Heatproof oxidized polypropylene composite material with long oxidative induction time and preparation method of heatproof oxidized polypropylene composite material

A technique for oxidation induction time and oxidized polypropylene, which is applied in the field of heat-resistant oxidized polypropylene composite materials with long oxidation induction time and its preparation, which can solve the problem of unsatisfactory thermal and oxygen aging resistance of polypropylene composite materials and difficulty in meeting reliability requirements. Requirements, prone to problems such as thermal oxidation aging, to achieve excellent thermal oxidation induction time, convenient to meet industrial production, long thermal oxidation induction time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

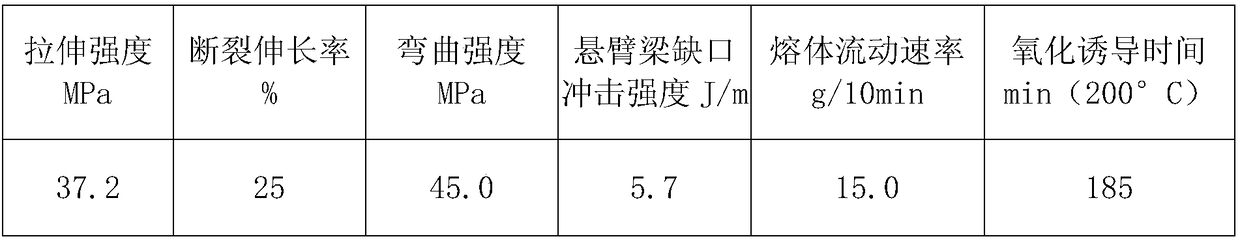

Embodiment 1

[0036] A heat-resistant oxidized polypropylene composite material with long oxidation induction time, composed of the following components in mass percentages: PP (abbreviation of polypropylene, the same below) 60%, talc 30%, mica 5%, toughening Agent ethylene-propylene binary copolymer 2%, γ-aminopropyl triethoxysilane 0.4%, tetra [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid] pentaerythritol ester 0.65 %, tris(2,4-di-tert-butylphenyl) phosphite 0.15%, distearyl thiodipropionate 0.4%, calcium stearate 0.2%, and epoxy resin 1.2%;

[0037] The preparation method of the heat-resistant oxidized polypropylene composite material with long oxidation induction time includes the following steps:

[0038] a. Ingredients: According to PP (abbreviation of polypropylene, the same below) 60%, talc 30%, mica 5%, toughening agent ethylene-propylene copolymer 2%, γ-aminopropyl triethoxysilane 0.4%, tetra[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid] pentaerythritol ester 0.65%, tri...

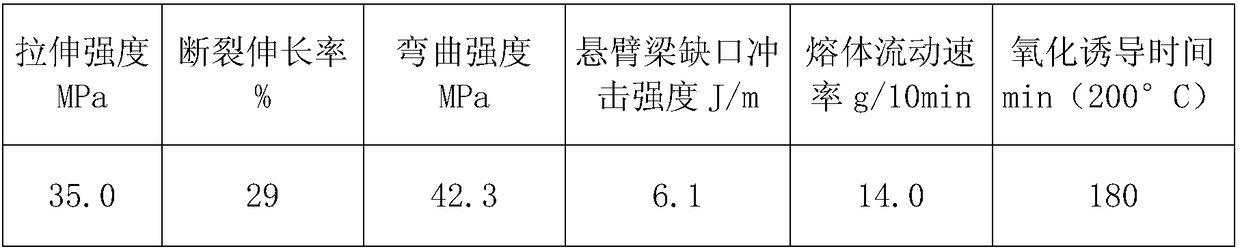

Embodiment 2

[0047] A heat-resistant oxidized polypropylene composite material with long oxidation induction time, consisting of the following components in mass percentages: PP 60.0%, talc 30%, mica 4%, ethylene-propylene terpolymer 3%, γ -Aminopropyltriethoxysilane 0.4%, tetra[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol ester 0.6%, tris(2,4-di-tert-butyl Phenyl) phosphite 0.2%, dilauryl thiodipropionate (or antioxidant DLTP) 0.3%, calcium stearate 0.2%, and epoxy resin 1.3%.

[0048] The preparation method of the heat-resistant oxidized polypropylene composite material with long oxidation induction time includes the following steps:

[0049] a. Ingredients: According to PP 60.0%, talc 30%, mica 4%, ethylene-propylene terpolymer 3%, γ-aminopropyl triethoxysilane 0.4%, tetra[β-(3,5- Di-tert-butyl-4-hydroxyphenyl) propionic acid] pentaerythritol 0.6%, tris(2,4-di-tert-butylphenyl) phosphite 0.2%, dilauryl thiodipropionate 0.3%, The mass percentages of 0.2% calcium stear...

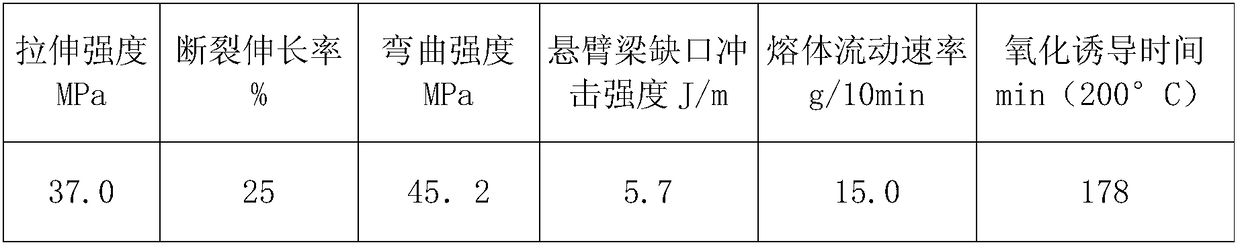

Embodiment 3

[0058] A heat-resistant oxidized polypropylene composite material with long oxidation induction time, composed of the following components in mass percentages: PP 60.0%, talc 29%, short glass fiber 5%, polyolefin elastomer 3%, γ- Aminopropyl triethoxysilane 0.4%, β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate 0.6%, tris(2,4-di-tert-butyl) Phenyl) phosphite 0.2%, dilauryl thiodipropionate (or antioxidant DLTP) 0.35%, calcium stearate 0.2%, and epoxy resin 1.25%.

[0059] The preparation method of the heat-resistant oxidized polypropylene composite material with long oxidation induction time includes the following steps:

[0060] a. Ingredients: According to PP 60.0%, talc 29%, short glass fiber 5%, polyolefin elastomer 3%, γ-aminopropyl triethoxysilane 0.4%, β-(3,5-di-tert-butyl 4-hydroxyphenyl) octadecyl propionate 0.6%, tris(2,4-di-tert-butylphenyl) phosphite 0.2%, dilauryl thiodipropionate (or anti- Oxygen agent DLTP) 0.35%, calcium stearate 0.2%, and epoxy resin 1.25% by mas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com