A kind of graphene oxide composite material modified by silver carbonate nanospheres and its preparation method and application

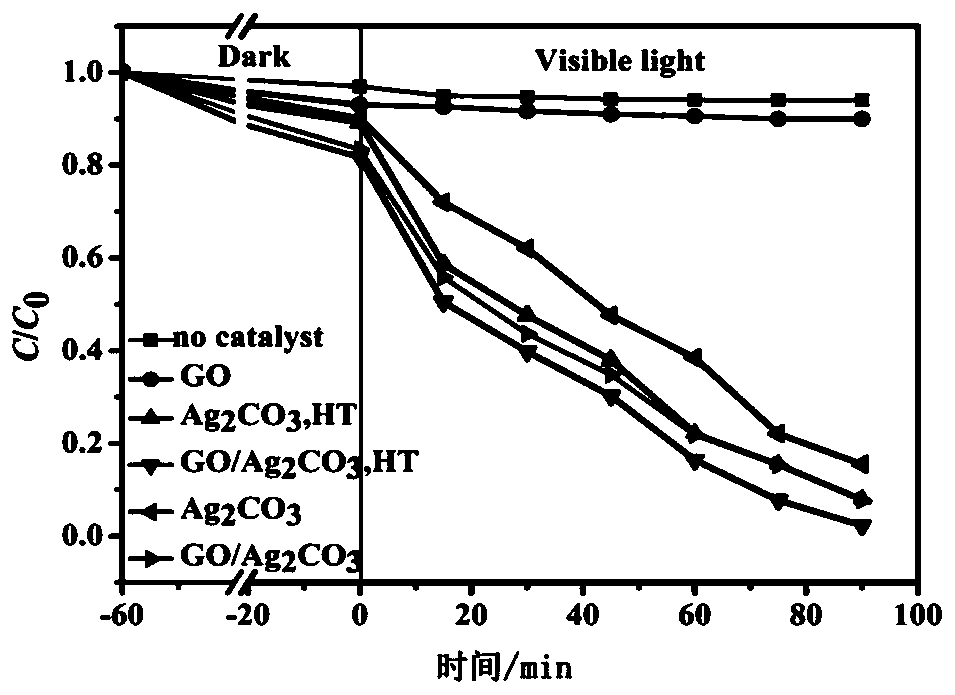

A composite material, silver carbonate technology, applied in chemical instruments and methods, nanotechnology, nano optics, etc., can solve the problems of instability and low catalytic activity, and achieve the effect of improving photocatalytic performance and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

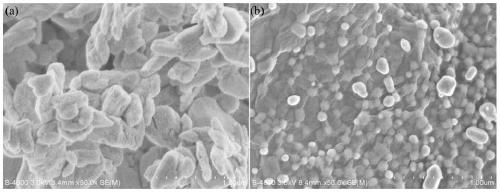

[0026] A graphene oxide composite material modified by silver carbonate nanospheres. Rod-shaped nano-silver carbonate is modified on the surface of graphene oxide through electrostatic self-assembly and then transformed into nanospheres, with an average particle size of about 50nm.

[0027] A preparation method of a graphene oxide composite material modified by silver carbonate nanospheres, the steps are as follows:

[0028] Step 1. Under the condition of avoiding light, add 20ml 3.5mmol / L surfactant cetyltrimethylammonium bromide solution to 20ml 0.1m / L silver nitrate aqueous solution, then add 10ml 0.1m / L of sodium carbonate aqueous solution was transferred to the autoclave after being thoroughly mixed for 1 hour by magnetic stirring.

[0029] Hydrothermal reaction at 70°C for 2 hours, after the product was naturally cooled to room temperature, it was centrifuged and washed with ethanol for 3 times, and finally dried to obtain rod-shaped nano-silver carbonate;

[0030] Ste...

Embodiment 2

[0032] A graphene oxide composite material modified by silver carbonate nanospheres, the rod-shaped nanometer silver carbonate is modified on the surface of graphene oxide and then transformed into nanospheres, with an average particle size of about 100nm.

[0033] A preparation method of a graphene oxide composite material modified by silver carbonate nanospheres, the steps are as follows:

[0034] Step 1. Add 40ml of 3.5mmol / L surfactant cetyltrimethylammonium bromide solution to 40ml of 0.1m / L silver nitrate aqueous solution, and then add 20ml of 0.1m / L of sodium carbonate aqueous solution, fully mixed by magnetic stirring for 1 hour, then transferred to an autoclave, hydrothermally reacted at 70 ° C for 2 hours, after the product was naturally cooled to room temperature, it was washed with ethanol for 3 times, and finally dried to obtain Rod nano-silver carbonate;

[0035] Step 2. Ultrasonically disperse 3.0 mg of graphene oxide in ethylene glycol under light-proof condi...

Embodiment 3

[0037] A graphene oxide composite material modified by silver carbonate nanospheres. After the rod-shaped nano silver carbonate is modified on the surface of graphene oxide, it is transformed into nanospheres with an average particle size of about 70nm.

[0038] A preparation method of a graphene oxide composite material modified by silver carbonate nanospheres, the steps are as follows:

[0039] Step 1. Add 30ml 3.5mmol / L surfactant cetyltrimethylammonium bromide solution to 30ml 0.1m / L silver nitrate aqueous solution, and then add 15ml 0.1m / L of sodium carbonate aqueous solution, fully mixed by magnetic stirring for 1 hour, then transferred to an autoclave, hydrothermally reacted at 70 ° C for 2 hours, after the product was naturally cooled to room temperature, it was washed with ethanol for 3 times, and finally dried to obtain Rod nano-silver carbonate;

[0040] Step 2. Ultrasonically disperse 2.0 mg of graphene oxide in ethylene glycol under light-proof conditions. Take ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com