Edible oil with proportional coordination of fatty-acids by using soya bean oil catalyzed by biological enzyme, and its preparing method

A bioenzyme-catalyzed soybean oil and fatty acid technology is applied in the production/processing of edible oil/fat, food preparation, application, etc. It can solve the problems of not reaching the chemical molecular level, acid rise, long-term storage and easy stratification, etc. Achieve the effect of uniform and stable combination, increase content, and no chemical residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] (1) Take 12 kilograms of perilla oil, add 25 L of 4% (wt) NaOH solution, saponify and reflux for 1 h, then add 1 L of hot water to the saponification solution, extract twice with petroleum ether, and use 10% (wt) HCl for the lower layer solution Adjust the pH value to 2, separate the oil layer after standing, wash with distilled water until neutral, and obtain 10 kg of perilla oil fatty acid after drying.

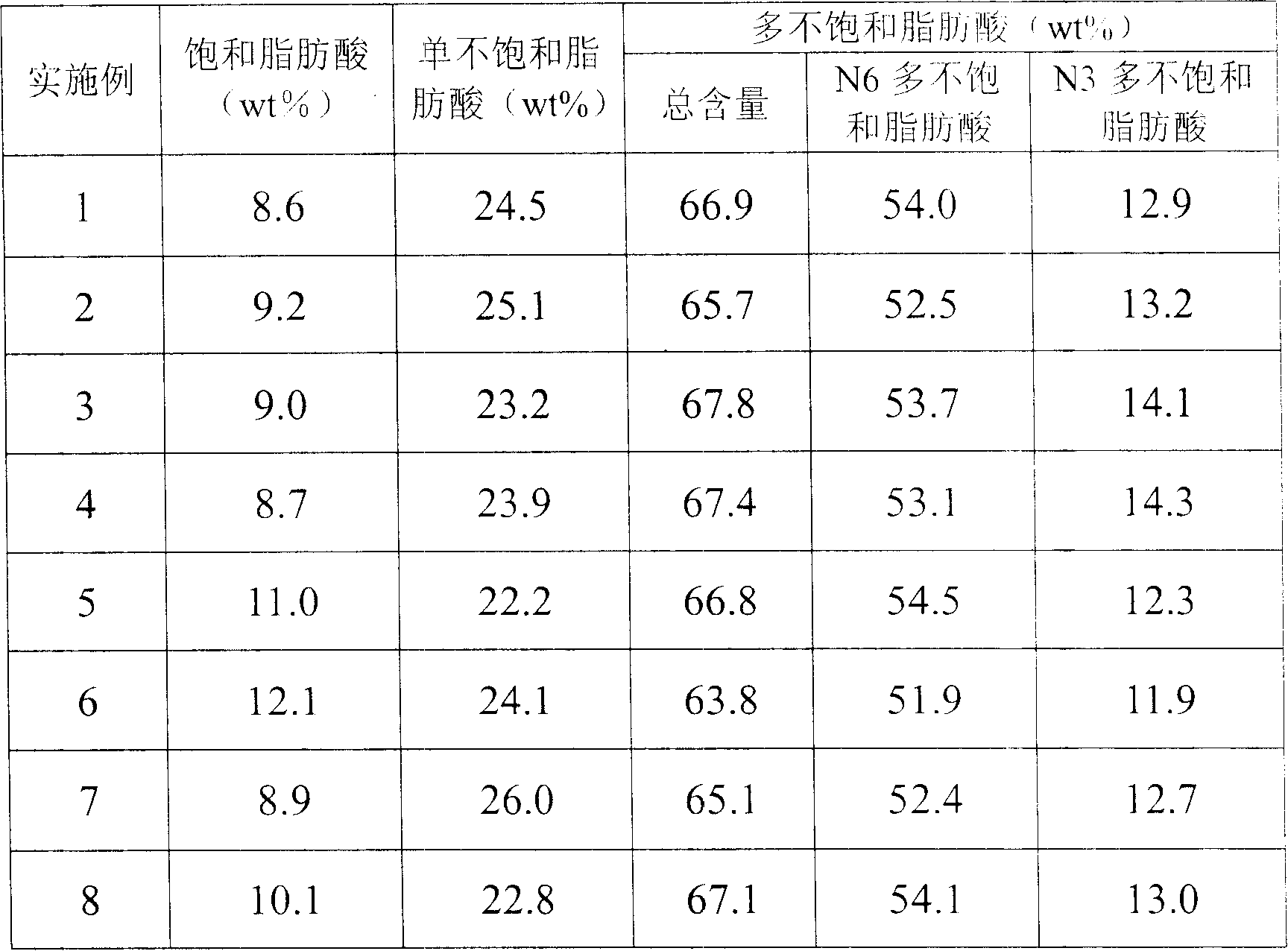

[0016] (2) Take 100 kg of refined soybean oil and perilla oil fatty acid obtained in step (1), add 3.7 kg of Novozymes Lipozyme TLIM lipase, stir and mix at 30°C, react for 3 hours, filter, and undergo deacidification treatment to obtain product. Its fatty acid composition is shown in Table 1, and product acid value is shown in Table 2.

Embodiment 2

[0018] (1) Take 4 kilograms of linseed oil and 7 kilograms of perilla oil, add 18L of 5% (wt) NaOH solution, saponify and reflux for 1.2h, then add 0.8L hot water to the saponified solution, extract 3 times with petroleum ether, and the lower layer solution Adjust the pH value to 2.5 with 10% (wt) HCl, separate the oil layer after standing, wash with distilled water until neutral, and obtain 9 kg of mixed fatty acids after drying.

[0019] (2) Take 100 kilograms of refined soybean oil and linseed oil fatty acid obtained in step (1), add 2.1 kilograms of Lipase F-AP15 lipase, stir and mix at 45° C., react for 4 hours, filter, and obtain the product through deacidification treatment. Its fatty acid composition is shown in Table 1, and product acid value is shown in Table 2.

Embodiment 3

[0021] (1) Take 21 kilograms of perilla oil, add 45L of 4.5% (wt) NaOH solution, saponify and reflux for 2 hours, then add 1.1L hot water to the saponification solution, extract 2 times with petroleum ether, and use 10% (wt) HCl adjusted the pH value to 3, separated the oil layer after standing, washed with distilled water until neutral, and obtained 18 kg of perilla oil fatty acid after drying.

[0022] (2) Take 100 kg of refined soybean oil and perilla oil fatty acid obtained in step (1), add 2.8 kg of Lvweikang lipase, stir and mix at 60° C., react for 2 hours, filter, and undergo deacidification treatment to obtain the product. Its fatty acid composition is shown in Table 1, and product acid value is shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com