Method for further curing adhesive layer of transfer printing film subjected to transfer printing

A technology for transferring printing film and curing method, which is applied in the production of special varieties of printed matter, such as printing, post-printing, and printing. , The effect of low curing shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1. Preparation of printing film

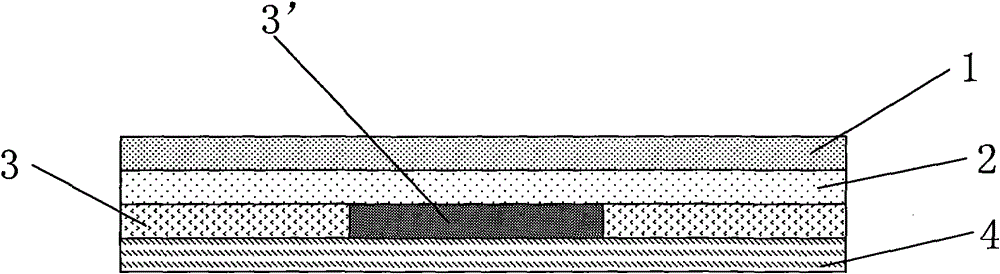

[0025] figure 1 It is the first printing film of the present invention. The top layer of the printing film is the base film 1, the second layer is the acrylic resin layer 2, the third layer is the printing ink layer 3, 3', and the fourth layer is the adhesive layer 4. The production process is as follows: using a gravure printing machine or a coating machine, an acrylic resin layer is applied to the surface of a base film as a release protection layer, and a pre-designed decorative image is printed on the acrylic resin layer with ink (mainly yellow) Text, use the gravure printing machine to directly print the adhesive on the graphic layer or coat the adhesive on the coating machine, rewind, slit and package the finished product.

[0026] The adhesive layer uses the following formula:

[0027] Epoxy resin 40%

[0028] Polyester acrylate resin 25%

[0029] TPGDA 10% produced by Sartomer

[0030] Cationic initiator produced by Ciba, USA 2617%

[003...

Embodiment 2

[0043] 1. Preparation of printing film

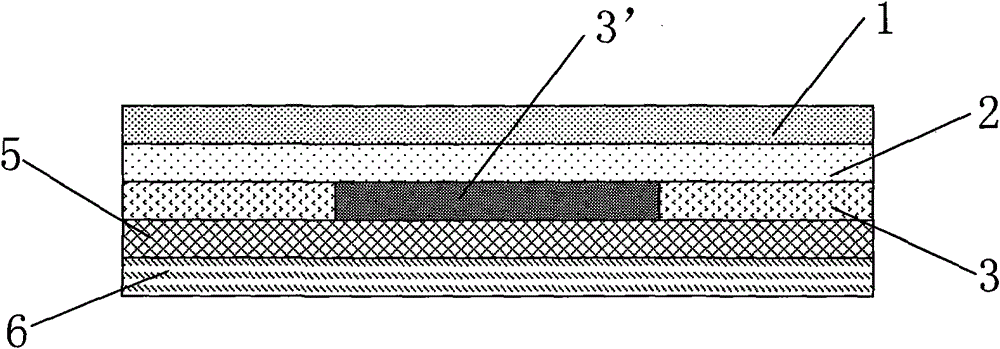

[0044] figure 2 It is another printing film of the present invention. The top layer of the printing film is base film 1, the second layer is acrylic resin layer 2, the third layer is printing ink layer 3, the fourth layer is aluminum plating layer 5, and the fifth layer is Adhesive layer 4. The production process is as follows: using a gravure printing machine or a coating machine, an acrylic resin layer is applied to the surface of a base film as a release protection layer, and a pre-designed decorative image is printed on the acrylic resin layer with ink (mainly yellow) In the text, the graphic layer is vacuum-plated with aluminum, and then the adhesive is directly printed on the aluminum-plated layer with a gravure printing machine or the adhesive is coated on the coating machine, and the finished product is wound, slit, and packaged.

[0045] The adhesive layer uses the following formula:

[0046] Vinyl resin 40%

[0047] Polyurethane ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com