SBS modified asphalt

A technology of modified asphalt and matrix asphalt, used in building components, building insulation materials, buildings, etc., can solve the problems of poor weather resistance, aging, cracking, etc., and achieve excellent flexibility, improved weather resistance, and increased impact resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

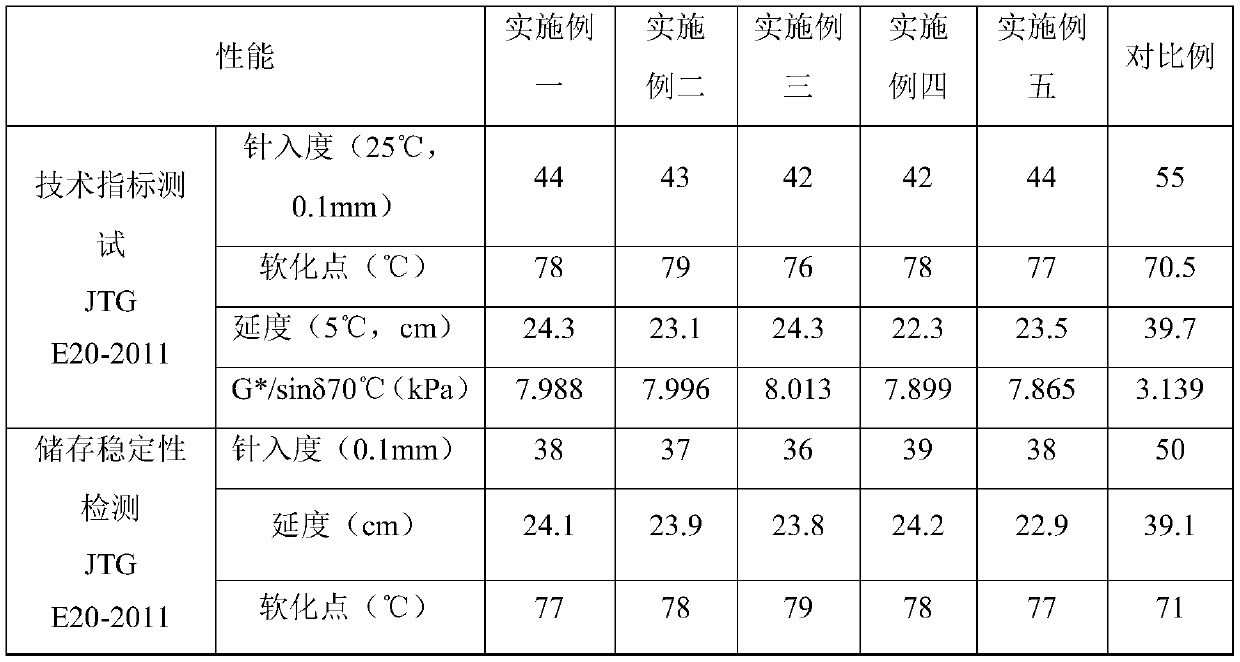

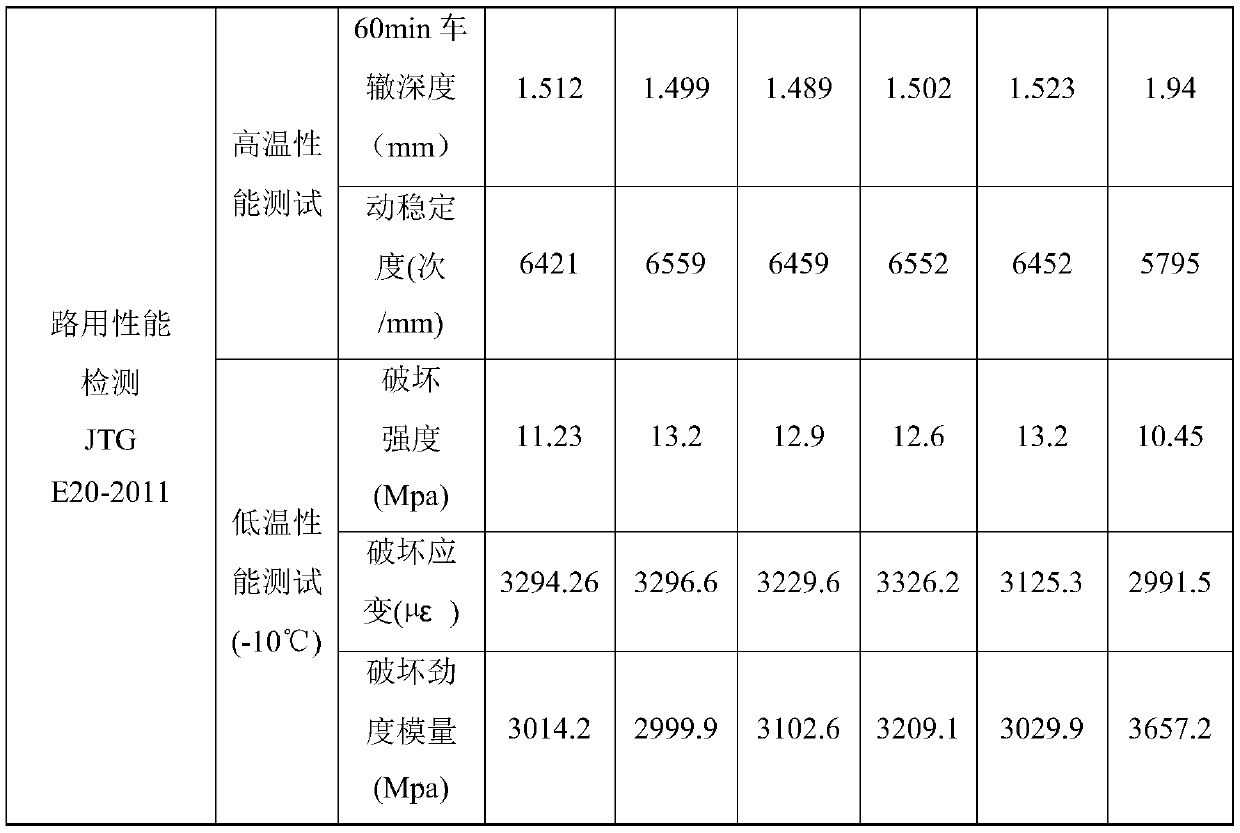

Examples

Embodiment 1

[0032] The highly weather-resistant SBS asphalt modifier comprises the following parts by weight: 46 parts of SBS matrix; 15 parts of high-density polyethylene; 9 parts of ultraviolet absorber; 7 parts of dispersant.

[0033] Among them: the average relative molecular mass of the SBS matrix is 140,000, the mass ratio of styrene to butadiene in the SBS matrix is 1.2, and the density of high-density polyethylene is 0.935g / cm 3 ;

[0034] The ultraviolet absorber is 2,4-dihydroxybenzophenone and hindered amine, and the mass ratio of hindered amine and 2,4-dihydroxybenzophenone is 2;

[0035] The dispersant is vinyl bis stearamide.

[0036] The preparation method of high weather resistance SBS asphalt modifier comprises the following steps:

[0037] Stir the SBS matrix at a temperature of 135° C. for 75 minutes to obtain a SBS melt;

[0038] Add 5 parts of high-density polyethylene into the SBS melt every 10 minutes, raise the temperature to 150°C, and stir for 90 minutes. ...

Embodiment 2

[0044] The highly weather-resistant SBS asphalt modifier comprises the following parts by weight: 50 parts of SBS matrix; 20 parts of high-density polyethylene; 10 parts of ultraviolet absorber; and 10 parts of dispersant.

[0045] Among them: the average relative molecular mass of the SBS matrix is 150,000, the mass ratio of styrene to butadiene in the SBS matrix is 1.5, and the density of high-density polyethylene is 0.938g / cm 3 ;

[0046] The ultraviolet absorber is 2,4-dihydroxybenzophenone and hindered amine, and the mass ratio of hindered amine and 2,4-dihydroxybenzophenone is 3;

[0047] The dispersant is vinyl bis stearamide.

[0048] The preparation method of high weather resistance SBS asphalt modifier comprises the following steps:

[0049] Stir the SBS matrix at a temperature of 139°C for 70 minutes to obtain a SBS melt;

[0050] Add 4 parts of high-density polyethylene into the SBS melt every 10 minutes, raise the temperature to 155 ° C, and stir for 60 min...

Embodiment 3

[0056] The highly weather-resistant SBS asphalt modifier comprises the following parts by weight: 55 parts of SBS matrix; 25 parts of high-density polyethylene; 12 parts of ultraviolet absorber; and 12 parts of dispersant.

[0057] Among them: the average relative molecular mass of the SBS matrix is 180,000, the mass ratio of styrene to butadiene in the SBS matrix is 2, and the density of high-density polyethylene is 0.939g / cm 3 ;

[0058] The ultraviolet absorber is 2,4-dihydroxybenzophenone and hindered amine, and the mass ratio of hindered amine and 2,4-dihydroxybenzophenone is 4;

[0059] The dispersant is vinyl bis stearamide.

[0060] The preparation method of high weather resistance SBS asphalt modifier comprises the following steps:

[0061] Stir the SBS matrix at a temperature of 140°C for 60 minutes to obtain a SBS melt;

[0062] Add 5 parts of high-density polyethylene into the SBS melt every 10 minutes, raise the temperature to 155°C, and stir for 70 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com