Device and method for preparing tea powder tablet substrates and tea powder tablet substrates

A technology for tea powder and tableting is applied in the field of tea powder tableting and devices for preparing tea powder tableting matrix, which can solve the problems of inability to meet the requirements of product hardness, poor compressibility of maltitol, unfavorable product transportation, and the like. Preservation and transportation, good mobility, and the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The invention also discloses a method for preparing tea powder compressed tablets, the tea powder compressed tablet comprises a tea powder compressed matrix and 1.8% to 2.2% magnesium stearate, and the tea powder compressed matrix comprises 85% to 90% % xylitol powder or sorbitol powder or maltitol powder, 10%~15% tea powder, and the added amount is 1.0%~1.5% of the total mass of tea powder and xylitol powder or sorbitol powder or maltitol powder The sodium carboxymethyl cellulose, the concentration of sodium carboxymethyl cellulose solution is 4% ~ 5%, the viscosity at 40 ℃ is 30mPa·s ~ 45mPa·s, described tea powder tabletting matrix adopts as claimed in claim 7 Prepared by the method for preparing the tea powder compressed tablet matrix described above, the preparation method of the tea powder compressed tablet also includes the following steps:

[0045] Step 5, adding magnesium stearate to the tea powder tabletting matrix obtained in step 4 and mixing, and then direc...

Embodiment 1

[0048] The first embodiment of the preparation method of tea powder compressed tablet of the present invention, it comprises the steps:

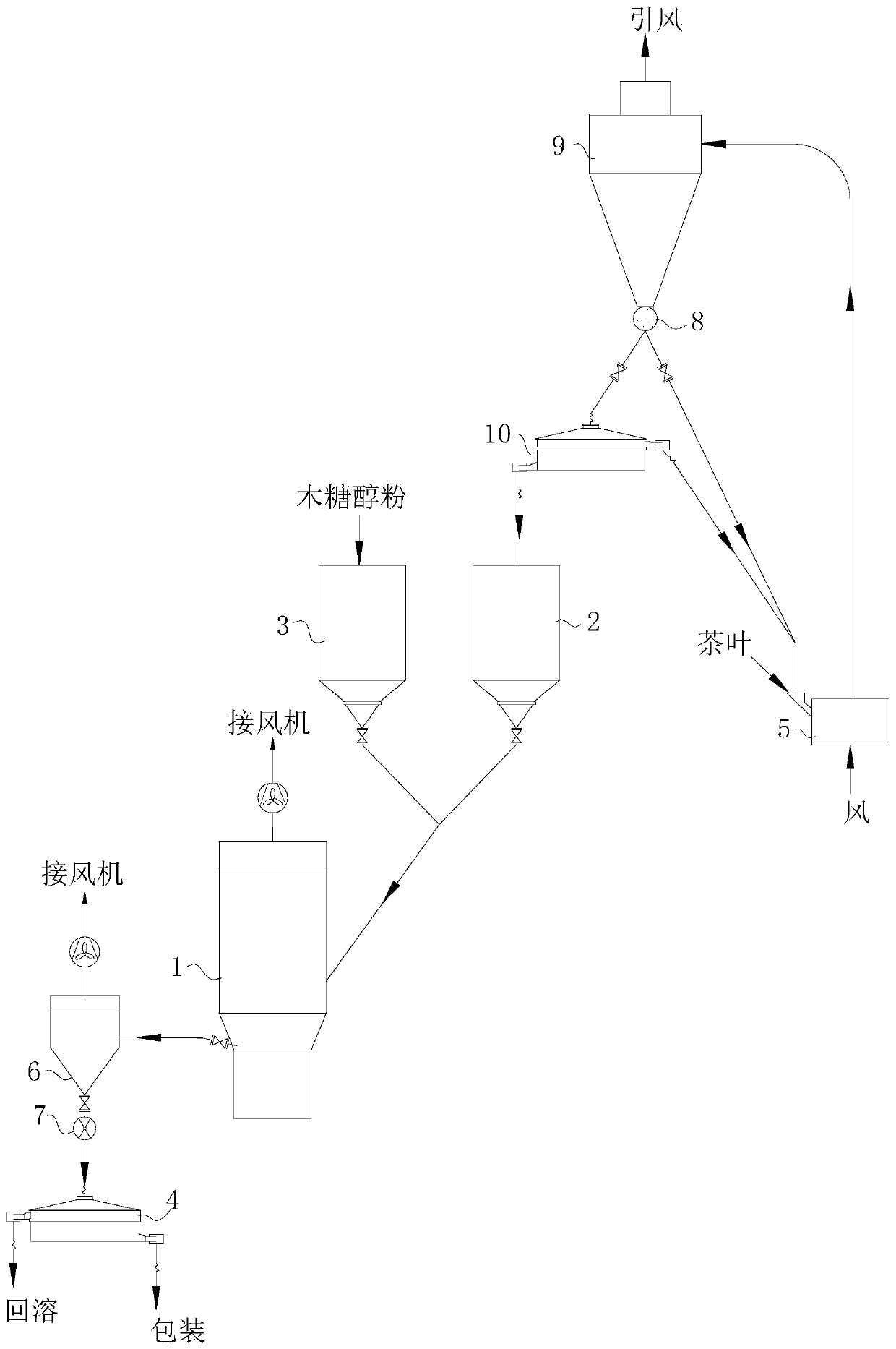

[0049] (11) Prepare tea powder. Start the air supply and induced air system to send the tea into the pulverizer. The tea leaves are pulverized by the pulverizer 5, separated by the separator 9, and sieved by the powder sieve 10. Silo 2. When feeding for the first time, the cyclone feeds and discharges the material until it is pulverized for circulation, so that the tea leaves can be pulverized for 2 minutes to 5 minutes. The amount of material in the first feed bin 2 is 50kg~80kg.

[0050] (12) Prepare xylitol powder. Prepare xylitol powder with a particle size of 100 mesh and a proportion greater than 75%, temporarily stored in the second silo 3, with an amount of 250kg to 300kg.

[0051] (13) Prepare spray liquid. The binder is sodium carboxymethyl cellulose CMC-Na powder, add water to control the solution concentration to 4%~5%, and ...

Embodiment 2

[0056] The second embodiment of the preparation method of the tea powder compressed tablet of the present invention, compared with embodiment 1, the steps of this embodiment are the same as those of embodiment 1, except that there are differences in the following steps and parameters, as follows:

[0057] (21) Material preparation: Xylitol powder accounts for 78.7% under 100 mesh, the ratio of tea powder to xylitol powder is 1:9, the concentration of binder CMC-Na is 4.5%, and the addition amount is 1.3%. Powder sieve 10 sieve mesh number 60 mesh.

[0058] (22) Granulation: Xylitol powder and tea powder are mixed and granulated in the granulator 1, the spray time is 100 minutes, and the mixture is dried at 65°C for 40 minutes.

[0059] (23) Screening and tableting: the tea powder tableting matrix granules obtained in step (22) are sieved through the granule sieve 4 to obtain the tea powder tableting matrix, and 2.0% magnesium stearate is added to it and mixed evenly, and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com