Method for measuring grease oxidation induction time based on screen printing modified electrode

A modified electrode and screen printing technology, which is applied in the direction of measuring devices, electrochemical variables of materials, and material analysis through electromagnetic means, can solve the problems of high cost of glassy carbon modified electrodes, inability to prepare batches conveniently, and easy fall-off of modifiers. , to achieve the effect of convenient and fast production, simple method and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

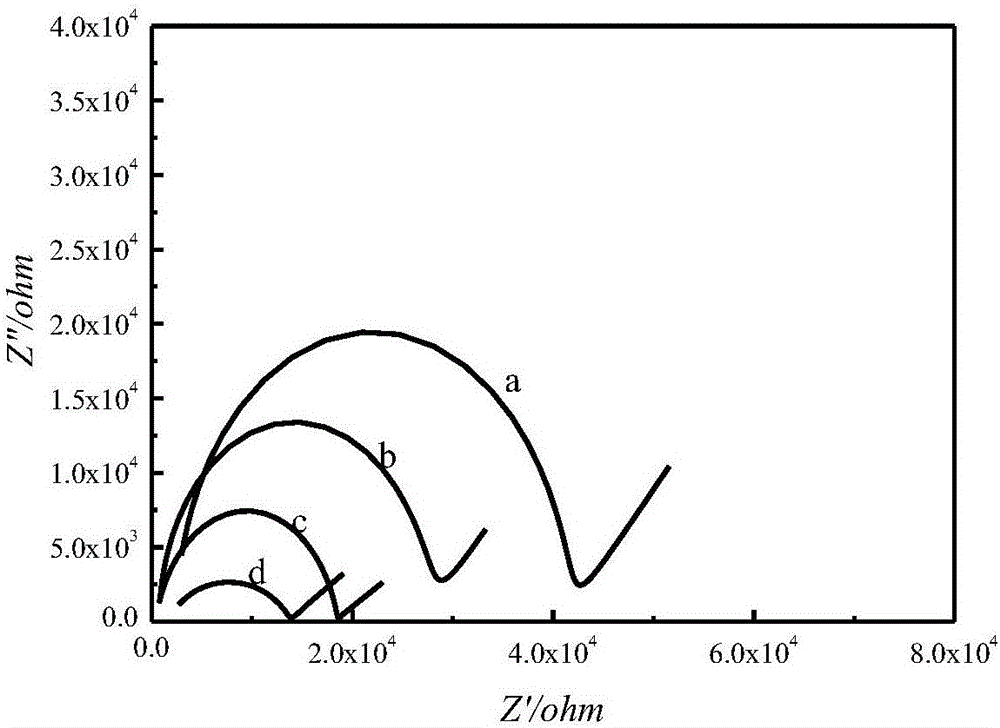

[0024] The construction of screen printing modified electrode, the steps are as follows, (1) carbon paste, graphene oxide and 1-butylpyridine hexafluorophosphate are added to an appropriate amount of carbon paste diluent (the mass ratio of carbon paste and graphene oxide is 125 : 1, the mass ratio of carbon paste and 1-butylpyridine hexafluorophosphate is 75: 1), ultrasonic, stirring and mixing, to obtain conductive paste; (2) print the silver paste on the surface of the printed substrate, put it into 90 ℃ Dry in an oven for 30 minutes; (3) print the conductive paste, and put it in a 90°C oven to dry for 30 minutes; (4) apply an insulating layer and dry it at room temperature; (6) Add an appropriate amount of graphite-phase carbon nitride into an appropriate amount of carbon slurry diluent to prepare a suspension with a concentration of 4 mg / mL, and ultrasonically disperse it; (7 ) Take 4 μL of the suspension and add it dropwise on the above-mentioned screen-printed electrode,...

Embodiment 2

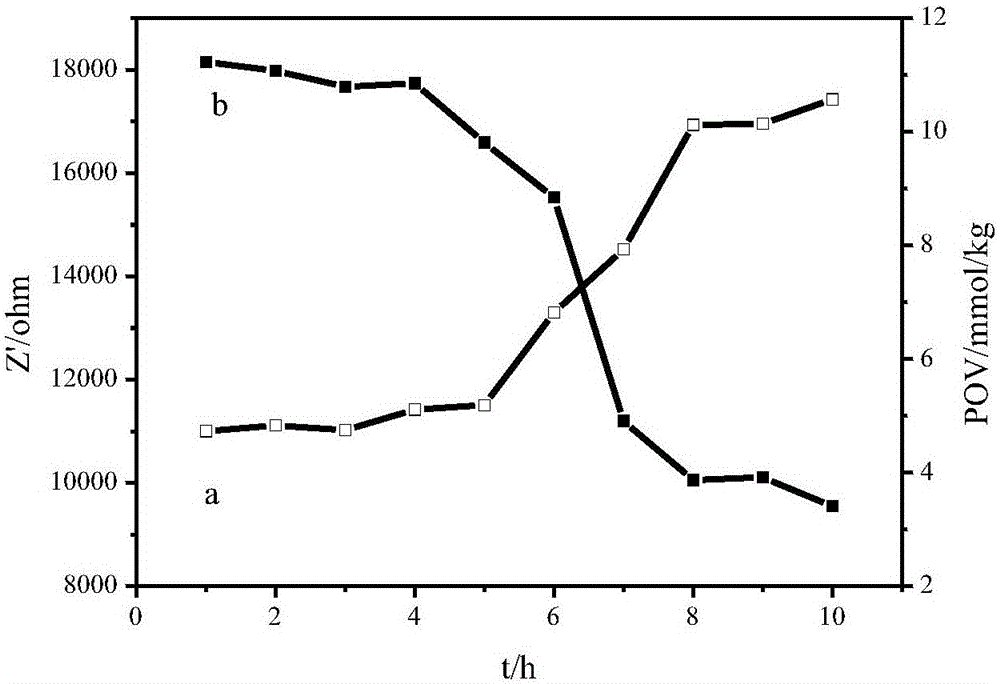

[0027] Grease oxidation induction time measurement, the steps are as follows, (1) take 0.20g grease sample in ethanol:chloroform=20:3 (V:V) as solvent; (2) screen printing modification constructed in Example 1 Put the electrode into the electrolytic cell of the oil sample to be tested, and measure the impedance of the oil oxidation process; (3) measure the peroxidation value of the oil synchronously according to the national standard method; obtain the relationship curve of the oil impedance value and the peroxidation value with time; (4 ) Obtain the impedance value of the solution through the equivalent circuit of the impedance spectrum; (5) Use the double tangent method to the above curve with a double tangent, and the time corresponding to the intersection point is the oxidation induction time of the oil.

[0028] Depend on figure 2 It can be seen that the induction time of olive oil in a water bath at 80°C is 6.01h and 5.98h, respectively, by making double tangents to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com