A kind of core-shell structure acrylate powder glue and preparation method thereof

An acrylate and core-shell structure technology, applied in the field of pressure-sensitive adhesives, can solve problems such as difficult application of complex and precise spaces, and restrictions on the use of water-based acrylate pressure-sensitive adhesives, and achieve long-term preservation, shortened preparation time, and production costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

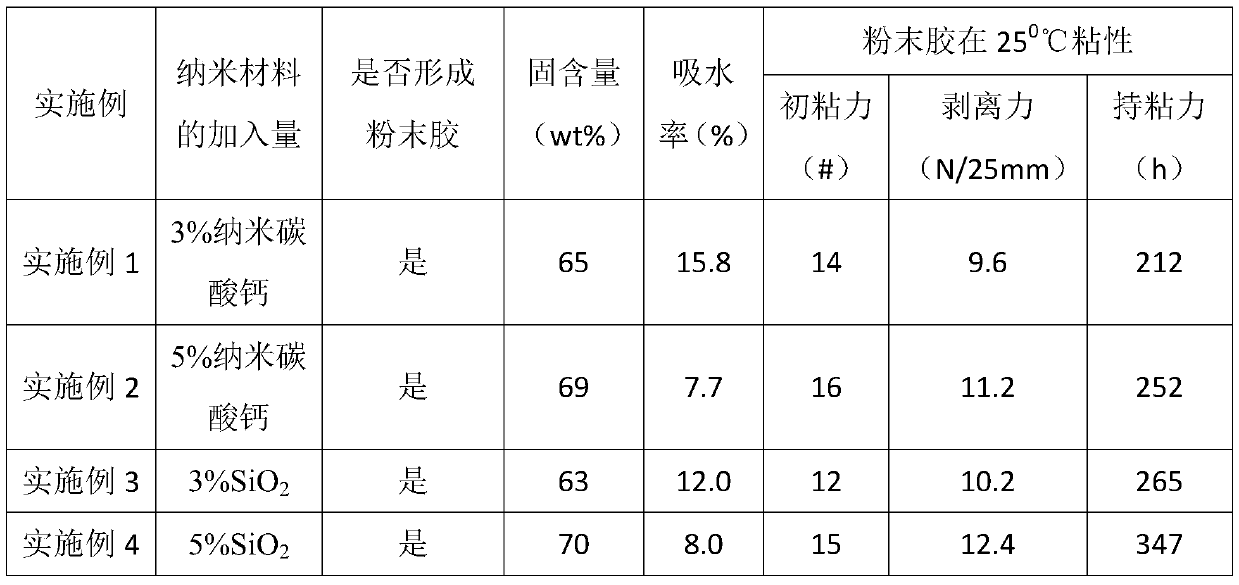

Examples

Embodiment 1

[0031] 1) Add 2.0g OP-10 to the Erlenmeyer flask, then add 50g of deionized water and magnetically stir until the emulsifier dissolves, then add 70g of butyl acrylate, 70g of isooctyl acrylate, 8g of hydroxyethyl acrylate, and 15g of vinyl acetate , 20 g of methyl methacrylate, 4 g of hydroxyethyl methacrylate, stirred (stirring speed 300 r / min) for 30 min to form a pre-emulsion.

[0032] 2) Add 0.2g NaHCO to a 500ml four-neck flask equipped with a thermometer, condenser, and stirring device 3 , then add 40ml of deionized water, the reaction temperature is 80°C, stir until dissolved; divide the pre-emulsion into two parts, add 30% mass of the pre-emulsion and 15g of ammonium persulfate aqueous solution dropwise at the same time, keep the temperature for 30min after 30min; The remaining pre-emulsion containing 4 drops of dodecyl mercaptan and 6 g of ammonium persulfate aqueous solution were added dropwise, and the addition was completed within 3.5 hours.

[0033] 3) The reacti...

Embodiment 2

[0037] 1) Add 2.0g of sodium lauryl sulfate to the Erlenmeyer flask, then add 45g of deionized water and magnetically stir until the emulsifier dissolves, then add 60g of butyl acrylate, 80g of isooctyl acrylate, 8g of hydroxyethyl acrylate, and acetic acid 10 g of vinyl ester, 25 g of methyl methacrylate, and 4 g of hydroxyethyl methacrylate were stirred (stirring speed 300 r / min) for 20 min to form a pre-emulsion.

[0038] 2) Add 0.3g NaHCO to a 500ml four-necked flask equipped with a thermometer, condenser, and stirring device 3 , then add 40ml of deionized water, the reaction temperature is 80°C, stir until dissolved; add 30% pre-emulsion and 15g ammonium persulfate aqueous solution dropwise at the same time, keep warm for 30min after 30min; then add the remaining pre-emulsion and 6g persulfate simultaneously Aqueous ammonium solution was added dropwise in 3 hours.

[0039] 3) The reaction temperature was raised to 90° C., and the temperature was kept for 1.5 h under stir...

Embodiment 3

[0043]1) Add 2.0g of nonylphenol polyoxyethylene ether ammonium sulfate to the Erlenmeyer flask, then add 50g of deionized water and magnetically stir until the emulsifier dissolves, then add 70g of butyl acrylate, 70g of isooctyl acrylate, and hydroxyethyl acrylate 8g, vinyl acetate 10g, methyl methacrylate 25g, hydroxyethyl methacrylate 4g, stirred (stirring speed 300r / min) for 30min to form a pre-emulsion.

[0044] 2) Add 0.2g NaHCO to a 500ml four-neck flask equipped with a thermometer, condenser, and stirring device 3 , then add 50ml of deionized water, the reaction temperature is 75 ° C, stir until dissolved; dropwise add 30% pre-emulsion and 15g ammonium persulfate aqueous solution at the same time, keep the temperature for 30min after 40min; then add the remaining pre-emulsion and 6g persulfate at the same time Aqueous ammonium solution was added dropwise in 3.5 hours.

[0045] 3) The reaction temperature was raised to 85° C., and kept under stirring condition for 1 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com