MXene reinforced silicate adhesive ceramic coating and preparation method thereof

A ceramic coating and silicate glue technology, applied in the direction of alkali metal silicate coatings, coatings, etc., can solve the problem that the friction and wear properties cannot meet the requirements of engineering equipment, high mechanical strength, layer-by-layer structure, and high curing temperature , to achieve the effect of good wear resistance and friction reduction, simple preparation process and low friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

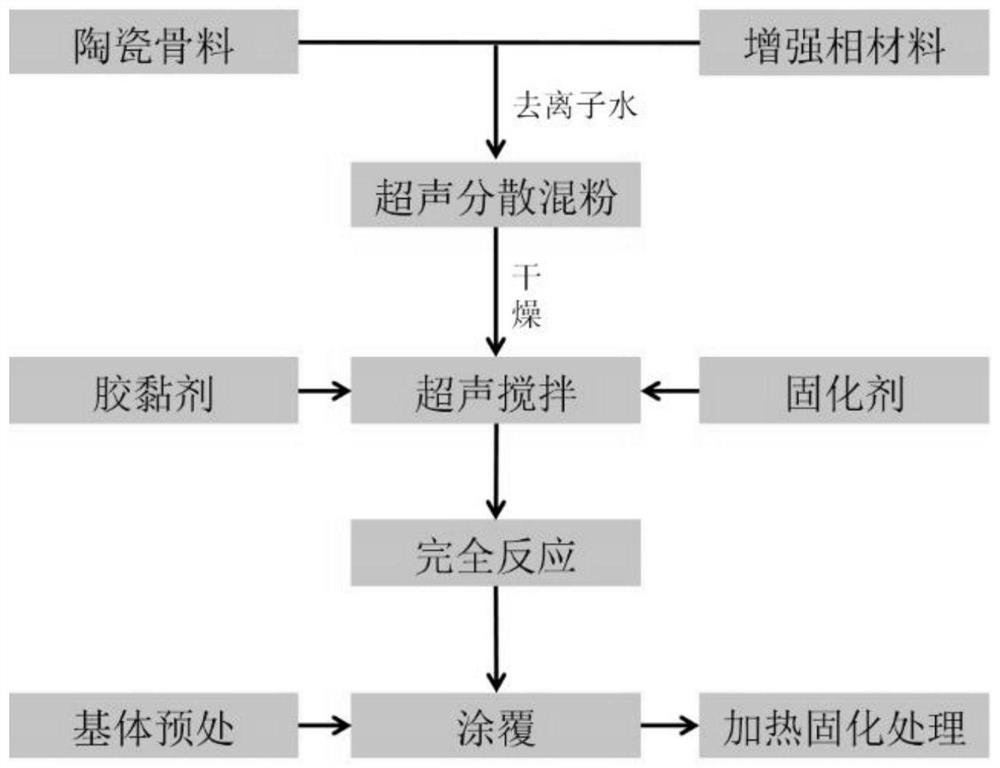

[0033] A kind of preparation method of MXene strengthened silicate adhesive ceramic coating, such as figure 1 shown, including the following steps,

[0034] (1) Substrate pretreatment: the 304 steel substrate was polished with sandpaper, ultrasonically cleaned in absolute ethanol for 15 minutes to remove surface stains, washed with deionized water, dried, and finally the surface was sandblasted.

[0035] (2) Slurry preparation: Weigh 4.825g (38.6wt%) aggregate alumina, 0.05g (0.4wt%) MXene (Ti 3 C 2 ), then pour it into a beaker and use an ultrasonic cell disruptor to carry out ultrasonic dispersion in deionized water for 20 minutes; measure 7.5g (60wt%) of the obtained silicate adhesive, and add it to the mixture after ultrasonic dispersion, Add 0.125g (1wt%) of silicon phosphate as a curing agent and perform ultrasonic stirring for 5 minutes; finally, evenly coat the uniformly mixed slurry on the surface of the pretreated 304 steel substrate.

[0036] (3) Curing treatment...

Embodiment 2

[0038] A kind of preparation method of MXene strengthened silicate adhesive ceramic coating, such as figure 1 shown, including the following steps,

[0039] (1) Substrate pretreatment: the 304 steel substrate was polished with sandpaper, ultrasonically cleaned in absolute ethanol for 15 minutes to remove surface stains, washed with deionized water, dried, and finally the surface was sandblasted.

[0040] (2) Slurry preparation: Weigh 4.775g (38.2wt%) aggregate alumina, 0.1g (0.8wt%) MXene (Ti 3 C 2), then pour it into a beaker and use an ultrasonic cell disruptor to carry out ultrasonic dispersion in deionized water for 20 minutes; measure 7.5g (60wt%) of the obtained silicate adhesive, and add it to the mixture after ultrasonic dispersion, Add 0.125g (1wt%) of silicon phosphate as a curing agent and perform ultrasonic stirring for 5 minutes; finally, evenly coat the uniformly mixed slurry on the surface of the pretreated 304 steel substrate.

[0041] (3) Curing treatment: ...

Embodiment 3

[0043] A kind of preparation method of MXene strengthened silicate adhesive ceramic coating, such as figure 1 shown, including the following steps,

[0044] (1) Substrate pretreatment: the 304 steel substrate was polished with sandpaper, ultrasonically cleaned in absolute ethanol for 15 minutes to remove surface stains, washed with deionized water, dried, and finally the surface was sandblasted.

[0045] (2) Slurry preparation: Weigh 4.725g (37.8wt%) aggregate alumina, 0.15g (1.2wt%) MXene (Ti 3 C 2 ), then pour it into a beaker and use an ultrasonic cell disruptor to carry out ultrasonic dispersion in deionized water for 20 minutes; measure 7.5g (60wt%) of the obtained silicate adhesive, and add it to the mixture after ultrasonic dispersion, Add 0.125g (1wt%) of silicon phosphate as a curing agent and perform ultrasonic stirring for 5 minutes; finally, evenly coat the uniformly mixed slurry on the surface of the pretreated 304 steel substrate.

[0046] (3) Curing treatment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com