Method for preparing patterned functional film based on template deposition

A patterning and template technology, applied in anodizing, ion implantation plating, electrolytic coatings, etc., can solve the problem of poor degradation efficiency and light absorption and utilization efficiency, difficult selective absorption and reflection of visible light, poor wear resistance and friction reduction, etc. The problem is to achieve good degradation efficiency and light absorption and utilization efficiency, convenient and feasible preparation, and good wear resistance and friction reduction effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

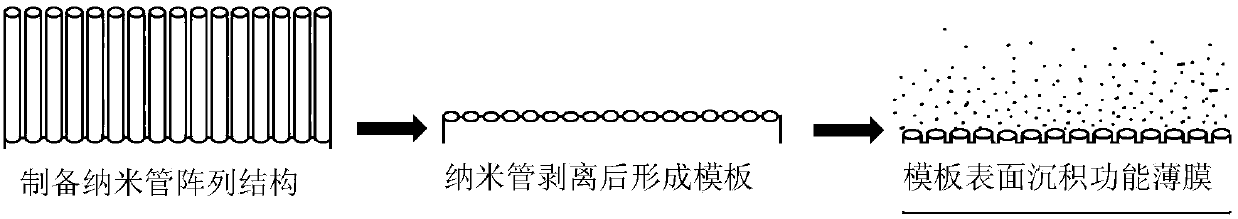

[0011] The structure and use of the present invention will now be further described with reference to the accompanying drawings. Such as Figure 1-Figure 4 As shown, the steps of the embodiment of the method are as follows: (1) Perform surface pretreatment on the pure titanium metal substrate, first wash it in a 5-20wt.% sodium hydroxide aqueous solution for 2-10min, and the temperature of the alkaline washing solution is 40-150 ℃. After washing with clean water, put it in the pickling solution for 2-10 minutes. The ratio of the pickling solution is hydrofluoric acid (10ml): nitric acid (40ml): deionized water (300ml). The acid-washed pure titanium metal substrate is then ultrasonically cleaned in an acetone solution, taken out and air-dried. (2) Configure fluoride electrolyte for electrochemical anodic oxidation, NH in electrolyte 4 The content of F is 0.25wt.%, the content of deionized water is 2wt.%, and the rest is ethylene glycol. (3) Anodize the pure titanium diaphragm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com