Electrochemical method for measuring oxidation inducing time of grease

A technology of induction time and oil oxidation, applied in the fields of analytical chemistry and oil analysis and detection, it can solve the problems of large experimental error, low sensitivity, poor oil conductivity, etc., and achieve the effect of simple method and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

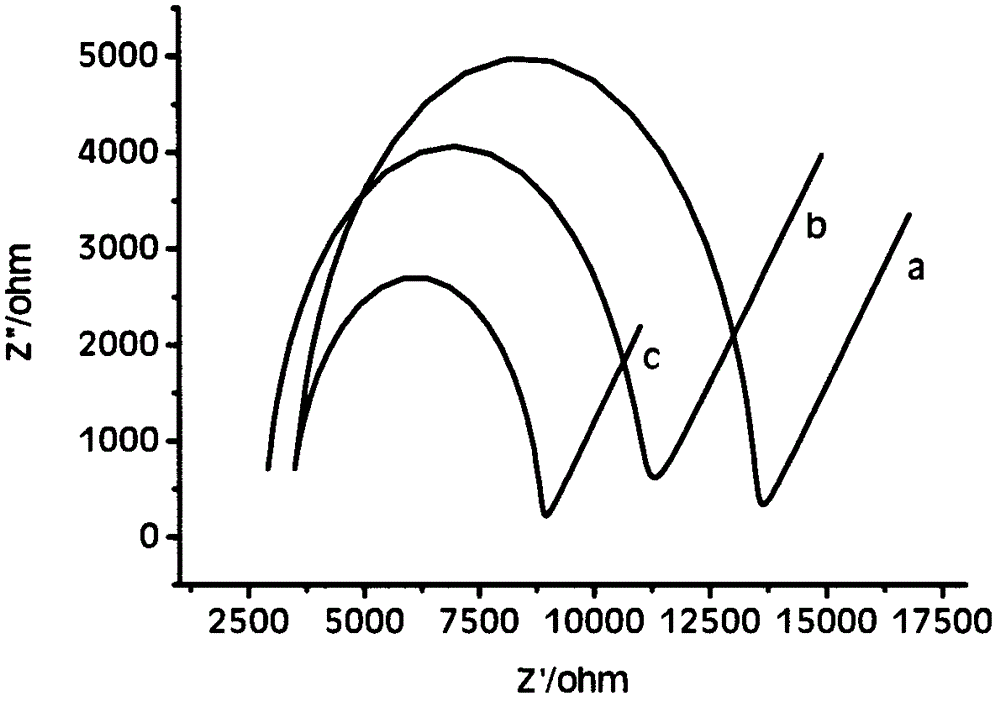

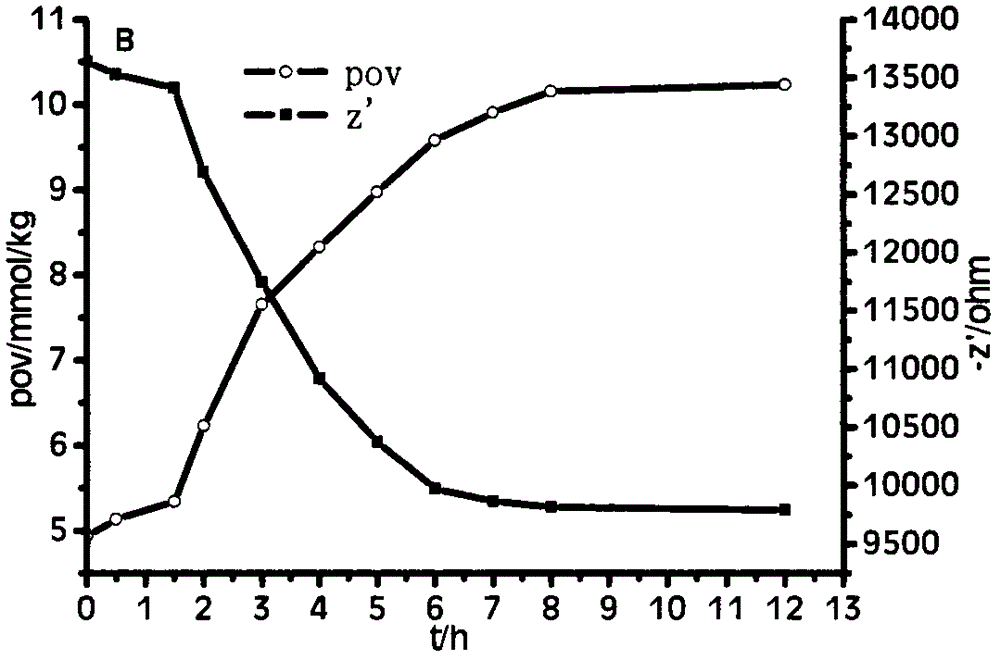

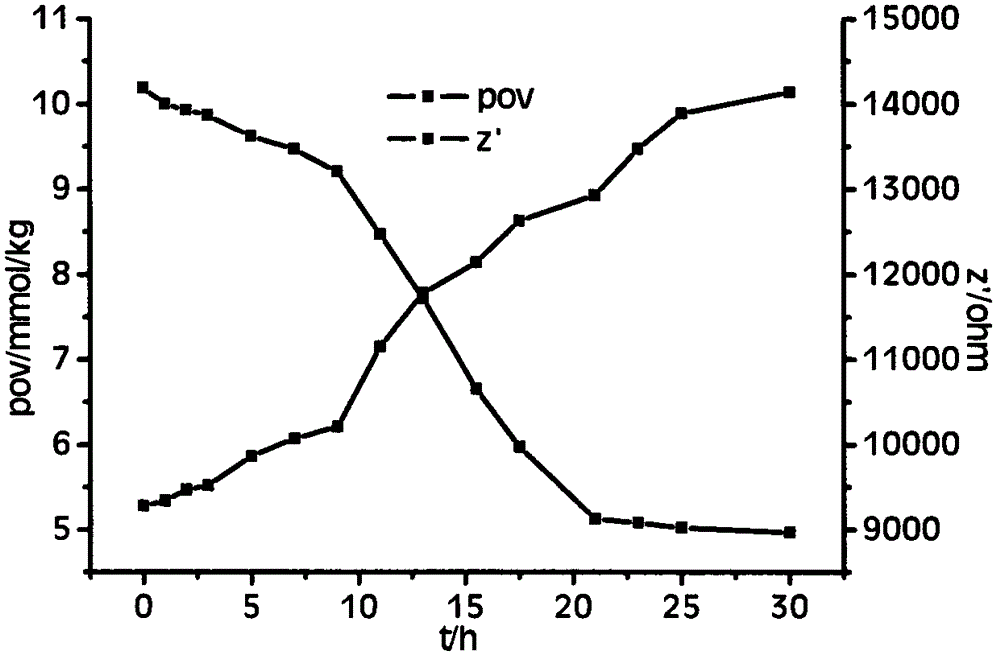

[0024] An electrochemical method for measuring the oxidation induction time of grease, the steps are as follows, (1): the glassy carbon electrode is successively filled with 0.3 and 0.05 μm Al 2 o 3 The powder is ground on the buckskin until the electrode surface is as bright as a mirror. Sonicate with absolute ethanol and ultrapure water for 5 min in turn, and dry at room temperature for later use. (2): Place the treated glassy carbon electrode in 1.0g / L graphene, 0.05mol / L NaCl suspension, pass N 2 Deoxygenation. The saturated calomel electrode was used as the reference electrode, and the platinum sheet electrode was used as the counter electrode. Using cyclic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com