Pulse electrodeposited ni-co-p/hbn composite coating and its preparation method

A technology of pulse electrodeposition and composite coating, applied in coatings, electrolytic coatings, etc., can solve the problems of short service life of the plating solution, aggravated the decomposition of the plating solution, poor stability of the plating solution, etc. Eliminate the effect of agglomeration and foaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0051] Form description:

[0052] Table 1 is the chemical composition table of 45 steel used in the present invention, red copper T2, aluminum-silicon alloy ZL109 and stainless steel 1Cr13 matrix material.

[0053] Table 2 is the main composition and process parameters of the plating solution in Examples 1-16 of the pulse electrodeposited Ni-Co-P / HBN composite coating of the present invention.

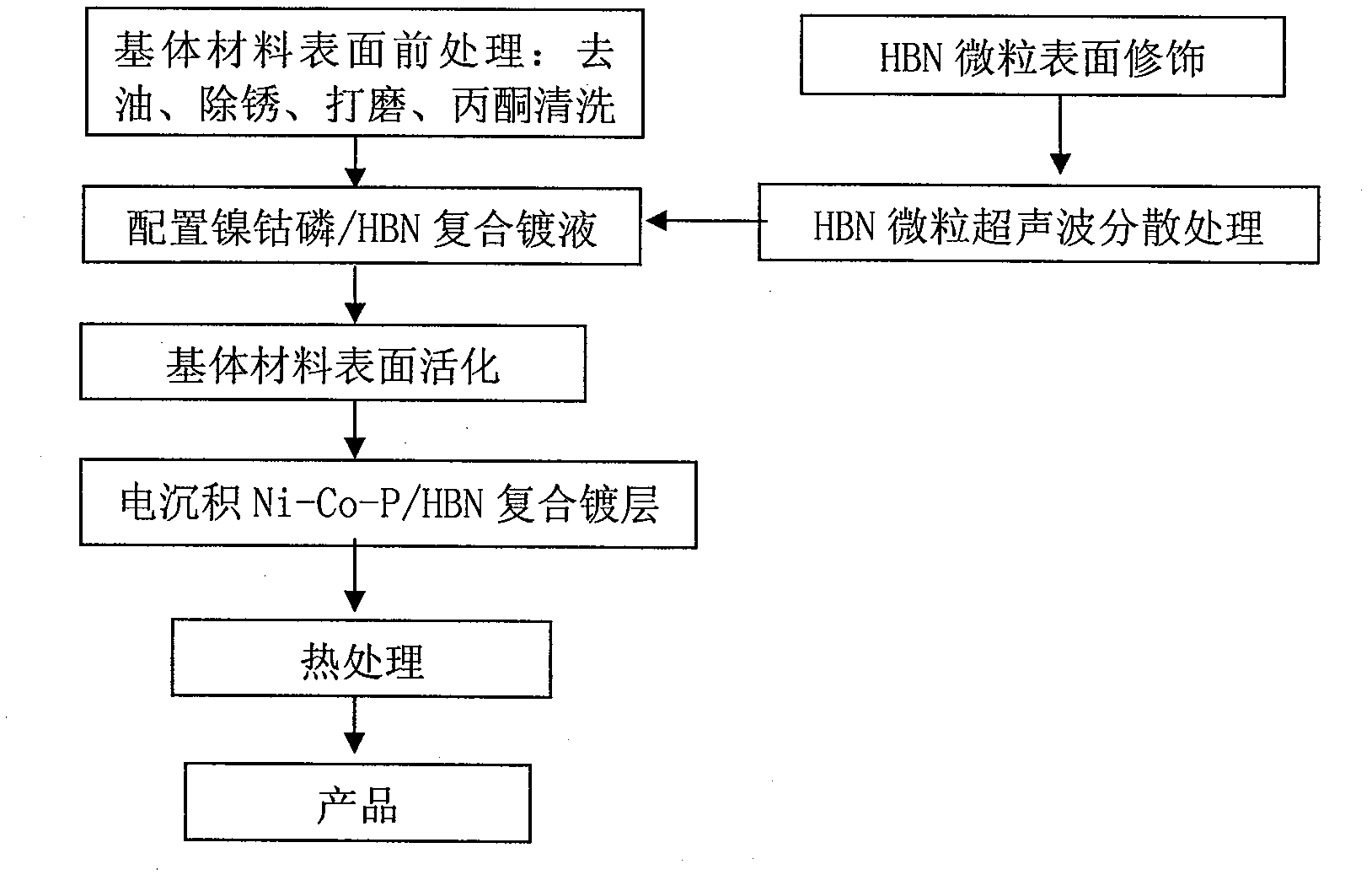

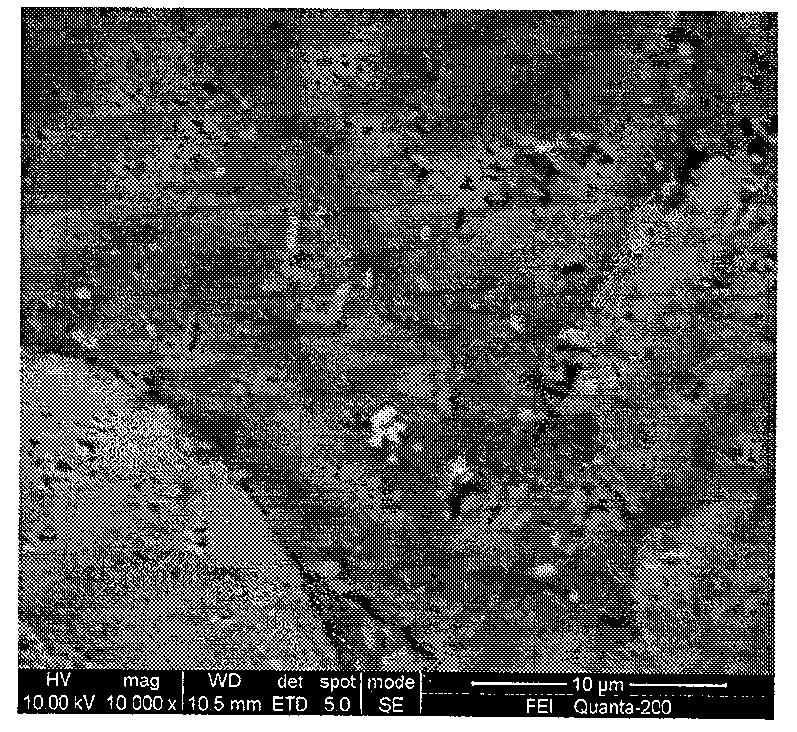

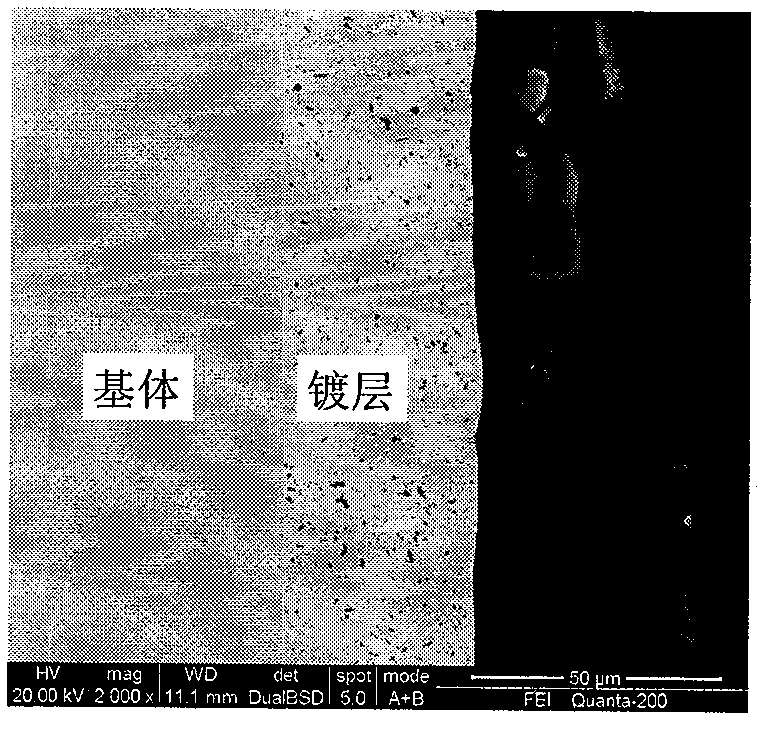

[0054] Combined with the figures and tables, a pulse electrodeposited Ni-Co-P / HBN composite coating of the present invention and its preparation method, it uses metal materials as the substrate, the surface of the substrate is pretreated first, and then nickel sulfate, cobalt chloride , sodium hypophosphite, citric acid, trisodium citrate, boric acid, and polyvinyl alcohol as the main components, and the composite plating solution with hexagonal boron nitride HBN powder as the dispersed phase. In the plating solution, through reasonable setting of pulse electrodeposition process param...

Embodiment 1

[0059] The base material is 45 steel, the chemical composition is shown in the figure (table), the sample size is: 50mm×12mm×2mm, the preparation operation steps of Ni-Co-P / HBN composite coating on the surface of 45 steel:

[0060] ① 45 steel surface degreasing treatment, the formula is mass fraction: sodium hydroxide 20g / L, sodium carbonate 30g / L, sodium phosphate 8g / L, OP-10 emulsifier 2ml / L volume fraction; temperature 80°C;

[0061] ② Rust removal treatment on the surface of 45 steel, the formula is: sulfuric acid 100ml / L volume fraction, hexamethylenetetramine 12g / L mass fraction, temperature 50°C;

[0062] ③ Use 180#, 360#, 600# sandpaper to polish the 45 steel after degreasing and derusting treatment in sequence, then use acetone to ultrasonically clean the surface of the substrate, and dry it for later use;

[0063] ④ Surface modification treatment of HBN particles: HBN powder was treated with 20% HCl solution to remove iron and impurities, soaked for 24 hours, and the...

Embodiment 2

[0069] The base material is 45 steel, the chemical composition is shown in the figure (table), the sample size is: 50mm×12mm×2mm, the preparation operation steps of Ni-Co-P / HBN composite coating on the surface of 45 steel:

[0070] ① 45 steel surface degreasing treatment, the formula is mass fraction: sodium hydroxide 20g / L, sodium carbonate 30g / L, sodium phosphate 8g / L, OP-10 emulsifier 2ml / L volume fraction, temperature 80°C;

[0071] ② Rust removal treatment on the surface of 45 steel, the formula is: sulfuric acid 100ml / L volume fraction, hexamethylenetetramine 12g / L mass fraction, temperature 50°C;

[0072] ③ Use 180#, 360#, 600# sandpaper to polish the 45 steel after degreasing and derusting treatment in sequence, then use acetone to ultrasonically clean the surface of the substrate, and dry it for later use;

[0073] ④ Surface modification treatment of HBN particles: HBN powder was treated with 20% HCl solution to remove iron and impurity, soaked for 24 hours, and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com