Special polyethylene double-wall corrugated pipe outer wall material with high bending modulus and high oxidation induction time and preparation method of special material

A technology of double-wall corrugated pipe and flexural modulus, which is applied in the field of special materials for the outer wall of polyethylene double-wall corrugated pipes and its preparation, can solve the problem of large fluctuations in the powder content of special materials, insignificant filling and reinforcing effects, ultra-fine talc powder Easy to agglomerate and other problems, to achieve the effect of stable and convenient production, uniform oxidation performance and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

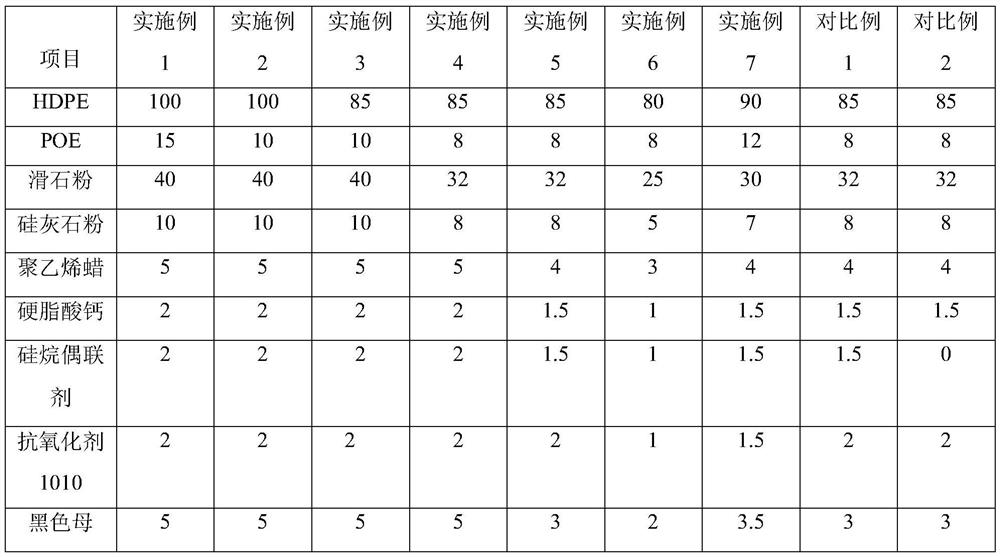

[0039] In Example 3 and Example 4, the silane coupling agent is A-1120, and POE is a copolymer of ethylene and octene; the powder fineness D50 of talcum powder is 3.86 μm; the melt index of HDPE is 1.5g / 10min; The powder fineness D50 of wollastonite powder is 5μm, and the aspect ratio is 16. The rotating speed in step 1 of embodiment 3 and embodiment 4 is 1000r / min, the temperature is 120°C, the mixing time is 10min, and the stirring time is 10min; the processing temperature in step 2 is 210°C.

experiment example 1

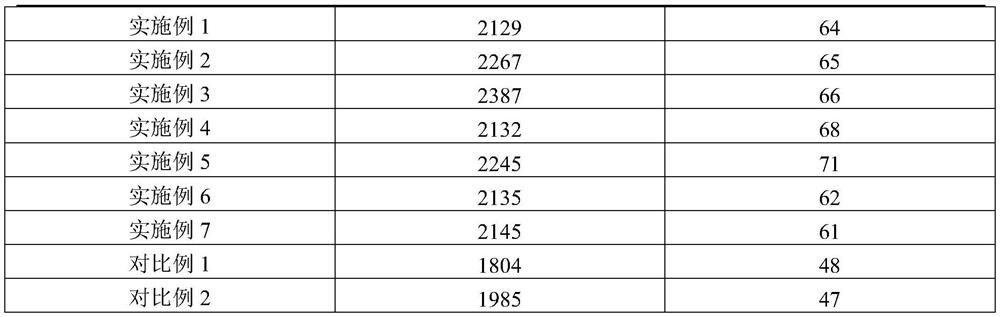

[0045] Carry out following performance test to the polyethylene double-wall corrugated pipe special material that the embodiment of the present invention and comparative example make:

[0046] According to GB / T3682.1-2018, GB / T1033.1-2008, GB / T9341-2008, GB / T19466.6-2009, melt index, density test, bending strength and oxidation induction were carried out on the materials prepared in the examples time. The test results are recorded in Table 2.

[0047] The detection data of table 2 embodiment and comparative example

[0048]

[0049]

[0050] Combined with Table 1, compare the experimental data in Table 2:

[0051] Analysis of comparative results:

[0052] From the experimental data of Examples 1 to 5, it can be seen that the special material prepared by the formula of the present invention has good flexural modulus and anti-oxidation performance, which are improved compared with the performance of the special material in the prior art.

[0053] Comparing Comparative ...

experiment example 2

[0056] This experimental example investigates the influence of talcum powder with different powder fineness D50 on the bending performance and oxidation resistance time of the final special material for the outer wall of polyethylene double-wall corrugated pipe.

[0057] Method is: method and component content are the same as embodiment 5, and difference is that the fineness of the talcum powder that adopts is different, and the results are shown in table 2:

[0058] Table 2 Performance results of special materials made from talcum powder with different fineness

[0059] project D50(μm) Bending strength (MPa) Oxidation induction time (min) Example 5 3.86 2245 71 Example 8 3.28 2257 70 Example 9 4.06 2216 69 Example 10 4.52 2208 69 Example 11 5.00 2208 68 Example 12 6.00 2204 65 Example 13 6.54 2082 66 Example 14 8.57 1989 67 Example 15 10.86 1950 63

[0060] From the experimental data in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Melt finger | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com