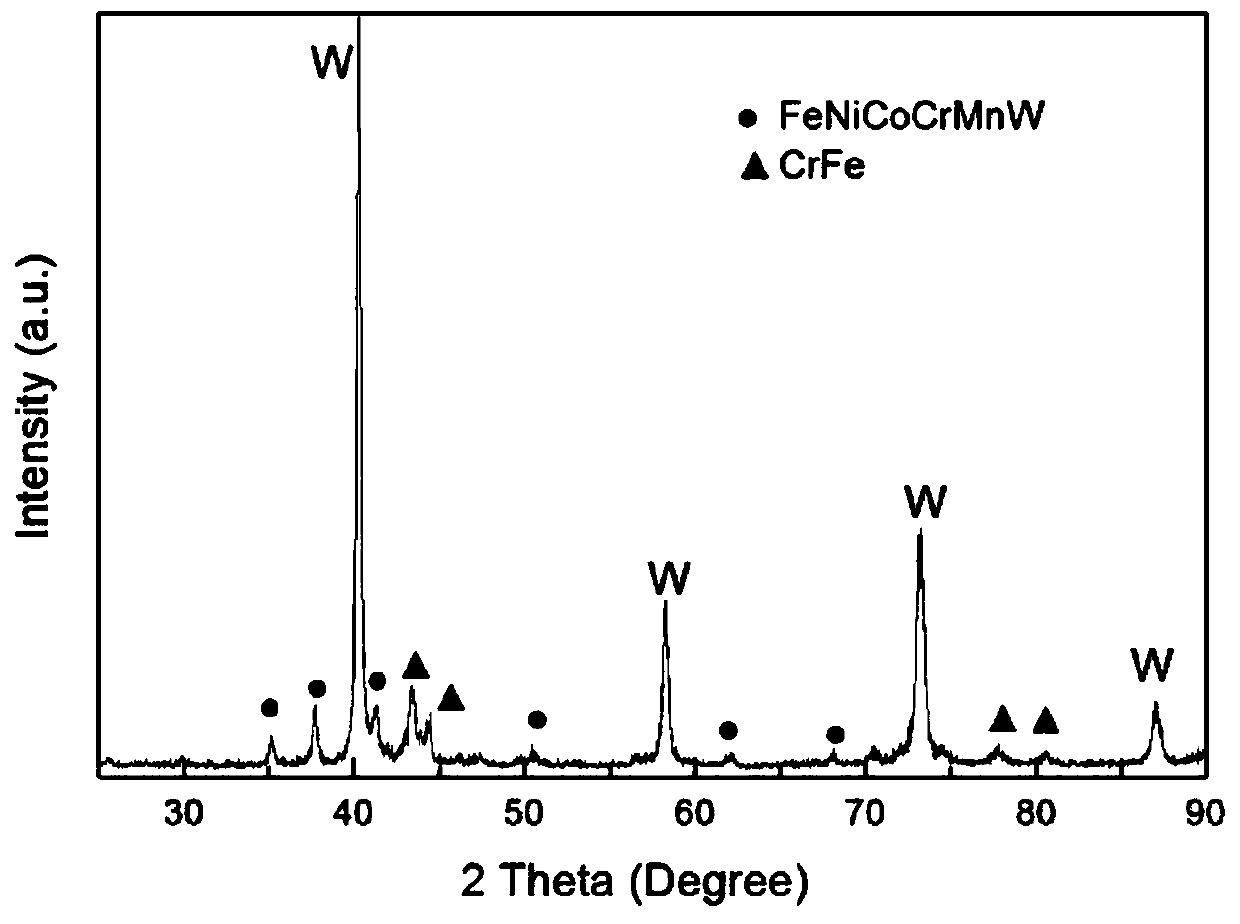

[0030] A high-strength tungsten-based alloy material with a mass fraction of FeNiCoCrMn of 20% was prepared. 1) Prepare FeNiCoCrMn (mole fraction) multi-principal alloy powder. The raw materials are high-purity iron, nickel, cobalt, chromium, manganese and other bulk metal materials, which are melted into a multi-principal alloy melt at 1600 ° C. The melt is heated in high-purity argon FeNiCoCrMn multi-principal alloy powder (with a particle size of 50 microns) having a simple solid solution structure was atomized under air. 2) Weigh tungsten powder (with a particle size of 25 microns) and FeNiCoCrMn multi-principal alloy powder according to the mass fraction of 80% W and 20% FeNiCoCrMn multi-principal alloy powder. Time 30h, mix evenly, vacuum dry and sieve after ball milling, prepare W-FeNiCoCrMn x al y The composite powder (with a particle size of 21 microns) was then sintered in a vacuum hot-press sintering furnace at a sintering temperature of 1300° C., a pressure of 30...

Embodiment 3

[0032] A high-strength tungsten-based alloy material with a FeNiCoCr mass fraction of 20% was prepared. 1) Prepare FeNiCoCr (mole fraction) multi-principal alloy powder. The raw materials are high-purity iron, nickel, cobalt, chromium and other bulk metal materials, which are melted into a multi-principal alloy melt at 2000 ° C. The melt is under high-purity argon Atomized FeNiCoCr multi-principal alloy powder (particle size: 30 microns) with a simple solid solution structure. 2) Weigh tungsten powder (with a particle size of 10 microns) and FeNiCoCr multi-principal alloy powder according to the mass fraction of 80% W and 20% FeNiCoCr multi-principal alloy powder. Time 60h, mix evenly, vacuum dry and sieve after ball milling, prepare W-FeNiCoCrMn x al y The composite powder (with a particle size of 15 microns) is then sintered in a vacuum hot-press sintering furnace, the sintering temperature is 1500°C, the pressure is 30MPa, and the sintering time is 2.5h. The Vickers hard...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com