Patents

Literature

33results about How to "Uniform and stable combination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite,fabrication and recovery methods thereof, catalyst, antibiosis or antiviral compounds

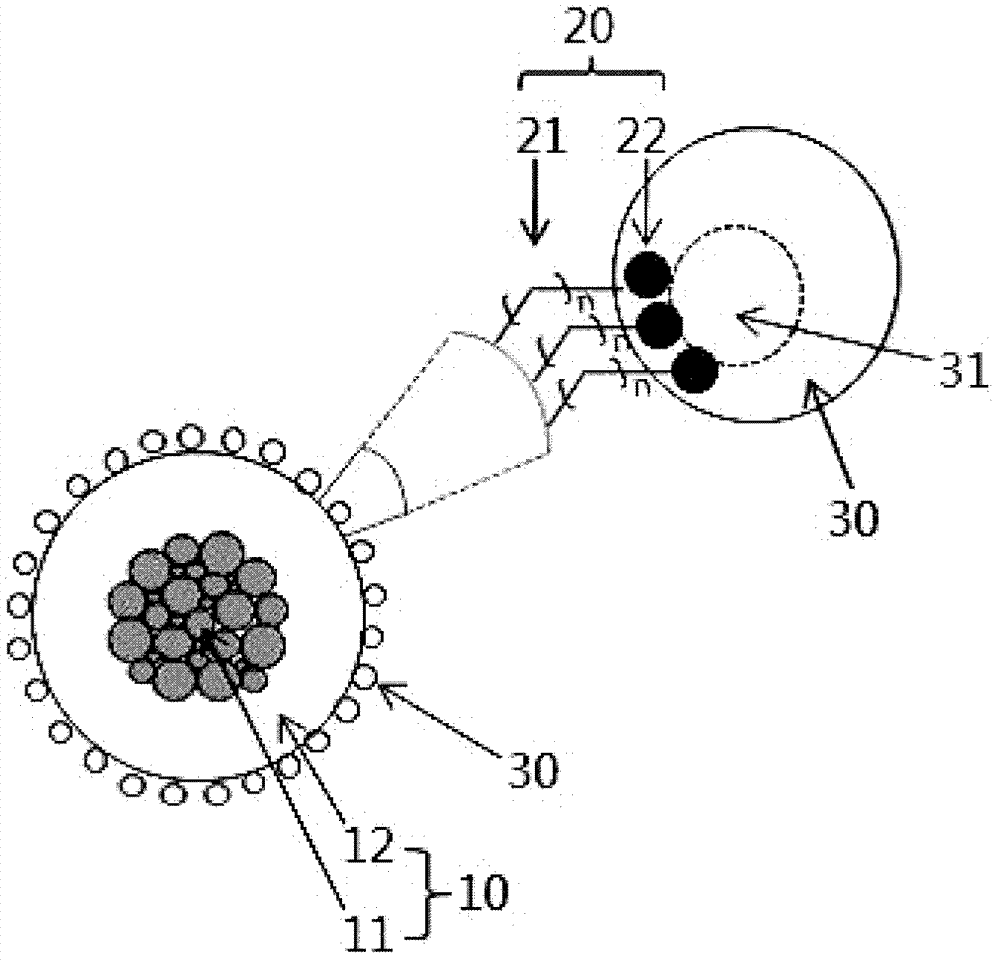

InactiveCN102728385AUniform and stable combinationEasy to recycleBiocideMaterial nanotechnologyAntibiosisRecovery method

Owner:KOREA INST OF SCI & TECH

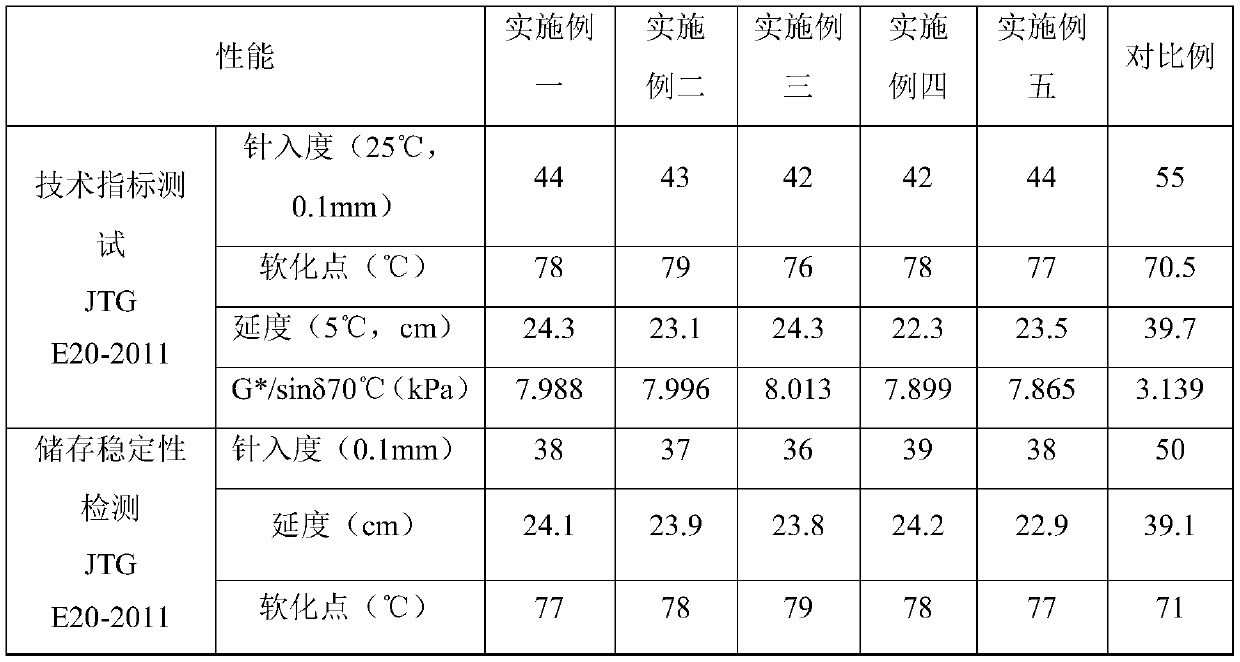

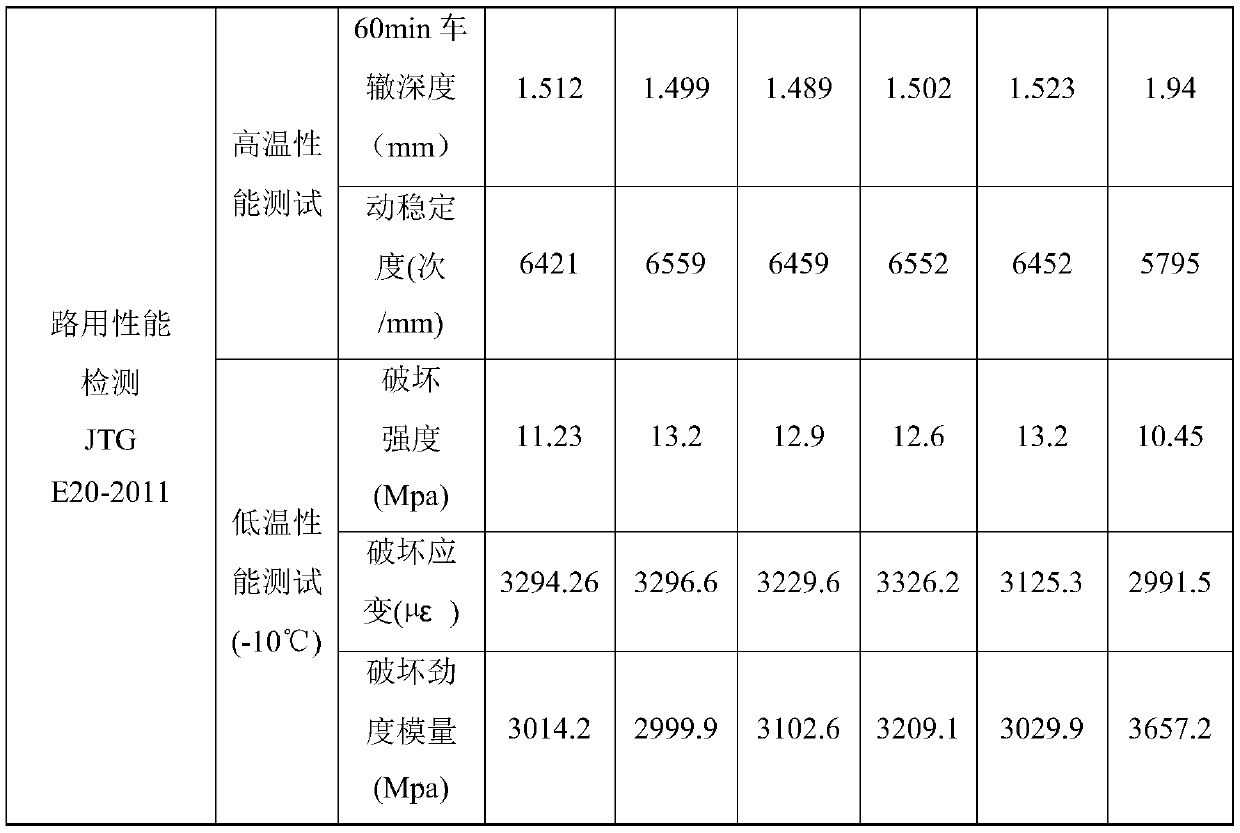

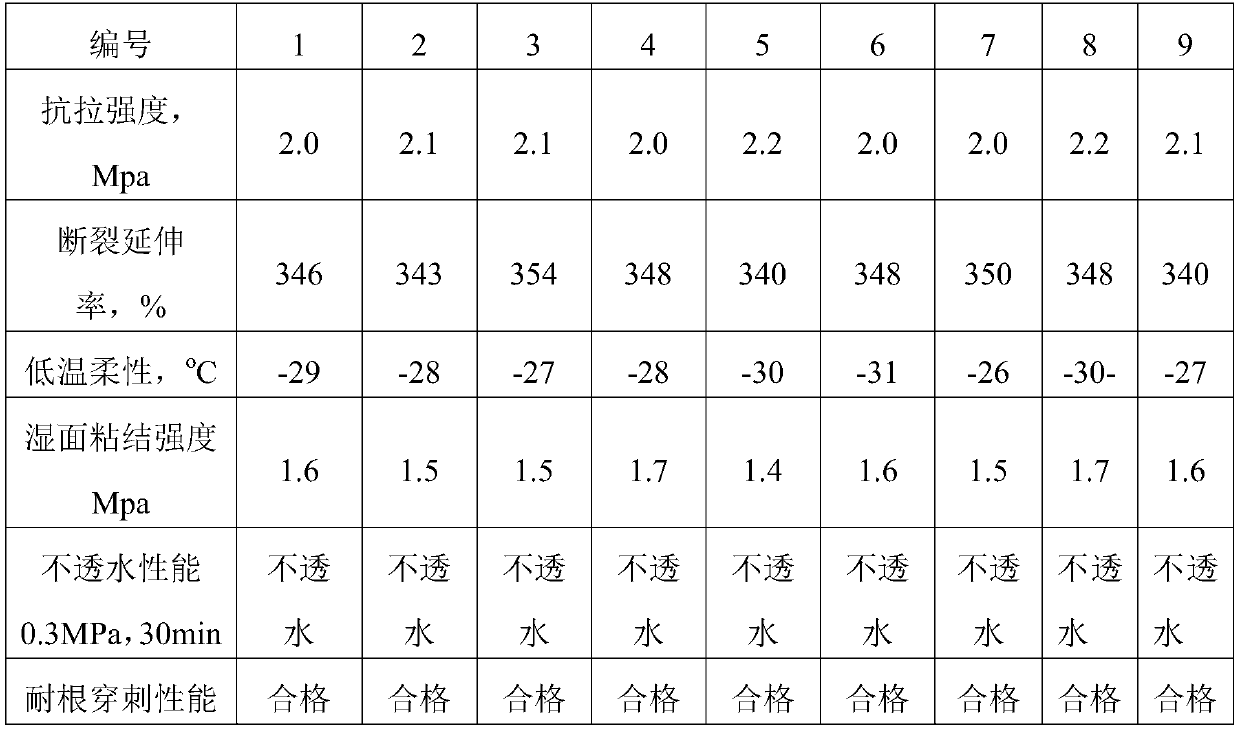

SBS modified asphalt

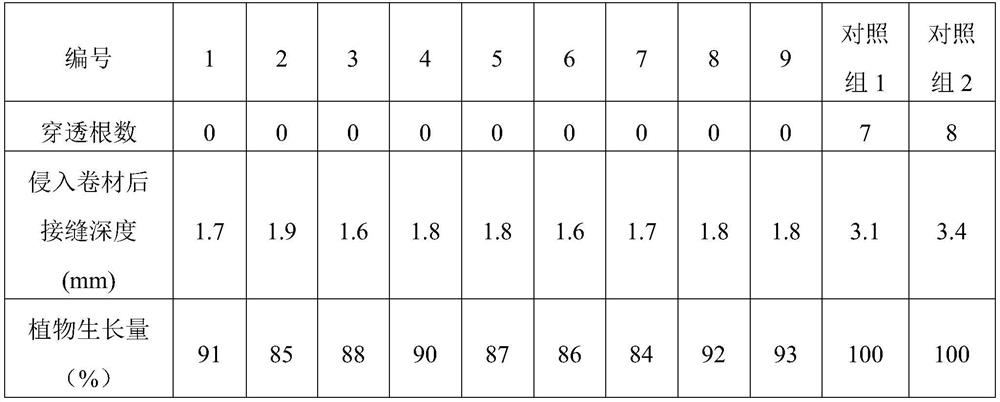

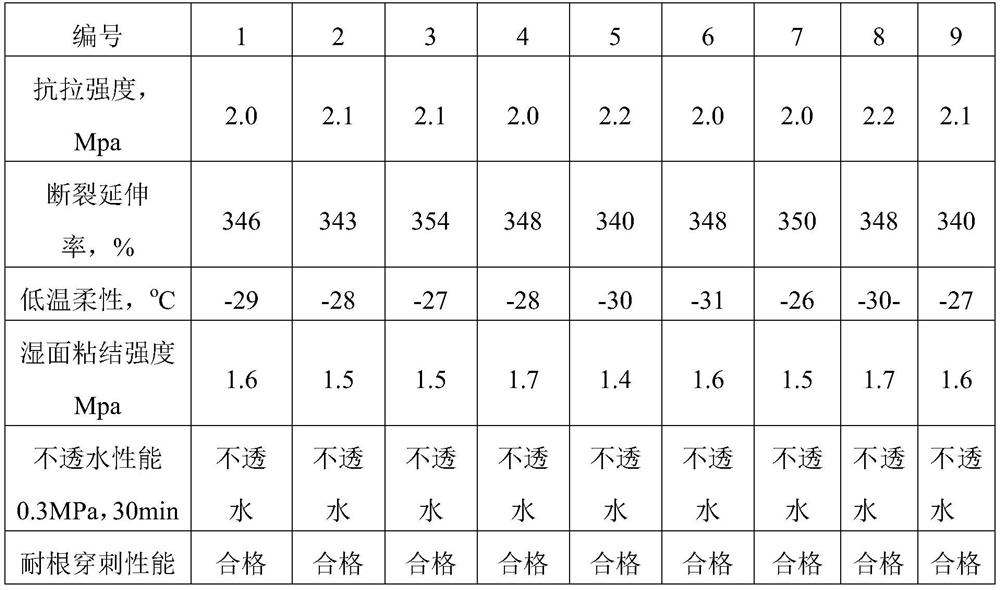

InactiveCN109825100AGood weather resistanceGood high temperature anti-ruttingBuilding insulationsWeather resistanceEngineering

The invention discloses SBS modified asphalt, which relates to the field of modified asphalt and aims to solve the problem of poor weather resistance of the existing SBS modified asphalt. The technical key points of the SBS modified asphalt comprise the following parts by weight: 95-125 parts of matrix asphalt; 23-45 parts of SBS asphalt modifiers with high weatherability; 12-25 parts of rubber oil; 9-21 parts of shielding anti-ultraviolet agents; 12-25 parts of bonding agents; and 10-26 parts of asphalt stabilizers. By adding the SBS asphalt modifiers with high weatherability and other functional additives, the weatherability of the SBS modified asphalt can be effectively improved, and the service life of the SBS modified asphalt is prolonged.

Owner:南京国路沥青有限公司

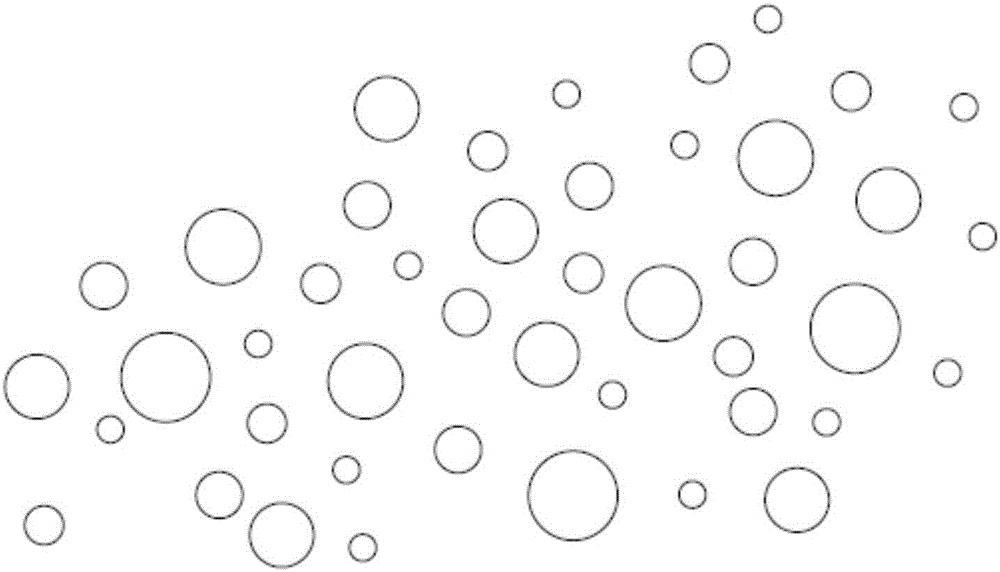

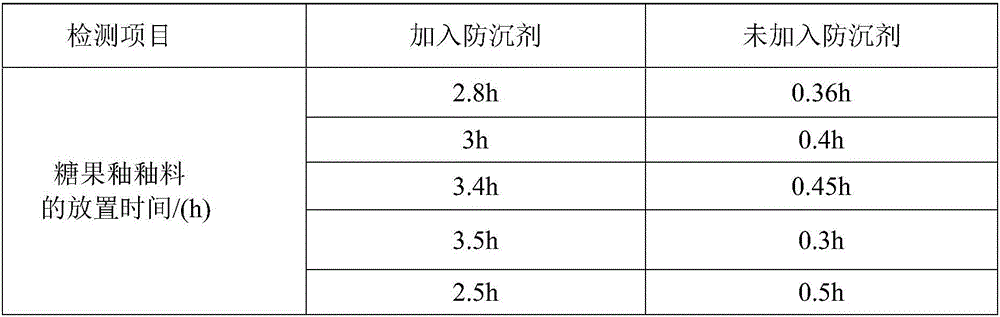

Sintered candy glaze with concave and convex texture and preparation method of porcelain tile

The invention discloses a sintered candy glaze with a concave and convex texture and a preparation method of a porcelain tile. A glaze of the sintered candy glaze with the concave and convex texture comprises printing ink and a transparent frit, wherein the mass ratio of the printing ink to the transparent frit is (2.5-3.5):(0.5-1.5); and the transparent frit is regular spherical particles. According to the sintered candy glaze with the concave and convex texture, the concave and convex texture of the burnt brick surface effect is finer; the decoration effect is more abundant; and the preparation method of the porcelain tile has the advantages of being simple in preparation technology, simple in operation, free of polishing treatment, high in stereoscopic impression of the brick surface effect and low in defective rate.

Owner:FOSHAN SHIWAN HOPO CERAMICS CO LTD

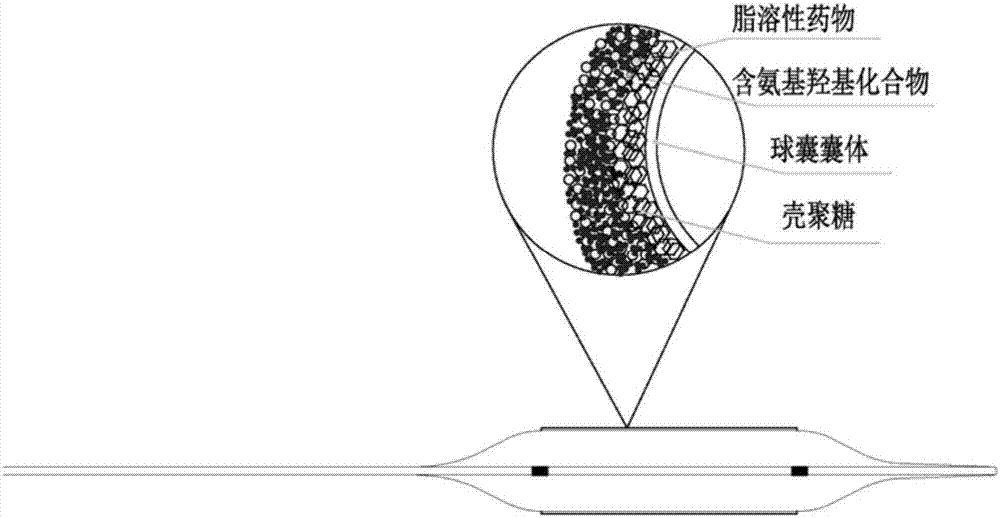

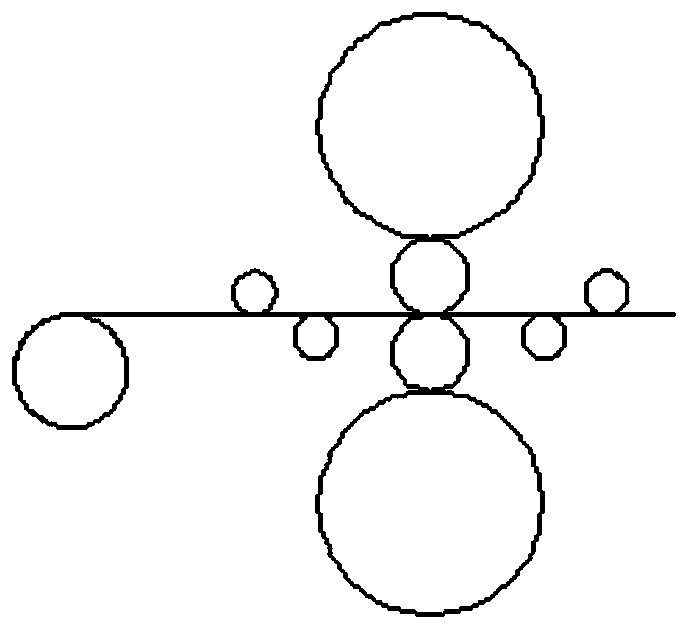

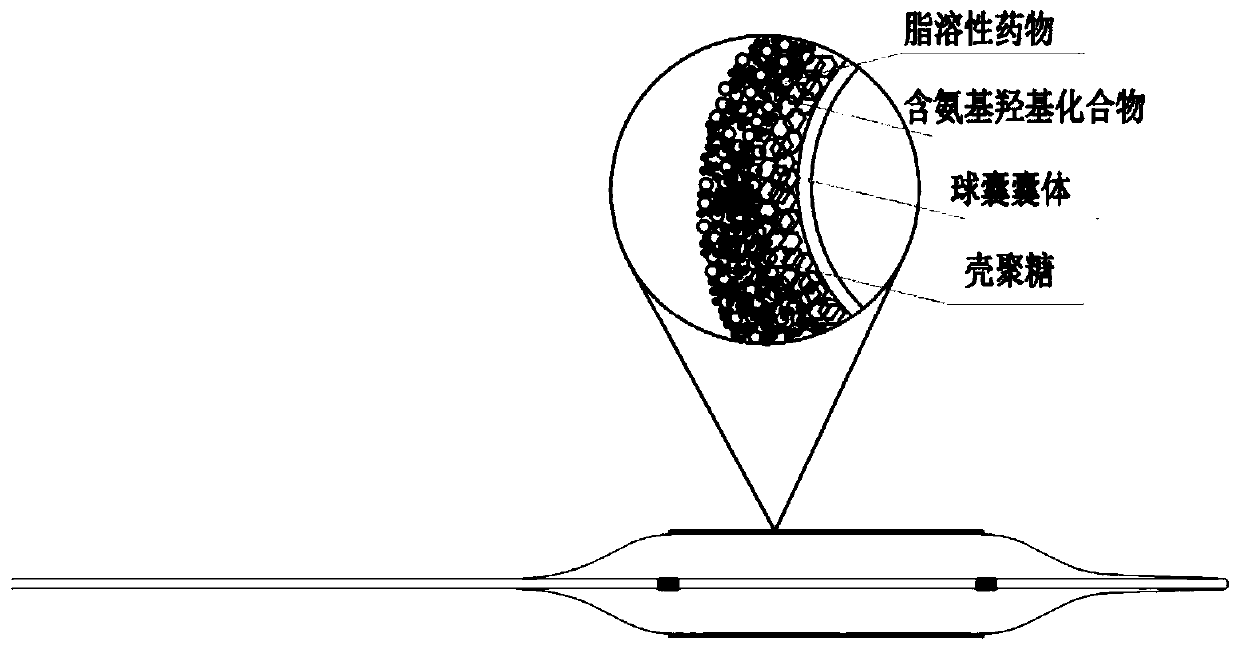

Preparation method of drug balloons as well as drug balloons prepared by preparation method and application thereof

The invention provides a preparation method of drug balloons as well as the drug balloons prepared by the preparation method and application thereof. The preparation method is characterized by comprising the following steps: curing chitosan to surfaces of balloons to obtain balloons with surfaces modified by the chitosan; spraying a drug solution on the obtained balloons with the surfaces modified by the chitosan to obtain the balloons with surfaces provided with drug coatings; carrying out surface solvation treatment on the balloons and carrying out segmented folding and packing to obtain the drug balloons. According to the drug balloons prepared by the preparation method provided by the invention, the drug coatings can be uniformly and firmly combined on the surfaces of the balloons and not easily fall off; drugs are prevented from being washed off in an in-vivo conveying process; the loss of drugs is reduced and the utilization rate of the drugs is improved; the preparation method provided by the invention is accurate, stable and efficient, is suitable for industrial large-scale production and has a wide application prospect.

Owner:LEPU MEDICAL TECH (BEIJING) CO LTD

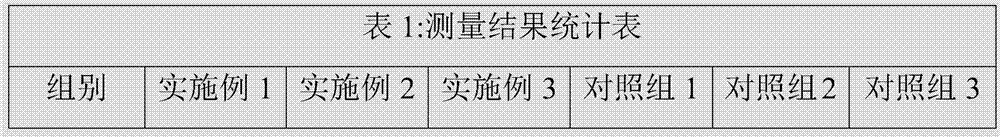

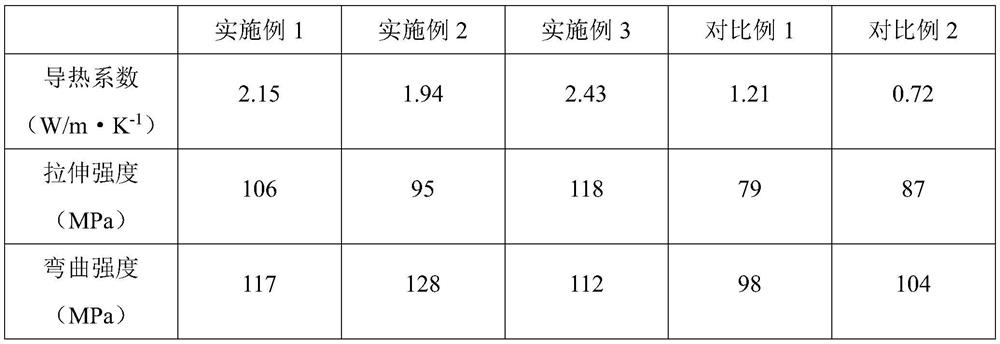

PPS composite material for nanometer injection molding and preparation process thereof

The invention relates to the field of a plastic cement novel material, in particular to a PPS composite material for nanometer injection molding and a preparation process thereof. The PPS composite material for nanometer injection molding is prepared from the following ingredients in parts by weight: 50 to 80 parts of resin, 5 to 35 parts of continuous long carbon fiber, 2 to 10 parts of silicon dioxide, 3 to 8 parts of tougheners, 0.5 to 1 part of antioxidizers, 0.5 to 2 parts of coupling agents and 0.5 to 1 parts of lubricating agents. The toughener is maleic anhydride grafted styrene-ethylene-butadiene-styrene; the laser additive is nanometer copper powder modified by acrylic ester. The PPS composite material for nanometer injection molding has the advantages of good mechanical performance, high bonding force with metal materials and good heat resistance, so that the NMT (nano molding technology) process requirements can be better met.

Owner:深圳市华盈新材料有限公司

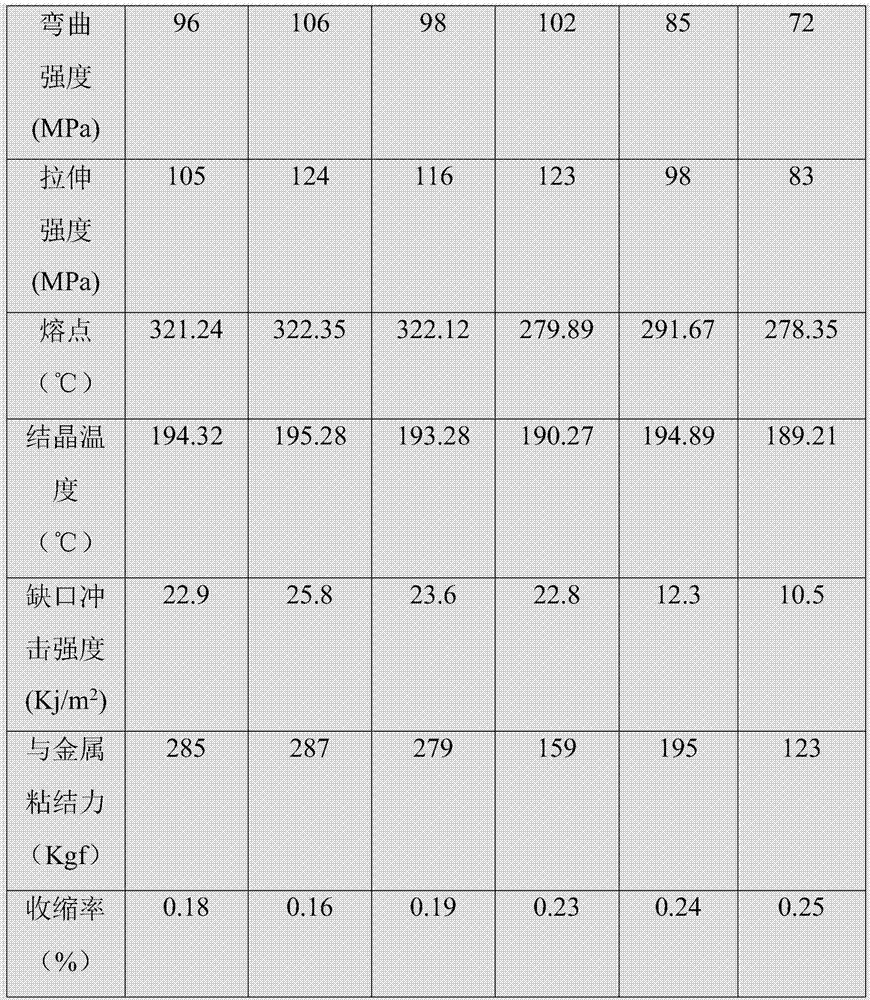

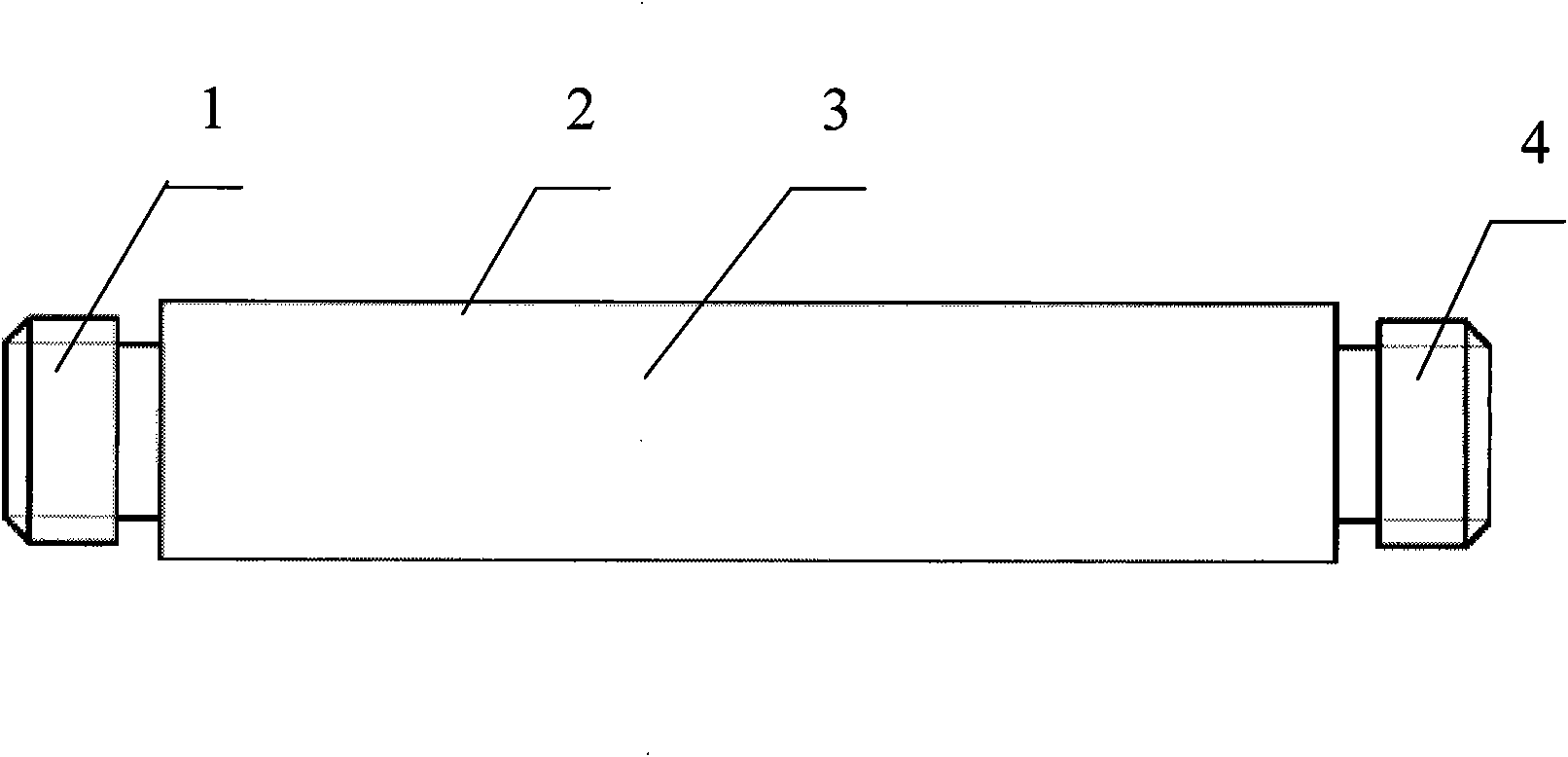

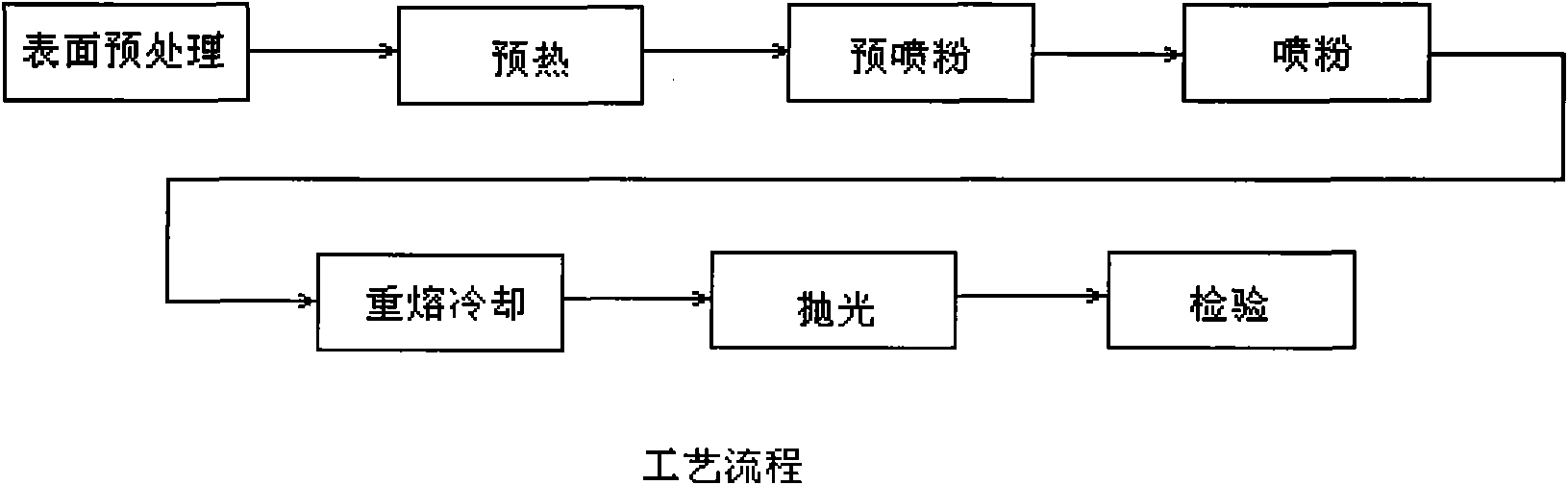

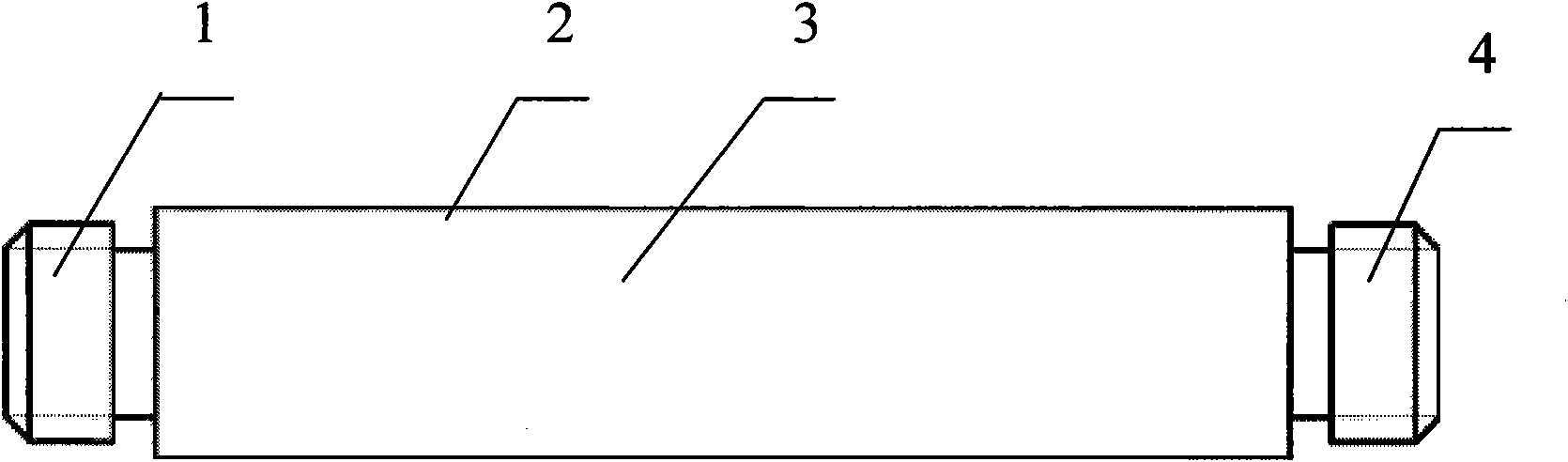

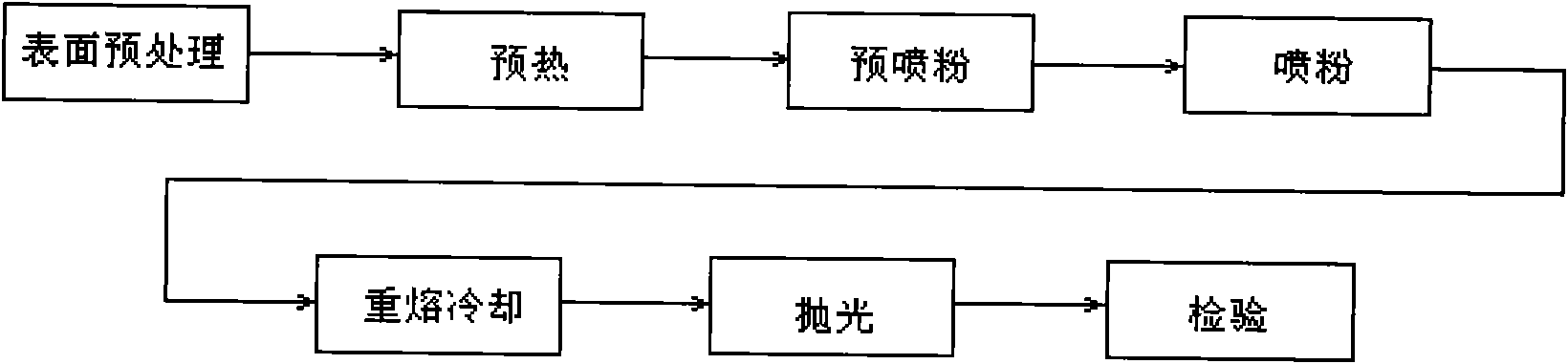

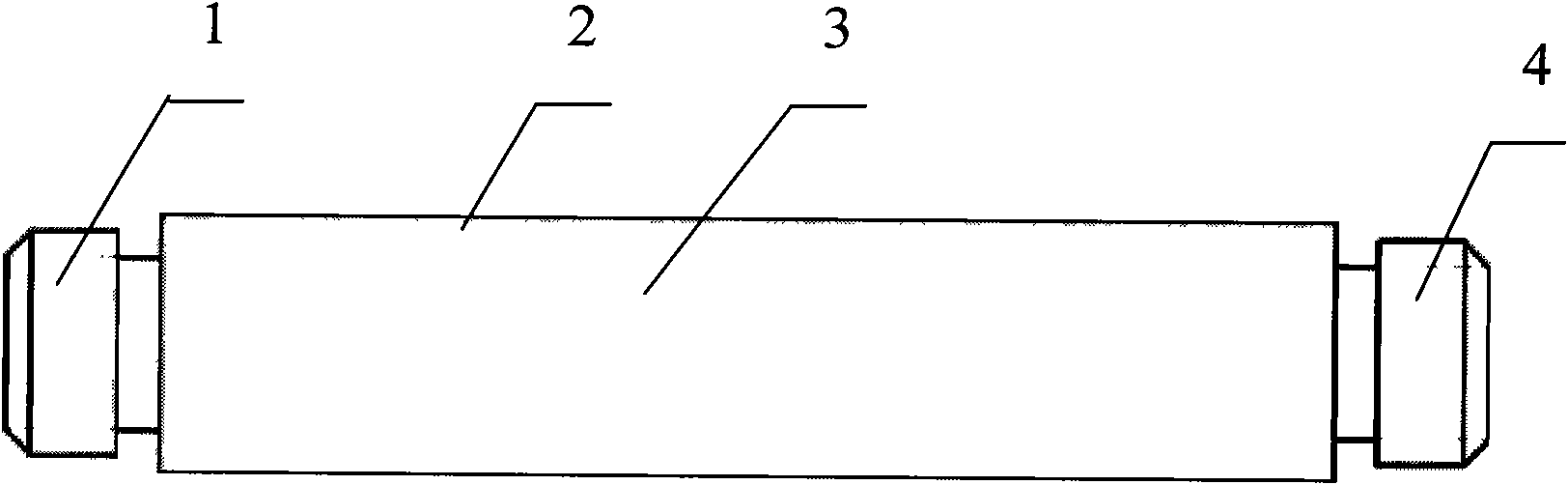

Bidirectional protecting oil pump plunger and hot spray processing technique for alloy coating of same

InactiveCN101586558ALess powderTightly boundMolten spray coatingPositive displacement pump componentsWear resistantAlloy coating

The invention relates to a bidirectional protecting oil pump plunger and a hot spray processing technique for an alloy coating of the same. The protecting oil pump plunger comprises a long cylinder, wherein two ends of the cylinder are provided with external threads and are connected with a valve cover; and the surface of the plunger is sprayed with a corrosion-resistant and wear-resistant AOC alloy coating; the thickness of the alloy coating is more than 0.25mm; the alloy coating comprises the following components: 14 to 17 percent of chromium, less than 8 percent of iron, 3.5 to 5 percent of silicon, 2.8 to 3.8 percent of boron, 0.5 to 1 percent of carbon and 65.2 to 78.9 percent of nickel; and after the working procedures of surface roughening activating treatment, spraying, remelting and polishing, a wear-resistant and corrosion-resistant coating is formed on the surface of the plunger. The process has simple and convenient operation; the coating is combined closely after spraying; the performance of a basal body of the plunger is not influenced during spraying; and the thickness of the coating is more than 0.25 mm, and the coating can resist outside wearing and corrosion, and reduce the wearing to the inner surface of a pump cylinder of an oil well pump.

Owner:ANTON OILFIELD SERVICES (GRP) LTD

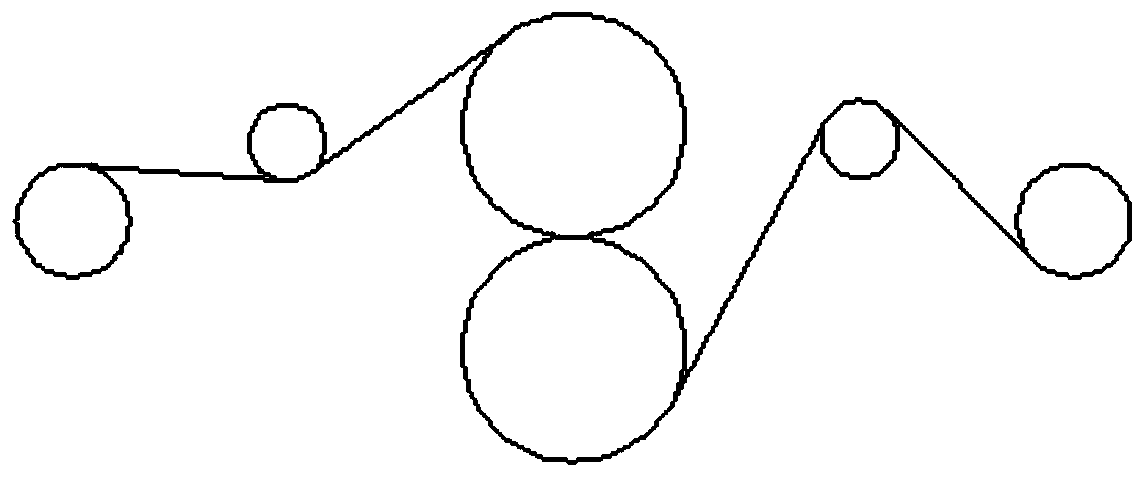

Asynchronous cold rolling forming process of aluminum alloy stainless steel composite plate

ActiveCN110883093AIncrease rolling capacityImprove rolling precisionTemperature control deviceWork cooling devicesComposite plateLine heating

The invention discloses an asynchronous cold rolling forming process of an aluminum alloy stainless steel composite plate. The process comprises the following process steps: 1, rolling and compoundinga stainless steel plate and an aluminum alloy plate in an asynchronous rolling mode, and 2, after asynchronous rolling, diffusing and annealing the composite plate, specifically, in the step 1, online heating is carried out on the opposite surface of the composite plate surface of the stainless steel plate, online cooling is carried out on the opposite surface of the composite plate surface of the aluminum alloy plate online, and the heating temperature is 350 DEG C-850 DEG C; the temperature of the composite plate surface of the stainless steel plate from which the composite plate is rolledis lower than 650 DEG C, and the temperature of the composite plate surface of the aluminum alloy plate from which the composite plate is rolled is lower than 300 DEG C; the rolling reduction rate is20%-90%; the different speed ratio of a roller for asynchronous cold rolling is 1.05-1.50; the thickness ratio of the aluminum alloy plate to the stainless steel plate is 1.5-4.0; and in the step 2, the annealing temperature is 250 DEG C-500 DEG C and the annealing time is 15-120 min. The single-side online heating process for rolling the composite plate is creatively provided so as to improve theinterface bonding strength of the composite plate and realize rolling compounding in an interface semi-melting state.

Owner:JIANGYIN KANGRUI MOLDING TECH CO LTD

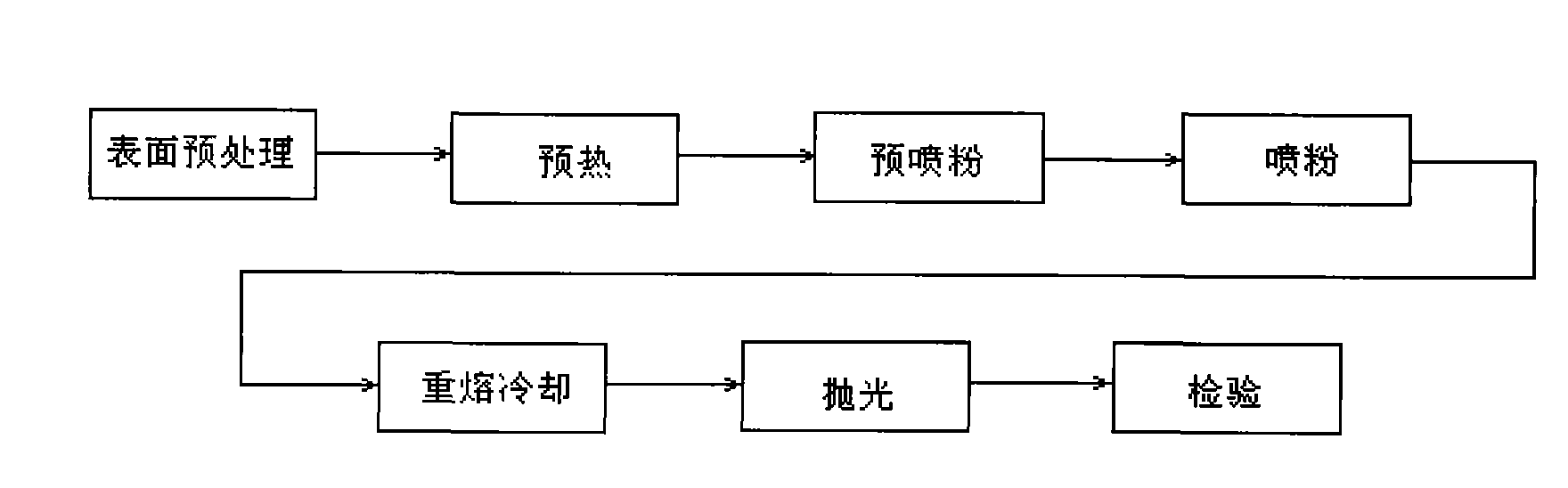

Hot spray processing technique for alloy coating of AOF bidirectional protecting oil pump plunger

InactiveCN101586237AReduce coating stressHigh bonding strengthHeat inorganic powder coatingOil wellAlloy coating

The invention relates to a hot spray processing technique for an alloy coating of an AOF bidirectional protecting oil pump plunger. The processing technique comprises the following steps: carrying out surface oil removal treatment on an oil pump plunger blank; burnishing and roughening the blank by an abrasive band; preheating the treated blank to 300 DEG C for surface activation; then pre-spraying alloy powder with the thickness about 0.2 mm to protect the surface of the plunger from contacting air indirectly; continuously spraying till the ultimate thickness of the coating reaches 0.4 mm; heating the plunger blank by an intermediate induction heating device after spraying is completed for remelting of the alloy coating, wherein the remelting temperature is about 1,000 DEG C; and finally burnishing and polishing to prepare the AOF bidirectional protecting oil pump plunger by using No.100 and No.200 abrasive bands. The processing technique has simple and convenient operation, the coating is combined closely after spraying; the performance of a basal body of the plunger is not influenced during coating; and the thickness of the coating is more than 0.25 mm, and the coating can resist outside wearing and corrosion, and reduce the wearing to the inner surface of a pump cylinder of an oil well pump.

Owner:ANTON OILFIELD SERVICES (GRP) LTD

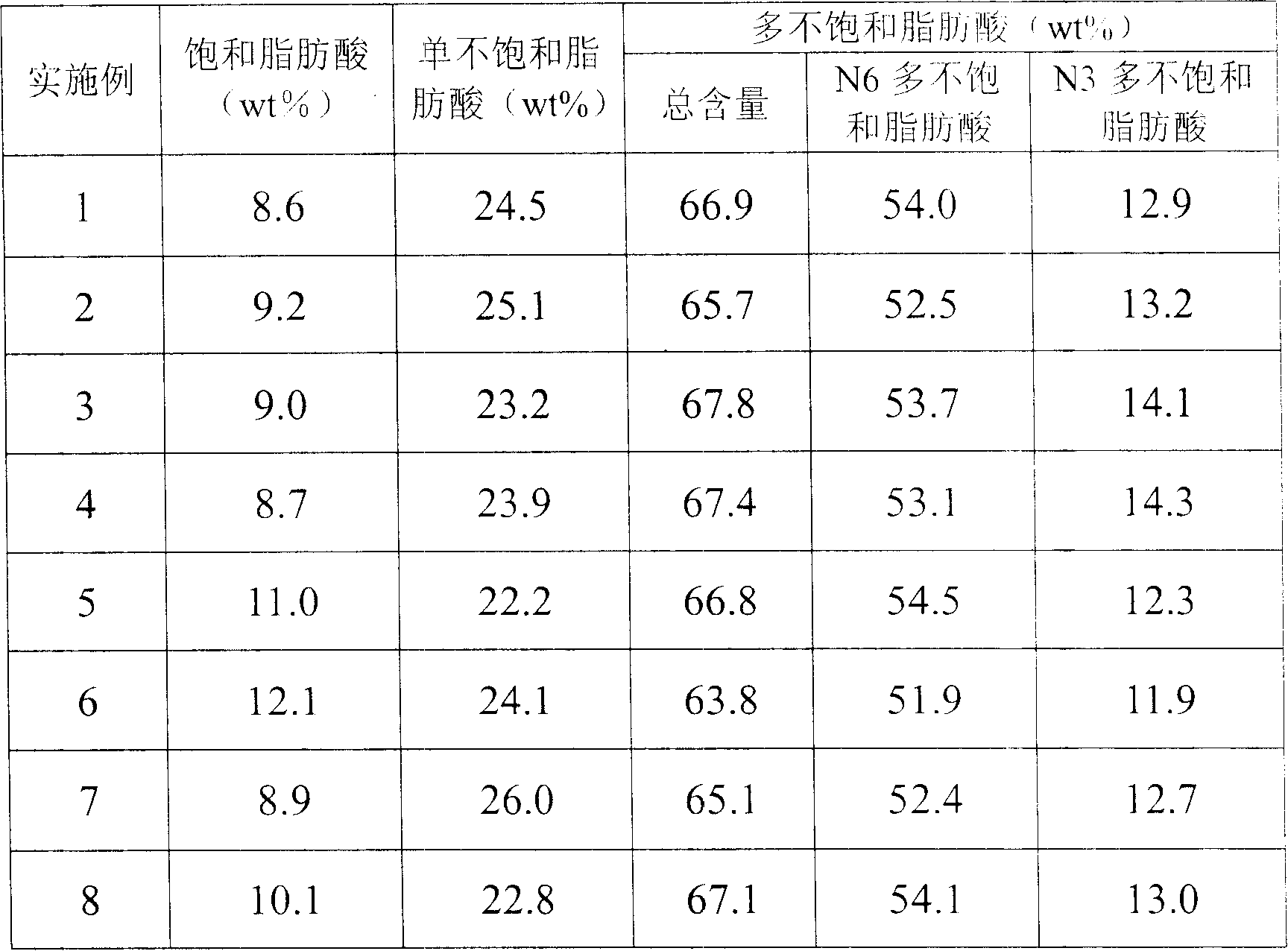

Edible oil with proportional coordination of fatty-acids, and its producing method catalyzed by biological enzyme

ActiveCN101002585AUniform and stable combinationFree of chemical residueFood preparationEdible oils/fats production/working-upUnsaturated fatty acidEnzyme

An edible oil containing proportionally fatty acid composed of saturated fatty acid, mono-unsaturated-fatty acid and poly-unsaturated-fatty acid is prepared through enzyme-catalytic synthesis reaction between the plant oil rich in N6-series poly-unsaturated-fatty acid and the plant oil rich in N3-series one.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Colored stainless steel based on ion implantation and preparation method thereof

InactiveCN102021525BThe process steps are simpleProcess environment is cleanVacuum evaporation coatingSputtering coatingRoom temperatureHardness

The invention relates to a colored stainless steel based on ion implantation and a preparation method thereof. The technical scheme is as follows: placing a stainless steel to be colored in a vacuum chamber of an ion implantation apparatus, vacuumizing to 0.1-1*10<-5>Pa, and implanting ions on the surface of the stainless steel to obtain the colored stainless steel, wherein the accelerating voltage for ion implantation is 10-100kV, and the ion implantation amount is 1*10<17>-1*10<19> ions / cm<2>; or placing a stainless steel to be colored in a vacuum chamber of an ion implantation apparatus, vacuumizing to 0.1-1*10<-5>Pa, and implanting ions on the surface of the stainless steel, wherein the accelerating voltage for ion implantation is 10-100kV, and the ion implantation amount is 5*10<15>-5*10<19> ions / cm<2>; and taking out, carrying out heat treatment, and cooling to room temperature in the furnace to obtain the colored stainless steel. The invention has the advantages of simple process and clean environment, and the obtained colored stainless steel has the characteristics of multiple color varieties, high reproducibility, uniform color, beautiful appearance, high durability and no separation. Compared with the stainless steel prior to preparation, the surface hardness and the corrosion resistance are obviously improved.

Owner:WUHAN UNIV OF SCI & TECH

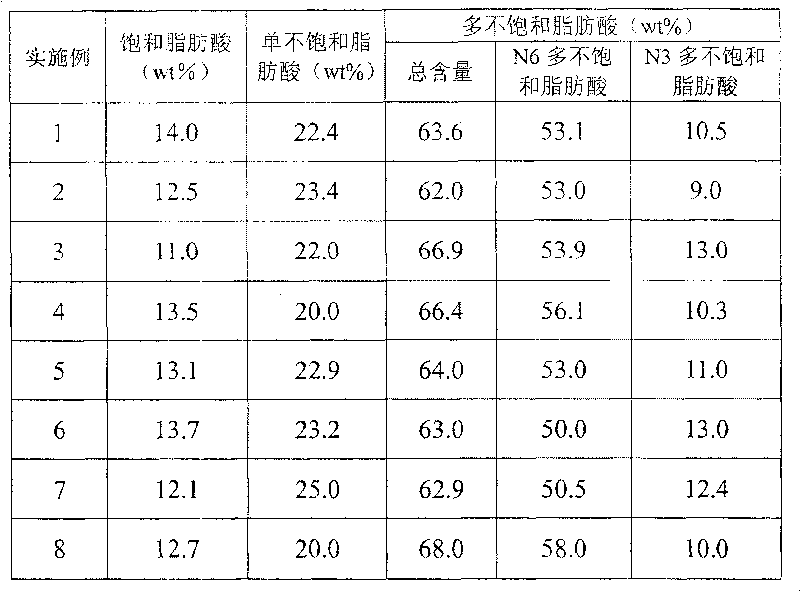

Nutrition health oil rich in nervonic acid and alpha-linolenic acid and preparation method of nutrition health oil

InactiveCN109077127AAccurate site of actionHigh selectivityEdible oils/fatsLong chain fatty acidVegetable oil

Discloses is nutrition health oil rich in nervonic acid and alpha-linolenic acid. The nutrition health oil comprises, by weight, 1-3.5wt% of nervonic acid, 35-50wt% of alpha-linolenic acid and the balance of long-chain fatty acid. Under normal pressure and solvent-free conditions, vegetable oil rich in nervonic acid and vegetable oil rich in alpha-linolenic are catalyzed by biological enzyme for transesterification, filtration is performed after reaction is completed, and filtrate obtained is the nutrition health oil rich in nvervonic acid and alpha-linolenic acid. The nutrition health oil hasthe advantages of low price, both nervonic acid and alpha-linolenic can be supplemented in accordance with the human body's daily needs, the nutritional health oil is uniform and stable in structure,and the composing proportion of nervonic acid and alpha-linoenic acid is scientifically coordinative.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

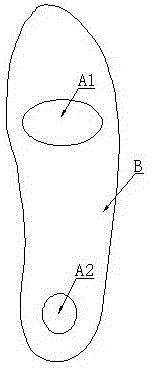

Composite functional shoe pad and preparation technique thereof

InactiveCN104352026ASimple processUniform and stable combinationInsolesDomestic articlesPerspirationComposite function

The invention relates to a composite functional shoe pad. The shoe pad is divided into an area A and an area B, wherein the area A is divided into a sole area A1 and a heel area A2, the area A is made of a closed cell polyurethane foam material, the other part is the area B, and the area B is made of a fine cell polyurethane foam material. The composite functional shoe pad is prepared by using a mold I and a mold II through a two-time injection technique. The composite functional shoe pad provided by the invention selects different foam materials for providing functional protection according to different physiological parts of a foot, can satisfy walking and moving demands of people, and can better play roles of perspiration, weight bearing and stress reduction. The process is simple, the fine cell polyurethane foam material and the closed cell polyurethane foam material are bonded more uniformly and firmly than materials directly glued, and the composite functional shoe pad is suitable for large-scale production and application.

Owner:JIHUA 3515 LEATHER & SHOES

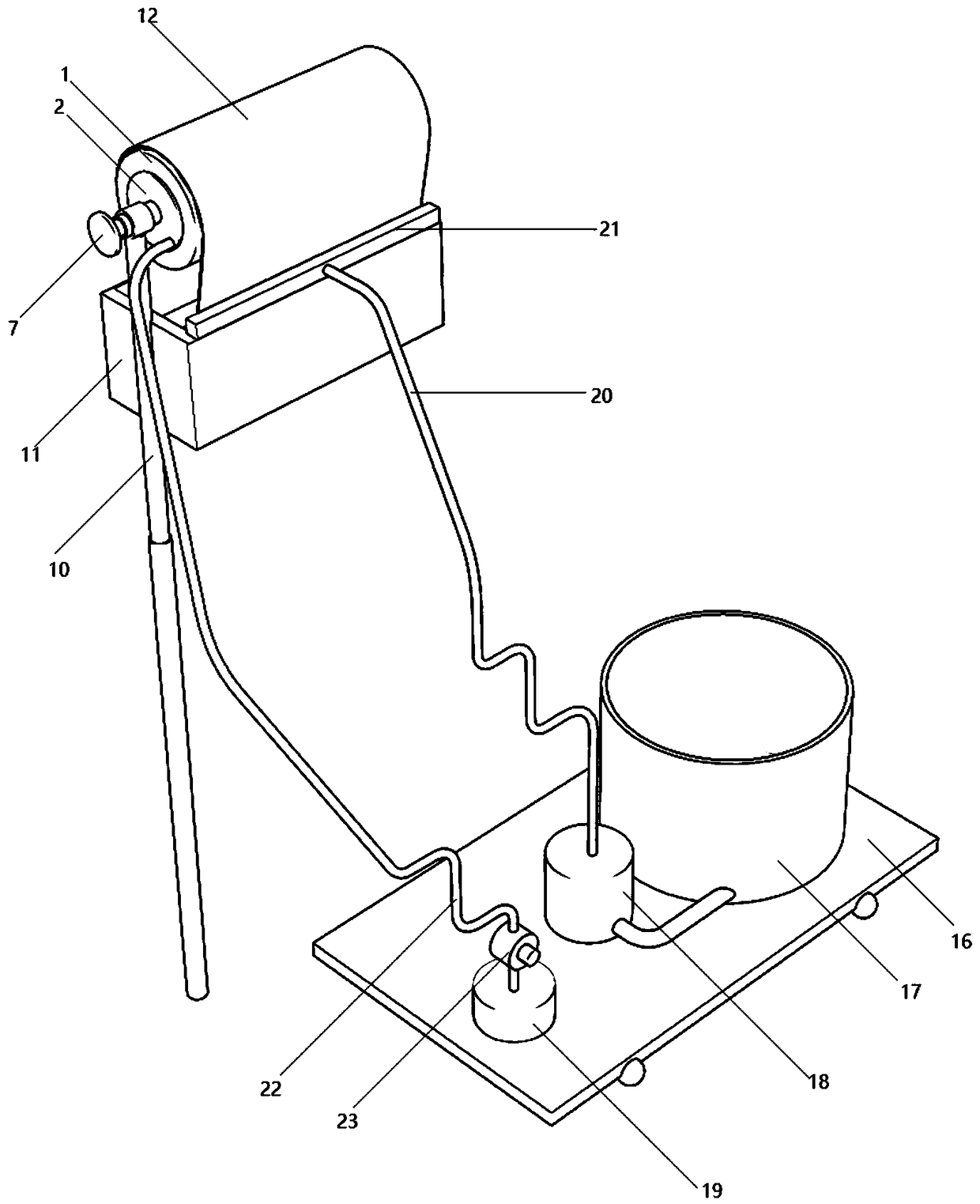

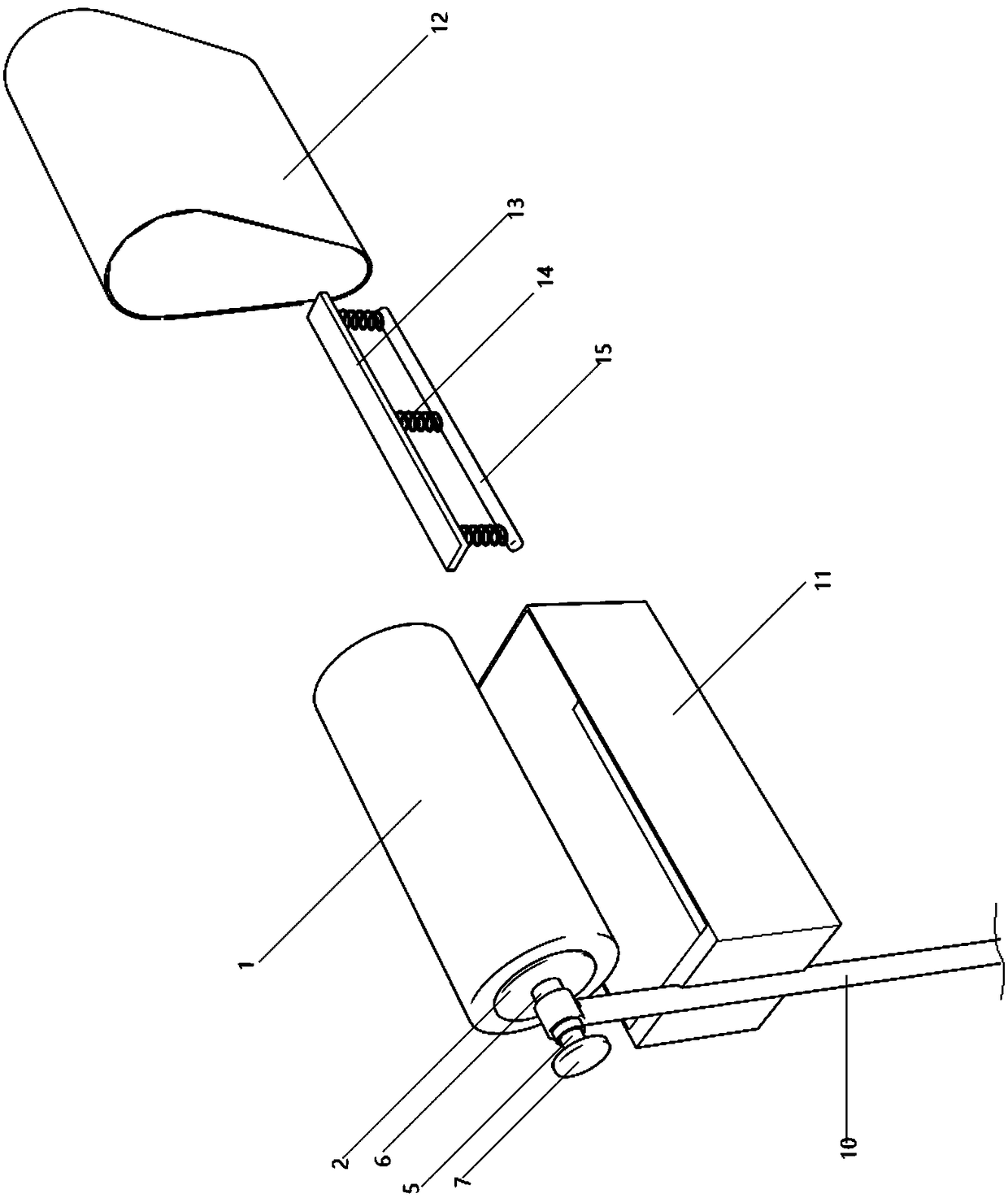

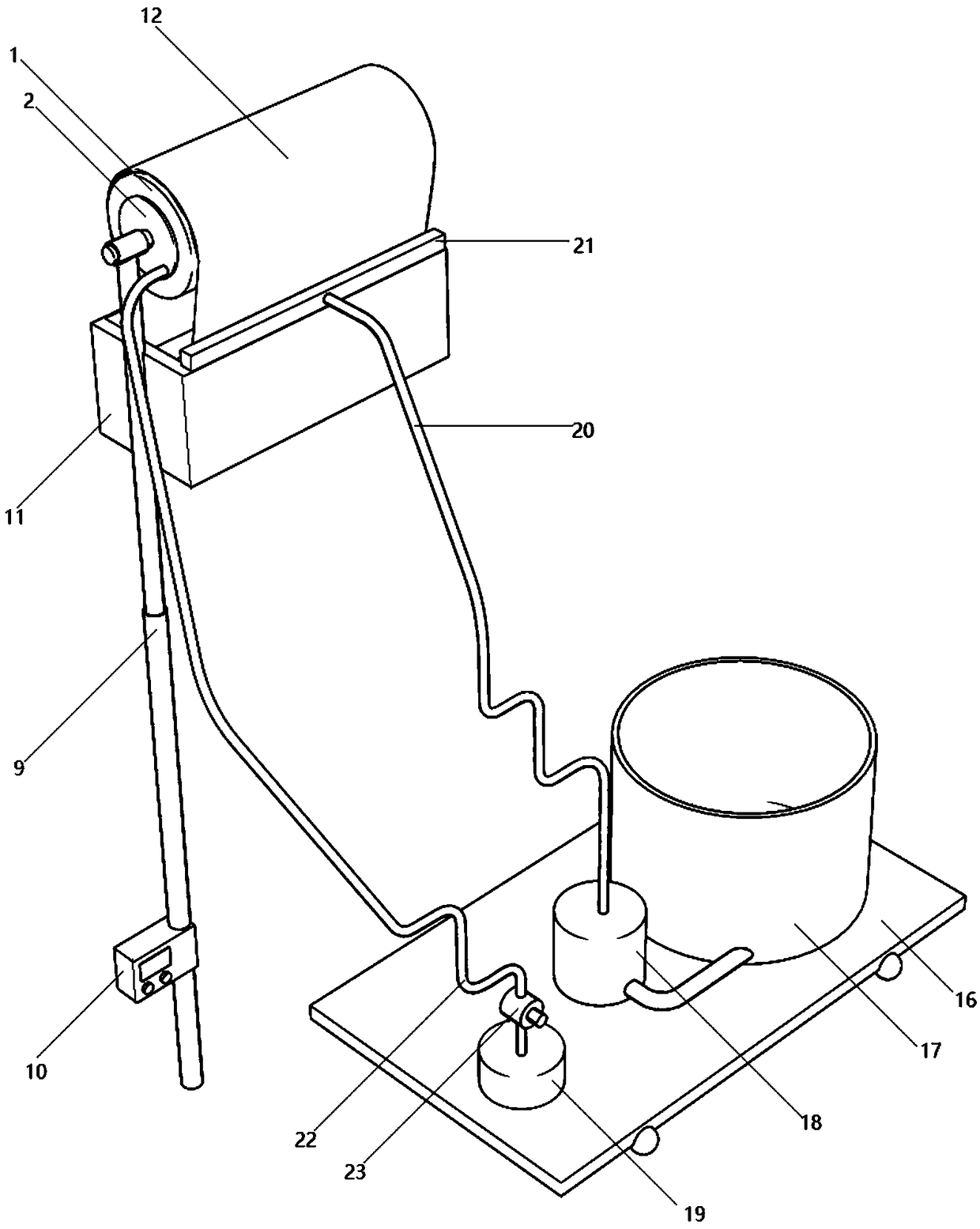

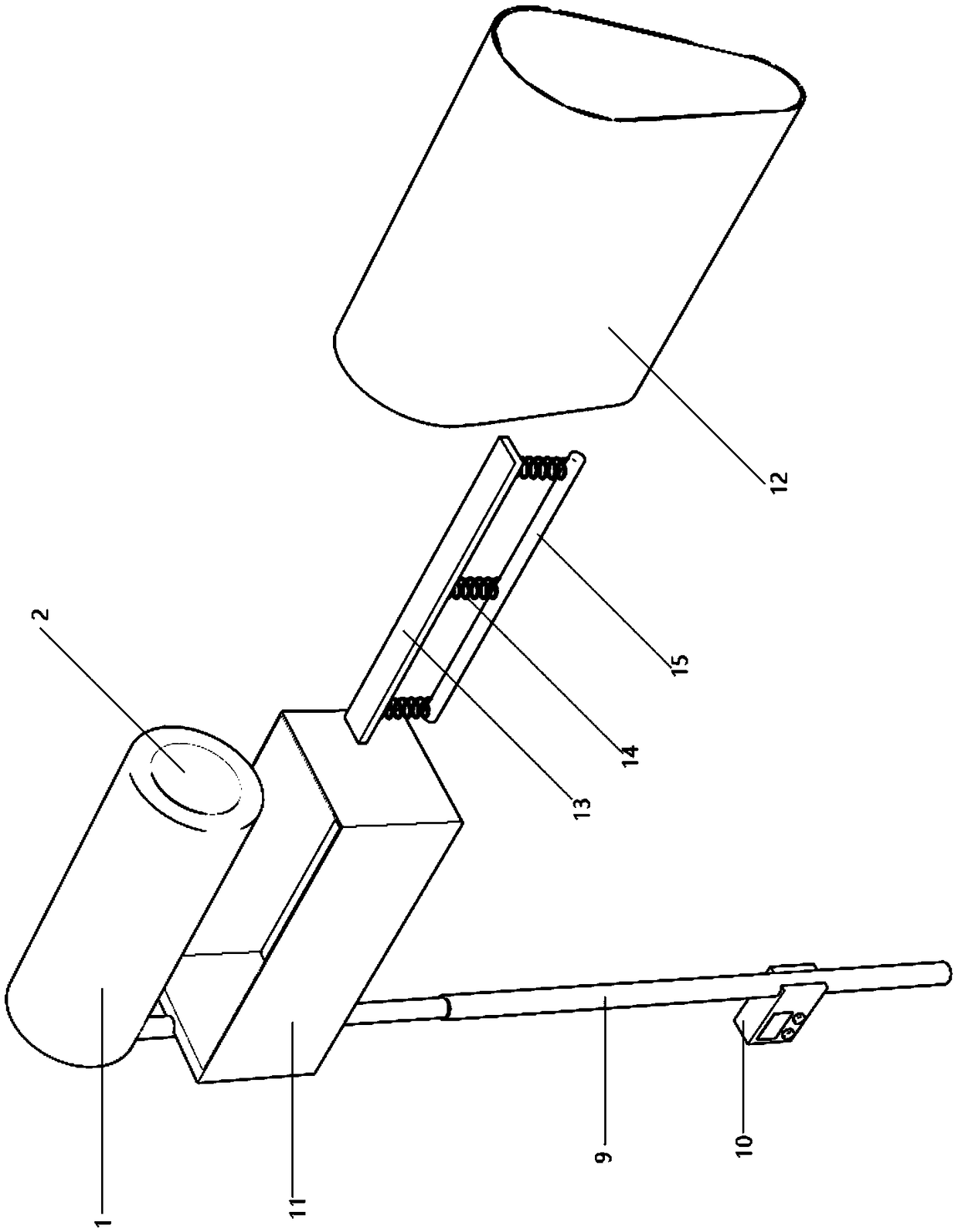

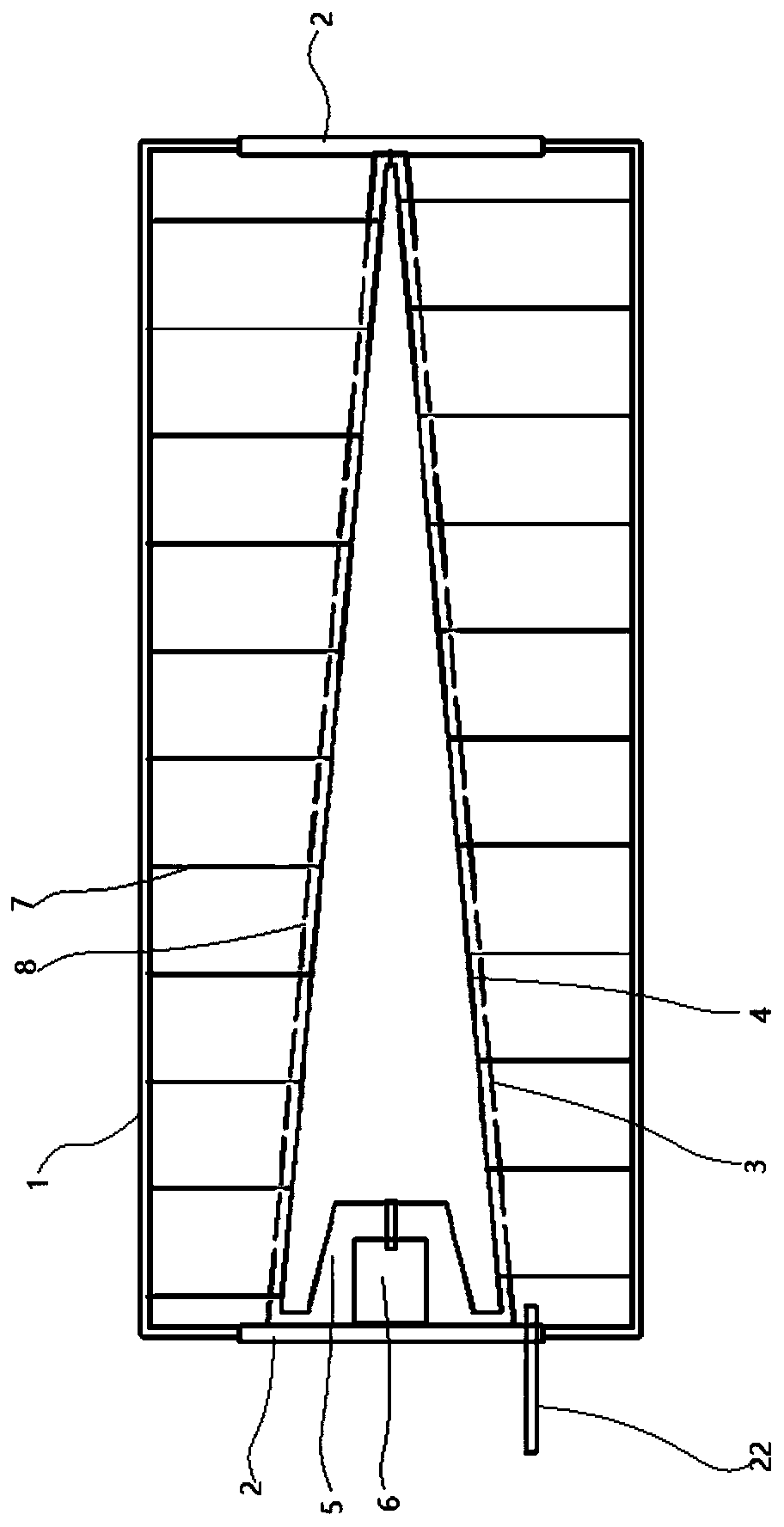

Ceiling paint-brushing device for building construction

InactiveCN109296179AUniform and stable combinationEvenly paintedBuilding constructionsBrush deviceLacquer

The invention discloses a ceiling paint-brushing device for building construction and relates to the technical field of building construction. The ceiling paint-brushing device comprises a brushing unit and a supplying unit. The brushing unit comprises a shape-fixing rolling device and a brushing device; the shape-fixing rolling device comprises a cylindrical elastic bag; a circular-truncated-cone-shaped wire reel is mounted in a limiting sleeve shell in a rotating fit mode; shape-fixing wires are evenly and fixedly connected to the inner wall of the elastic bag; the brushing device comprisesa collecting box and an annular brushing belt; and the supplying unit comprises a moving plate, and a paint barrel, a supplying pump and an inflation pump are mounted on the moving plate. The ceilingpaint-brushing device has the beneficial effects that the brushing unit can deform to adapt to even brushing of the plane, the near-arc-shaped edge, the arc-shaped end face and the like; and through inflation expansion of the elastic bag, each part, making contact with a ceiling, of the brushing belt can better bear force, and the paint is bonded with the ceiling more evenly and firmly.

Owner:陈玉振

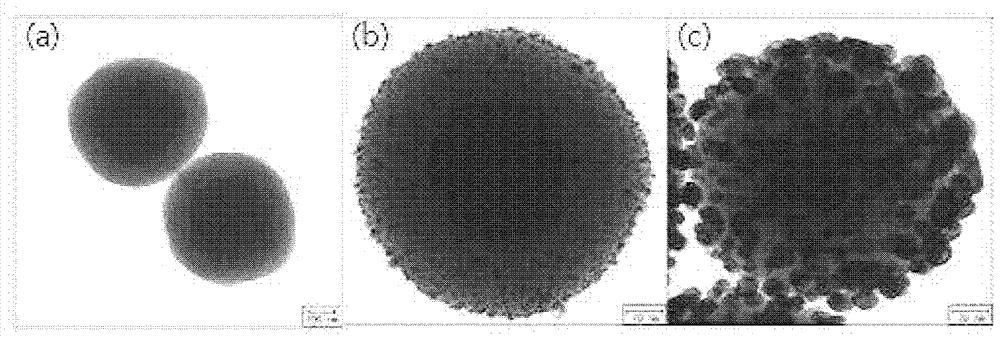

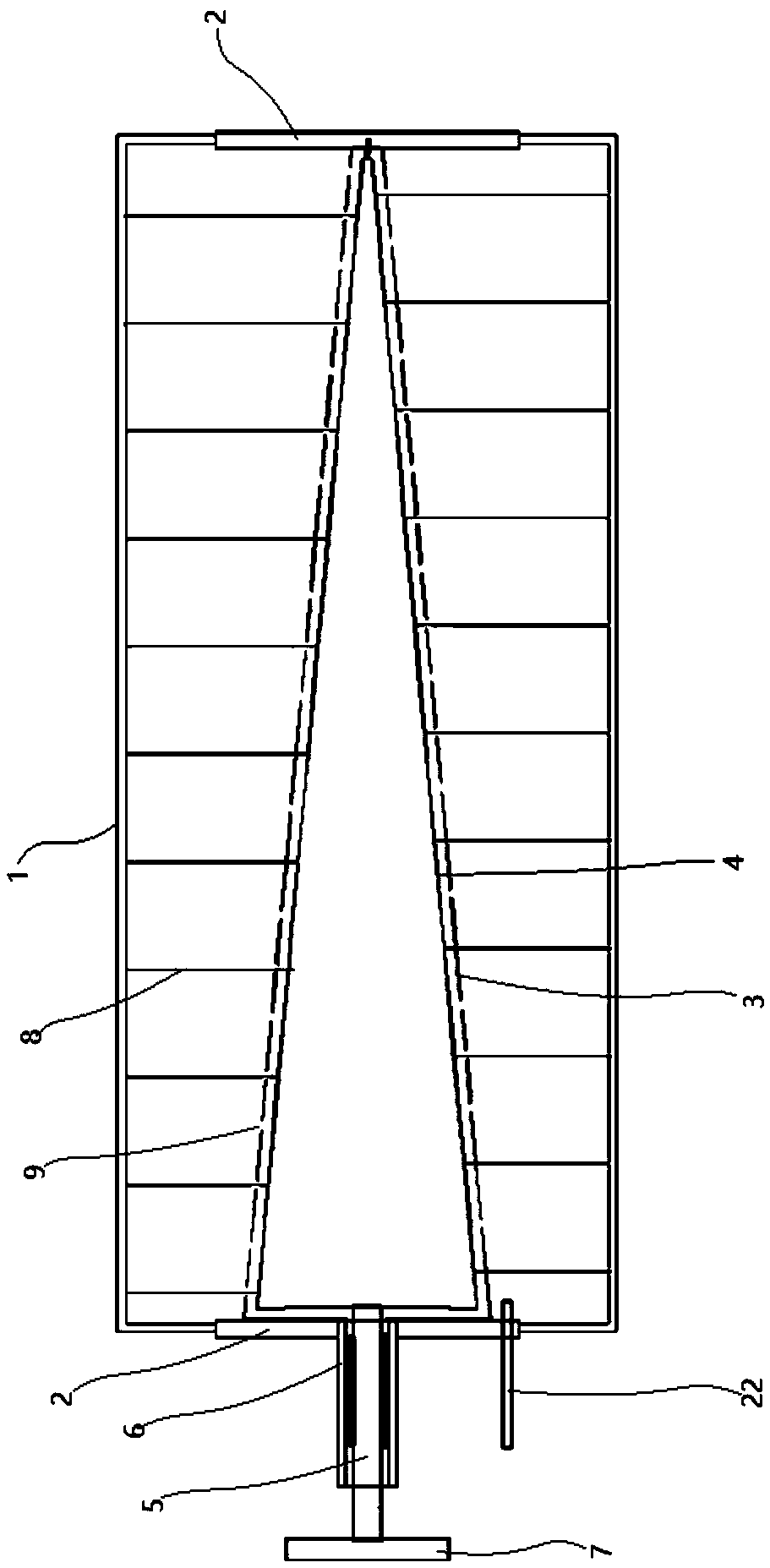

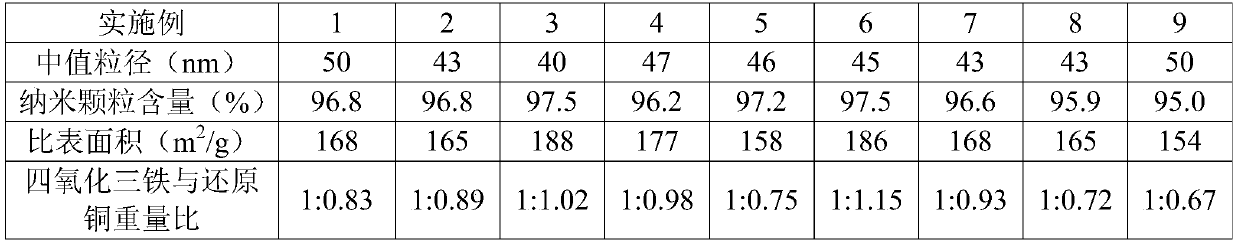

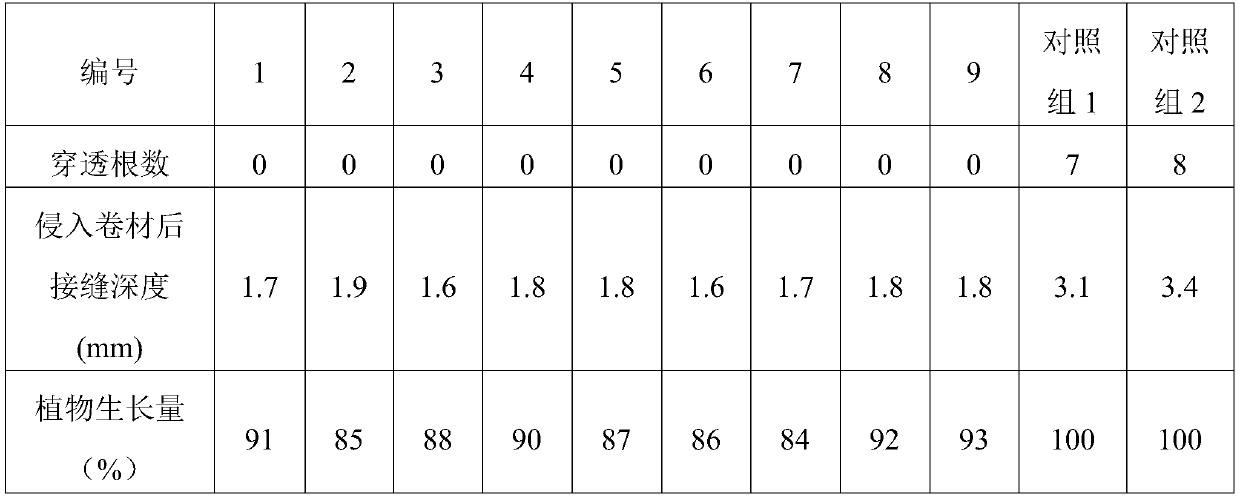

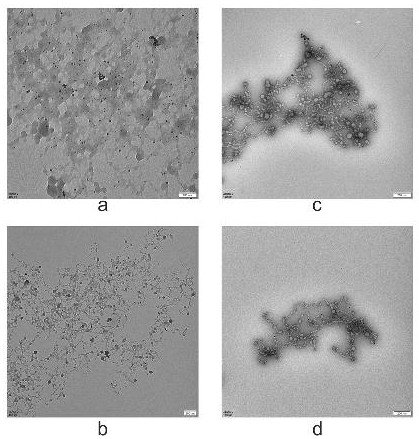

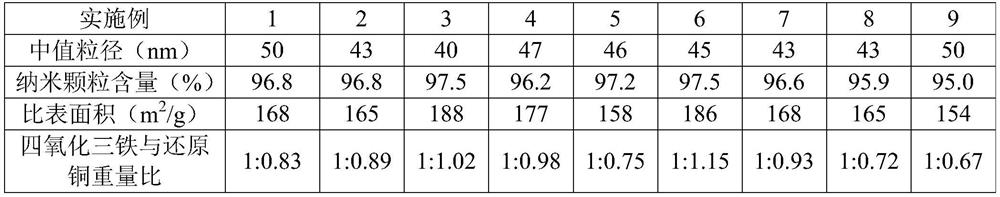

Ferroferric oxide copper-loaded nanoparticle as well as preparation method and application thereof in preparation of root retarding material

ActiveCN110240733AImprove solubilityHas the ability to complex metal ionsBuilding insulationsCopper chlorideCell membrane

The invention discloses a ferroferric oxide copper-loaded nanoparticle as well as a preparation method and application thereof in preparation of a root retarding material. The ferroferric oxide copper-loaded nanoparticles refer to nanoparticles formed by loading reduced copper nanogrannules uniformly on the surfaces of ferroferric oxide nanospheres, wherein the weight ratio of ferroferric oxide to reduced copper in each nanoparticle is 1:(0.3-1.2). The method comprises the following steps: dispersing ferroferric oxide nanospheres in chloroform; sequentially adding a copper chloride solution, sodium citrate and hydrolyzed gelatin, performing stirring at a temperature of 40-50 DEG C for 2-4 h, performing washing, and performing magnetic attraction to separate products so as to obtain the ferroferric oxide copper-loaded nanoparticles. The root retarding effect of a root retarding agent product prepared by utilizing the ferroferric oxide copper-loaded nanoparticle as an additive is achieved by virtue of interference of copper ions on substances in plants and destruction to root cell membranes while the copper ions are in contact with root cells, taproot growth is inhibited, lateral root growth is promoted, and root retardance and puncture prevention effects are achieved.

Owner:HUBEI UNIV OF TECH

Bidirectional protecting oil pump plunger and hot spray processing technique for surface of same

InactiveCN101586560ALess powderTightly boundMolten spray coatingPositive displacement pump componentsThermal sprayingWear resistant

The invention relates to a directional protecting oil pump plunger and a hot spray processing technique for the surface of the same. The protecting oil pump plunger comprises a long cylinder; two ends of the cylinder are provided with external threads and are connected with a valve cover; the surface of the plunger is sprayed with a layer of corrosion-resistant and wear-resistant AOC alloy coating; the thickness of the alloy coating is more than 0.25 mm; and after the working procedures of surface roughening activating treatment, spraying, remelting and polishing, a wear-resistant and corrosion-resistant coating is formed on the surface of the plunger. The processing technique has simple and convenient operation; the coating is combined closely after spraying; the performance of a basal body of the plunger is not influenced during spraying; and the thickness of the coating is more than 0.25 mm, and the coating can resist outside wearing and corrosion and reduce the wearing to the inner surface of a pump cylinder of an oil well pump.

Owner:ANTON OILFIELD SERVICES (GRP) LTD

Bidirectional protecting oil pump plunger and hot spray processing technique for surface of same

InactiveCN101586559AReduce stressHigh bonding strengthMolten spray coatingPositive displacement pump componentsThermal sprayingWear resistant

The invention relates to a bidirectional protecting oil pump plunger and a hot spray processing technique for the surface of the same. The protecting oil pump plunger comprises a long cylinder, wherein two ends of the cylinder are provided with external threads and connected with a valve cover; and the surface of the plunger is sprayed with a layer of corrosion-resistant and wear-resistant AOC alloy coating. The processing technique comprises the following steps: carrying out surface oil removal treatment on a plunger blank; burnishing and roughening the plunger blank; preheating the plunger blank for surface activation; pre-spraying alloy powder to protect the surface of the plunger from contacting air indirectly; continuously spraying till the ultimate thickness of the coating reaches 0.4 mm; heating the plunger blank after spraying for remelting of the alloy coating; and finally burnishing and polishing the plunger blank to prepare the bidirectional protecting oil pump plunger with the coating of which the thickness is more than 0.25 mm. The processing technique has simple and convenient operation, the coating is combined closely after spraying; the performance of a basal body of the plunger is not influenced during coating; and the thickness of the coating is more than 0.25 mm, and the coating can resist outside wearing and corrosion, and reduce the wearing to the inner surface of a pump cylinder of an oil well pump.

Owner:ANTON OILFIELD SERVICES (GRP) LTD

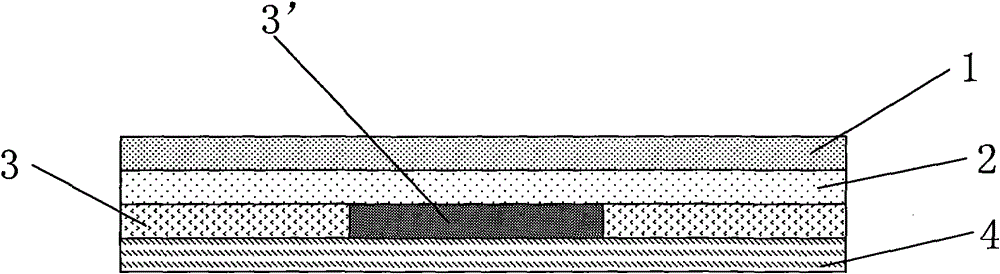

High-heat-dissipation metal aluminum-based copper-clad plate

InactiveCN113043680AImprove stabilityImprove cooling effectMetal silicidesSynthetic resin layered productsMicrosphereFirming agent

The invention discloses a high-heat-dissipation metal aluminum-based copper-clad plate. The copper-clad plate is formed by pressing a copper foil plate, a heat dissipation insulating layer and an aluminum substrate which are sequentially arranged from top to bottom. The heat dissipation insulating layer comprises the following components in parts by weight: 100 parts of epoxy resin, 20-40 parts of heat conduction filler, 2-8 parts of curing accelerator and 20-50 parts of curing agent. The heat conduction filler is prepared by coating boron nitride with modified hollow microspheres, and the modified hollow microspheres are porous hollow microspheres prepared by compounding tantalum disilicide powder and basic cobalt carbonate. The epoxy resin is used as a matrix, and the added heat-conducting filler not only enhances the heat dissipation capability of the epoxy resin, but also enhances the mechanical property of the epoxy resin, so that the heat dissipation insulating layer has the characteristics of high heat conductivity, high stability and the like, and heat accumulated by a heating element can be quickly, timely and effectively transferred; and normal operation of equipment is ensured.

Owner:SHENZHEN CHUANGHUI ALLIANCE TECH

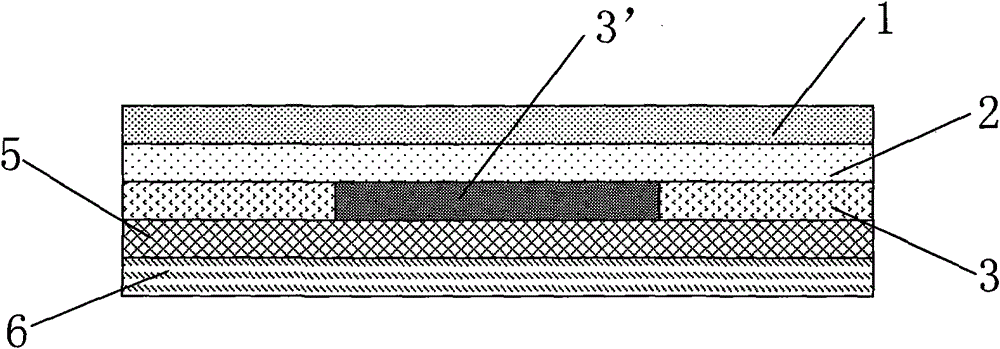

Graphene-coated glass wool felt resin composite material plate and preparation method thereof

The invention discloses a graphene-coated glass wool felt resin composite material plate and a preparation method thereof. The composite material plate is composed of graphene-coated glass wool felt with the volume fraction of 10-25% and a resin matrix with the volume fraction of 75-90%. The composite material plate is characterized in that the graphene-coated glass wool felt is composed of glassfiber cotton felt and graphene, and the glass fiber cotton felt is composed of glass fiber monofilaments and a binder; and the graphene uniformly coats the surface of the binder to form a continuous coating structure. The preparation method comprises the following steps of: (1) modifying the surfaces of glass fibers; (2) modifying the glass fibers with graphene oxide; (3) reducing the graphene oxide; and (4) carrying out vacuum impregnation, heating and curing on a resin prepreg. The graphene-coated glass wool felt is adopted as a reinforcing phase, the high-temperature resistance and the mechanical property of the composite material plate are improved, and the electromagnetic shielding performance of a composite material substrate is improved by filling resin.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Ceiling paint-brushing device for building construction

ActiveCN109296178AUniform and stable combinationEvenly paintedBuilding constructionsBrush deviceLacquer

The invention discloses a ceiling paint-brushing device for building construction and relates to the technical field of building construction. The ceiling paint-brushing device comprises a brushing unit and a supplying unit. The brushing unit comprises a shape-fixing rolling device and a brushing device; the shape-fixing rolling device comprises a cylindrical elastic bag; a circular-truncated-cone-shaped wire reel is mounted in a limiting sleeve shell in a rotating fit mode; shape-fixing wires are evenly and fixedly connected to the inner wall of the elastic bag; the brushing device comprisesa collecting box and an annular brushing belt; and the supplying unit comprises a moving plate, and a paint barrel, a supplying pump and an inflation pump are mounted on the moving plate. The ceilingpaint-brushing device has the beneficial effects that the brushing unit can deform to adapt to even brushing of the plane, the near-arc-shaped edge, the arc-shaped end face and the like; and through inflation expansion of the elastic bag, each part, making contact with a ceiling, of the brushing belt can better bear force, and the paint is bonded with the ceiling more evenly and firmly.

Owner:江苏万嘉新材料科技有限公司

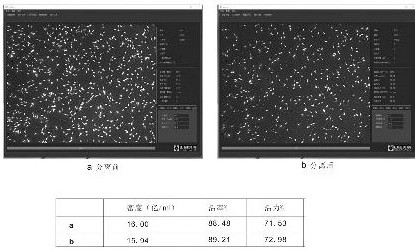

Method for rapidly typing mammal sperms by using biologically modified beta-cyclodextrin nano magnetic particles

ActiveCN114733455AEasy to separateEfficient separationMaterial nanotechnologyCell dissociation methodsTLR8Motility

The invention provides a method for rapidly typing mammal sperms by using biologically modified beta-cyclodextrin nano magnetic particles, by which a large amount of sperms can be separated even in a short time, and the motility of the separated sperms can be prevented from being reduced. On one hand, the nano magnetic particle can be used as a carrier of biomacromolecules, and because the nano magnetic particle is coated with a TLR7 / TLR8 ligand, the nano magnetic particle not only has the characteristic of specifically recognizing X / Y sperms, but also has the characteristic of magnetism, so that the nano magnetic particle has more advantages in the aspects of separating, purifying and concentrating target sperms from a complex sample and the like; the method has the advantages of rapidness (5-20 minutes), high specificity, simplicity and convenience in operation, wide application range (almost applicable to treatment of all samples) and the like. The defects of low separation efficiency, relatively strong interaction among particles and relatively poor dispersity of conventional micron-sized immunomagnetic particles can be overcome.

Owner:北京田园奥瑞生物科技有限公司

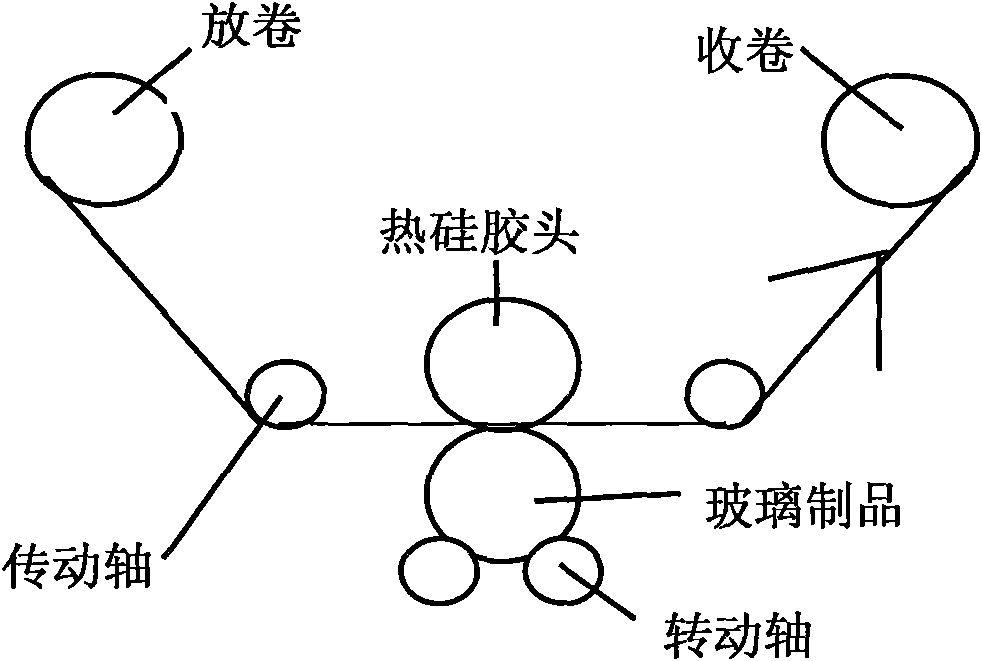

Method for further curing adhesive layer of transfer printing film subjected to transfer printing

ActiveCN102152685BImprove mobilityWill not affect changesDecorative surface effectsPolyureas/polyurethane adhesivesUV curingShrinkage rate

A method for ultraviolet curing an adhesive layer in a thermal transfer film is disclosed. The method includes the following steps: sticking the adhesive layer on a surface of printing stock through heating and pressurizing; peeling a carrier layer in the thermal transfer film to transfer an image layer in the thermal transfer film onto the surface of printing stock; and further curing the adhesive layer by subjecting to an ultraviolet radiation. The adhesive layer comprises prepolymer, reactive diluents, resin, curing agent and additives. The curing agent comprises cationic photoinitiator and free-radical photoinitiator. This method has the advantage of good curing effect, improved adhesive performance, lower curing shrinkage rate and excellent image surface smoothness.

Owner:广东东田转印新材料有限公司

Preparation method of high-polymer material for water blocking

The invention discloses a preparation method of a high-polymer material for water blocking. The high-polymer material comprises the following raw materials in parts by weight: 260 parts of acrylic acid, 281 parts of 50% sodium hydroxide solution, 26 parts of acrylamide, 392 parts of deionized water, 7.5 parts of ethoxylated pentaerythritol tetraacrylate, 1.5 parts of propylene diamine and 0.8 part of initiator. The preparation method comprises the following steps: adding the acrylic acid, the deionized water and the 50% sodium hydroxide solution into a reactor, and neutralizing; then adding the acrylamide, the ethoxylated pentaerythritol tetraacrylate and the propylene diamine; introducing nitrogen gas to remove oxygen for 10 minutes, and stirring; adding the initiator, and initiating polymerization reaction at 5-8 DEG C to obtain a colloid; and granulating, drying, crushing, and screening. According to the invention, the preparation method is simple in production process and stable in technical performance; the high-polymer material has a high water absorption rate and achieves a high swelling rate when encountering water; and the high-polymer material has a good water blocking effect and favorable heat stability and degradation resistance, is not influenced by a high-temperature environment, and can be uniformly and firmly combined with a substrate.

Owner:SHANDONG NUOER BIOLOGICAL TECH

Ferric iron tetroxide-loaded copper nanoparticles and its preparation method and application in the preparation of root-resistant materials

ActiveCN110240733BImprove solubilityHas the ability to complex metal ionsBuilding insulationsLateral rootCell membrane

The invention discloses a ferric oxide-supported copper nano-particle and its preparation method and its application in the preparation of root-blocking materials; The reduced copper nanoparticles, wherein, in each nanoparticle, the weight ratio of ferric iron tetroxide to reduced copper is 1:0.3-1.2. In this method, ferric ferric oxide nanoparticle balls are first dispersed in chloroform, then copper chloride solution, sodium citrate and hydrolyzed gelatin are added in sequence, stirred at a temperature of 40-50°C for 2-4h, washed, and the product is separated by magnetic absorption That is, copper nanoparticles supported by ferric oxide are obtained. In the present invention, the root-blocking effect of the root-blocking agent prepared by using ferric iron tetroxide-loaded copper nanoparticles as an additive depends on the interference of copper ions on substances in plants, and the destruction of root cell membranes when copper ions come into contact with root cells, thereby inhibiting taproot. Growth, promote the growth of lateral roots, and achieve the effect of root resistance and anti-puncture.

Owner:HUBEI UNIV OF TECH

Asynchronous cold rolling forming process of aluminum alloy and stainless steel clad plate

ActiveCN110883093BIncrease rolling capacityImprove rolling precisionTemperature control deviceWork cooling devicesLine heatingComposite plate

The invention discloses an asynchronous cold rolling forming process of an aluminum alloy stainless steel clad plate, which comprises the following process steps: adopting an asynchronous rolling method to roll and clad the stainless steel plate and the aluminum alloy plate; after the asynchronous rolling, diffusion annealing the clad plate; In the S1 step, the opposite surface of the composite plate surface of the stainless steel plate is heated online, and the opposite surface of the composite plate surface of the aluminum alloy plate is cooled online, and the heating temperature is 350 ° C to 850 ° C; The temperature of the clad plate surface of the stainless steel plate of the clad plate is lower than 650°C, and the temperature of the clad plate surface of the aluminum alloy plate rolled out of the clad plate is lower than 300°C; the rolling reduction rate is 20% to 90%; the roll of the asynchronous cold rolling The speed ratio is 1.05-1.50; the thickness ratio of the aluminum alloy plate and the stainless steel plate is 1.5-4.0; in the S2 step, the annealing temperature is 250°C-500°C, and the annealing time is 15-120min. The invention creatively proposes a one-side online heating process for rolling a composite plate to improve the bond strength of the interface of the composite plate and realize rolling and compounding in a semi-molten state of the interface.

Owner:JIANGYIN KANGRUI MOLDING TECH CO LTD

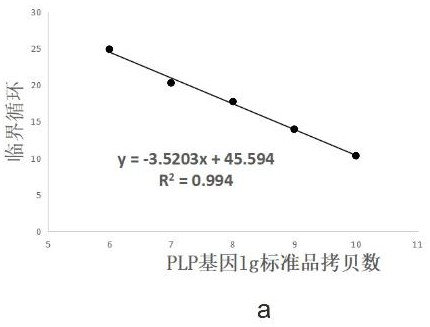

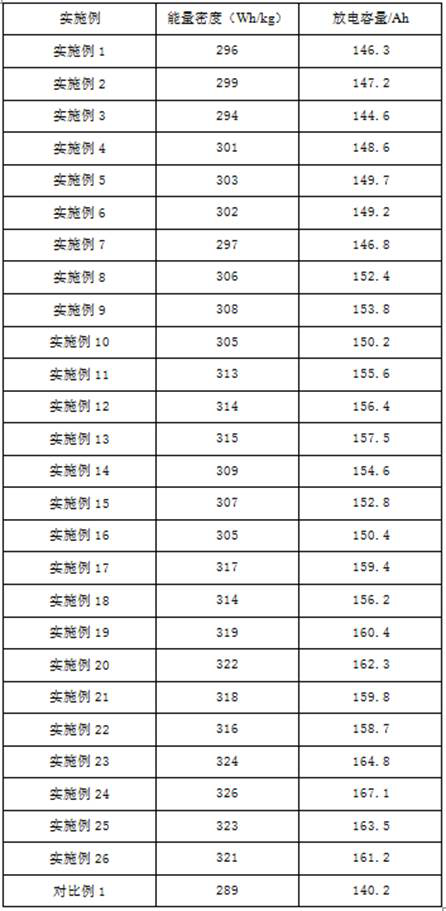

Method for preparing high-compaction lithium manganese iron phosphate by explosion method

ActiveCN114314551AIncrease compaction densityPromote formationCell electrodesSecondary cellsPhysical chemistryIron phosphate

The invention relates to the technical field of lithium manganese iron phosphate, in particular to a method for preparing high-compaction lithium manganese iron phosphate through an explosion method. According to the method for preparing the high-compaction lithium manganese iron phosphate through the explosion method, the molecular formula of the lithium manganese iron phosphate is LiMnxFe1-xPO4, and the preparation method comprises the following steps that S1, precursor powder is prepared; s2, preparing an emulsion matrix; s3, preparing a blasting charge; s4, explosive synthesis; and S5, ball-milling refining: carrying out dry ball-milling on the crude lithium manganese iron phosphate for 2-8 hours to obtain the high-compaction lithium manganese iron phosphate. The preparation method disclosed by the invention has the advantages that the formation of high-compaction nanoscale lithium manganese iron phosphate is facilitated, the compaction density of the lithium manganese iron phosphate is improved, and the electrochemical performance and the energy density of the material can be further improved. In addition, raw materials used in the explosion method are cheap, the synthesis process is simple, the preparation time is short, the energy consumption is low, and large-scale preparation is facilitated.

Owner:江苏贝特瑞纳米科技有限公司

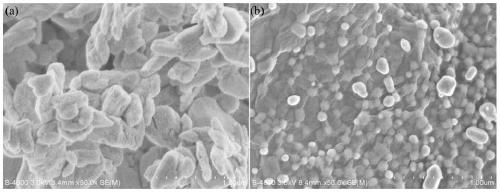

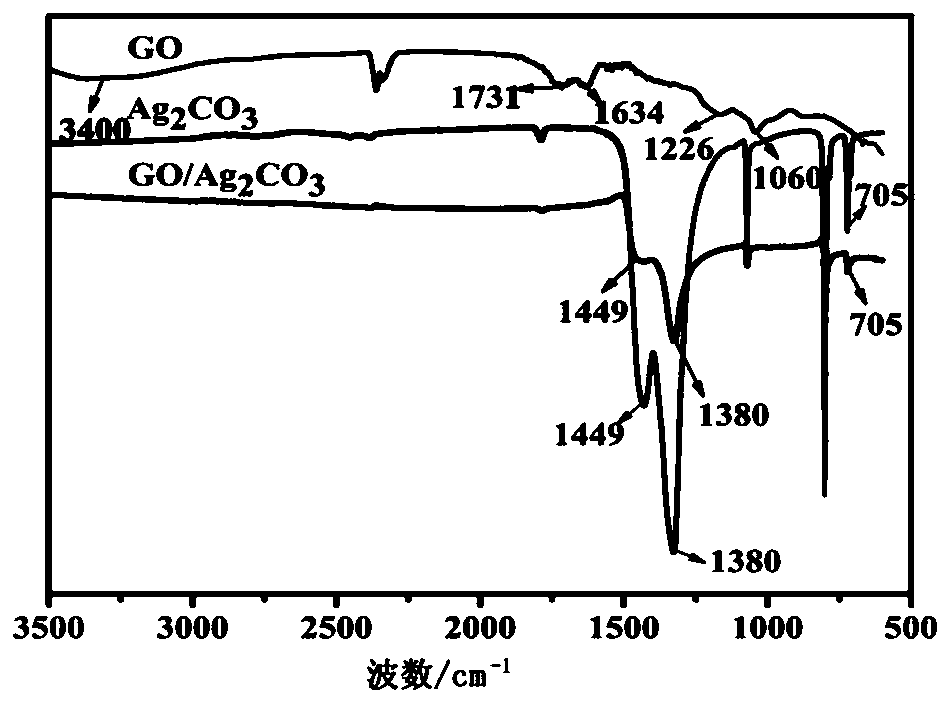

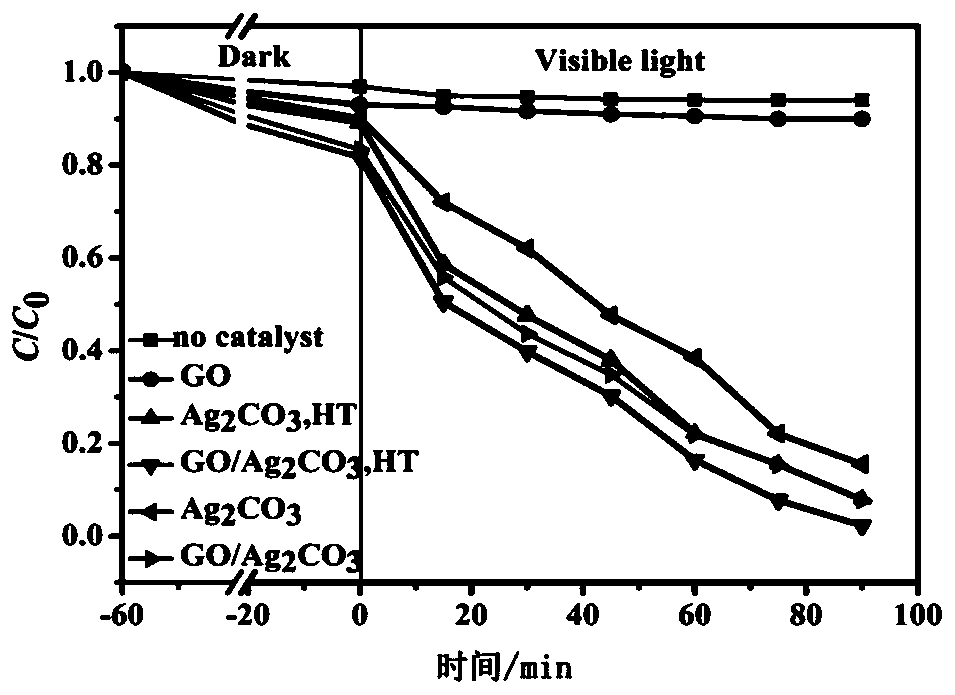

A kind of graphene oxide composite material modified by silver carbonate nanospheres and its preparation method and application

InactiveCN106914261BEasy to controlUniform and stable combinationMaterial nanotechnologyPhysical/chemical process catalystsSilver carbonateOxide composite

A silver carbonate nanosphere-modified graphene oxide composite material and its preparation method and application belong to the technical field of photocatalytic nanomaterials. Rod-shaped silver carbonate nanoparticles are modified onto the surface of graphene oxide and transformed into nanospheres with a particle size of 50~100nm. The preparation method is: under light-proof conditions, add surfactant to silver nitrate solution, and then add sodium carbonate solution dropwise. After magnetic stirring and mixing, hydrothermal reaction, washing, and drying are performed to obtain rod-shaped nano silver carbonate. The graphene oxide and the obtained rod-shaped nano silver carbonate are mixed and reacted, and the product is centrifuged, washed, and dried to obtain the final product. This composite material solves the problems that nanometer silver carbonate alone as a photocatalytic material will show instability, poor reusability, and low catalytic activity under visible light conditions. It can efficiently photocatalytically degrade phenol under visible light, thereby providing a Photocatalytic materials that can be applied to the degradation of organic pollutants in wastewater treatment systems.

Owner:HOHAI UNIV

Edible oil with proportional coordination of fatty-acids by using soya bean oil catalyzed by biological enzyme, and its preparing method

ActiveCN101002584BUniform and stable combinationFree of chemical residueFood preparationEdible oils/fats production/working-upEnzyme catalysisDietary Oils

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

A preparation method of a drug balloon, the prepared drug balloon and its application

ActiveCN107376030BPrevent washoutReduce lossesMedical devicesCatheterDrugs solutionPharmaceutical drug

The invention provides a preparation method of drug balloons as well as the drug balloons prepared by the preparation method and application thereof. The preparation method is characterized by comprising the following steps: curing chitosan to surfaces of balloons to obtain balloons with surfaces modified by the chitosan; spraying a drug solution on the obtained balloons with the surfaces modified by the chitosan to obtain the balloons with surfaces provided with drug coatings; carrying out surface solvation treatment on the balloons and carrying out segmented folding and packing to obtain the drug balloons. According to the drug balloons prepared by the preparation method provided by the invention, the drug coatings can be uniformly and firmly combined on the surfaces of the balloons and not easily fall off; drugs are prevented from being washed off in an in-vivo conveying process; the loss of drugs is reduced and the utilization rate of the drugs is improved; the preparation method provided by the invention is accurate, stable and efficient, is suitable for industrial large-scale production and has a wide application prospect.

Owner:LEPU MEDICAL TECH (BEIJING) CO LTD

Edible oil with proportional coordination of fatty-acids, and its producing method catalyzed by biological enzyme

ActiveCN101002585BUniform and stable combinationProcess environmental protectionEdible oils/fats production/working-upVegetable oilFatty acid binding

An edible oil containing proportionally fatty acid composed of saturated fatty acid, mono-unsaturated-fatty acid and poly-unsaturated-fatty acid is prepared through enzyme-catalytic synthesis reaction between the plant oil rich in N6-series poly-unsaturated-fatty acid and the plant oil rich in N3-series one.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

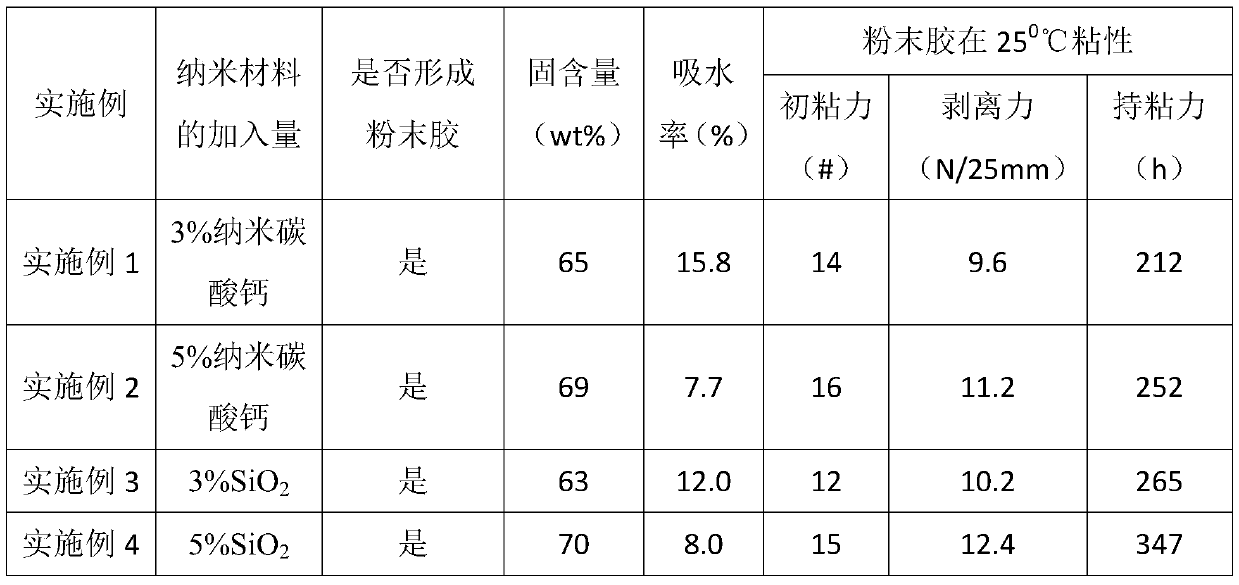

A kind of core-shell structure acrylate powder glue and preparation method thereof

ActiveCN108504313BEnhanced adhesive propertiesLow costNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceFunctional monomer

The invention discloses a waterborne acrylate adhesive powder with a core-shell structure and a preparation method thereof. The preparation method comprises the following steps of firstly, adding an emulsifier into water; then, adding a soft monomer, a hard monomer and a functional monomer, uniformly mixing, and magnetically stirring, so as to form a pre-emulsifier; heating to 75 to 80 DEG C, adding a buffer solution into a reactor, dripping 20 to 50% of pre-emulsifier by mass and 1 / 2 to 3 / 4 of initiator by mass under the N2 (nitrogen) atmosphere, and stirring to react, so as to prepare a primary emulsifier; after warming, dripping the left initiator and pre-emulsifier, adding a chain transfer agent, warming for 1 to 2h after the dripping is finished, cooling, and discharging the material;adding a coupling agent, nanometer calcium carbonate or SiO2 (silicon dioxide) and a polyvinyl alcohol water solution, dispersing, treating by ultrasonic waves at room temperature, spraying, and drying. The waterborne acrylate adhesive powder has the advantages that the environment-friendly and non-toxic effects are realized; the adhering property is guaranteed, and the good water-resistant property is realized; the waterborne acrylate adhesive powder can be used under the complicated and precise conditions; the production cost is low, the operation is simple, and the required time is short.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com