High-heat-dissipation metal aluminum-based copper-clad plate

A technology of metal aluminum and copper clad laminates, applied in the direction of metal silicide, metal layered products, electronic equipment, etc., can solve the problems of electronic components, logic circuit volume reduction, overall machine reliability decline, and operating frequency increase, etc., to improve Effects of mechanical properties, performance improvement, and heat dissipation enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

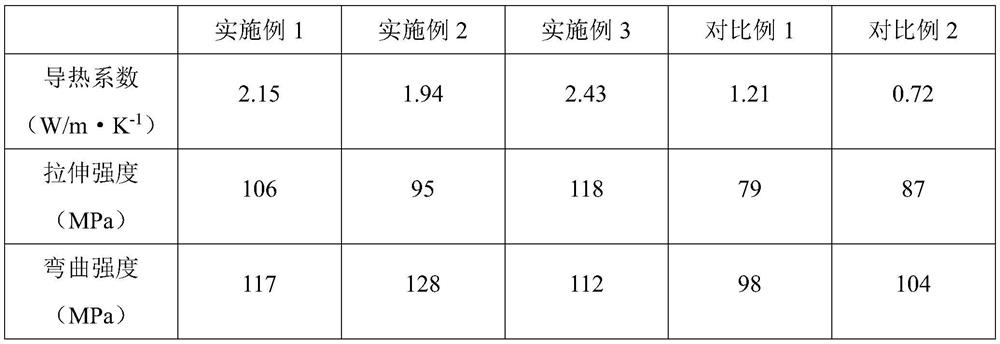

Examples

Embodiment 1

[0039] A high heat dissipation metal aluminum base copper clad laminate, which is formed by pressing a copper foil plate, a heat dissipation insulating layer and an aluminum substrate sequentially arranged from top to bottom;

[0040] The heat dissipation insulating layer is calculated by parts by weight, and includes the following components:

[0041] 100 parts of epoxy resin, 30 parts of thermal conductive filler, 6 parts of curing accelerator, 35 parts of curing agent;

[0042] Among them, the thermally conductive filler is prepared by coating boron nitride with modified hollow microspheres, and the modified hollow microspheres are porous hollow microspheres prepared by compounding tantalum disilicide powder and basic cobalt carbonate.

[0043] Described epoxy resin is the mixture of bisphenol A type epoxy resin, naphthalene ring epoxy resin and biphenyl epoxy resin, the weight ratio of bisphenol A type epoxy resin, naphthalene ring epoxy resin and biphenyl epoxy resin 32:8:...

Embodiment 2

[0067] A high heat dissipation metal aluminum base copper clad laminate, which is formed by pressing a copper foil plate, a heat dissipation insulating layer and an aluminum substrate sequentially arranged from top to bottom;

[0068] The heat dissipation insulating layer is calculated by parts by weight, and includes the following components:

[0069] 100 parts of epoxy resin, 20 parts of thermal conductive filler, 2 parts of curing accelerator, 20 parts of curing agent;

[0070] Among them, the thermally conductive filler is prepared by coating boron nitride with modified hollow microspheres, and the modified hollow microspheres are porous hollow microspheres prepared by compounding tantalum disilicide powder and basic cobalt carbonate.

[0071] Described epoxy resin is the mixture of bisphenol A type epoxy resin, naphthalene ring epoxy resin and biphenyl epoxy resin, the weight ratio of bisphenol A type epoxy resin, naphthalene ring epoxy resin and biphenyl epoxy resin It ...

Embodiment 3

[0095] A high heat dissipation metal aluminum base copper clad laminate, which is formed by pressing a copper foil plate, a heat dissipation insulating layer and an aluminum substrate sequentially arranged from top to bottom;

[0096] The heat dissipation insulating layer is calculated by parts by weight, and includes the following components:

[0097] 100 parts of epoxy resin, 40 parts of thermally conductive filler, 8 parts of curing accelerator, and 50 parts of curing agent;

[0098] Among them, the thermally conductive filler is prepared by coating boron nitride with modified hollow microspheres, and the modified hollow microspheres are porous hollow microspheres prepared by compounding tantalum disilicide powder and basic cobalt carbonate.

[0099] Described epoxy resin is the mixture of bisphenol A type epoxy resin, naphthalene ring epoxy resin and biphenyl epoxy resin, the weight ratio of bisphenol A type epoxy resin, naphthalene ring epoxy resin and biphenyl epoxy resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com