Energy-saving cooking pot with rotary gas

An energy-saving pot and screw technology, applied in cooking utensils, household appliances, applications, etc., can solve the problems of short contact time, energy loss and loss, small contact area, etc., and achieve low cost, high heat utilization rate, and large contact area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

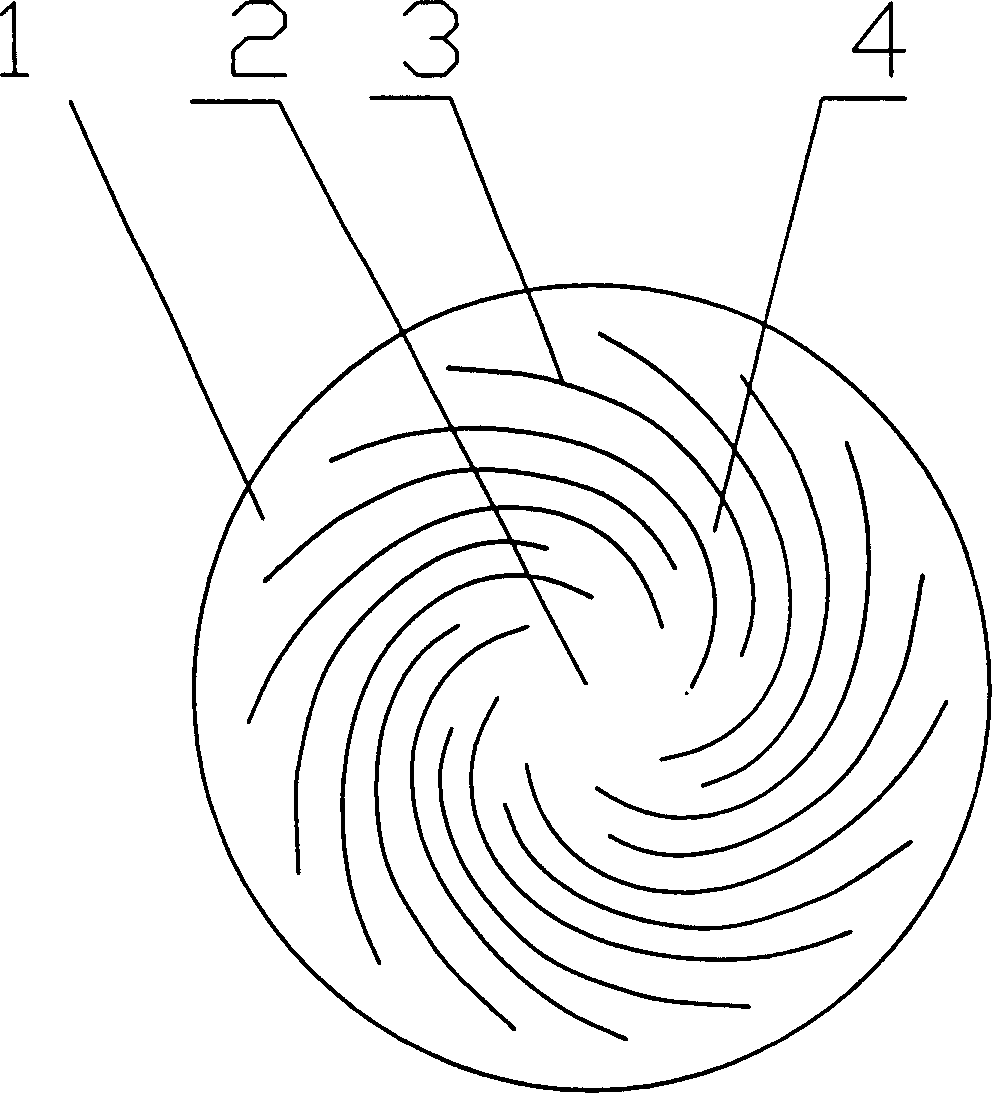

[0013] see figure 1 On the outer surface of the pot body 1 centering on the bottom center 2 of the pot body, there are spiral radial metal ribs 3 radiating involute left helically, the radial cross-section is triangular, and spiral smoke is formed between the spiral radial metal ribs 3 Road 4.

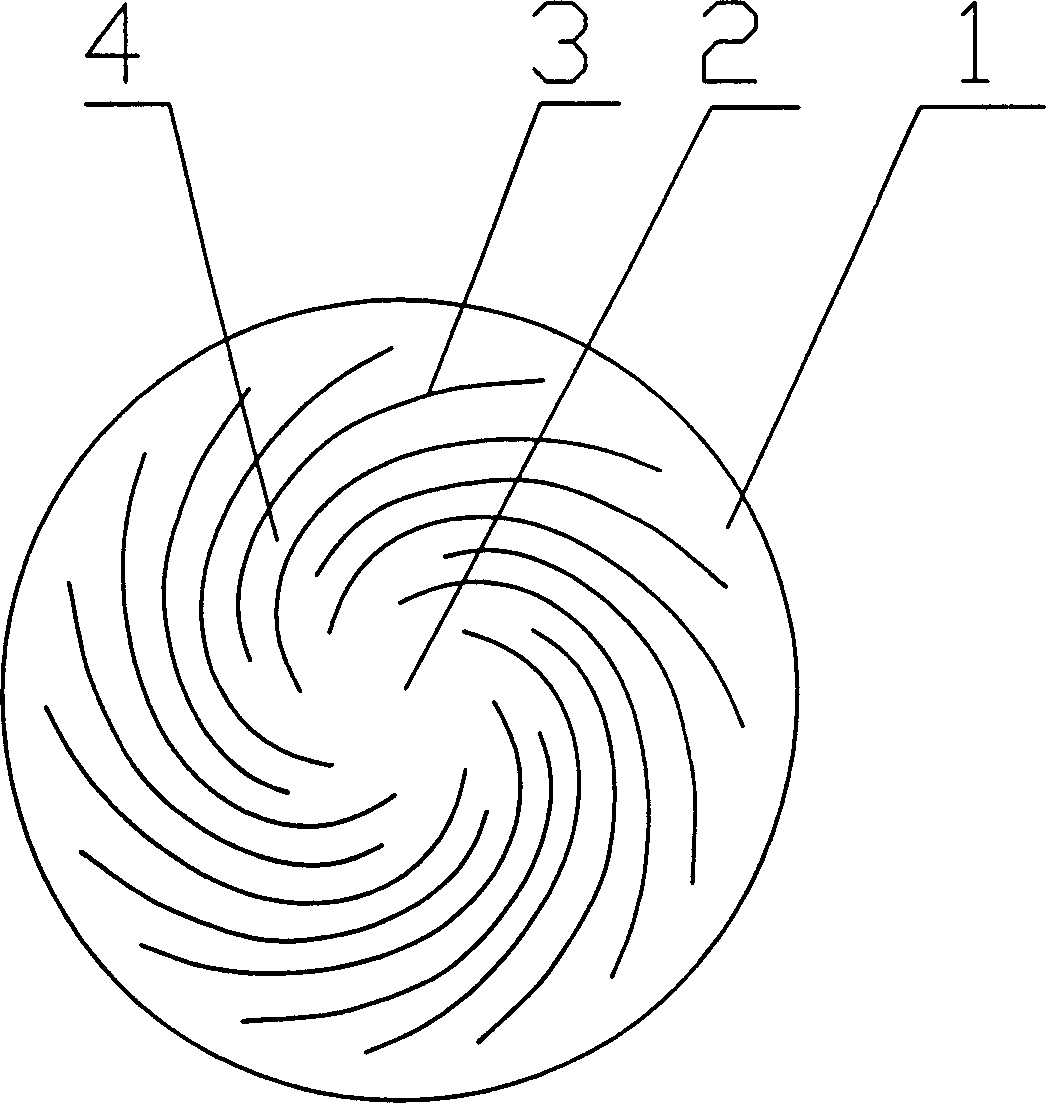

[0014] see figure 2 , on the outer surface of the pot body 1 centered on the bottom center 2 of the pot body, there are spiral radial metal ribs 3 radiating involute right helically, the radial cross-section is semicircular, and there are formed between the spiral radial metal ribs 3 Spiral flue 4.

[0015] When in use, the fire gas flow spirals up along the spiral flue 4 to generate a swirling heat flow, which prolongs the heat exchange time between the gas flow and the pot body 1 on the one hand, and on the other hand, presents a spiral ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com