Pure water hydraulic through-shaft type spherical distribution axial plunger pump

An axial plunger pump and hydraulic technology, which is applied to liquid variable volume machinery, pumps, multi-cylinder pumps, etc., can solve the problems of unreported actual effects, complex structure of the distribution shaft cone, and difficult processing. Achieve the effect of simple structure, good self-positioning ability and less leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

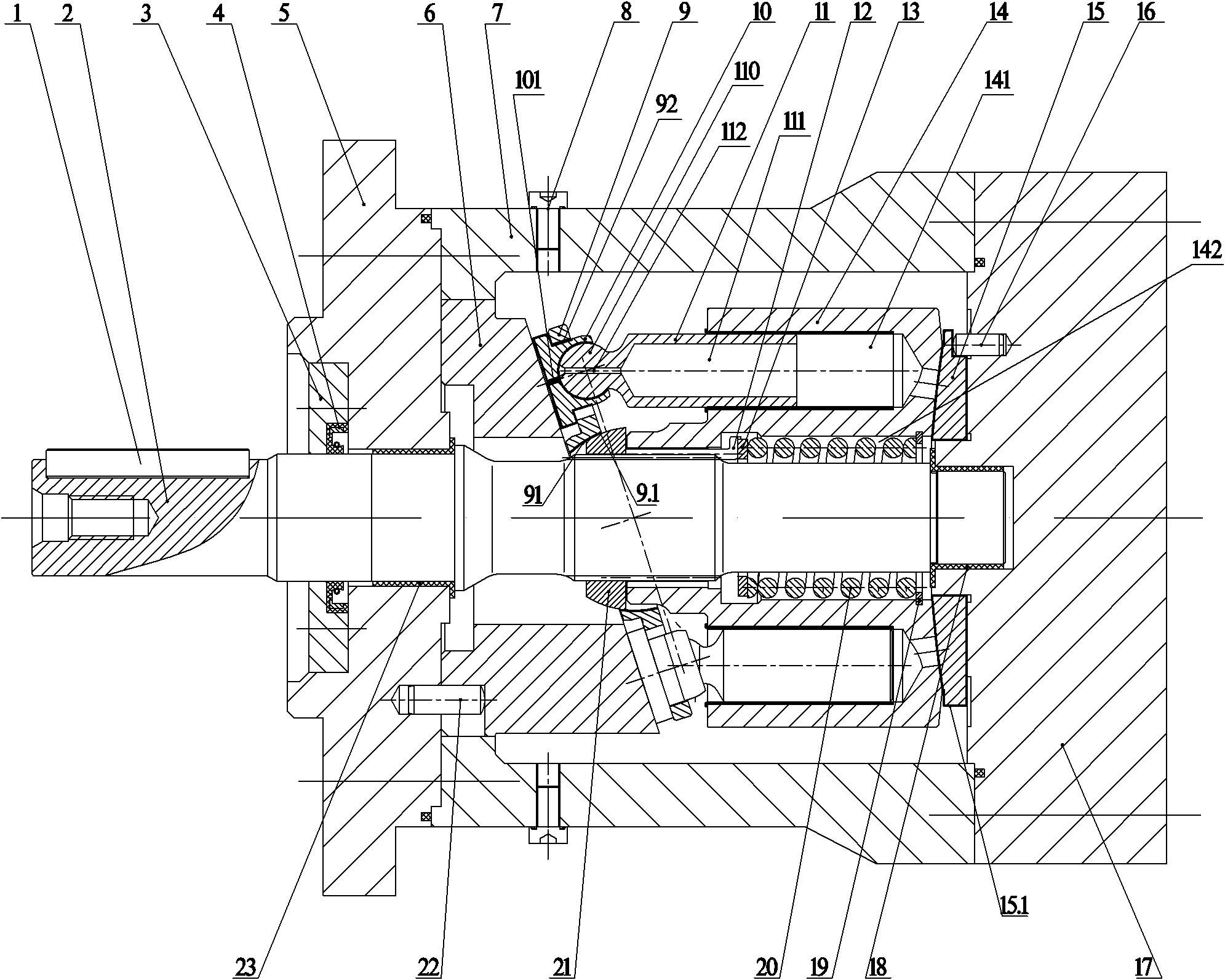

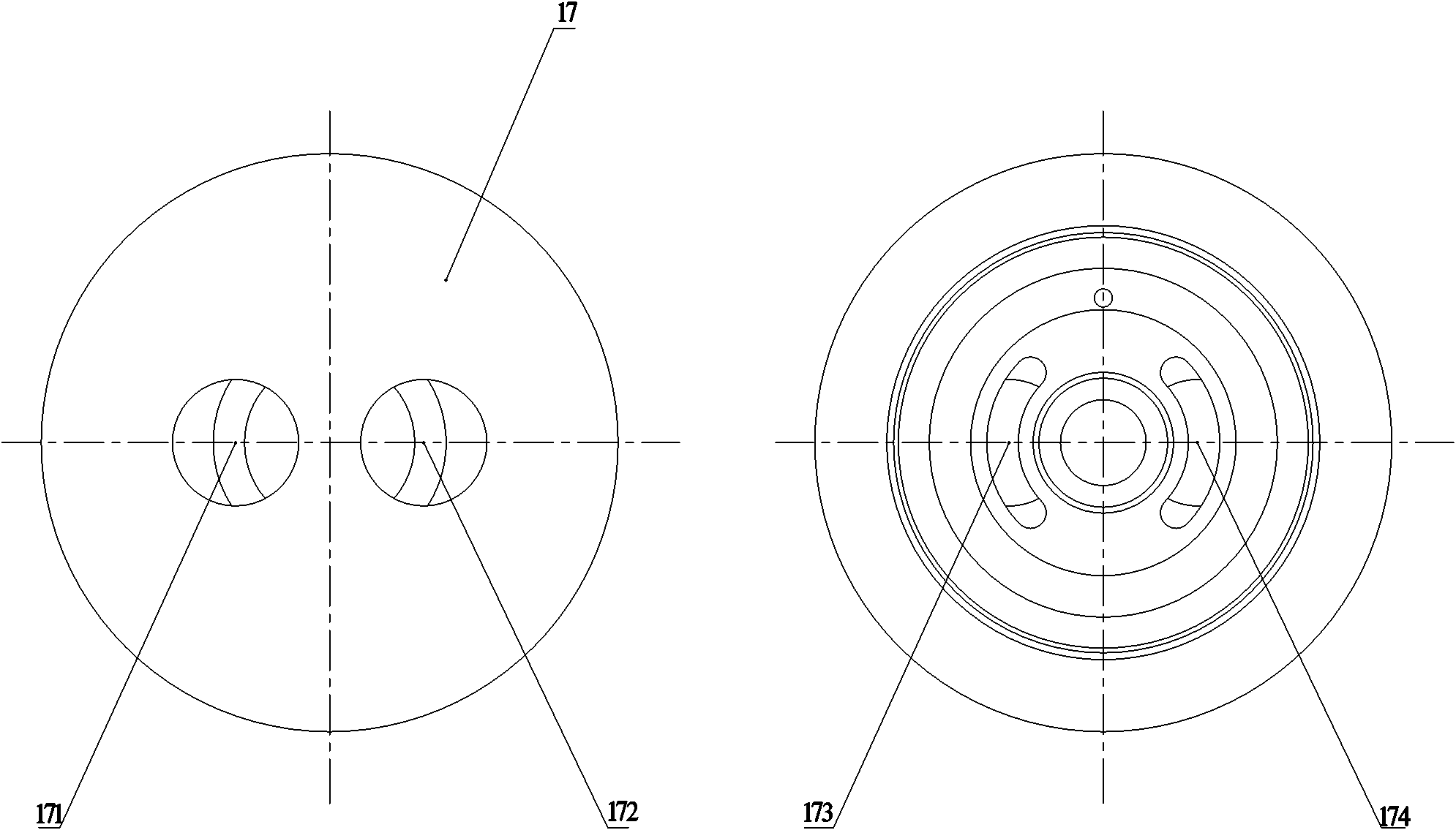

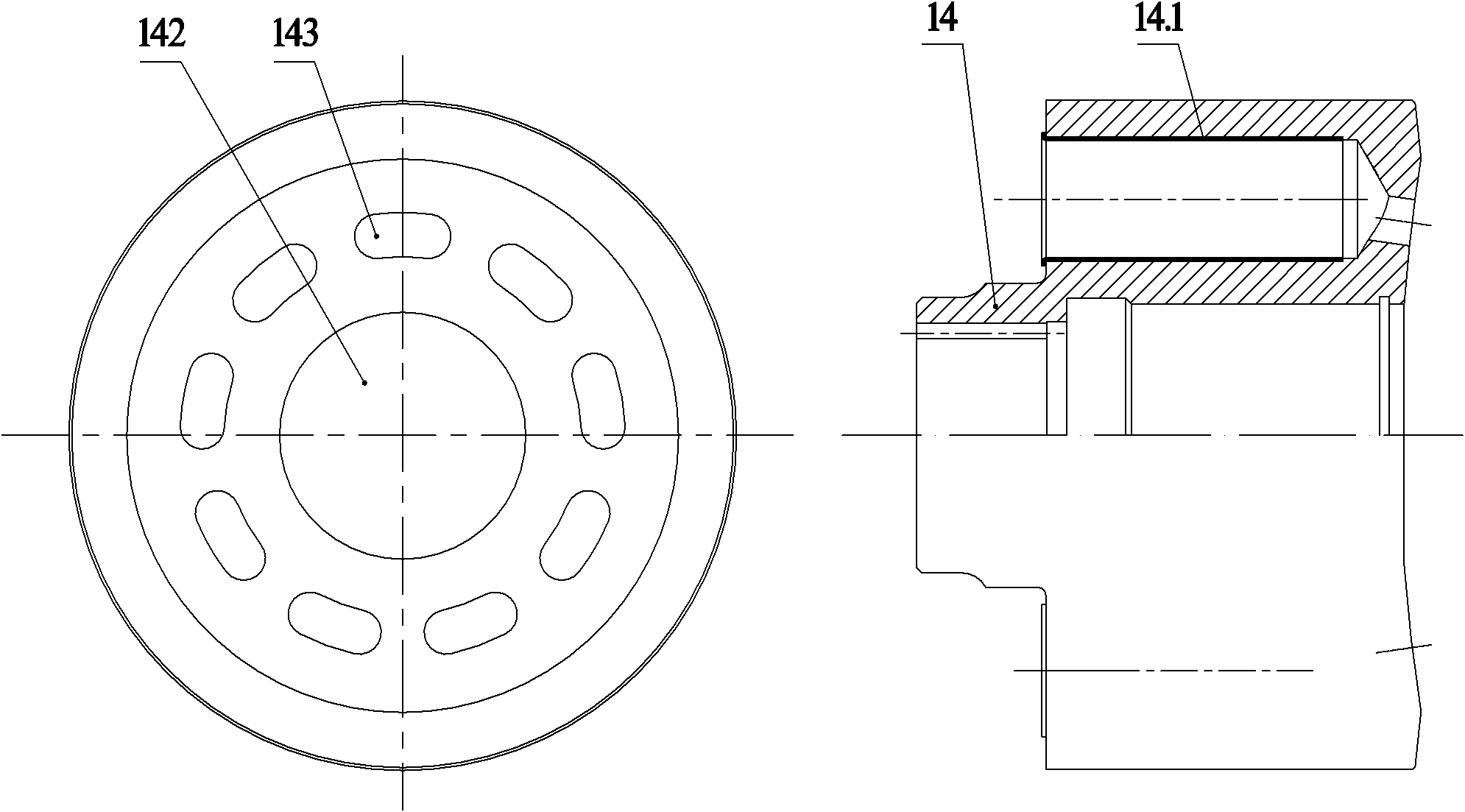

[0035] Embodiment 1, Figure 1~Figure 4 Combined with a pure water hydraulic shaft-through spherical distribution axial piston pump, it consists of a main shaft 2, a casing (composed of a front end cover 5, a housing 7 and a rear end cover 17), a cylinder body 14, and a plunger- Sliding shoe assembly (composed of plunger 11 and sliding shoe 10), swash plate 6, flow plate 15, ball hinge 21, return plate 9, center spring 20, front sliding bearing 23, rear sliding bearing 18, shaft seal 4 and shaft Covering 3 etc. constitutes. The casing 7 is provided with an exhaust screw 8 communicating with the inner cavity of the casing 7 , and the function of the exhaust screw 8 is to unscrew it during initial operation, so as to discharge residual air in the casing 7 .

[0036] A through-shaft structure is adopted, that is, the main shaft 2 runs through the front end cover 5, the housing 7 and the rear end cover 17 from left to right in turn; the main shaft 2 located on the left side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com