Special compounded level marking line color master batch for PP-RCT cold water pipe, and preparation method thereof

A technology of PP-RCT and PP-RCT3120, which is applied in the field of PP-RCT cold water pipe special compounding grade marking line color masterbatch and its preparation, can solve the problem of PP-RCT resin β crystal form change and low saturation of color lines , pipe performance decline and other issues, to achieve the effect of improving anti-aging ability, smooth surface and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

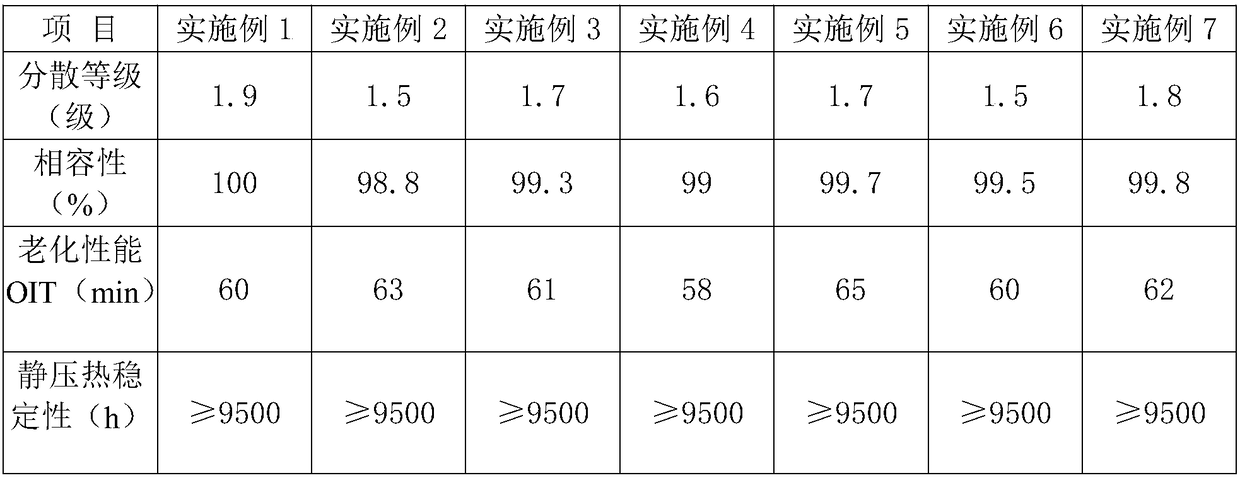

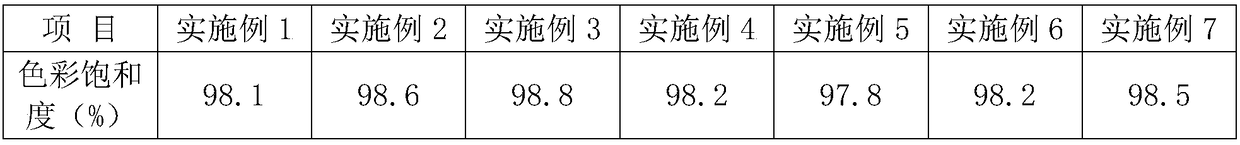

Examples

Embodiment 1

[0037] A kind of preparation method of PP-RCT cold water pipe special-purpose compounding material grade marking line color masterbatch, comprises the following steps:

[0038] 1) Place the surfactant in a drying box for dehumidification treatment, the temperature of the drying box is 80°C, and the drying time is 15 minutes;

[0039] 2) Weigh 75 parts of Yanshan Petrochemical PP-RCT3120, 6 parts of phthalocyanine blue 7090, 8 parts of hindered phenolic antioxidant, 9 parts of polyethylene wax and 6 parts of silane coupling agent in parts by weight , and then put the weighed components into the internal mixer for internal mixing for 20 minutes, and the working temperature of the internal mixer is 180°C;

[0040] 3) Add the banbury-mixed mixture to a three-roller grinder for grinding. The processing temperature of the grinder is 180°C, and the rotating speeds of the three rollers are 10r / min, 20r / min and 40r / min respectively;

[0041] 4) Add the ground mixture to the twin-screw...

Embodiment 2

[0043] A kind of preparation method of PP-RCT cold water pipe special-purpose compounding material grade marking line color masterbatch, comprises the following steps:

[0044] 1) Place the surfactant in a drying box for dehumidification treatment, the temperature of the drying box is 100°C, and the drying time is 10 minutes;

[0045] 2) Weigh 90 parts of Yanshan Petrochemical PP-RCT3120, 16 parts of phthalocyanine blue 7090, 18 parts of hindered phenolic antioxidant, 20 parts of polyethylene wax, and 15 parts of silane coupling agent in parts by weight , and then put the weighed components into the internal mixer for internal mixing for 30 minutes, and the working temperature of the internal mixer is 225°C;

[0046] 3) Add the banbury-mixed mixture to a three-roller grinder for grinding. The processing temperature of the grinder is 220°C, and the rotating speeds of the three rollers are 20r / min, 80r / min and 320r / min respectively;

[0047]4) Add the ground mixture to the twin...

Embodiment 3

[0049] A kind of preparation method of PP-RCT cold water pipe special-purpose compounding material grade marking line color masterbatch, comprises the following steps:

[0050] 1) Place the surfactant in a drying box for dehumidification treatment, the temperature of the drying box is 90°C, and the drying time is 13 minutes;

[0051] 2) Weigh 83 parts of Yanshan Petrochemical PP-RCT3120, 11 parts of phthalocyanine blue 7090, 13 parts of thiolipid antioxidant, 14 parts of hyperdispersant, and titanate coupling agent in parts by weight. 10 parts, and then put the weighed components into the internal mixer for internal mixing for 25 minutes, and the working temperature of the internal mixer is 200°C;

[0052] 3) Add the banbury-mixed mixture to a three-roller grinder for grinding. The processing temperature of the grinder is 200°C, and the rotating speeds of the three rollers are 20r / min, 60r / min and 200r / min respectively;

[0053] 4) Add the ground mixture to the twin-screw ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com