Ferroferric oxide copper-loaded nanoparticle as well as preparation method and application thereof in preparation of root retarding material

A technology of ferroferric oxide and nanoparticles, which is applied in building insulation materials, building components, buildings, etc., can solve the problems of high cost and large amount of copper, and achieve the effects of preventing agglomeration, good solubility, and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

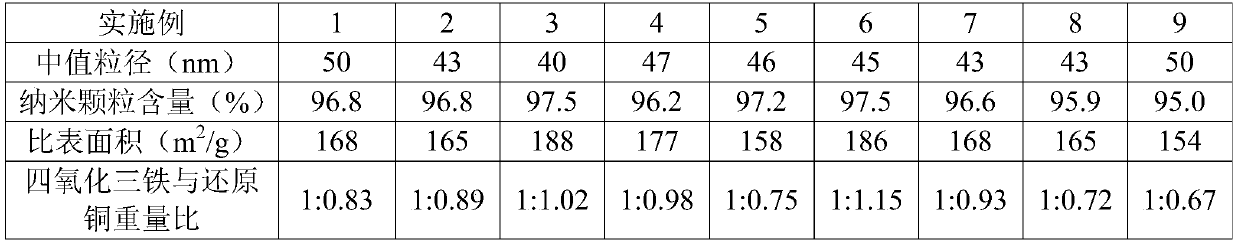

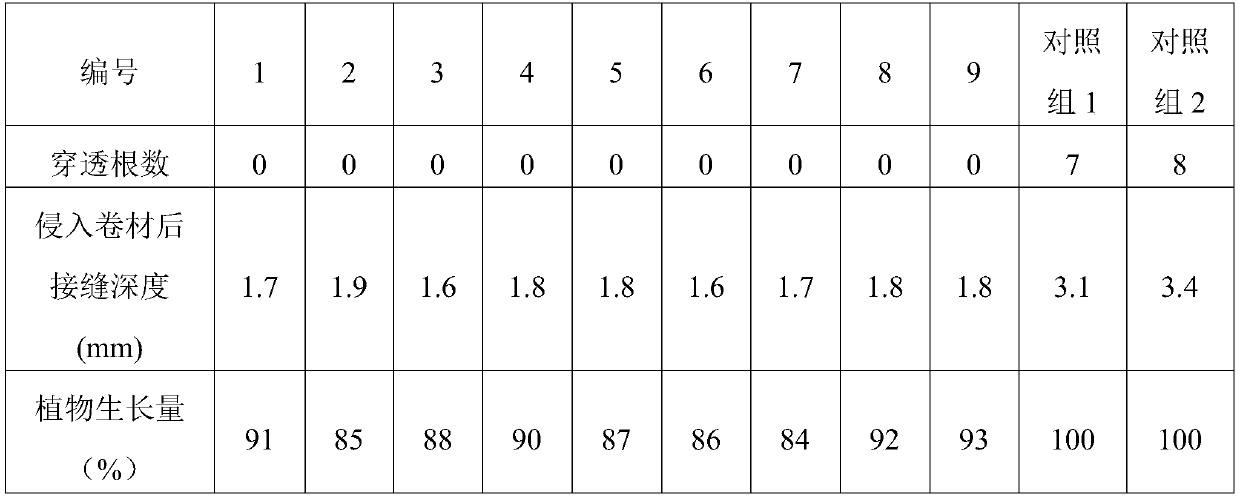

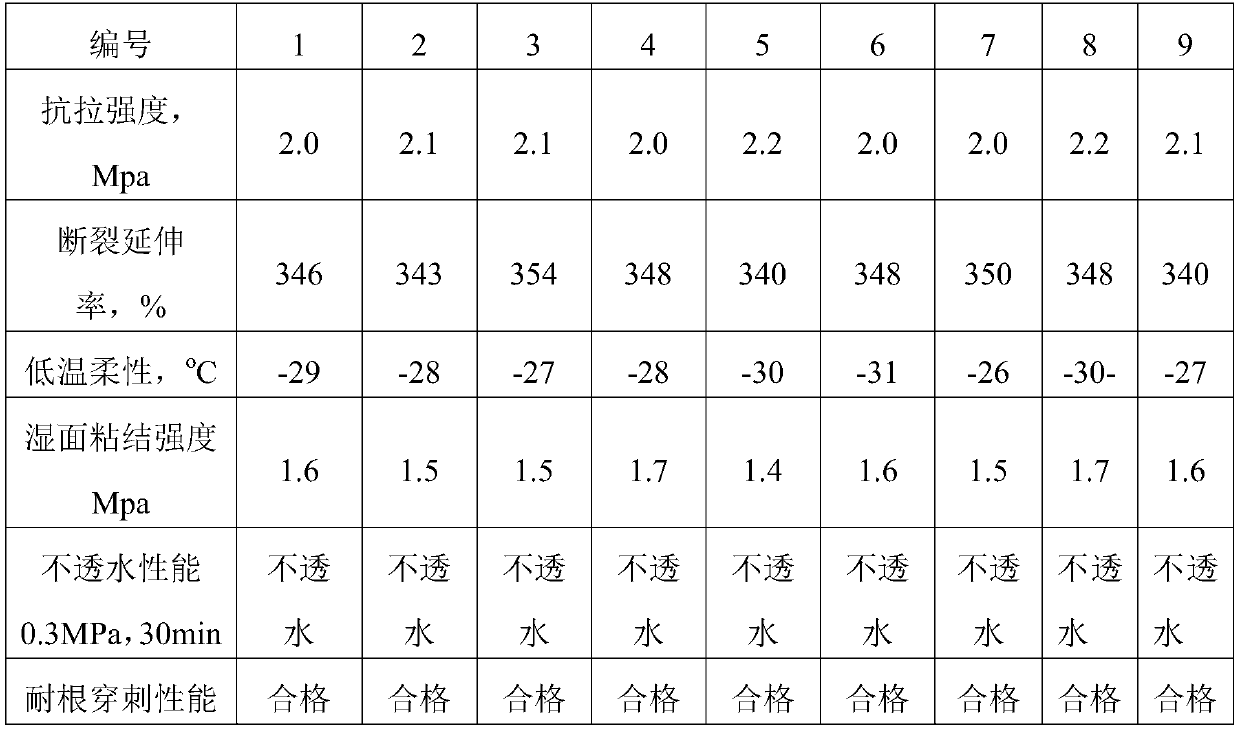

Examples

Embodiment 1

[0038] The preparation method of ferroferric oxide-loaded copper nanoparticles 1 comprises the following steps:

[0039] Step 1: Dissolve 4g of ferric chloride and 8g of ferrous chloride in 100g of deionized water to prepare a solution, add 50g of chloroform and 1g of polyepoxysuccinic acid, stir continuously at room temperature until completely dissolved, and prepare to obtain solution A;

[0040] Step 2: Add 8g of ammonia water to the above solution A, continue to stir and transfer the solution to a reaction kettle and heat it to 180°C, keep it for 3h, and obtain the mixed solution B after stabilization;

[0041] Step 3: Centrifuge the mixture solution B for 2 minutes at a speed of 8000r / min, wash and disperse with absolute ethanol, repeat 3 times to obtain a centrifuged product, dry the centrifuged product at 60°C and 15pa in vacuum to obtain trioxide Iron nanoparticle ball; Wherein, the particle diameter of ferric oxide nanoparticle ball is 10nm;

[0042] Step 4: take by ...

Embodiment 2

[0045] The preparation method of ferroferric oxide-loaded copper nanoparticles 2 comprises the following steps:

[0046] Step 1: Dissolve 5g of ferric chloride and 10g of ferrous chloride in 100g of deionized water to prepare a solution, add 60g of chloroform and 1.5g of polyepoxysuccinic acid, stir continuously at room temperature until completely dissolved, and prepare to obtain solution A;

[0047] Step 2: Add 8g of ammonia water to the above solution A, continue to stir and transfer the solution to a reaction kettle and heat it to 185°C, keep it for 3h, and obtain a mixed solution B after stabilization;

[0048] Step 3: Centrifuge the mixture solution B for 4 minutes at a speed of 10000r / min, then wash and disperse with absolute ethanol, repeat 3 times to obtain a centrifuged product, dry the centrifuged product at 60°C and 20pa in vacuum to obtain trioxide Iron nanoparticle ball; Wherein, the particle diameter of ferric oxide nanoparticle ball is 5nm;

[0049] Step 4: ta...

Embodiment 3

[0052] The preparation method of ferroferric oxide-loaded copper nanoparticles 3 comprises the following steps:

[0053] Step 1: Dissolve 6g of ferric chloride and 12g of ferrous chloride in 100g of deionized water to prepare a solution, add 100g of chloroform and 2g of polyepoxysuccinic acid, stir continuously at room temperature until completely dissolved, and prepare to obtain solution A;

[0054] Step 2: Add 10 g of ammonia water to the above solution A, continue to stir and transfer the solution to a reaction kettle and heat it to 200°C, keep it for 3 hours, and obtain a mixed solution B after stabilization;

[0055] Step 3: Centrifuge the mixture solution B for 6 minutes at a speed of 10000r / min, then wash and disperse with absolute ethanol, repeat 4 times to obtain a centrifuged product, dry the centrifuged product at 60°C and 25pa in vacuum to obtain trioxide Iron nanoparticle ball; wherein, the particle diameter of ferric oxide nanoparticle ball is 18nm;

[0056] Ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com